Patents

Literature

54results about How to "Avoid compromising production quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

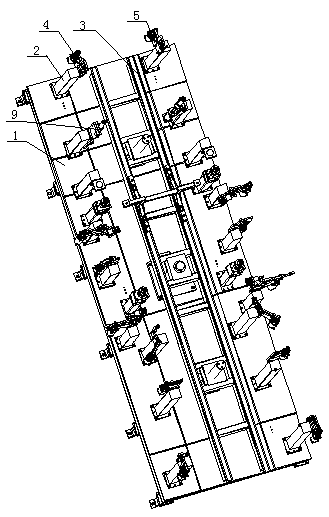

Plunger paste production line and production process

ActiveCN113955395AEasy to transportEasy to dipLiquid surface applicatorsConveyorsMaterial transferIndustrial engineering

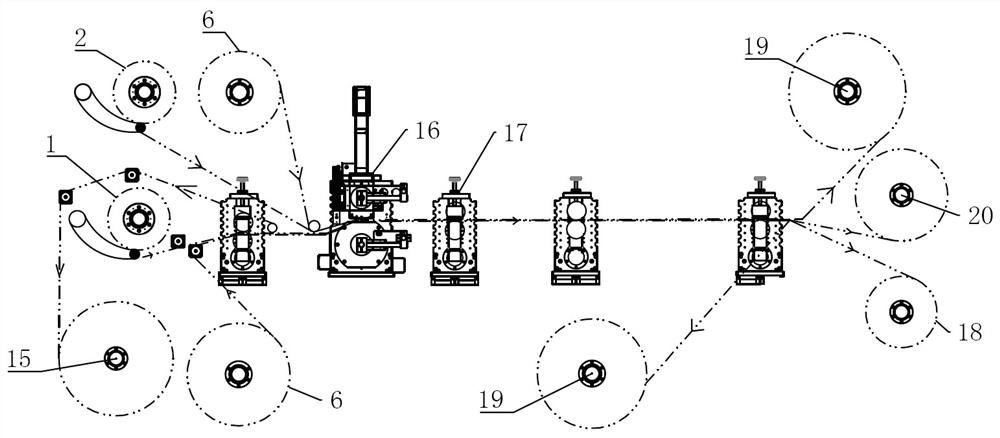

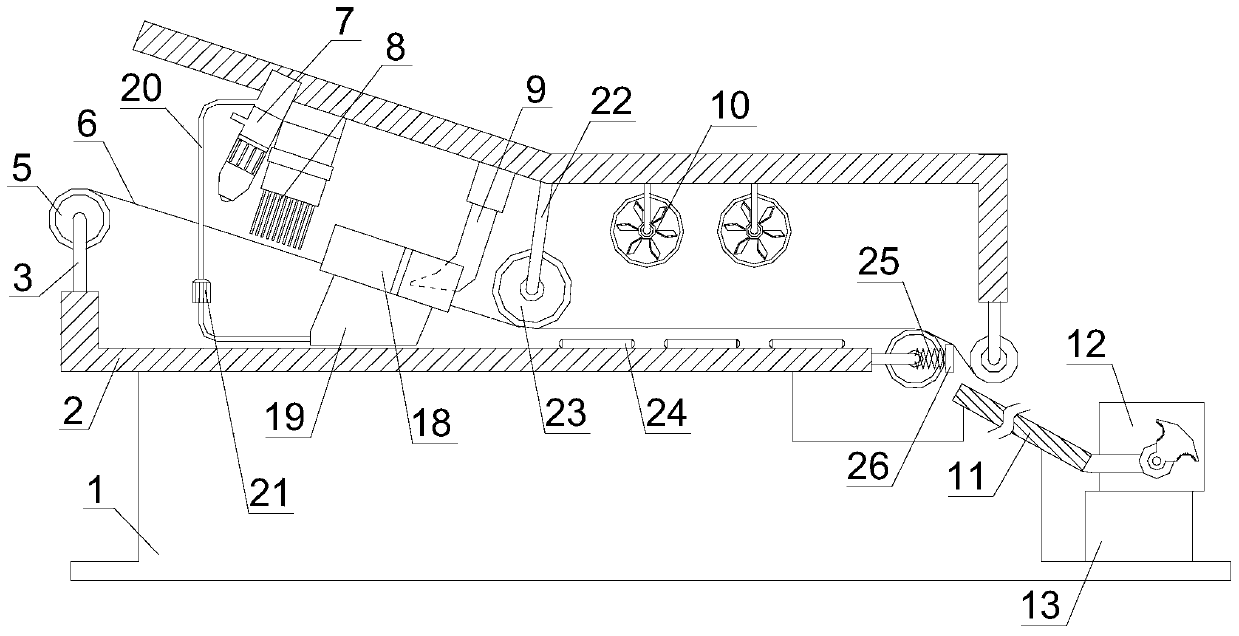

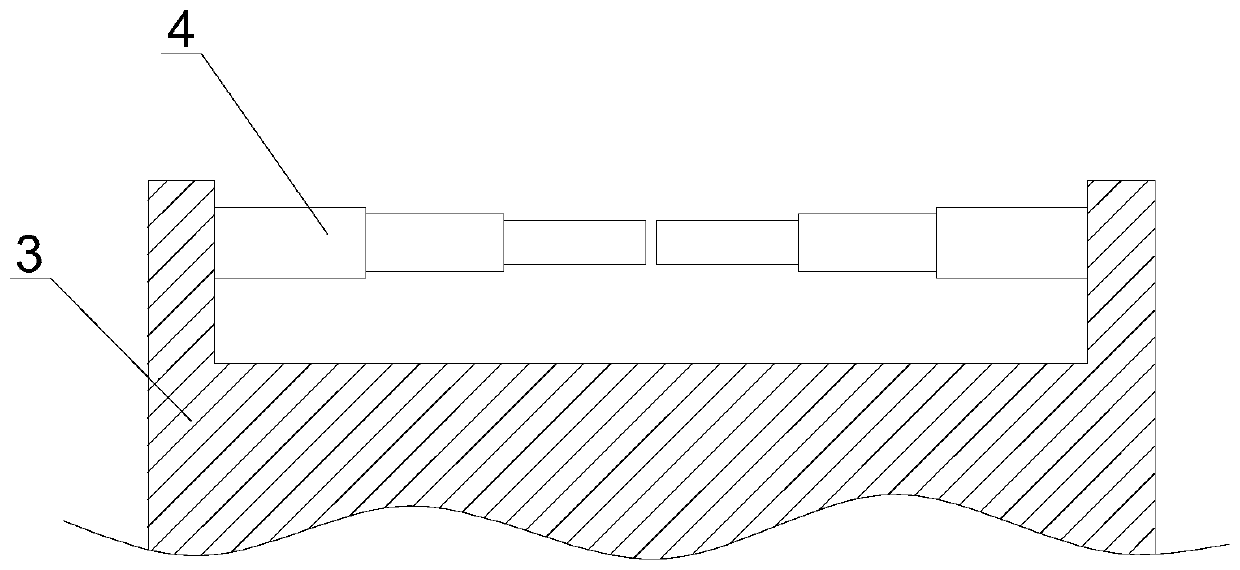

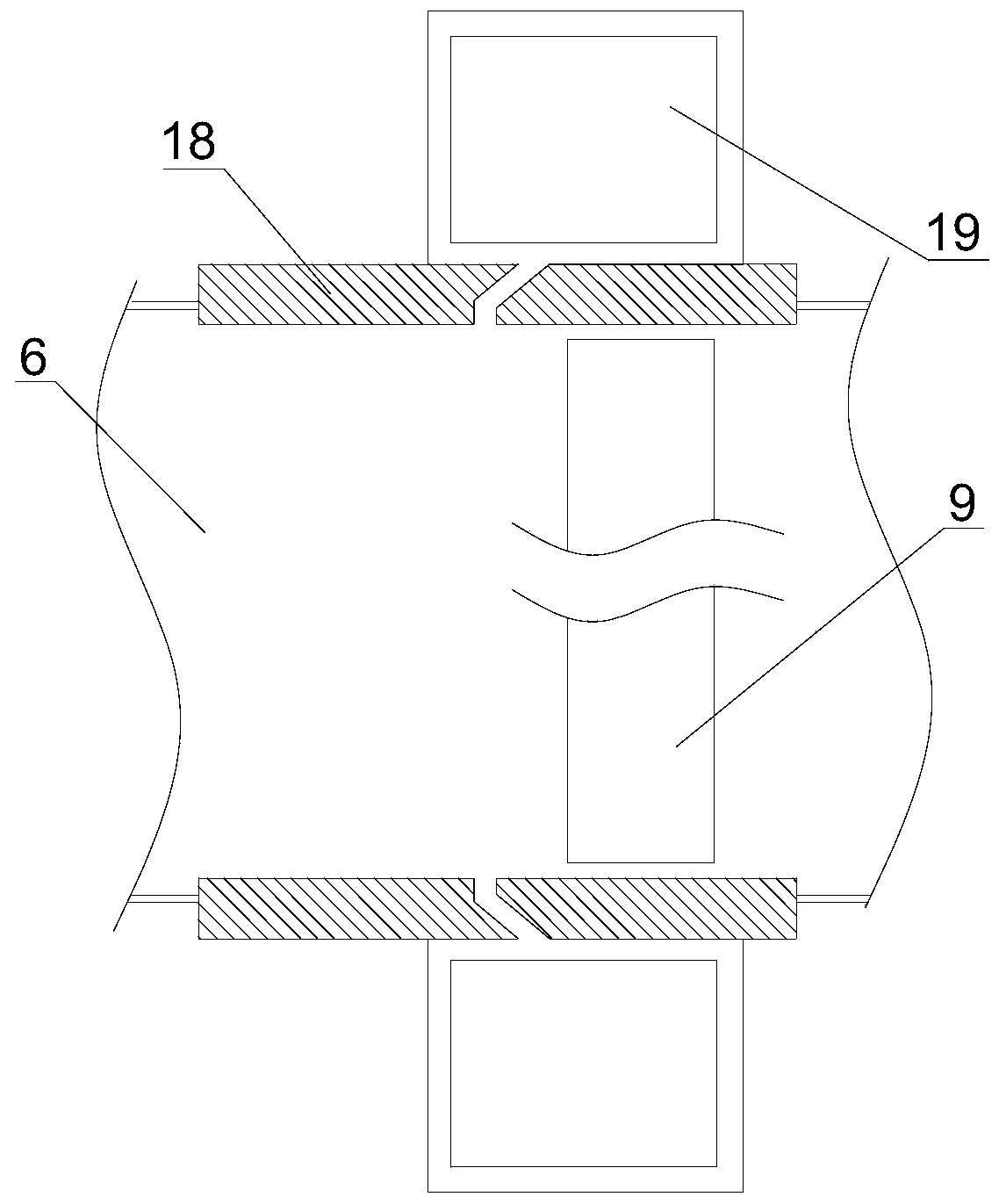

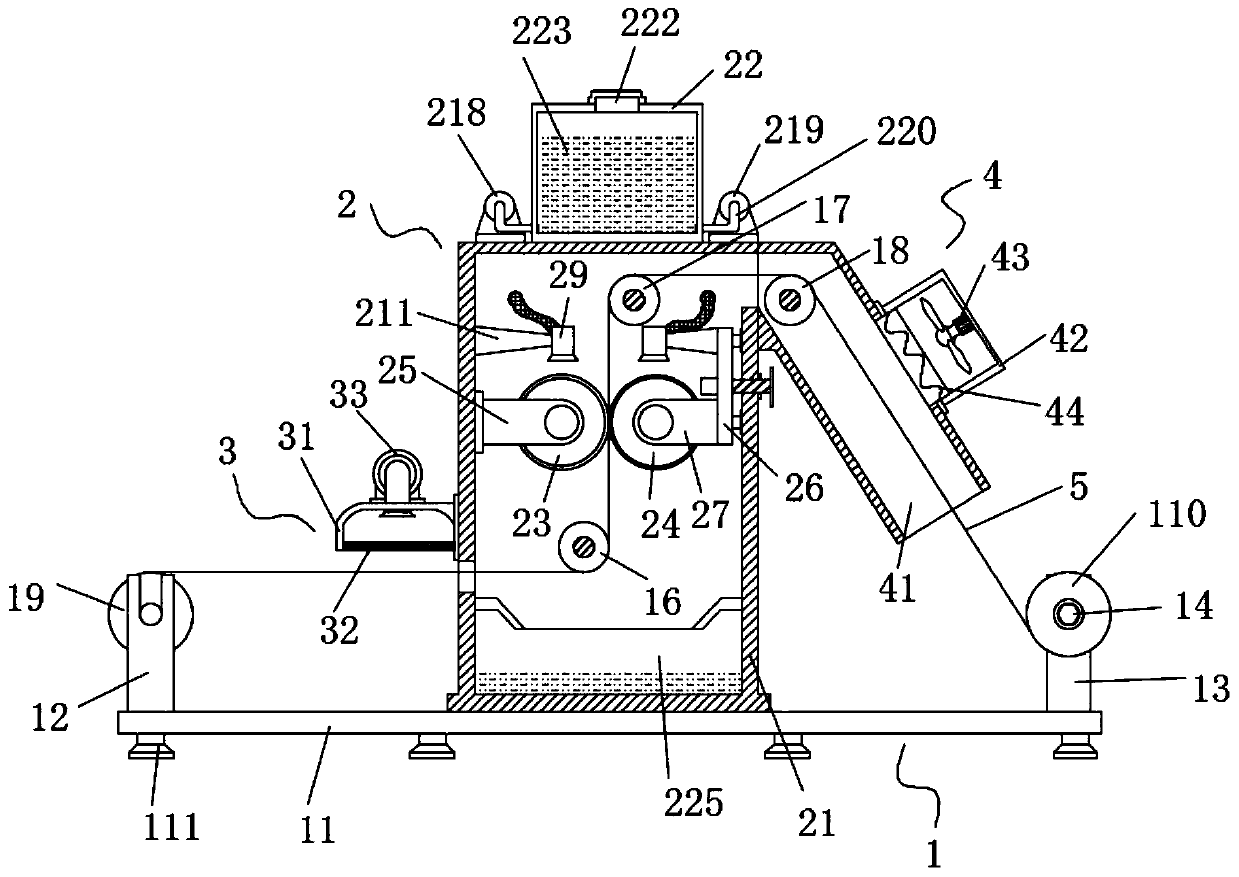

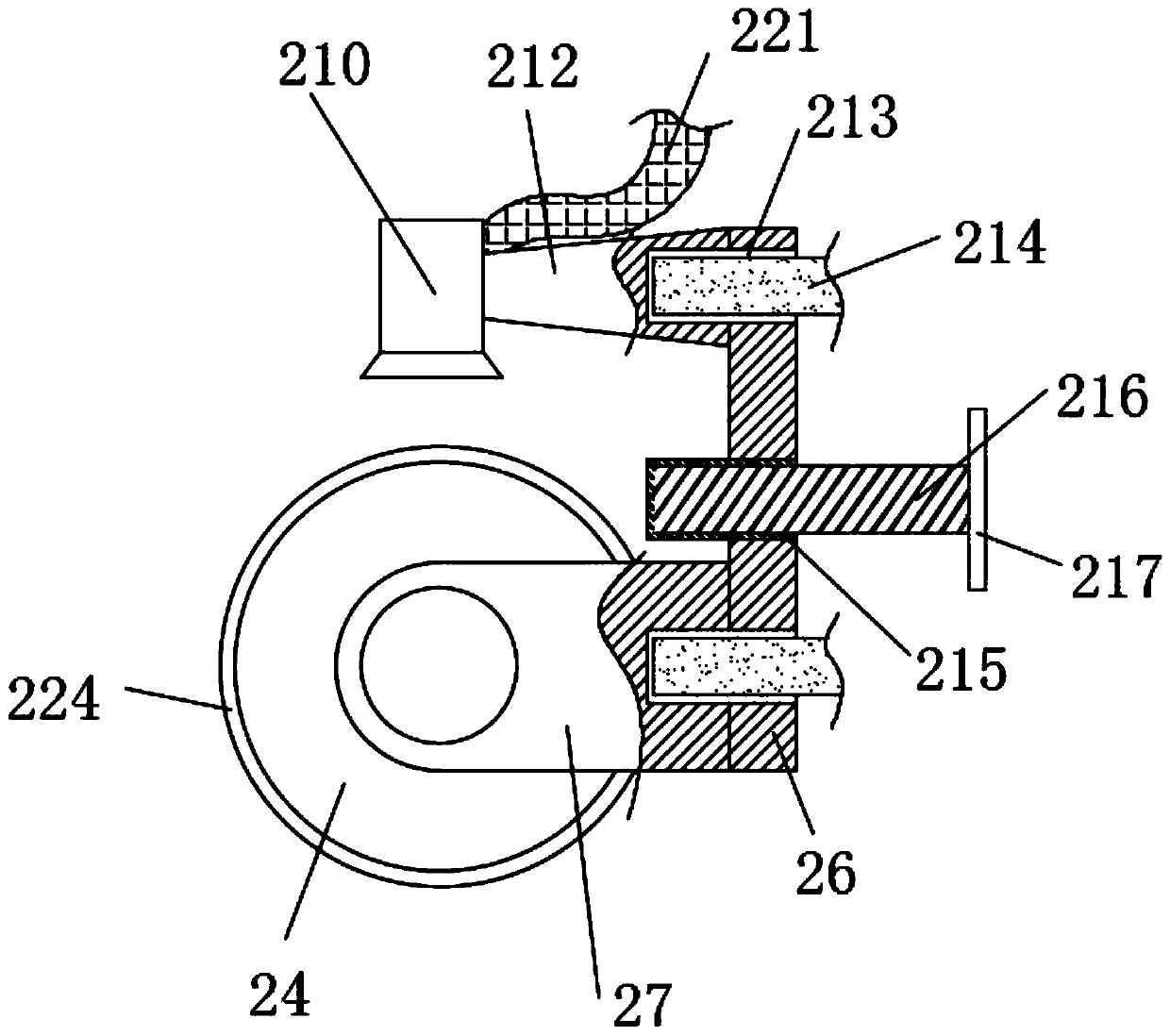

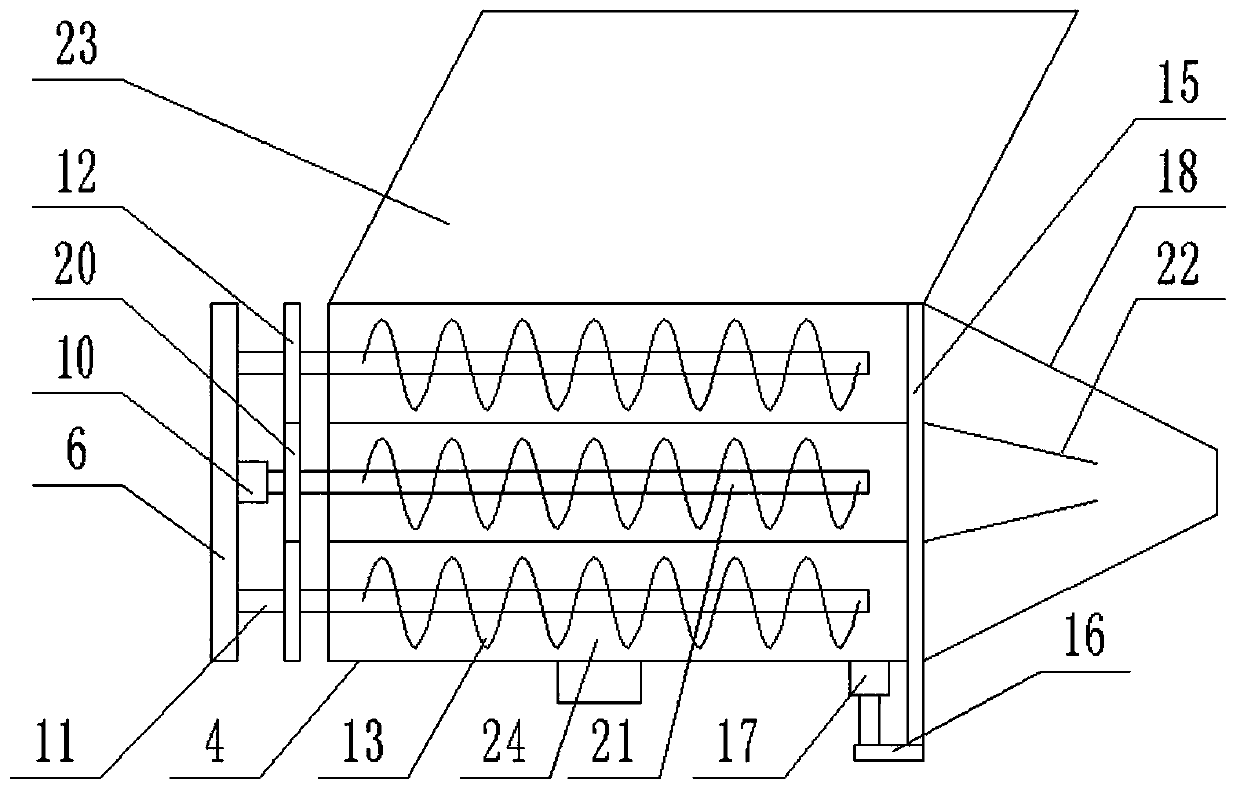

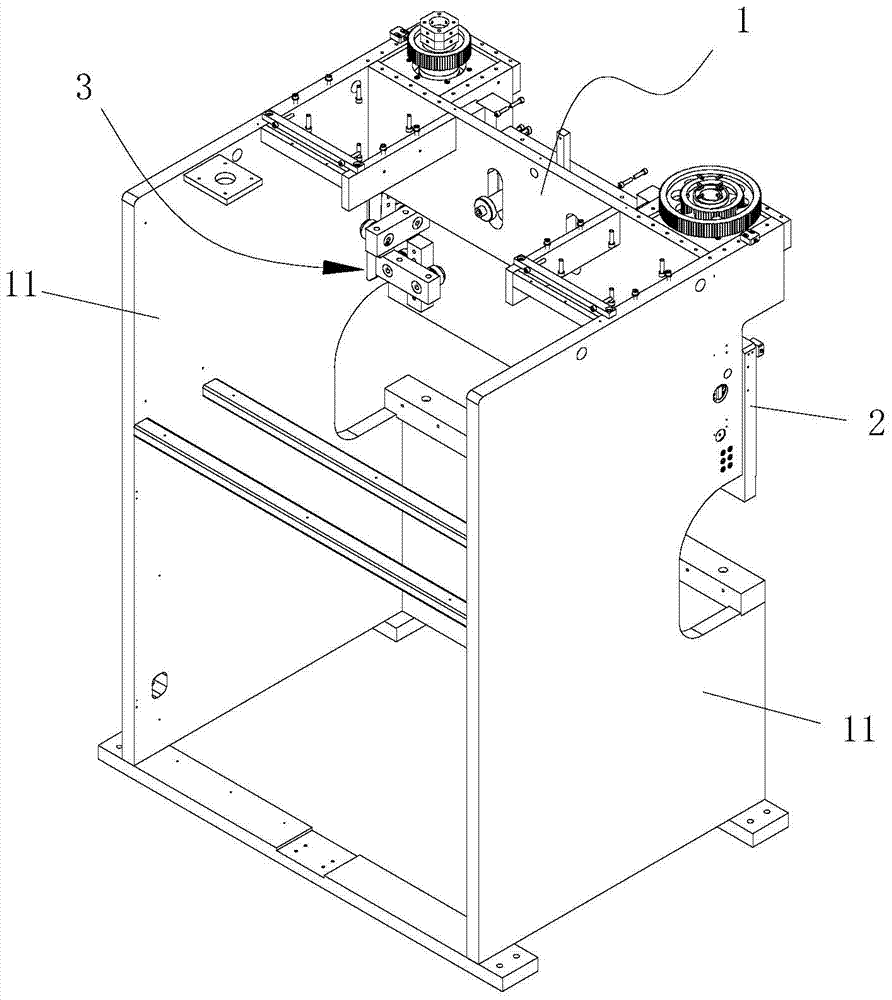

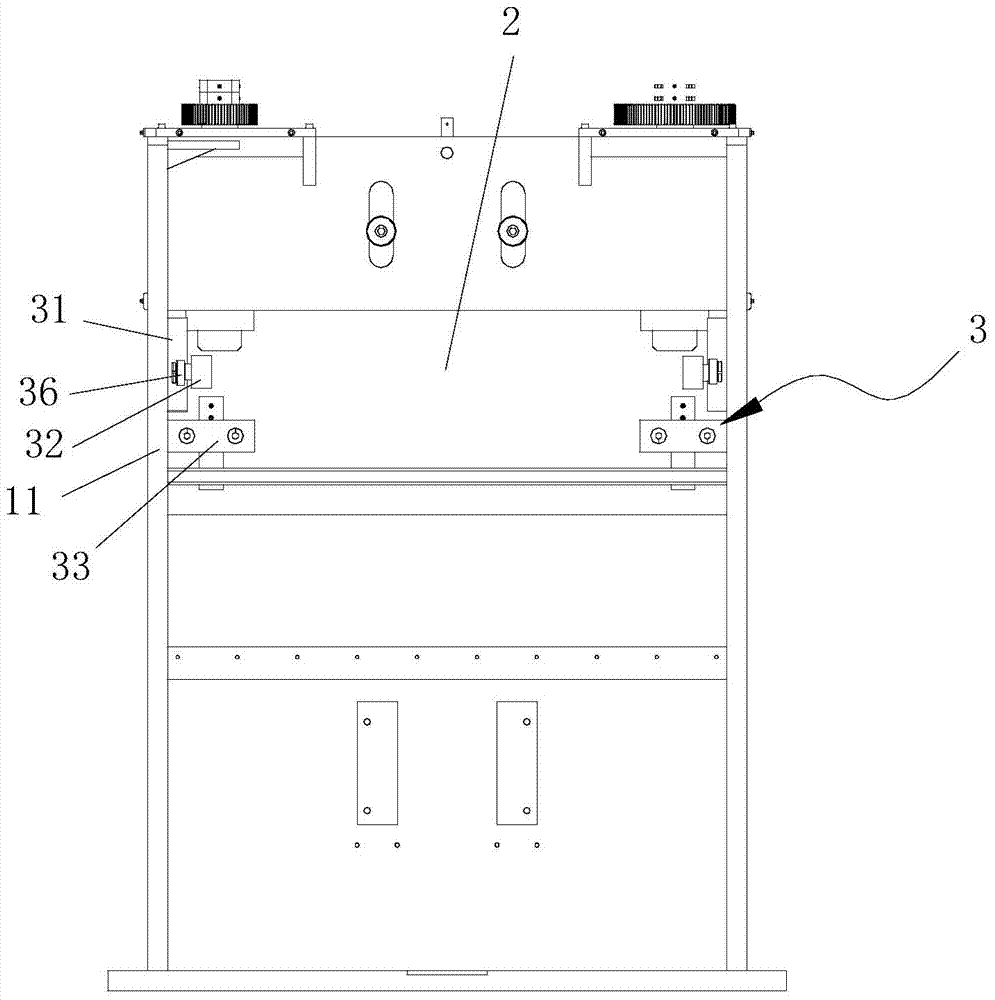

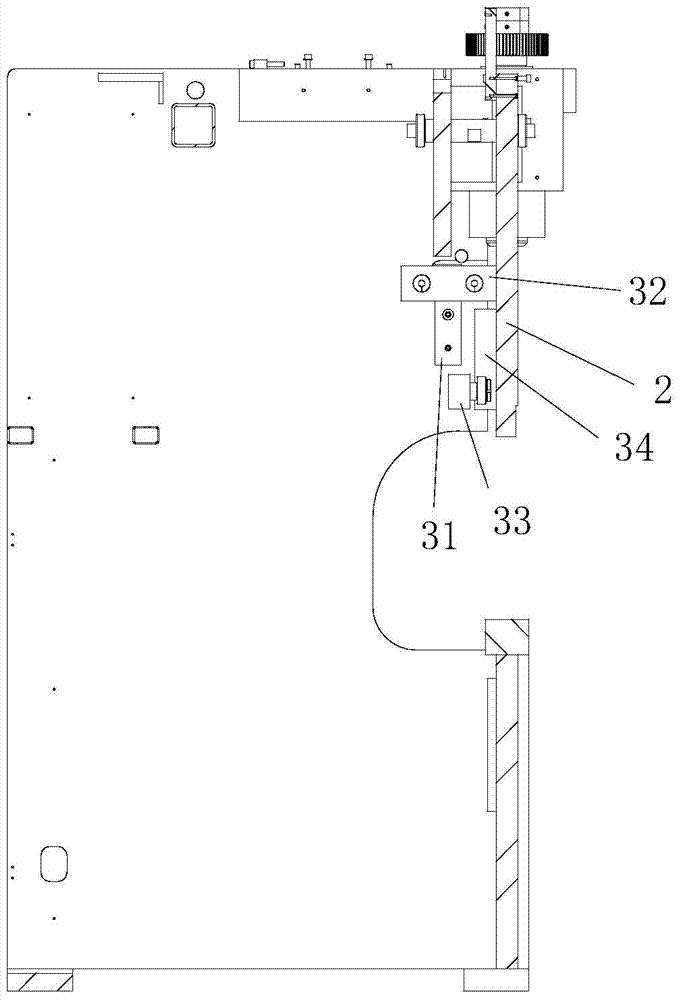

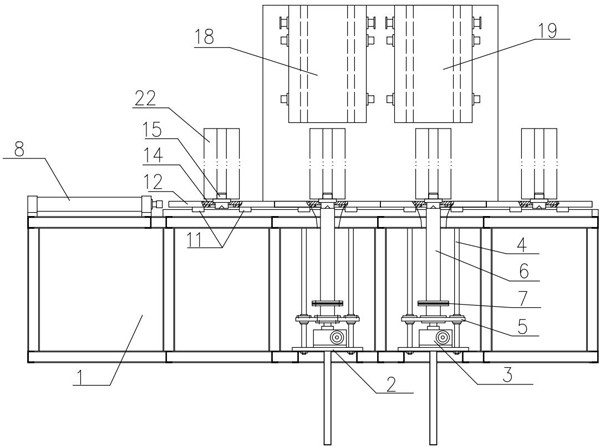

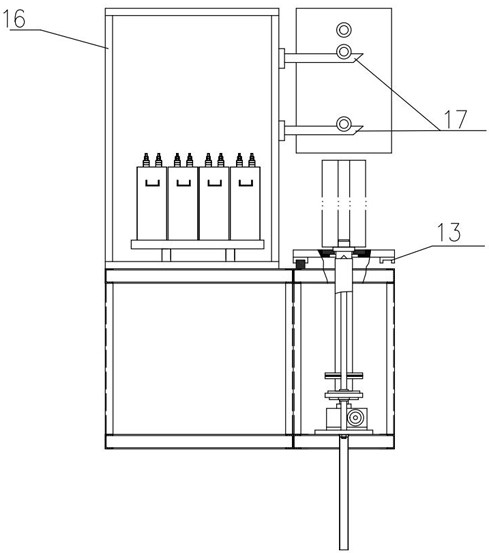

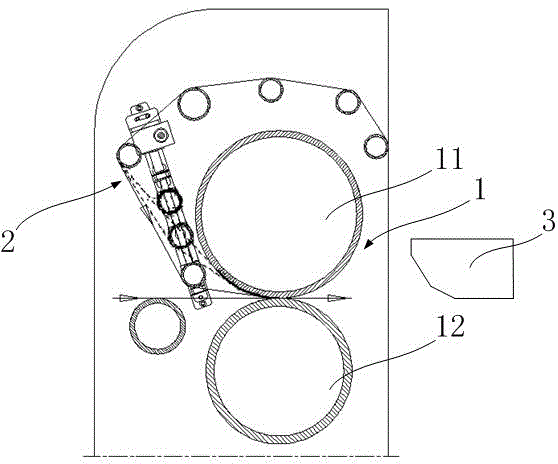

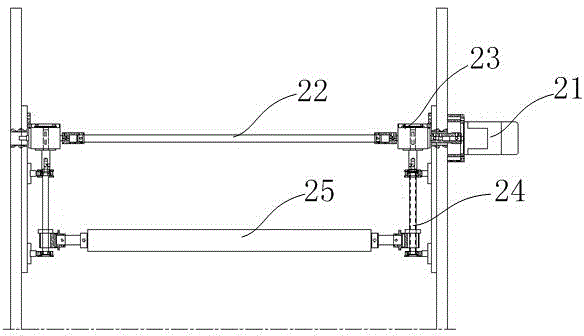

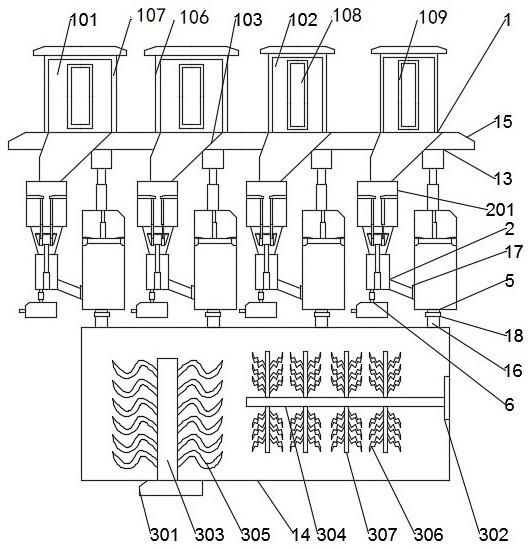

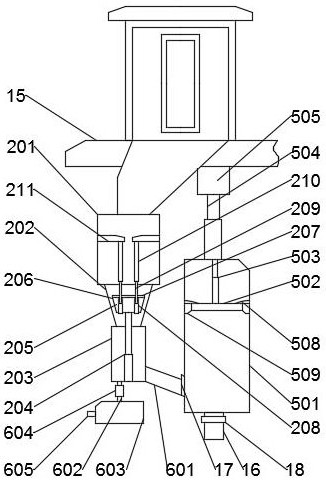

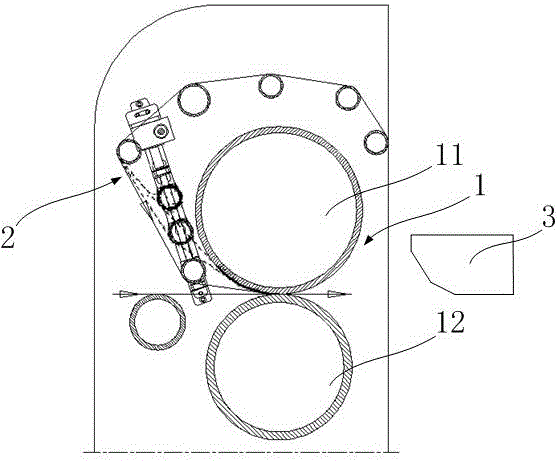

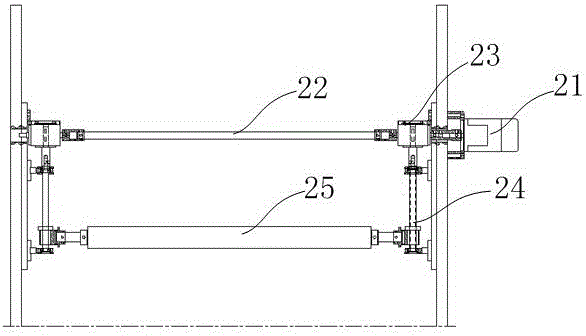

The invention relates to the technical field of plunger paste production, and provides a plunger paste production line and a production process. The plunger paste production line comprises a rotary conveying device, the rotary conveying device is connected with a gum dipping and drying device, the gum dipping and drying device is connected with a material transferring device, and the material transferring device is connected with a plunger paste assembling device; the rotary conveying device comprises a rotary conveying frame, a rotary chain and a positioning jig; the gum dipping and drying device comprises a gum dipping mechanism, a gum homogenizing mechanism and a drying box body; the material transferring device comprises a material transfer table, a material transfer mechanism and a material taking and placing mechanism; and the plunger paste assembling device comprises an assembling frame, and an axial adjusting type material shaft, a slotting assembly, a satellite type rotating assembly, a finished product taking mechanism and a multi-action material moving mechanism are arranged on the assembling frame. The production process of automatic feeding of plunger paste semi-finished products, gum dipping, drying, transferring, plunger paste assembling and attaching, and automatic discharging and collection of finished plunger paste in the plunger paste production process is achieved, and the plunger paste production efficiency is greatly improved.

Owner:SHANDONG HOACO AUTOMATION TECH

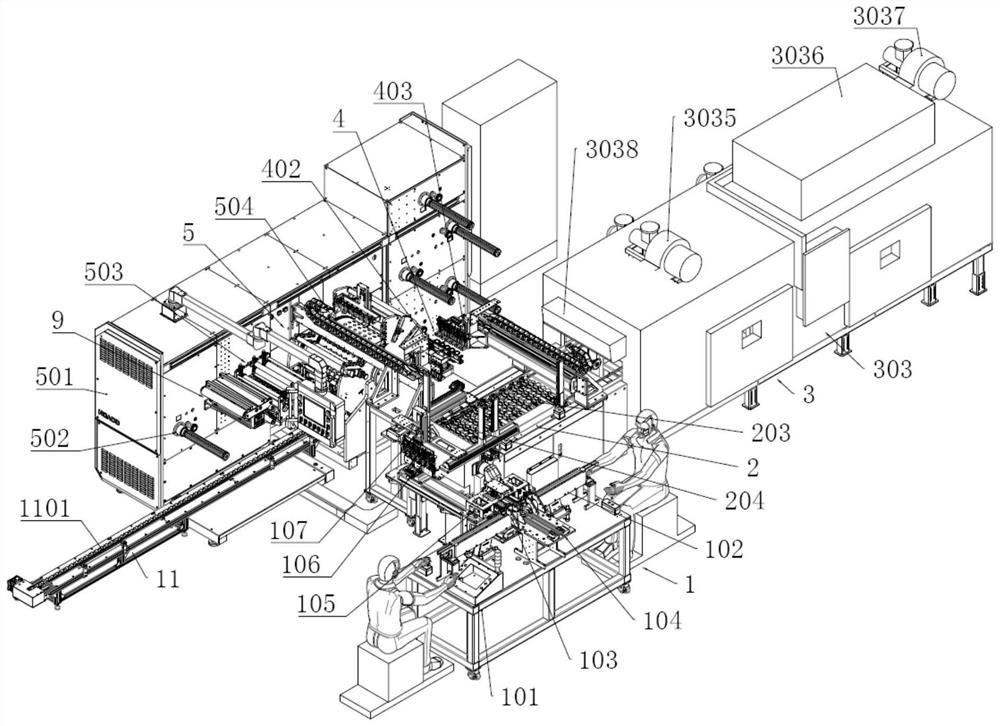

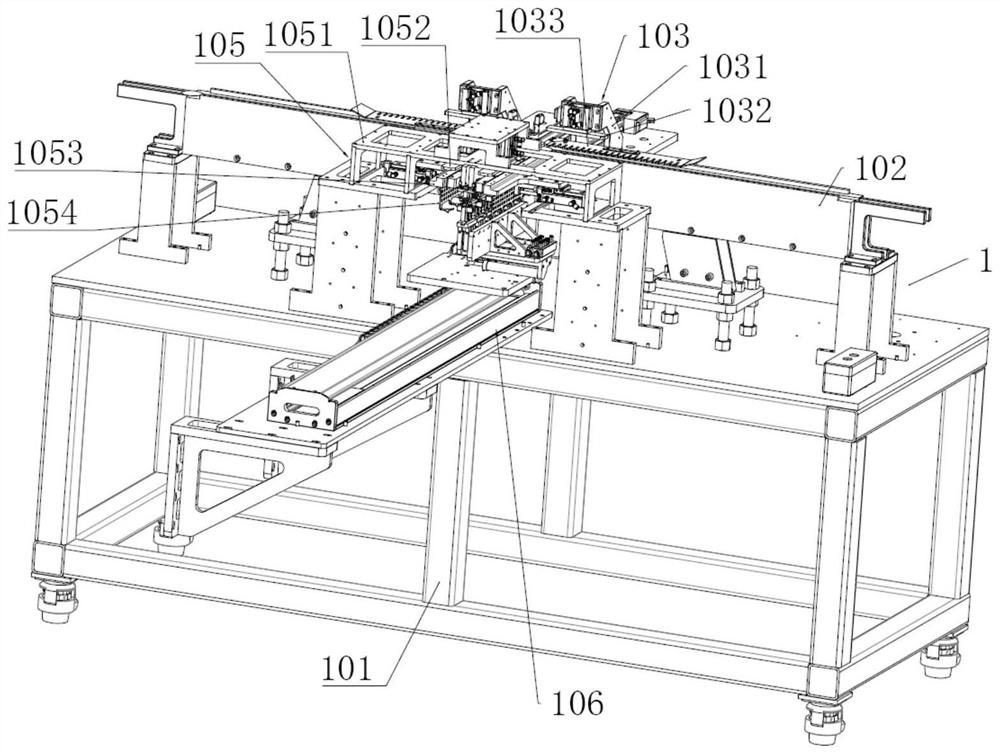

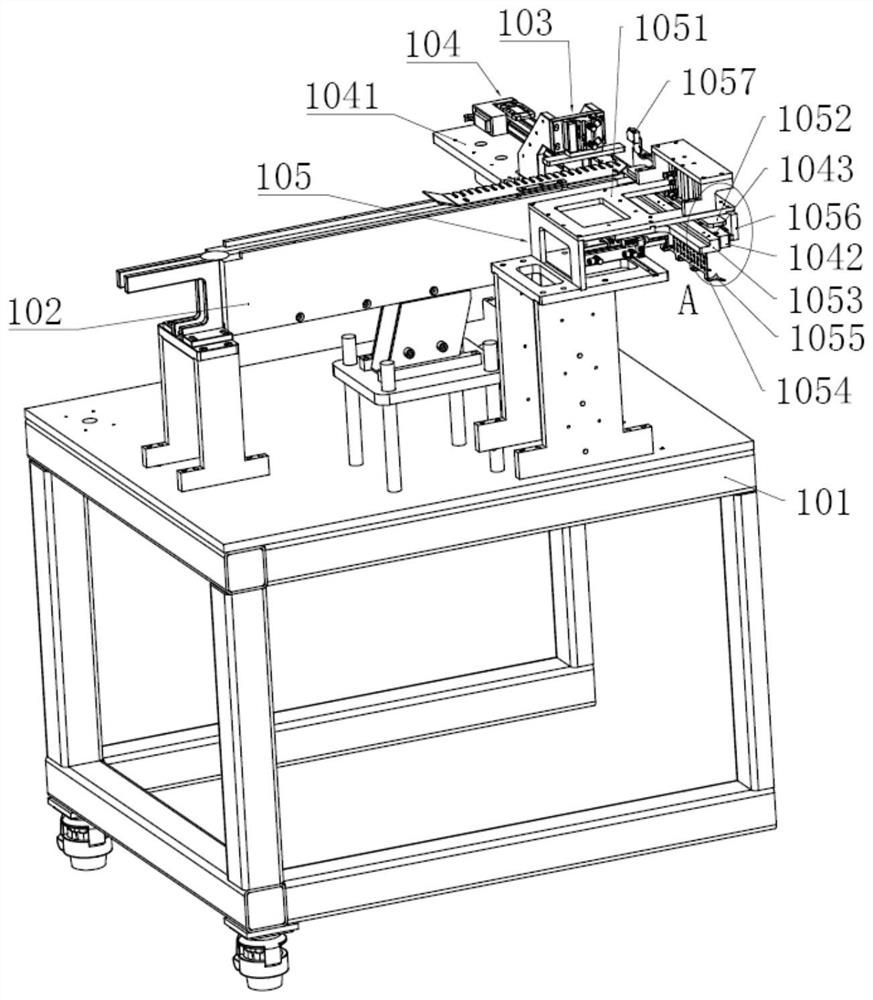

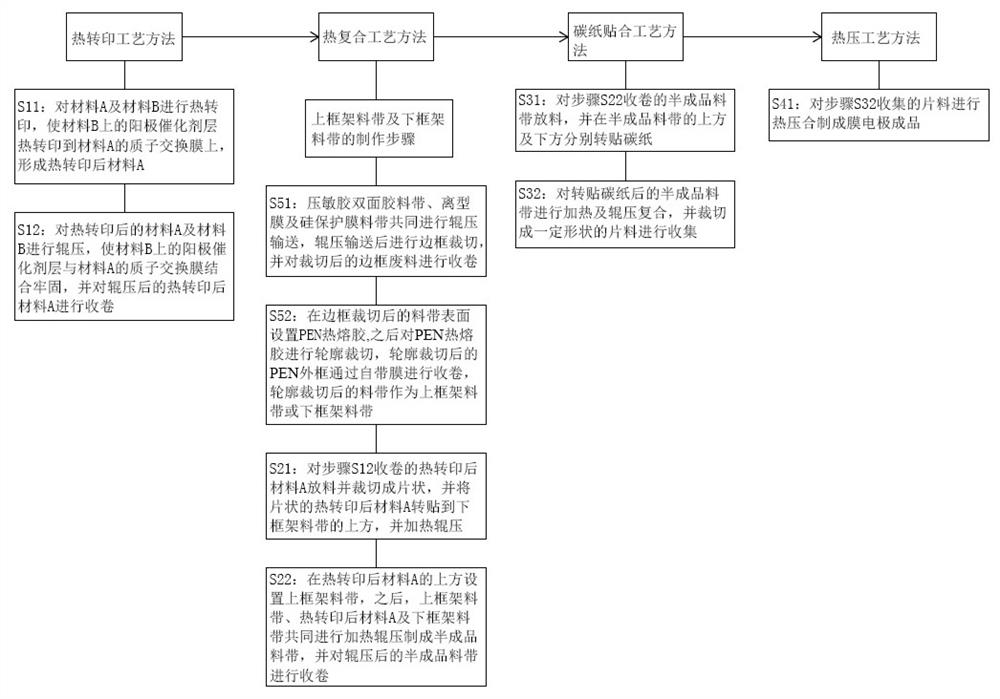

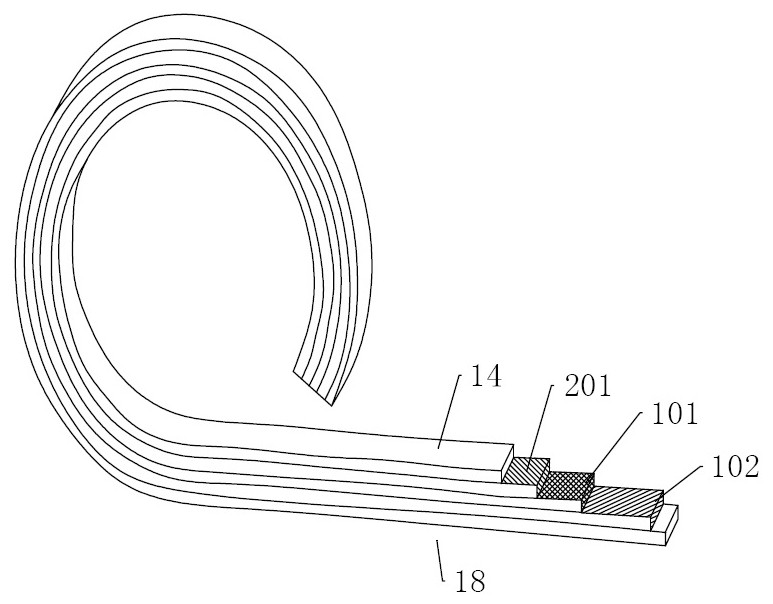

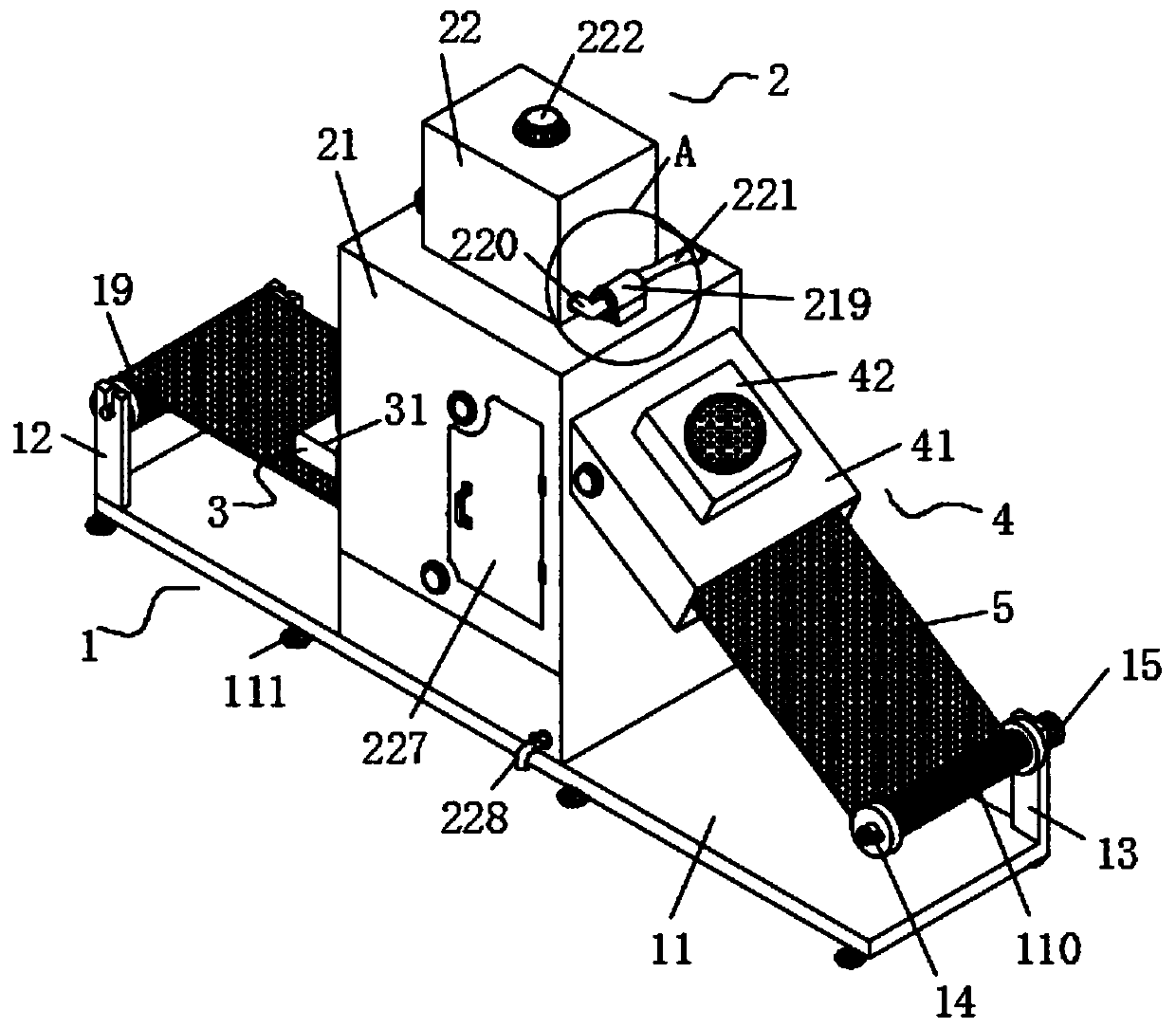

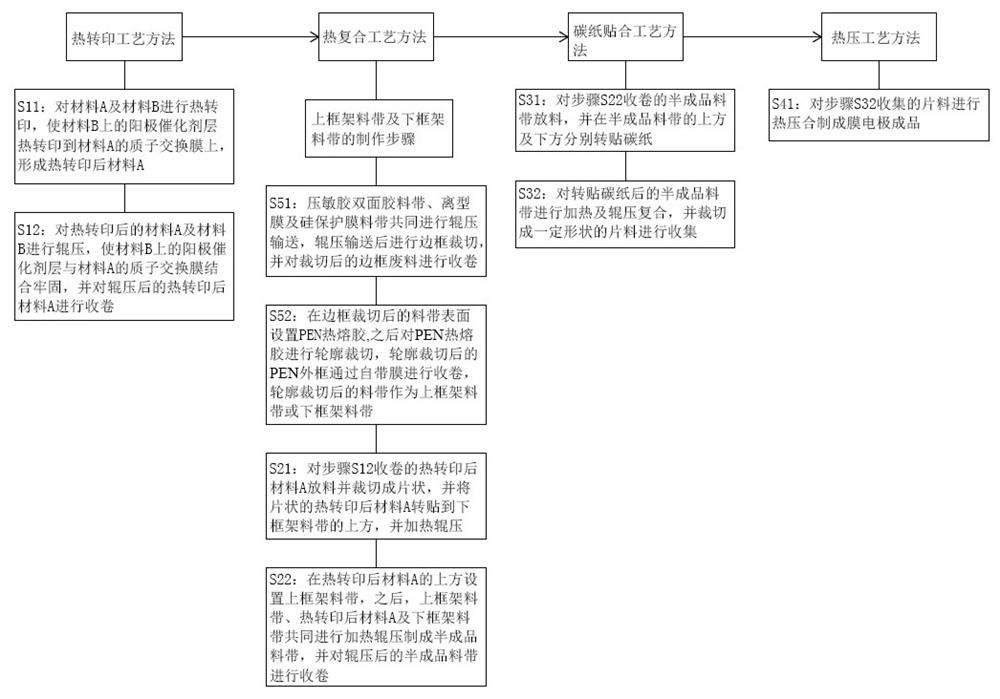

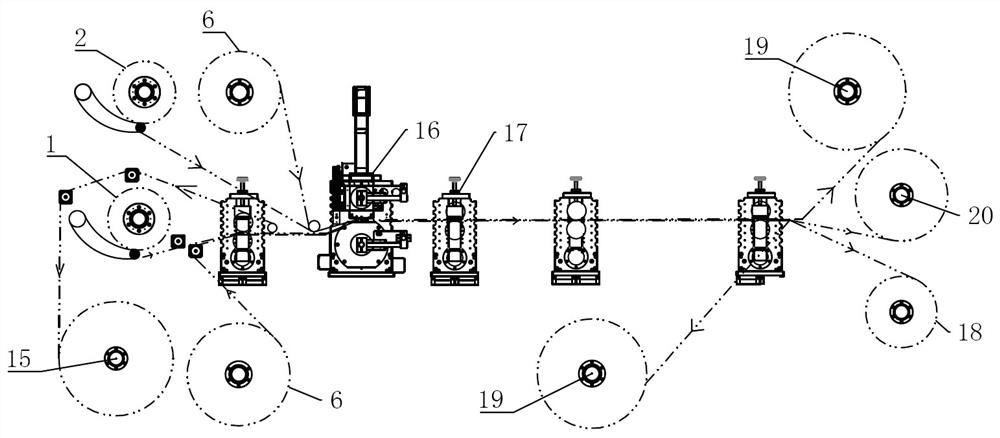

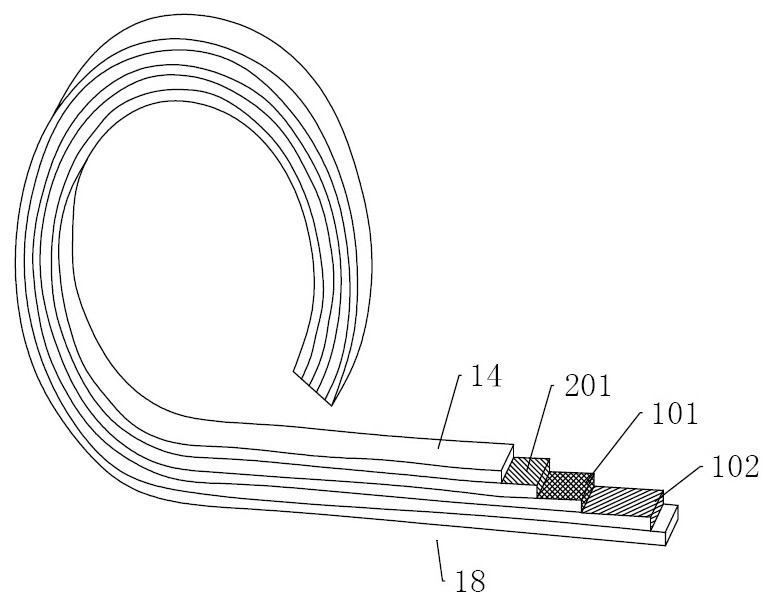

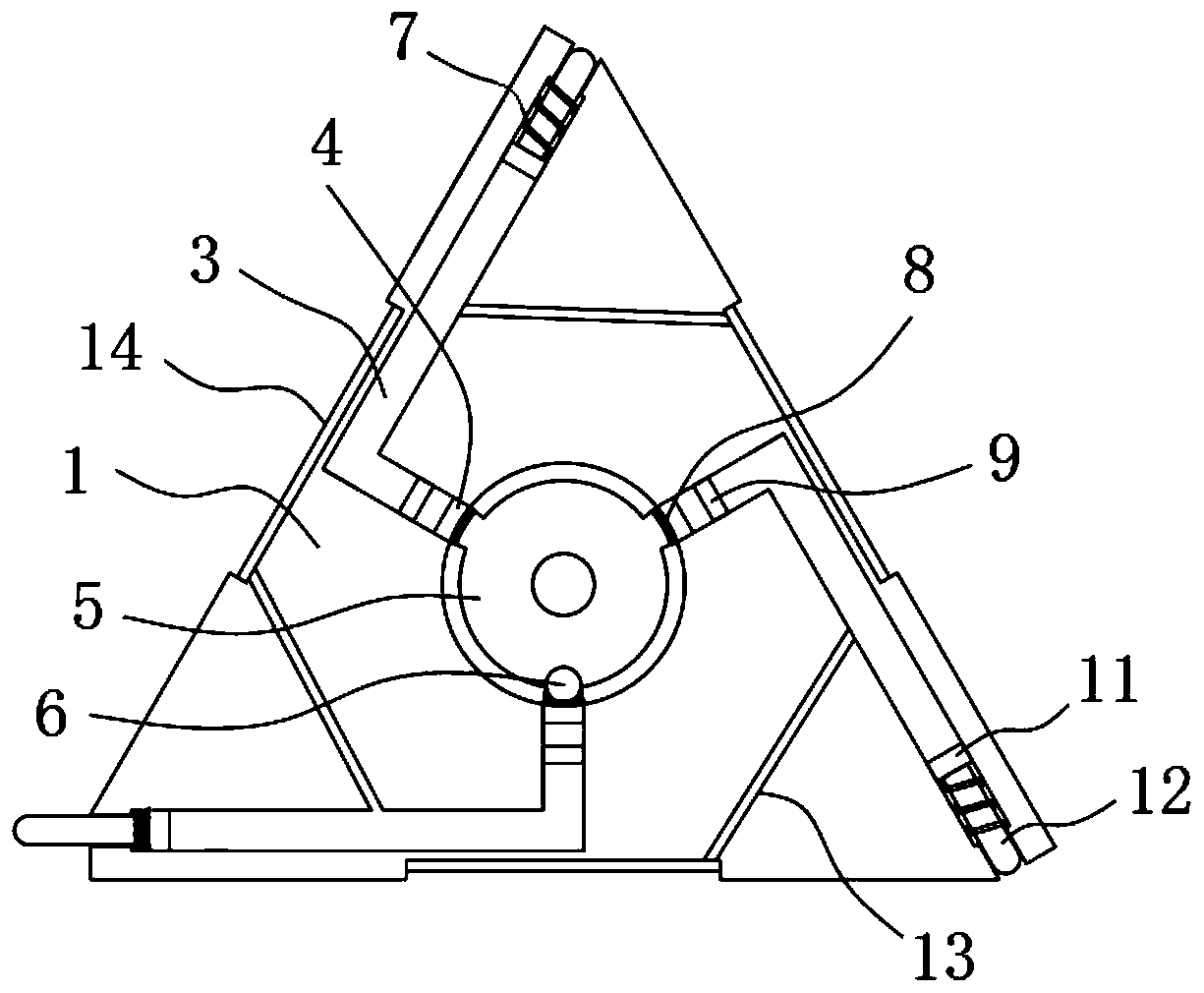

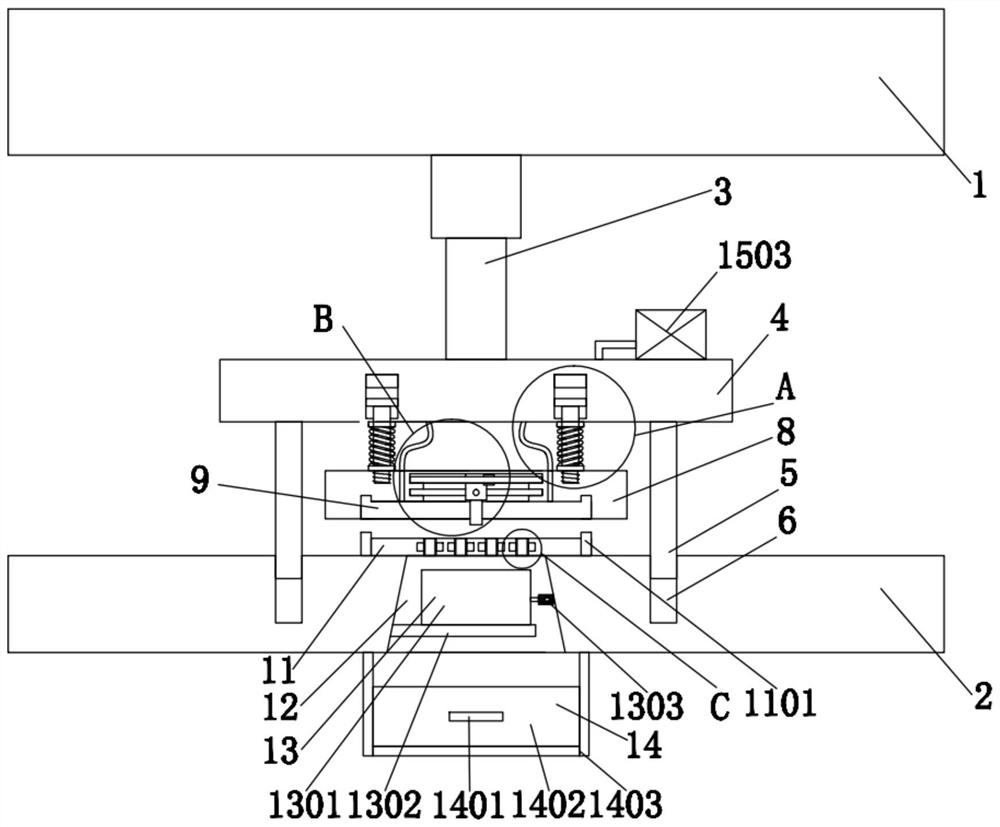

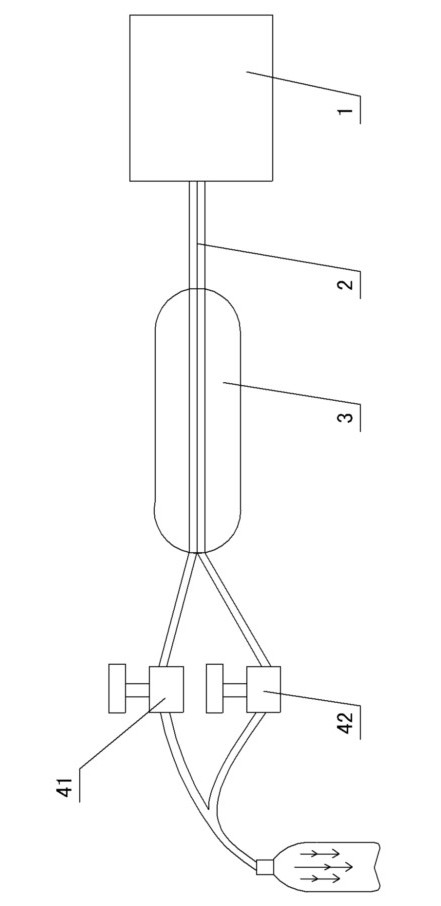

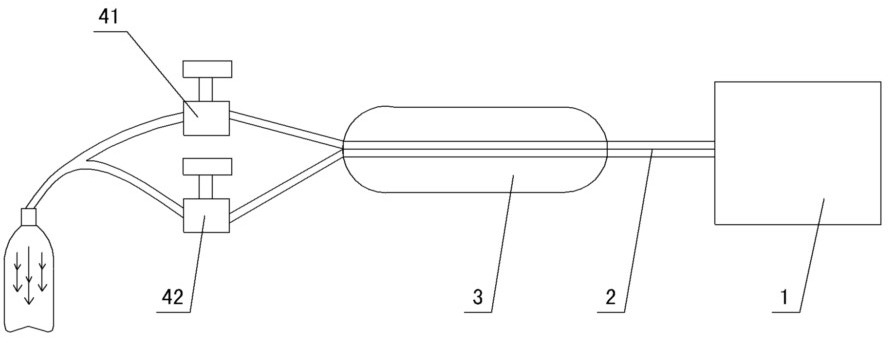

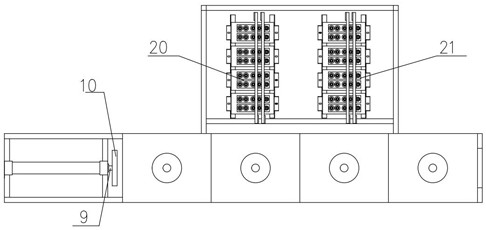

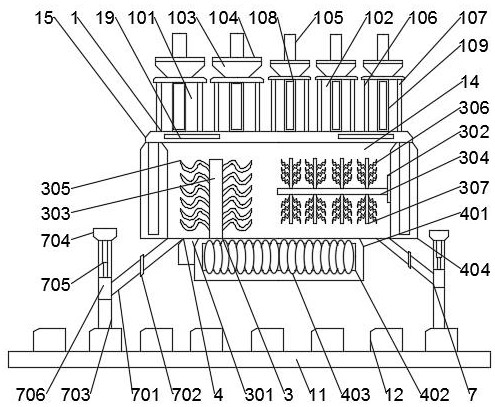

Process method for producing membrane electrode

ActiveCN113517459ASimple processComposite effect is goodFinal product manufactureCell electrodesManufacturing engineeringCarbon paper

The invention relates to the technical field of membrane electrode production processes, and provides a process method for producing a membrane electrode. The process method comprises a thermal transfer printing process method, a thermal compounding process method, a carbon paper laminating process method and a hot pressing process method. The thermal transfer printing process method comprises the following steps that S11, thermal transfer printing is performed on a material A and a material B; and S12, the material A and the material B subjected to heat transfer printing are rolled. The thermal compounding process method comprises the steps that S21, a material A subjected to thermal transfer printing is cut into sheets, and the sheets are transferred and pasted to the position above a lower frame material belt; and S22, an upper frame material belt is arranged above the material A subjected to heat transfer printing, and a semi-finished product material belt is formed through heating and rolling. The carbon paper laminating process method comprises the following steps: S31, respectively transferring and laminating carbon paper above and below a semi-finished product material belt; and S32, heating, rolling and compounding, and cutting into sheets. The hot-pressing process method comprises the following step of S41, carrying out hot pressing on a sheet material. Continuous automatic production of the membrane electrode is realized, and the production efficiency and quality of the membrane electrode are improved.

Owner:SHANDONG HOACO AUTOMATION TECH

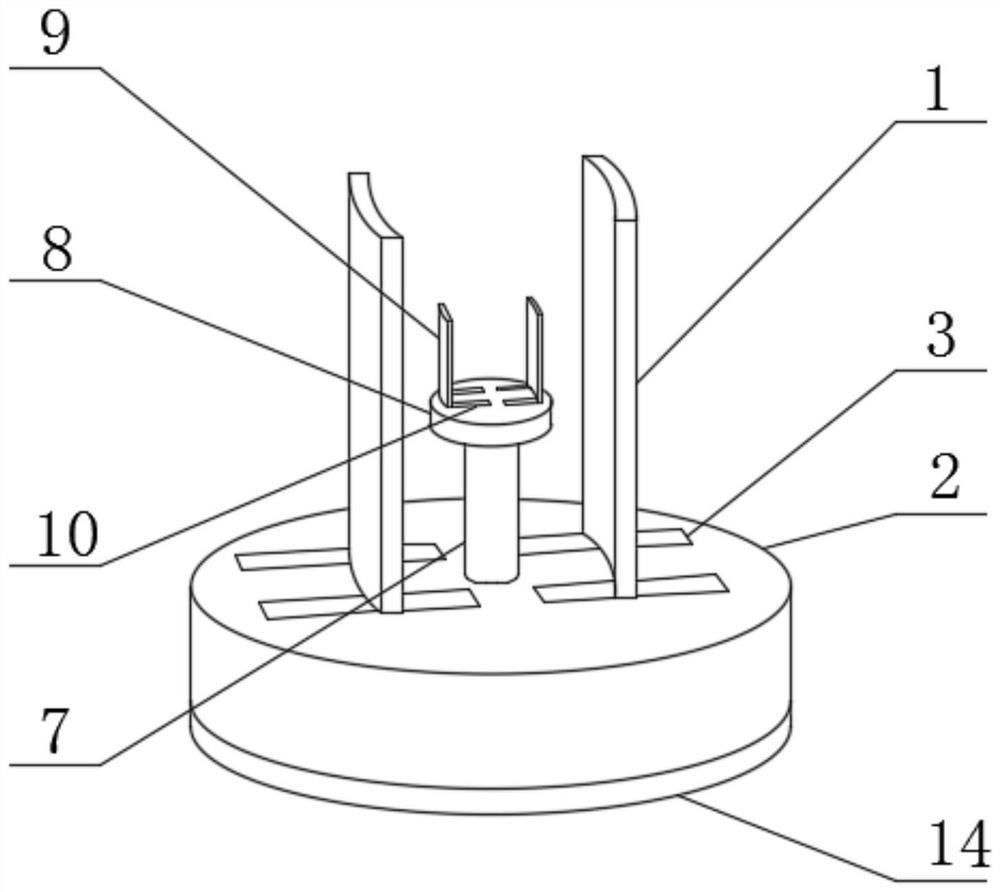

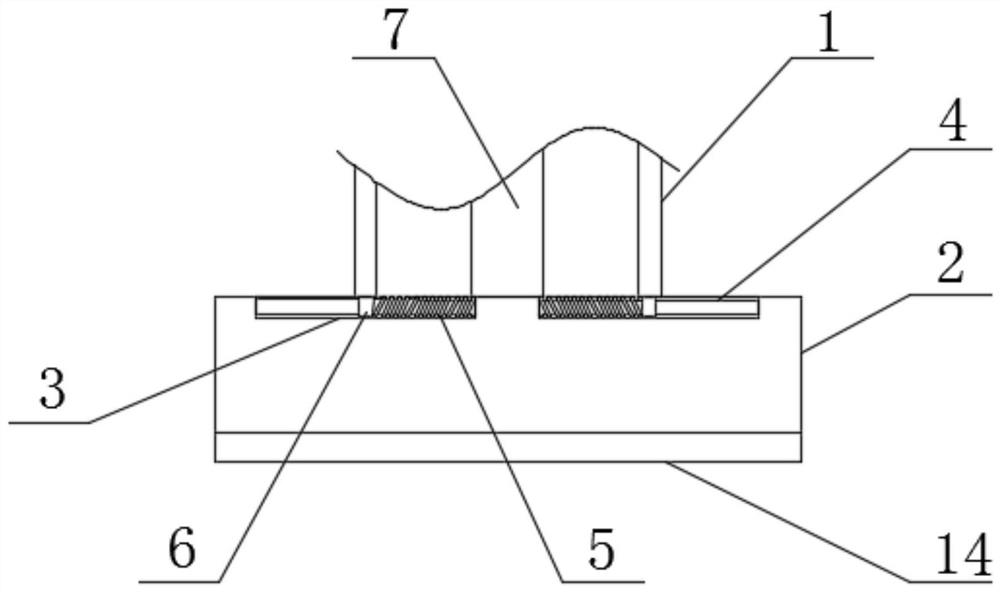

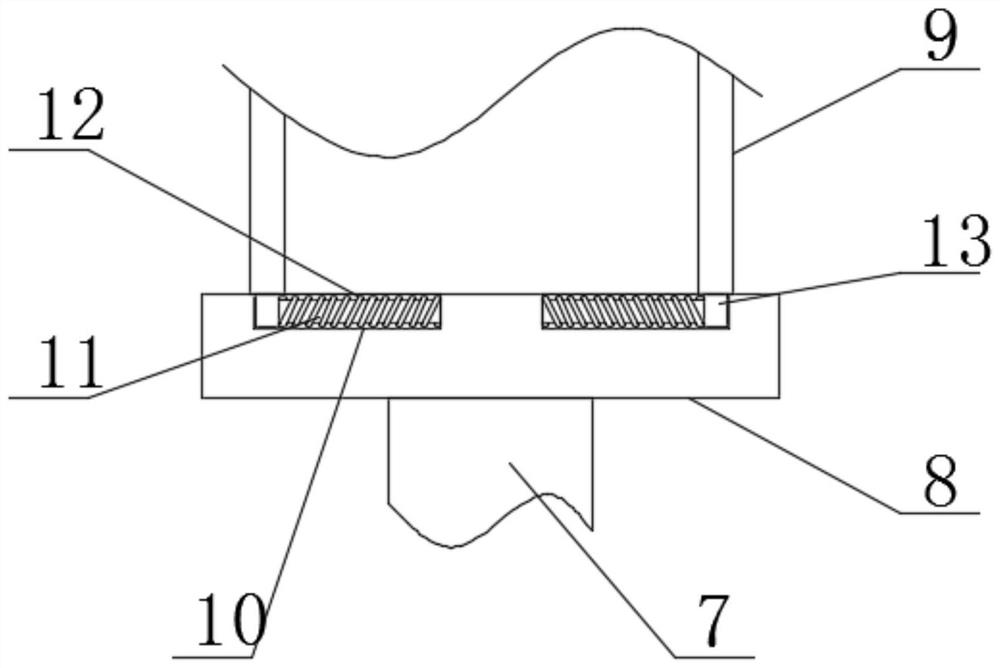

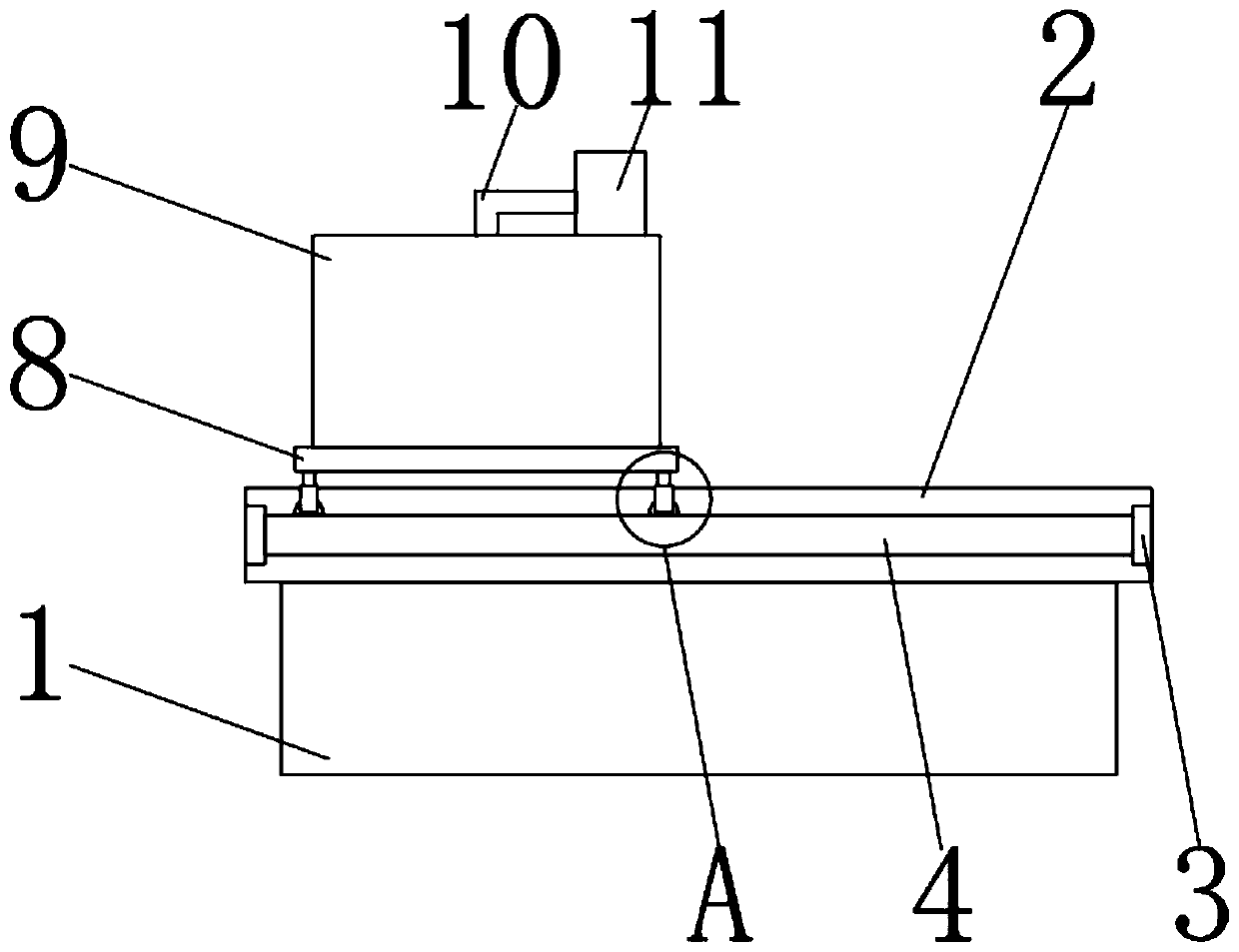

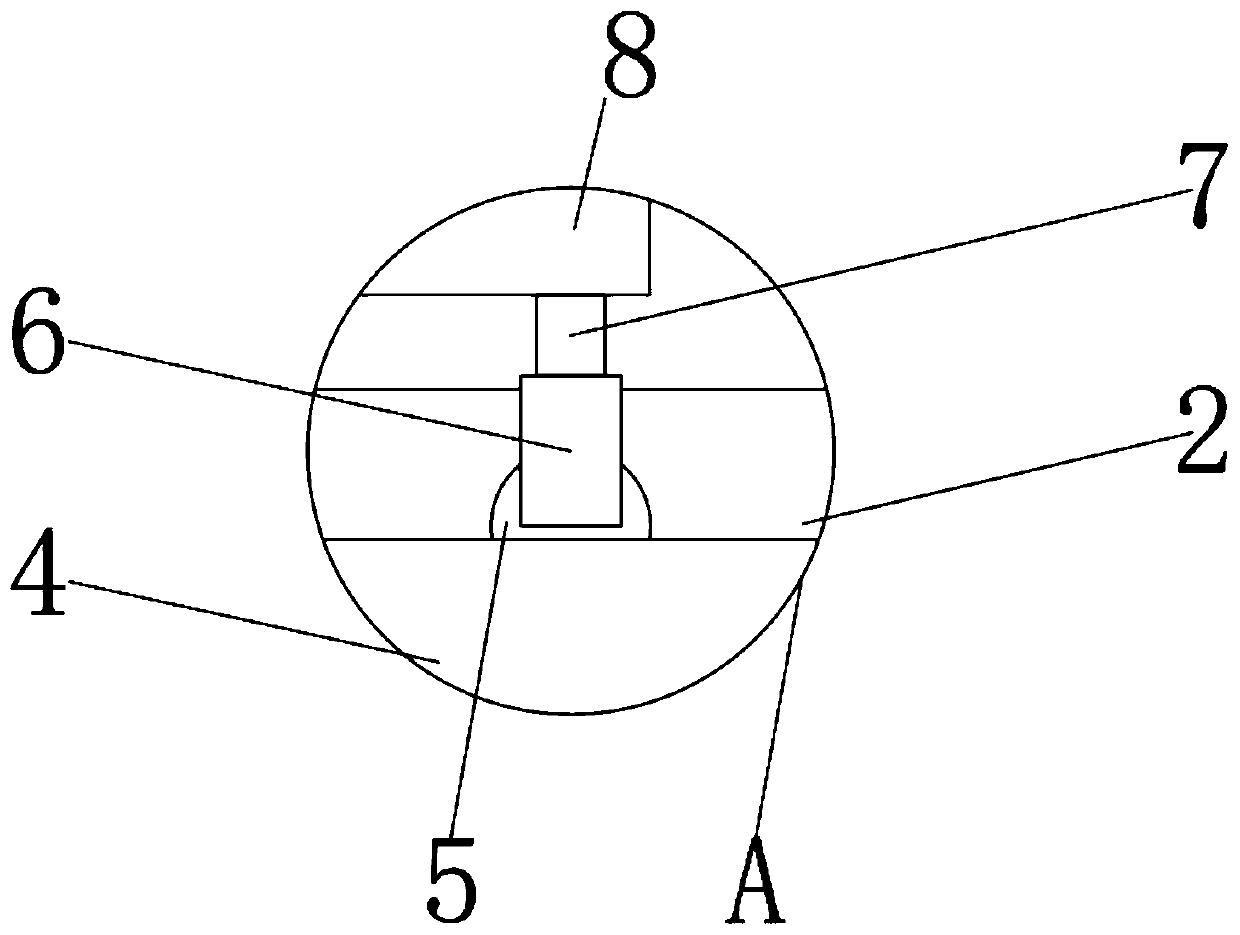

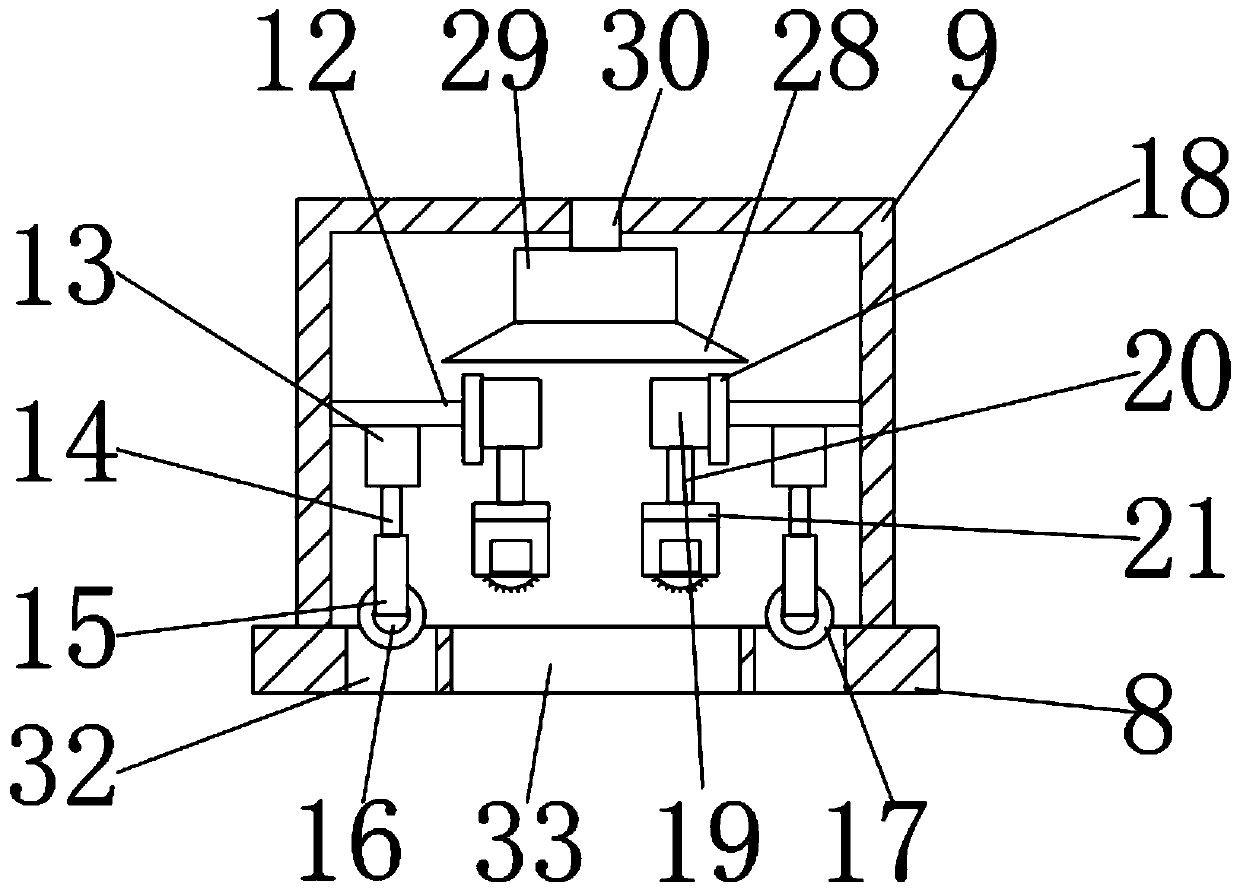

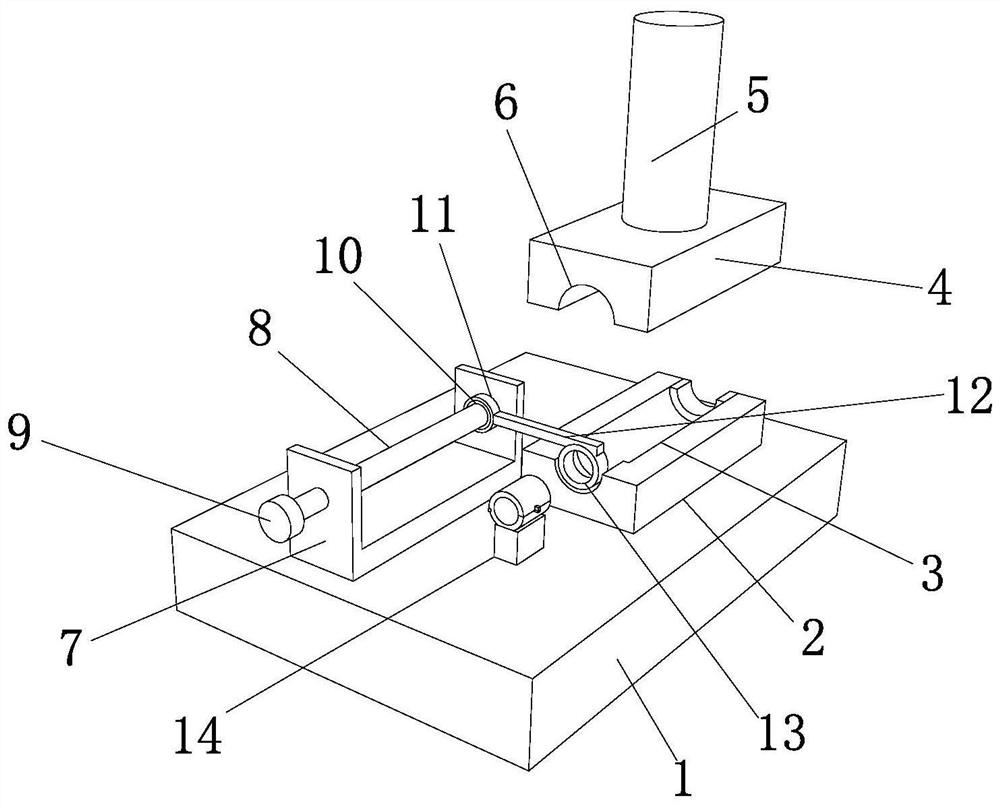

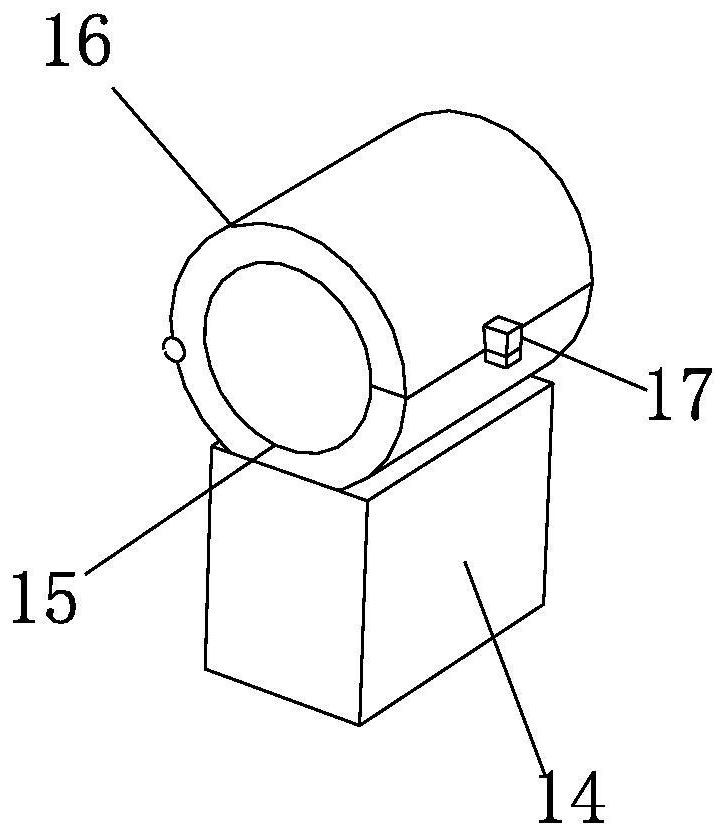

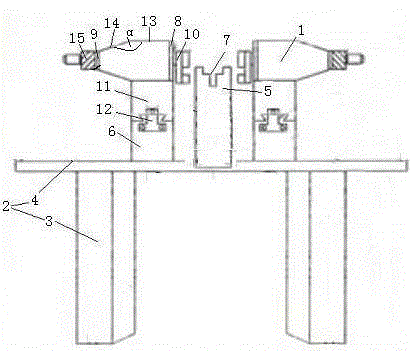

Bearing fixture structure for bearing production and processing

InactiveCN111791072AQuick fixAvoid burnsWork holdersPositioning apparatusIndustrial engineeringProduction quality

The invention relates to the technical field of bearing production and processing, specifically to a bearing fixture structure for bearing production and processing. A base plate is provided under a first clamping block, and a first chute is symmetrically formed in the upper surface of the base plate under the first clamping block; a first guide rod is fixed in the first chute; a first spring sleeves the first guide rod; the first spring and the first clamping block are connected by a first connecting block; a support column is fixed at the middle position of the upper surface of the base plate; and a support plate is fixed on the upper surface of the support column. The bearing fixture structure of the invention is simple in structure; and in the bearing production and processing process,a bearing can be quickly fixed using a fixture only by means of simple operation, so that the scald of workers during processing is prevented, the fixation stability is achieved, and moreover, the unnecessary economical loss of enterprises due to influence from the production quality caused by the surface wear of the bearing due to excessive clamping by the fixture can be prevented.

Owner:云和县达祥凯机械设计工作室

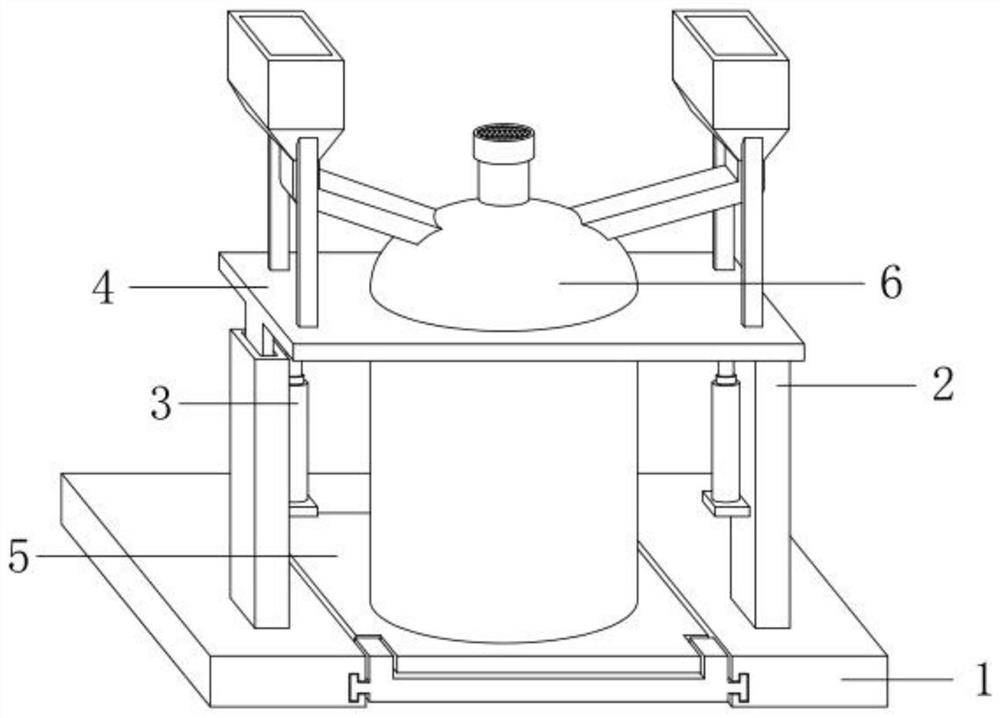

Cosmetic raw material mixing and stirring device

InactiveCN111939791AEasy to pourAvoid incomplete mixingTransportation and packagingRotary stirring mixersEngineeringProduction quality

A cosmetic raw material mixing and stirring device is disclosed. The device comprises a base, sliding ways, two first telescopic rods, and a lifting table, wherein a groove is formed in the middle ofthe front side of the base in the front-back direction; sliding grooves are formed in the left side and the right side of the inner wall of the groove in the base in the front-back direction correspondingly; the two sliding ways are connected with the left side and the right side of the upper surface of the base through screws in the up-down direction correspondingly; the two first telescopic rodsare arranged on the inner sides of the two sliding ways in the vertical direction correspondingly; the bottom ends of the first telescopic rods are connected with the outer walls of the sliding waysthrough bolts; sliding rails are arranged on the left side and the right side of the bottom end of the lifting table in the vertical direction. According to the cosmetic raw material mixing and stirring device, adaptability is enhanced, incomplete mixing of raw materials is avoided, the quality and the using effect of cosmetics are guaranteed, the stirred cosmetic raw materials can be taken out conveniently, raw material residues in a tank are prevented through pouring, people can clean the interior of the tank easily, and a situation that the raw materials deposit at the bottom of the tank and deteriorate to affect the production quality is avoided.

Owner:陈希凯

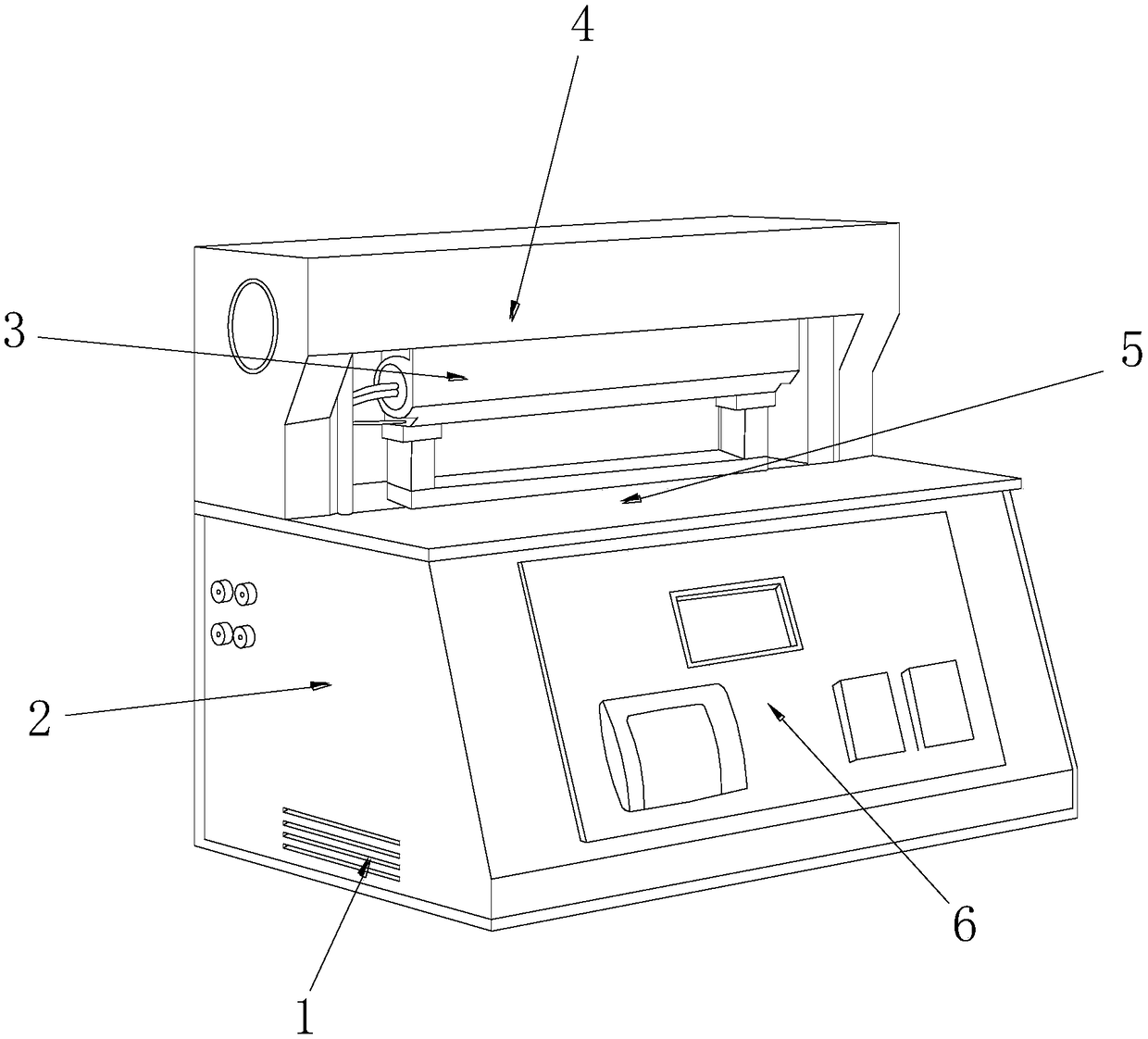

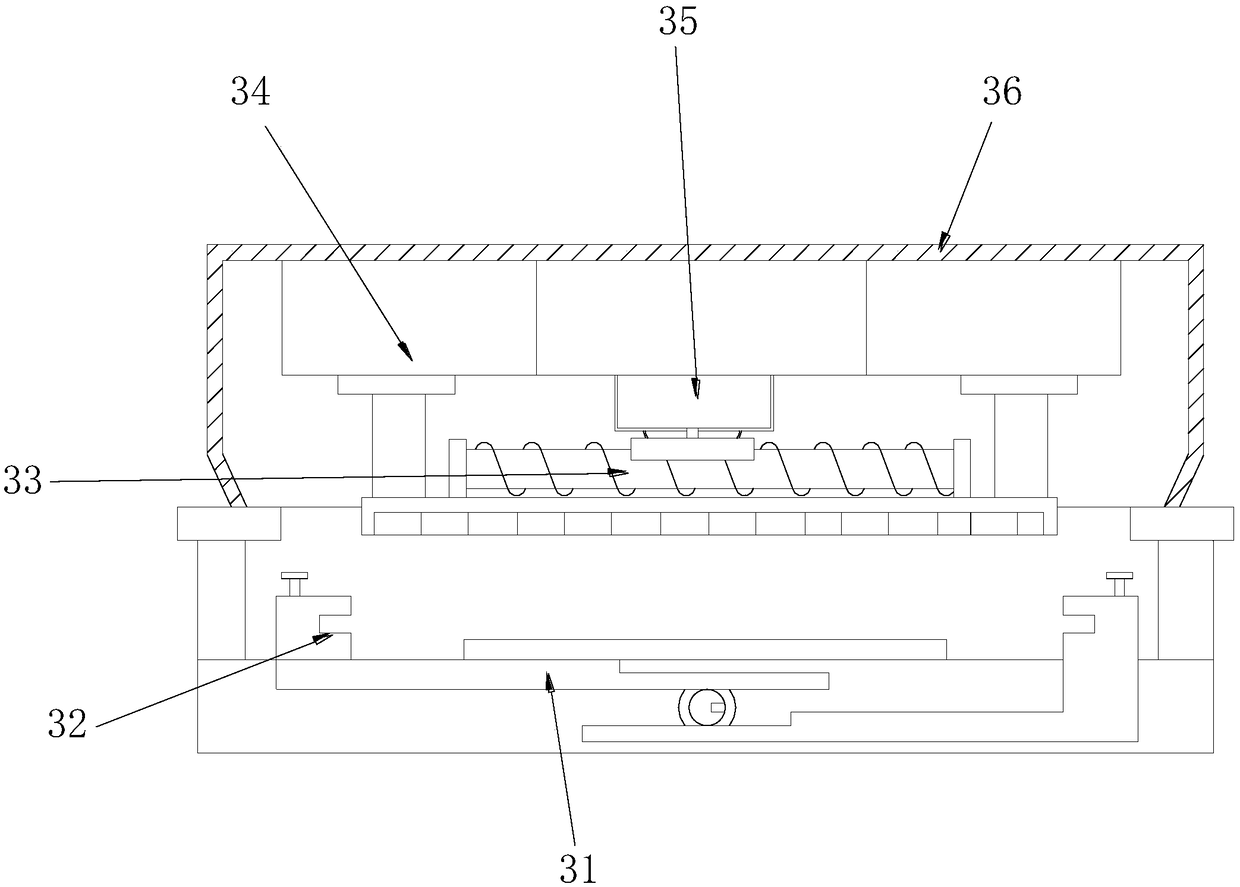

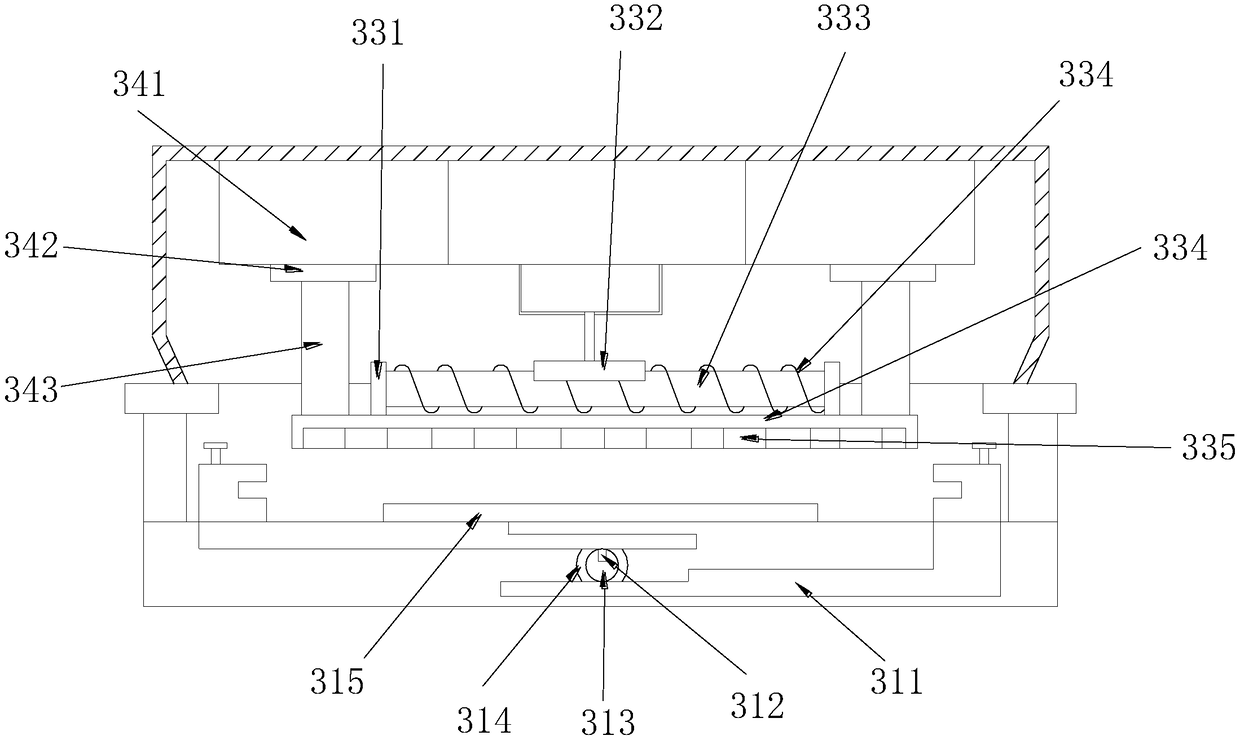

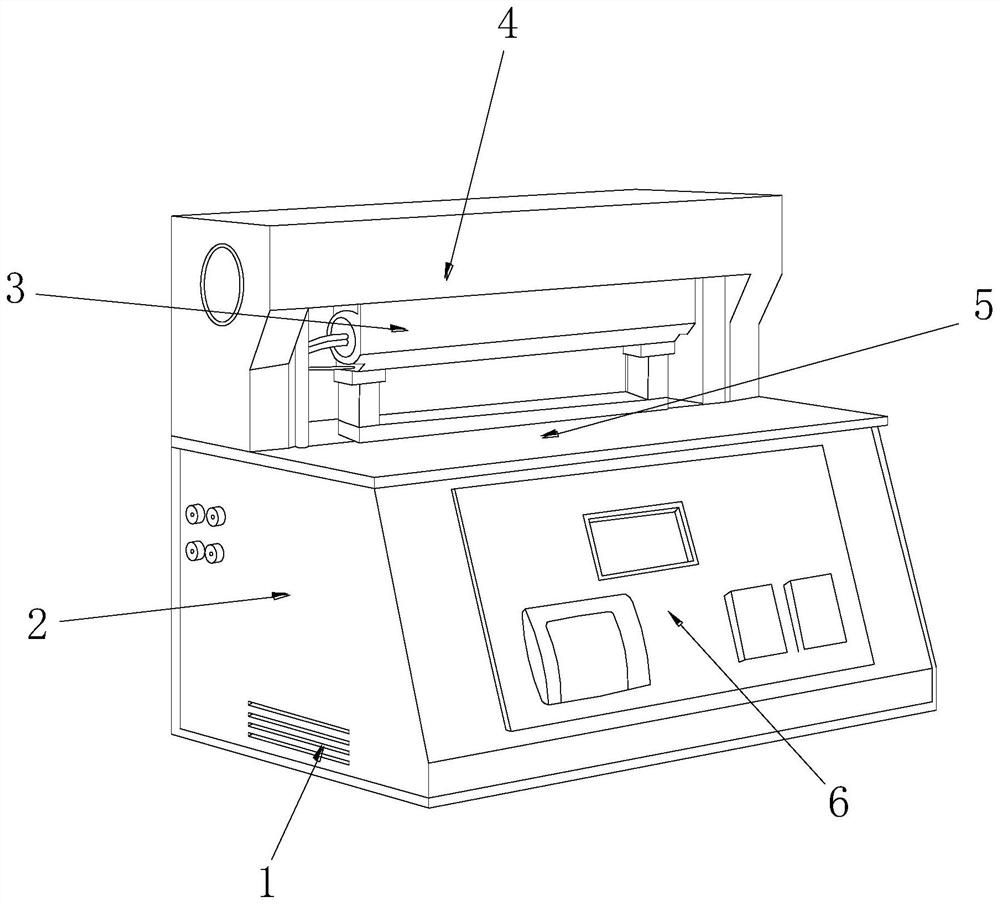

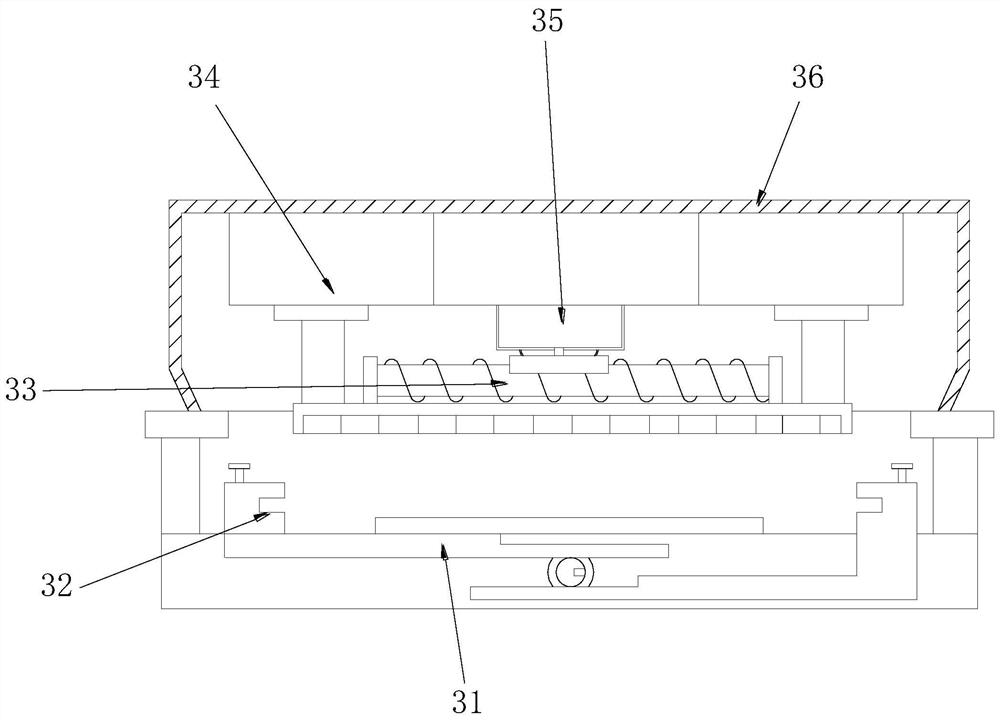

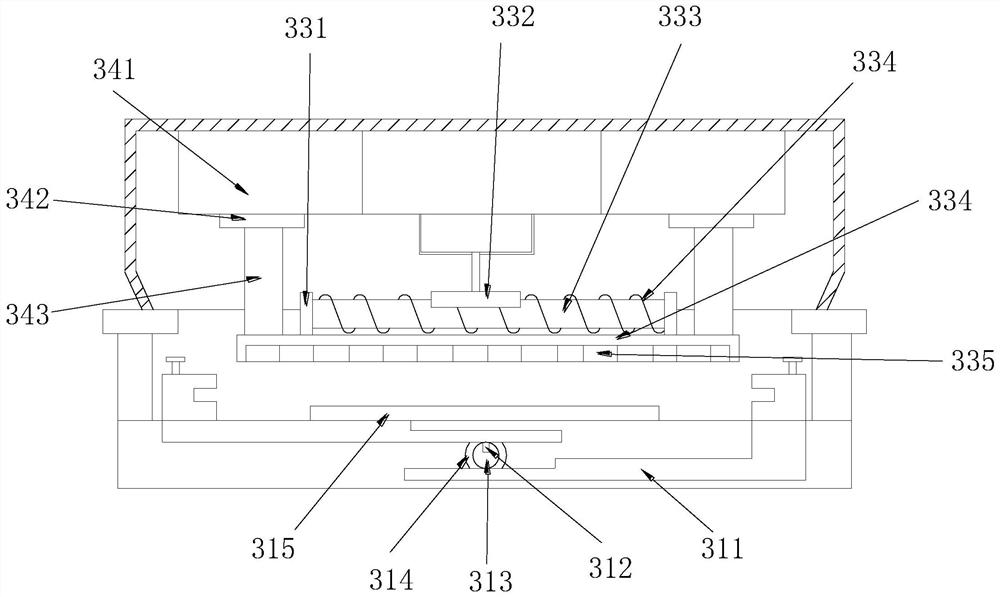

Plastic bag heat-sealing device

ActiveCN109229609AAvoid compromising production qualityWrapper twisting/gatheringEngineeringElectric power

The invention discloses a plastic bag heat-sealing device. The plastic bag heat-sealing device structurally comprises heat dissipation openings, a base, a heat-sealing machine, a support, a workbenchand an operation panel; the heat dissipation openings are formed in the left side of the base, the heat dissipation openings and the base are integrated, and the heat-sealing machine is located over the workbench; by improving part structures of the equipment, a retractable assembly can be matched with a power supply control assembly when moving downward and thus provides a power supply for a heating mechanism, and the situations are avoided that the heat-sealing machine is in a working state all the time, so that a large amount of electric power waste is caused, accordingly, the service lifeof the equipment is shortened, and abrasion of the equipment is aggravated; meanwhile, during clamping, through cooperation of a pull-level mechanism and a plastic bag sealing and clamping mechanism,a plastic bag is pulled tightly, wrinkles on a seal of the plastic bag are removed, and accordingly the situation is avoided that the wrinkles of the plastic bag are pressed and folded together duringpress heat-sealing, so that the production quality of the equipment is influenced.

Owner:海宁易通包装科技有限公司

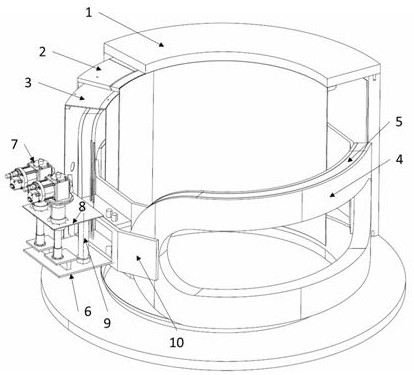

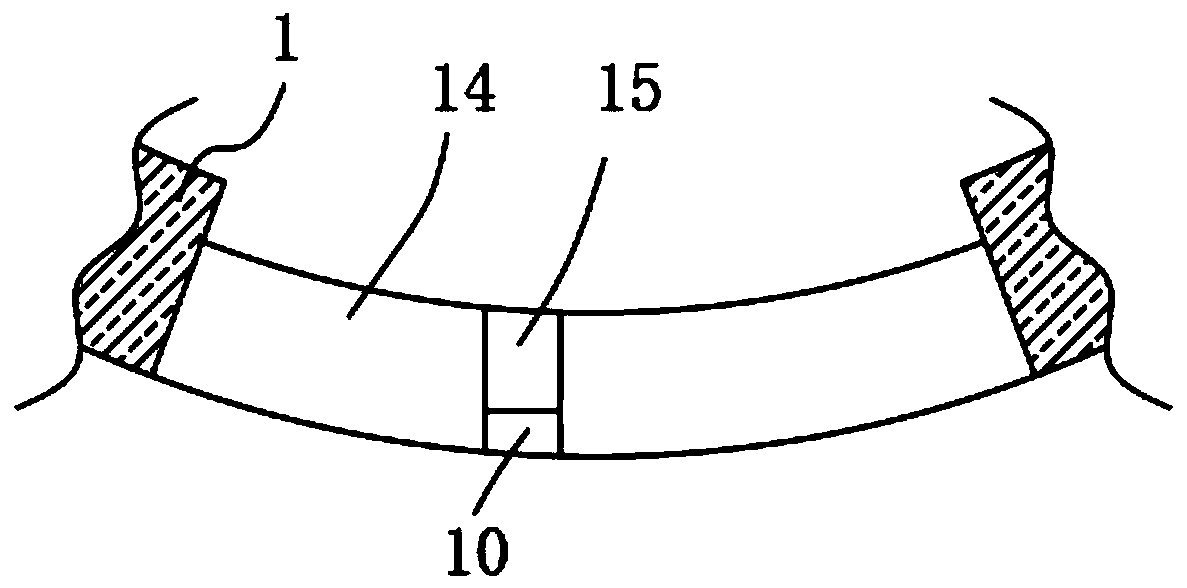

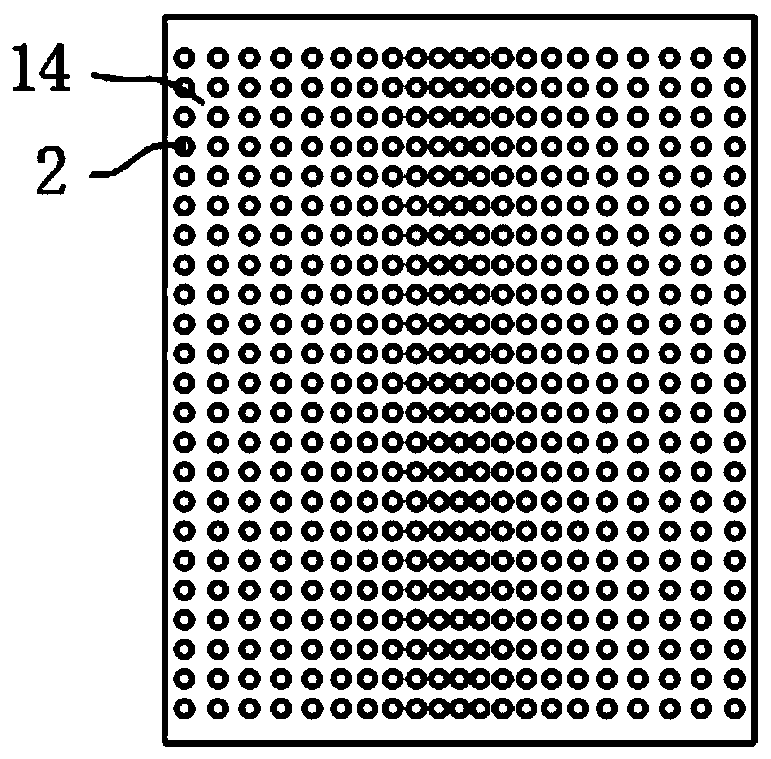

Magnetic control pulling single-crystal superconducting magnet for conduction cooling and cooling method thereof

PendingCN113436825ASpeed up coolingProblems affecting coolingSuperconducting magnets/coilsTest sampleSuperconducting Coils

A magnetic control pulling single-crystal superconducting magnet for conduction cooling comprises a coil framework, and an arc section of the coil framework is connected with a left and right coil cold conduction connecting device. The upper side of the left and right coil cold conduction connecting device is provided with a cold shield cold conduction device, and the lower side of the left and right coil cold conduction connecting device is provided with a coil cold conduction device; the first-stage cold head of a G-M refrigerator is connected with the second-stage cold head of the G-M refrigerator through a heat pipe; and the upper side of the cold shield cold conduction device is connected with the G-M refrigerator. The cooling method comprises the following steps: 1 setting the cooling magnetic control pulling single-crystal superconducting magnet; 2 filling the heat pipe with gas, and starting the G-M refrigerator to cool a test sample; and 3 achieving rapid cooling of the superconducting coil. The cooling method has the characteristic of high cooling efficiency.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

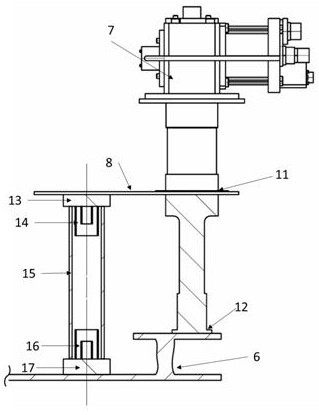

Clamp for automobile floor assembly

ActiveCN103624443AEasy to moveReasonable structural designWelding/cutting auxillary devicesAuxillary welding devicesMachiningEngineering

The invention provides a clamp for an automobile floor assembly. The clamp comprises a base, stand columns, lifting mechanisms and clamping mechanisms. The clamping mechanisms comprise the left clamping mechanism and the right clamping mechanism. The left clamping mechanism and the right clamping mechanism are symmetrically arranged. The left clamping mechanism is arranged at one end of the base, and the right clamping mechanism is arranged at the other end of the base. The lifting mechanisms are arranged in the middle of the base, the clamping mechanisms are respectively connected with the stand columns, and the stand columns are fixed to the base. The clamp for the automobile floor assembly is reasonable in structural design and capable of accurately positioning and effectively fixing the automobile floor assembly. The lifting mechanisms are arranged in the middle of the base, so that moving of the automobile floor assembly is facilitated, and convenience is provided for production machining. On the premise that the cost is low, the clamp for the automobile floor assembly can effectively fix the automobile floor assembly, operation is convenient, machining production is facilitated, production efficiency is improved, and meanwhile production benefits are increased.

Owner:JIANGSU KAWEI AUTOMOBILE IND GRP CO LTD

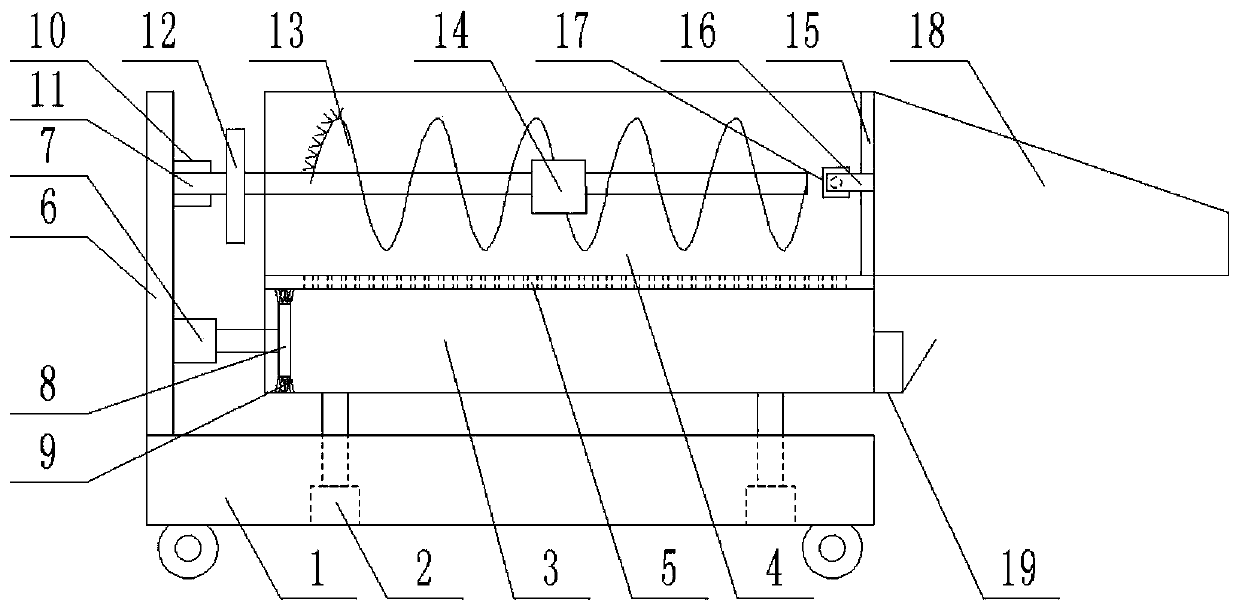

Electrician insulating tape processing device with automatic winding function

ActiveCN109692785AApply glue evenlySave paintLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention discloses an electrician insulating tape processing device with an automatic winding function. The electrician insulating tape processing device comprises a base, the upper end of the left side of the base is fixedly connected with a shell, the left end and the right end of the shell are fixedly connected with supporting strips correspondingly, telescopic rods are rotatably connectedto the inner sides of the supporting strips, the exteriors of the telescopic rods are movably connected with rollers correspondingly, and bare adhesive tape is arranged on the inner side of the shell; and the upper side of the inner surface of the shell is fixedly connected with an adhesive spraying device, a soft brush and a scraper in sequence from left to right, an air-drying fan is arranged on the right side of the scraper and fixedly connected with the upper side of the inner surface of the shell, the upper end of the middle of the base is fixedly connected with an oblique plate, the right side of the oblique plate is fixedly connected with a sectioning device, and a finished product box is arranged on the lower part of the front side of the sectioning device and fixedly connected with the upper end of the right side of the base. The electrician insulating tape processing device has the advantages that adhesive coating rewinding and adhesive tape sectioning processes are integrated, adhesive coating is uniform and flat, coating is saved, and fully-automatic equidistant sectioning is achieved.

Owner:全椒百顺塑胶有限公司

Antistatic gauze element and manufacturing equipment thereof

InactiveCN111013924AIncrease productivityLow costMechanical cleaningPressure cleaningManufacturing engineeringCoating

The invention discloses an antistatic gauze element and manufacturing equipment thereof. The antistatic gauze element and manufacturing equipment thereof comprises a bottom frame structure, a coatingstructure, an air blowing assembly and a drying assembly, wherein the bottom frame structure comprises a base, the coating structure comprises a coating box, the coating box is fixedly installed in the middle of the upper end face of the base, a coating box is fixedly installed in the middle of the upper end face of the coating box, a carrier roller I is rotationally connected with the lower end of the interior of the coating box, a carrier roller II is rotationally connected with the upper end of the interior of the coating box, and a coating roller I and a coating roller II are arranged in the middle of the interior of the coating box correspondingly. The antistatic gauze element and the manufacturing equipment thereof have the beneficial effects that the coating structure and the dryingassembly are arranged, gauze element base cloth can be rapidly dried after the gauze element base cloth is coated with antistatic coating, the production efficiency is improved, the air blowing assembly is arranged, air blowing treatment can be conducted on the surface of the gauze element base cloth to remove dust on the surface of the gauze element base cloth, the dust is prevented from affecting the production quality, the coating roller I and the coating roller II are attached to the two end faces of the gauze element base cloth for coating, consumption of the antistatic coating is reduced, and the cost is saved.

Owner:ANHUI JIAOYANG SOFT DOOR

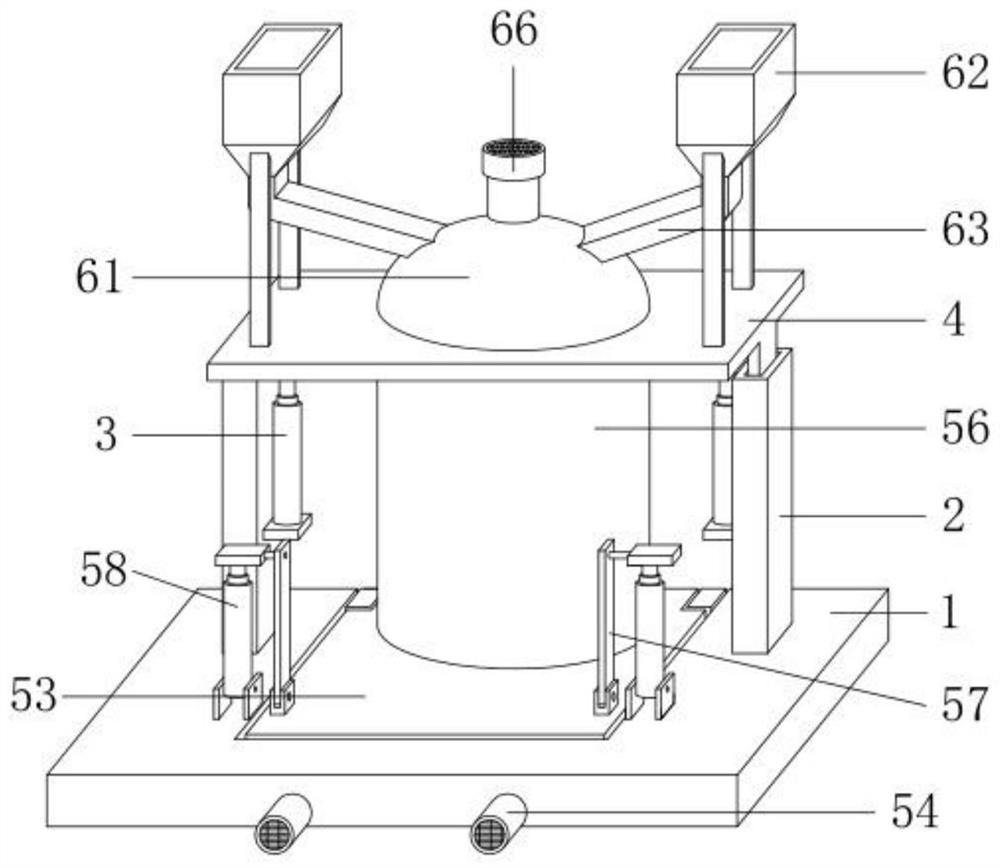

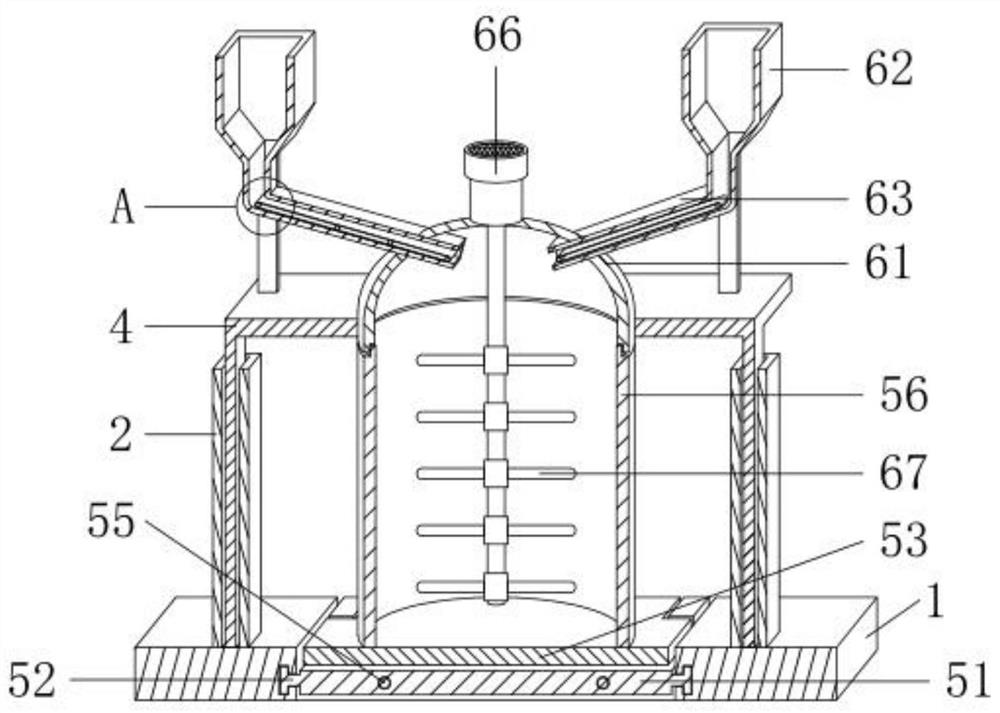

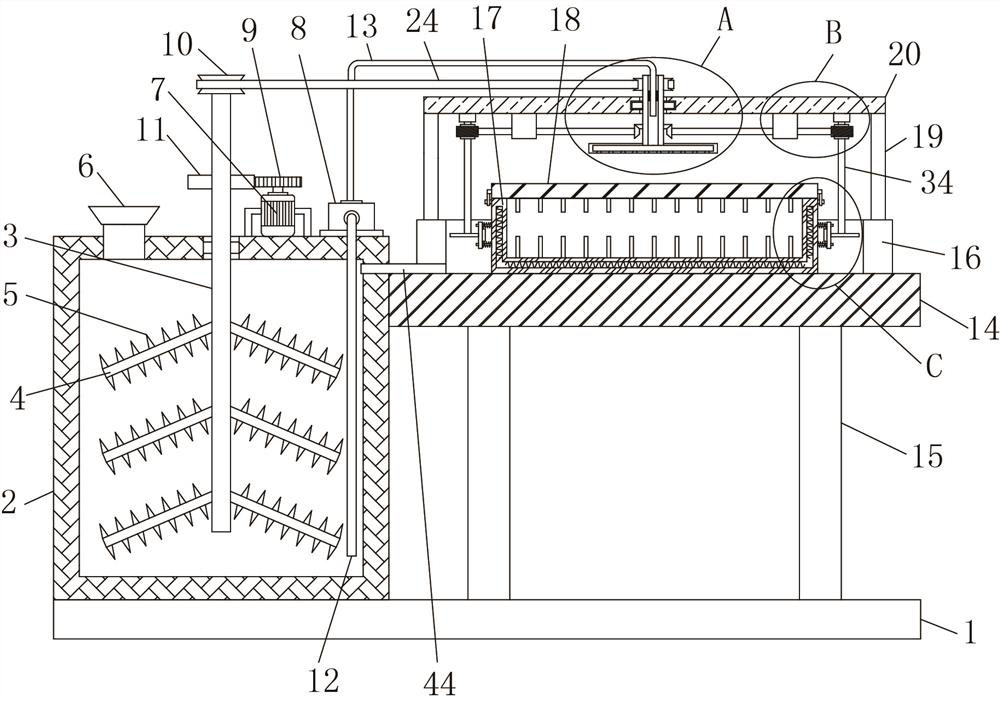

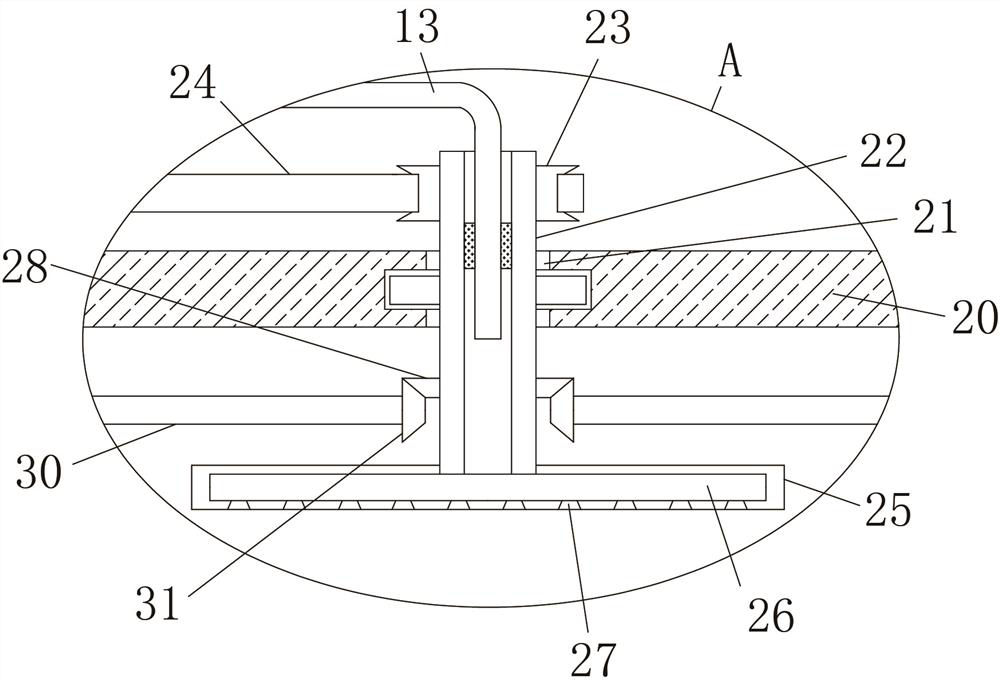

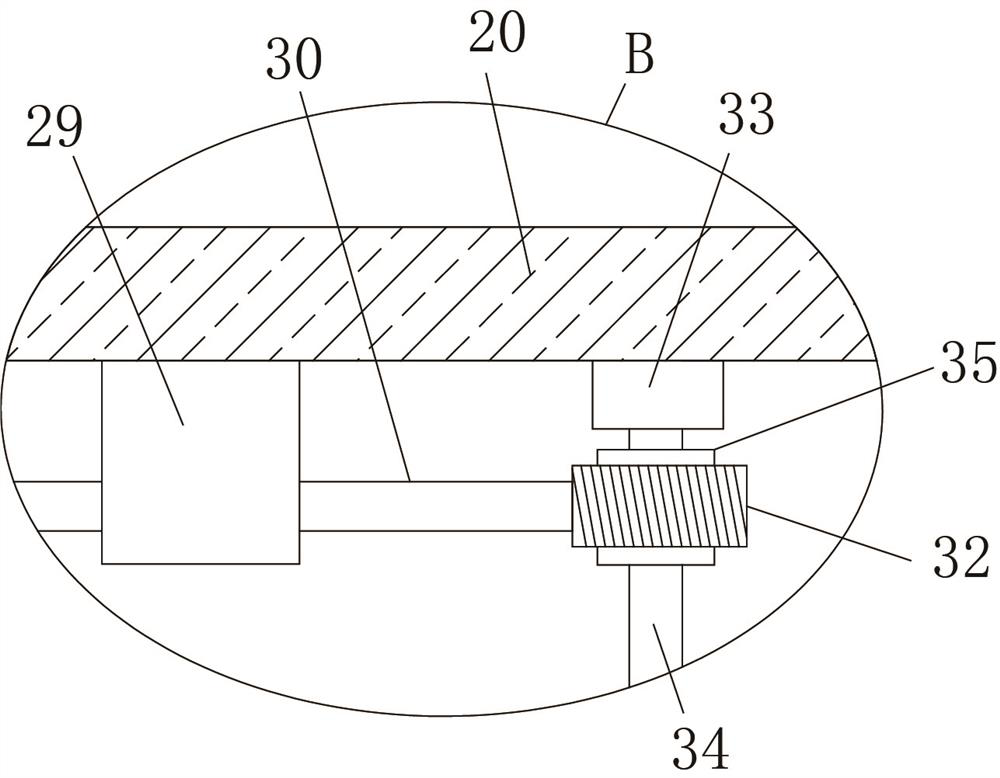

Mixer for shower gel production

InactiveCN109126521AImprove product qualityWith bactericidal functionRotary stirring mixersTransportation and packagingShower gelEngineering

The invention belongs to the field of shower gel production equipment and particularly relates to a mixer for shower gel production. To solve the technical problem of providing a mixer for the showergel production that is of sterilizing and defoaming functions, guarantees good production quality of shower gel, and enables shower gel material oil and water to be blended and become delicate after the shower gel material is mixed, the mixer for the shower gel production is characterized in that the mixer comprises a base, first brackets, a mixing tank, a feed pipe and a cover; the mixing tank isfixedly connected to the top of the base through two first brackets; a first motor is also fixedly connected to the top of the base; a first bearing seat and a third bearing seat are both embedded atthe bottom of the mixing tank. The mixer for the shower gel production has the advantages of having sterilizing and defoaming functions, guaranteeing the produced shower gel to be of good quality, and ensuring the oil and water of the shower gel material to be blended and the shower gel to become delicate.

Owner:吕红霞

A process for producing membrane electrodes

ActiveCN113517459BAvoid damageImprove bindingFinal product manufactureCell electrodesBonding processMembrane electrode assembly

Owner:SHANDONG HOACO AUTOMATION TECH

Transporting device for glass bottles

InactiveCN110834940AAvoid compromising production qualityAvoid crackingConveyorsPackagingStructural engineeringBottle

The invention discloses a transporting device for glass bottles. The transporting device comprises a transporting roller, and is characterized in that the transporting roller is formed by jointing multiple transporting plates; a cavity is further formed in the center of each transporting plate; three mounting grooves are arranged on the inner wall of each cavity at equal distance; two switching spring sheets are arranged in each mounting groove; a touch ball is further arranged in each cavity; three main sealing cavities in L shapes are arranged on each transporting plate; one end of each mainsealing cavity communicates with the corresponding mounting groove, and the other ends of the main sealing cavities face the pointed end positions of the transporting plates; and electromagnets are mounted at the end, close to the mounting grooves, of the main sealing cavities and are electrically connected with the switching spring sheets. According to bearing plates, the transporting devices stretch out only when glass bottles are received, and when the transporting plates suddenly break down and stop rotating, the situation that the first glass bottle on a transporting belt collides with the bearing plates, cracks are generated on the glass bottle, and production quality is influenced can be avoided.

Owner:绍兴市雨芸机械有限公司

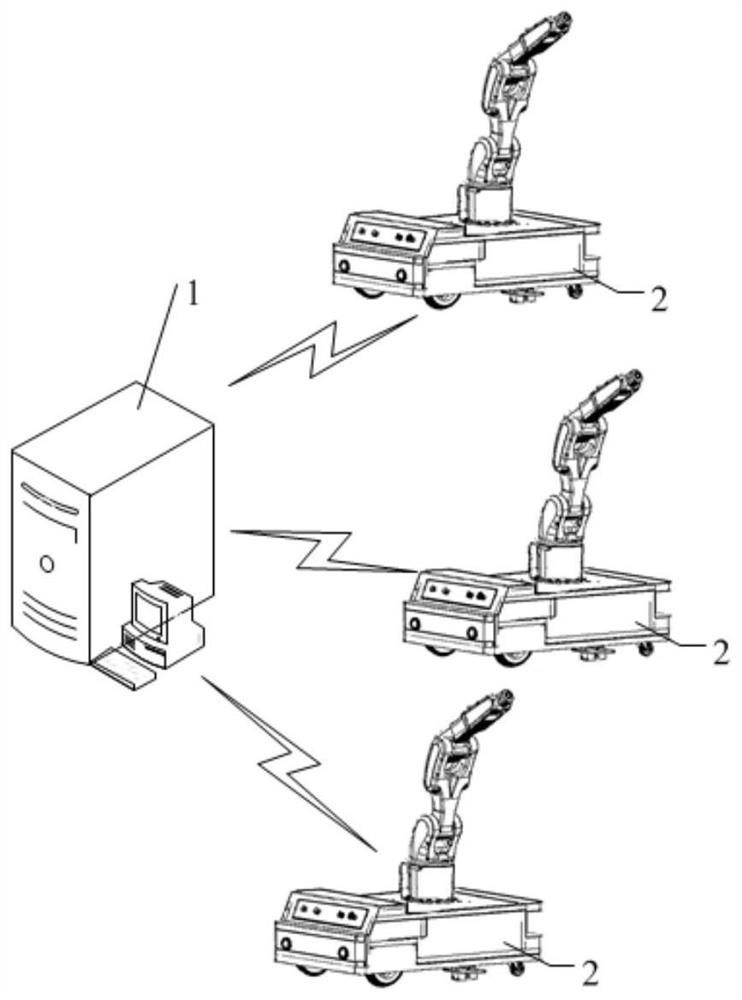

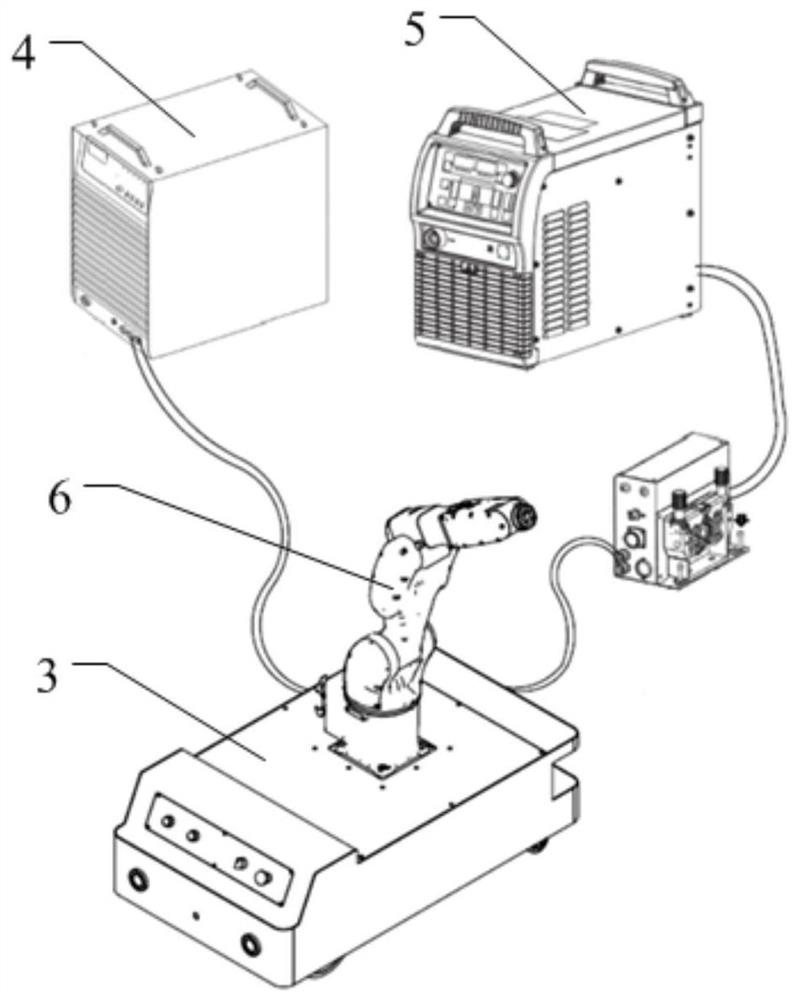

Steel internal cutting and welding process monitoring system

ActiveCN113172373AEasy to monitorReduce retrieval timeWelding/cutting auxillary devicesAuxillary welding devicesData informationMonitoring system

The invention provides a steel internal cutting and welding process monitoring system. The steel internal cutting and welding process monitoring system comprises a plurality of cutting and welding complete equipment and a cutting and welding monitoring server, wherein each cutting and welding complete equipment is provided with an AGV intelligent transferring device, a mechanical arm, a plasma cutting machine and welding equipment, the cutting and welding monitoring server is in communication connection with each cutting and welding complete equipment correspondingly, and the system can determine a plurality of associated welding and cutting sub-data matched with welding and cutting main data according to the welding and cutting main data monitored by welding and cutting personnel at present and generate and display the current monitoring welding and cutting state based on the obtained welding and cutting main data information and the multiple associated welding and cutting sub-data. According to the steel internal cutting and welding process monitoring system, if a fault occurs in the equipment operation process or the welding and cutting parameters cannot reach the range of design requirements, the corresponding welding and cutting data can be quickly found, and other data information associated with the corresponding welding and cutting data can be obtained, so that problems can be quickly found, the influence range of the problems is determined, the influence of the problems on the welding and cutting quality is reduced, and the influence on the whole production quality is avoided.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +1

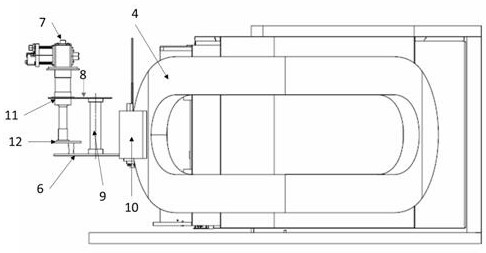

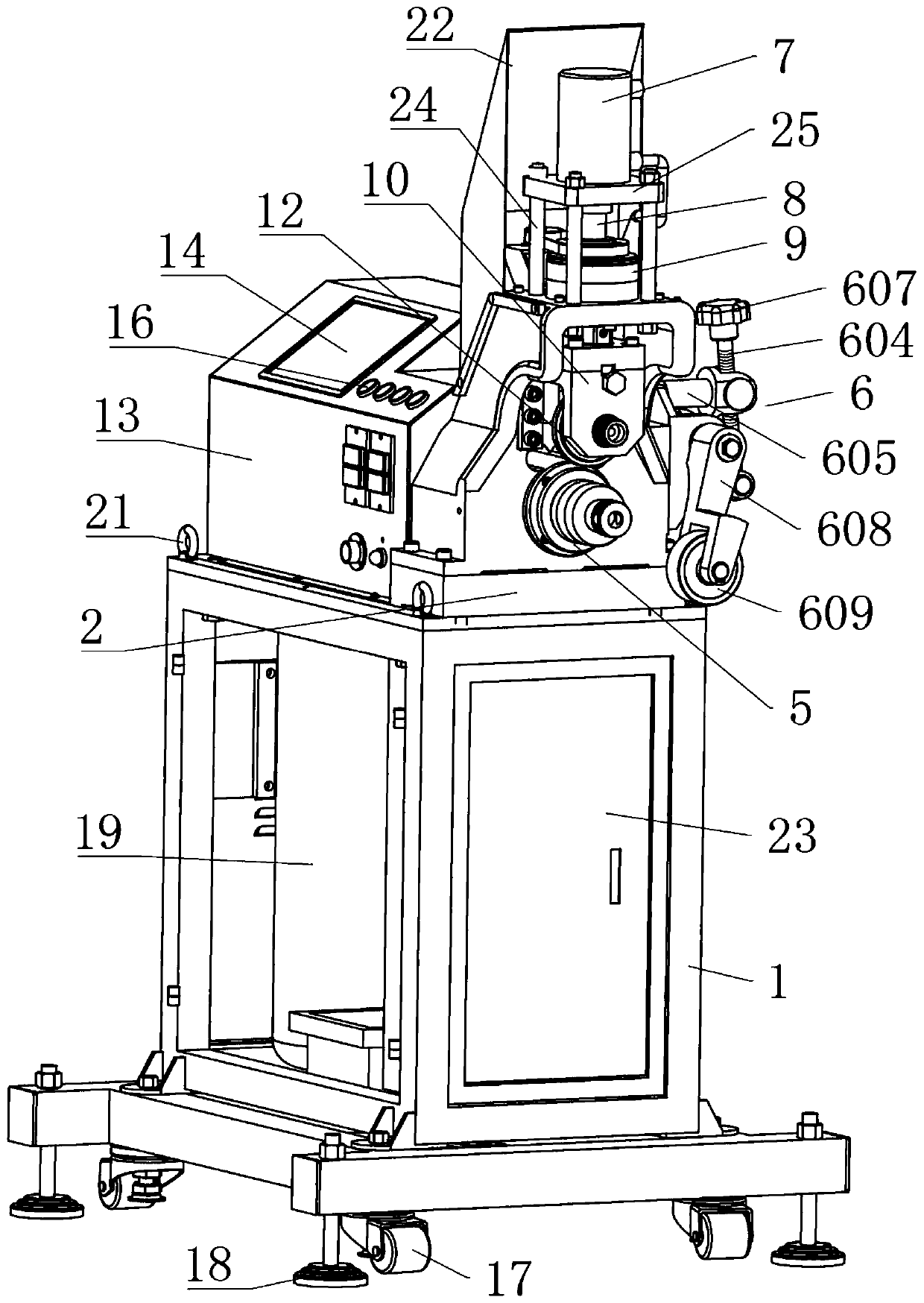

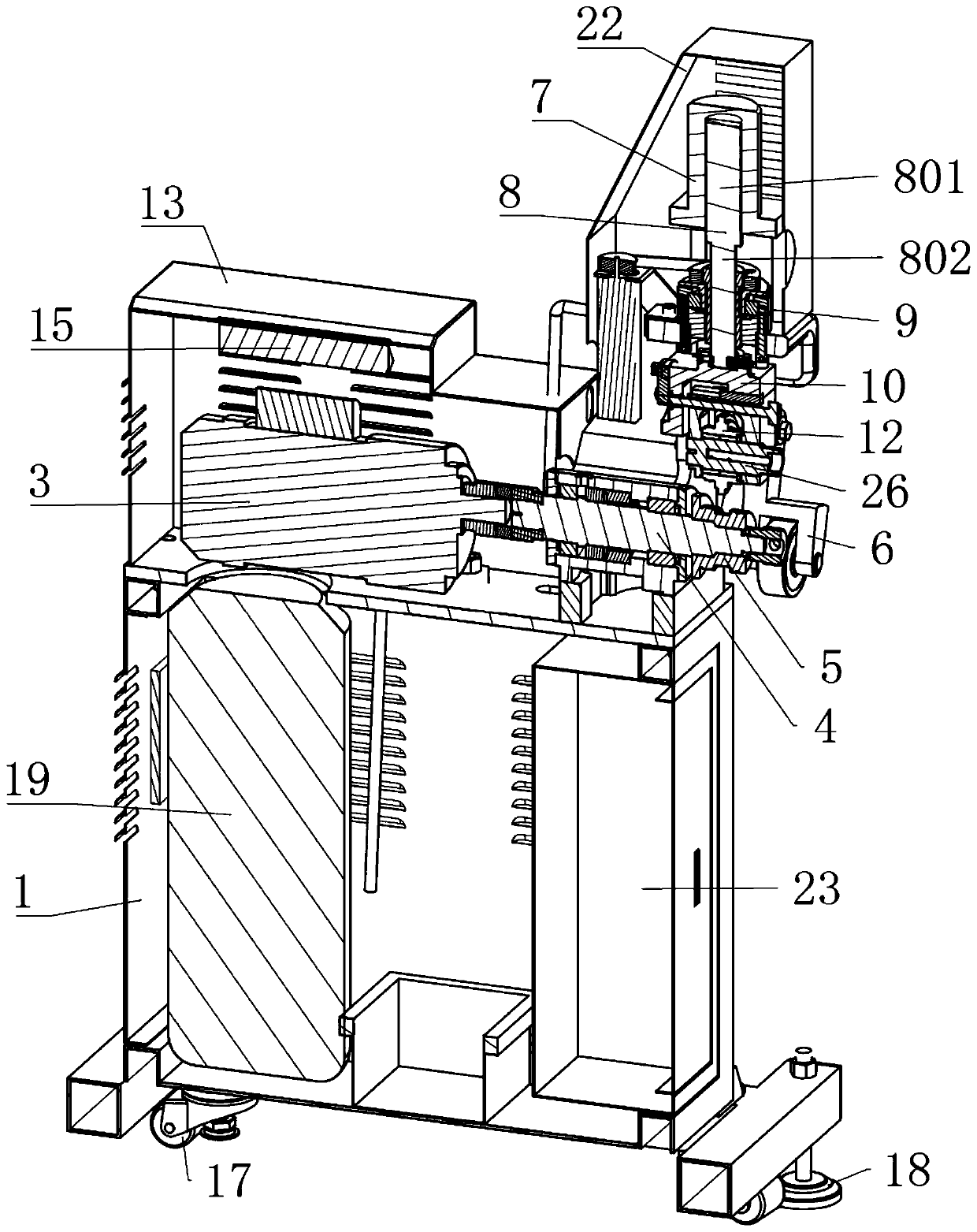

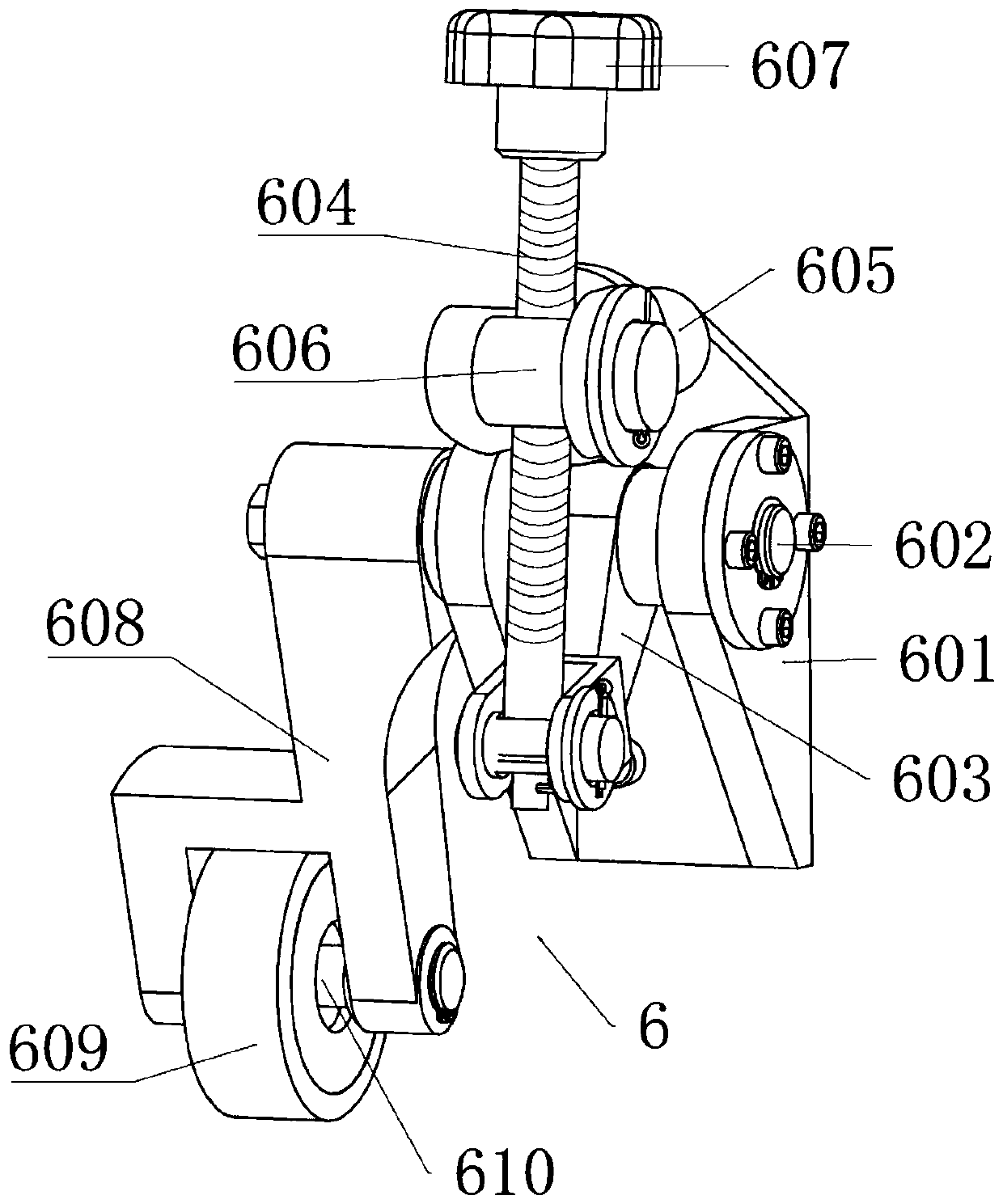

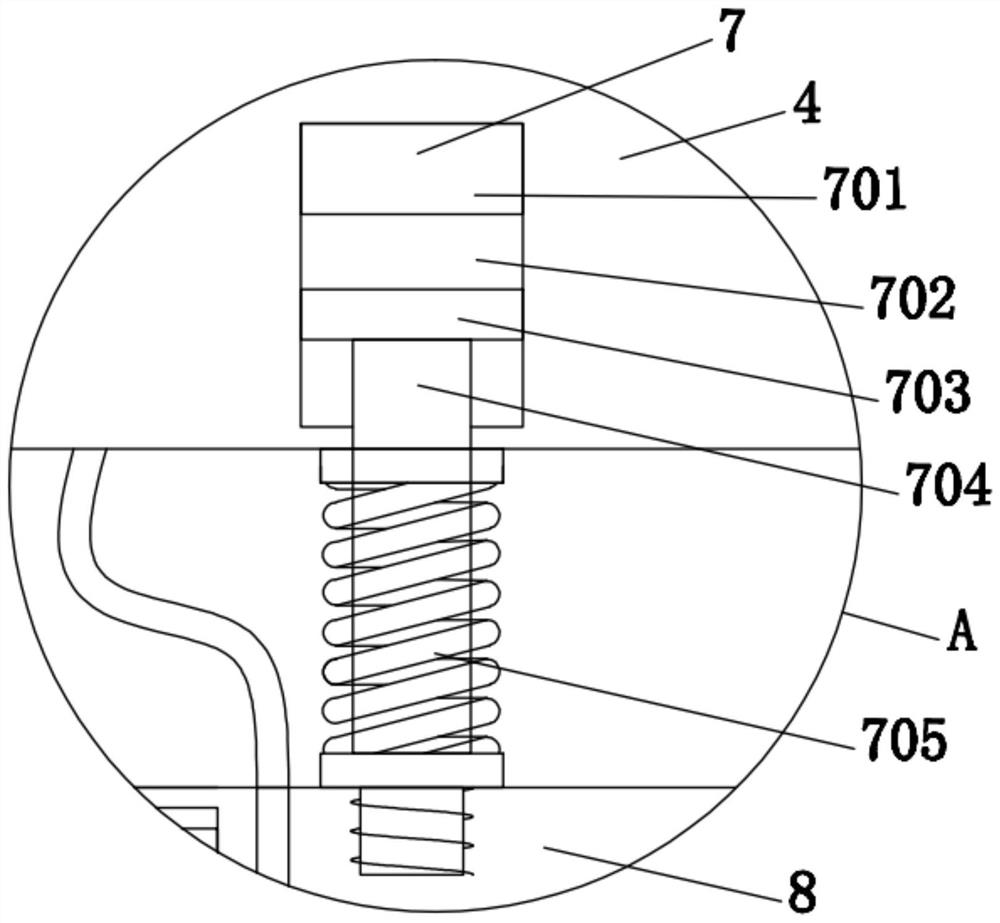

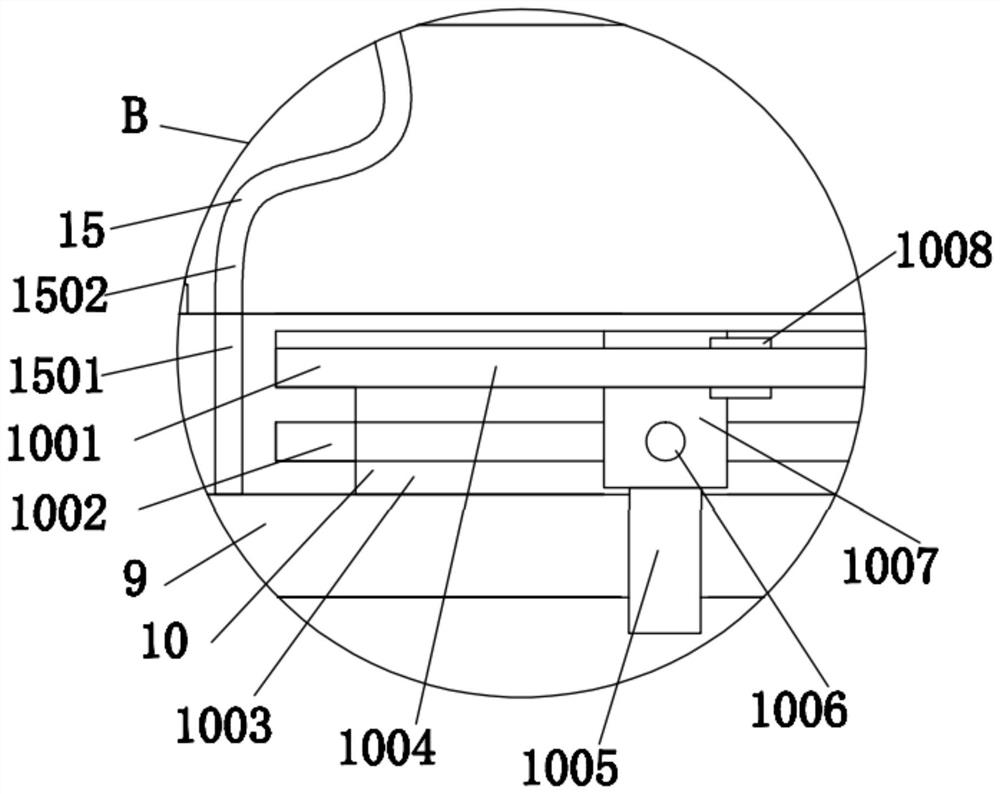

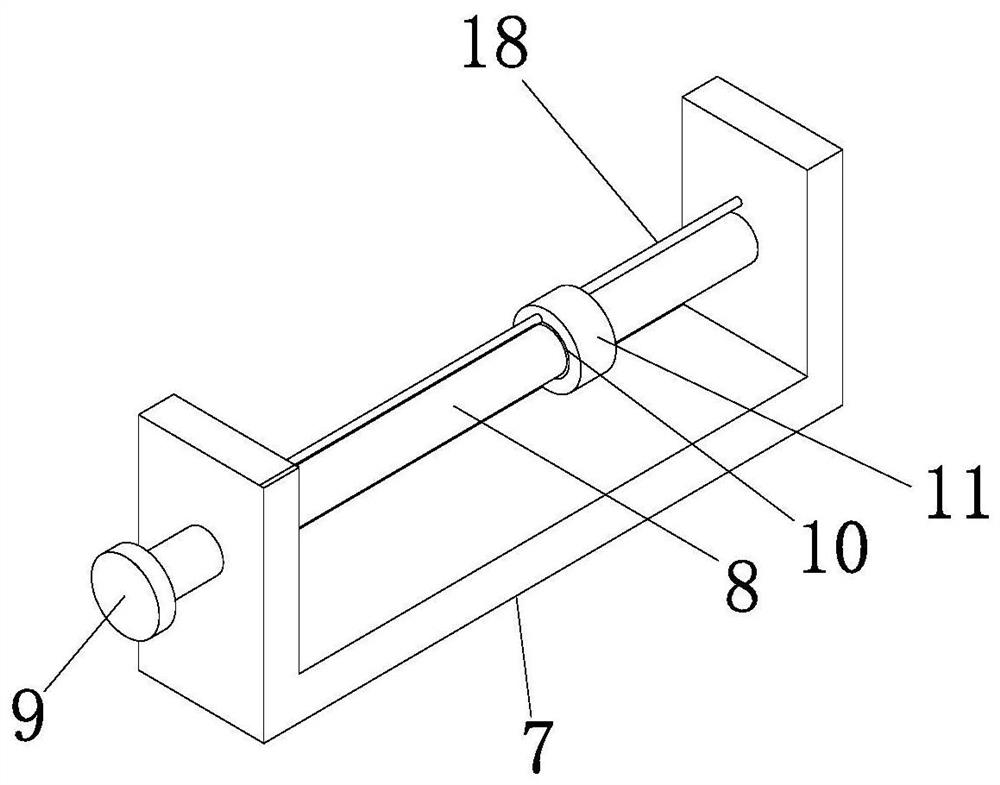

Automatic pipeline channeling machine and channeling method thereof

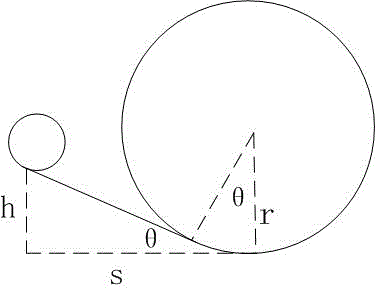

InactiveCN111389989AEasy to adjust the groove depthEasy to adjustHydraulic cylinderElectric machinery

The invention relates to the technical field of pipeline channeling, and provides an automatic pipeline channeling machine and a channeling method thereof. The automatic pipeline channeling machine comprises a machine body, a machine base is installed on the top of the machine body, a main shaft is installed on the machine base, the main shaft is provided with a lower pressing wheel, the machine base is further provided with an auxiliary supporting mechanism, a piston rod is arranged at the top of the machine base, the piston rod is sleeved with a spiral limiting mechanism, the spiral limitingmechanism is arranged on the machine base, the end part of the piston rod penetrates through the machine base and is connected with a pressing head, a guide mechanism is arranged between the pressinghead and the machine base, an upper pressing wheel is arranged on the pressing head, and a pipeline channeling space is formed between the upper pressing wheel and the lower pressing wheel; and a control box is arranged at the top of the machine body, a touch screen and a control switch are arranged on the control box, the touch screen is connected with a PLC, and the working process of a peed reducing motor and a hydraulic cylinder is controlled by the PLC. One-key starting of operation of the pipe channeling machine is realized, the quick selection and switching between different pipe typesare realized, manual adjustment is not needed, and the production efficiency is greatly improved.

Owner:邵志刚

Stamping device for mobile phone shell production

InactiveCN112371838AReduce the temperatureStable supportShaping toolsPerforating toolsHydraulic cylinderStructural engineering

The invention discloses a stamping device for mobile phone shell production, and belongs to the field of mobile phone shells. The stamping device comprises a top plate and a bottom plate; a hydrauliccylinder is connected to the bottom of the top plate in a bolted manner; a first die is connected to the bottom of the hydraulic cylinder in a bolted manner; first limiting columns are connected to the two sides of the bottom of the first die in a bolted manner; first limiting grooves are formed in the top of the bottom plate; the surfaces of the first limiting grooves are slidably connected withthe surfaces of the first limiting columns; a damping device is arranged at the bottom of the first die; the damping device is conveniently supported by arranging the first die; the stability of the device is improved through the first limiting columns and the first limiting grooves; the damping device can damp vibration of the device, and the product quality is improved; a first groove and an adjusting device facilitate movement of the position of a punch; a second through hole, a cleaning device and a collecting device facilitate cleaning and collecting of punched waste; and a gas blowing device can reduce the temperature of a third die, and the production efficiency of products is improved.

Owner:DEQING HANGZHOU SHELL INTELLIGENT TECH CO LTD

Heated air delivery pipe of plastic stretch blowing machine

InactiveCN102642300AAvoid compromising production qualityEasy to processHollow articlesElectricityAir compressor

A heated air delivery pipe of a plastic stretch blowing machine comprises an air delivery pipe with one end connected with an air storage tank and the other end connected with an air blowing valve. The heated air delivery pipe is characterized in that an electric heating device is arranged outside the wall of the air delivery pipe and used for heating the air delivery pipe and air in the air delivery pipe. The air pressurized by an air compressor enters the air storage tank, the air storage tank is connected with the air delivery pipe, the air in the air delivery pipe is blown into a plastic bottle pipe by the aid of the air blowing valve and an air blowing pipe, and the plastic bottle pipe is blown to form a plastic bottle. In order to meet the need of machining a thin-wall plastic container and lead the air blown into the bottle pipe to be hot air, the electric heating device is arranged outside a section of the air delivery pipe and used for heating the air delivery pipe and the compressed air in the air delivery pipe.

Owner:林明茳

Ion electrostatic rod dust removal device for coating machine

InactiveCN111389787ALess space for manual operationReduce labor costsDirt cleaningCleaning using toolsDust controlEngineering

The invention discloses an ion electrostatic rod dust removal device for a coating machine, and relates to the technical field of coating machine dust removal equipment. The device comprises a base, wherein the top of the base is fixedly connected with a coating machine body; one side of the coating machine body is fixedly connected with a fixing block; one side of the fixing block is fixedly connected with a sliding rail; the top of the sliding rail is movably connected with a pulley, the top of the pulley is fixedly connected with a telescopic sleeve; and the top end of the telescopic sleeveis fixedly connected with a telescopic column. According to the device, a cleaning brush does not need to be manually held by hand for cleaning, the manual operation space is small, the adopted laborcost is low, the cleaning speed is high, so that the labor cost is saved, static electricity on the coating machine body can be removed, dust on the coating machine body can be cleaned, the coating machine body does not need to be in direct contact with the coating machine body manually, secondary pollution is avoided, the dust removal effect is good, and the production quality is prevented frombeing influenced.

Owner:惠州市鑫亚凯立科技有限公司

Electric furnace feeding trolley capable of conveniently removing impurities and transporting various different materials

The invention discloses an electric furnace feeding trolley capable of conveniently removing impurities and transporting various different materials. The electric furnace feeding trolley comprises a traveling trolley body and a feeding bin; and the electric furnace feeding trolley is characterized in that electric cylinders I are vertically and fixedly connected to the two ends of the inner bottomof the traveling vehicle body, a impurity collecting bin is hinged to the tops of piston rods of the electric cylinders I, the top of the impurity collecting bin is fixedly connected with a sieve plate, the bottom of the feeding bin is fixedly connected to the top of the sieve plate, a plurality of through holes are formed in the sieve plate, a plurality of round holes corresponding to the through holes are formed in the top of the impurity collecting bin and the bottom of the feeding bin, the feeding bin communicates the impurity collecting bin through the through holes and the round holes,a discharging hopper is horizontally and fixedly connected to the bottom of one side of the feeding bin, and a plurality of feeding cavities are formed in the feeding bin. According to the electric furnace feeding trolley, different materials can be fed at one time, so that the charging time can be saved, and the working efficiency can be improved; impurities on the surface can be removed before material block fills an electric furnace cavity, so that influence of the production quality of the electric furnace is avoided, the impurities are convenient to collect, and meanwhile, the material blocks are convenient to enter the electric furnace cavity.

Owner:TIANJIN ZHONGDA PRECISION MACHINERY

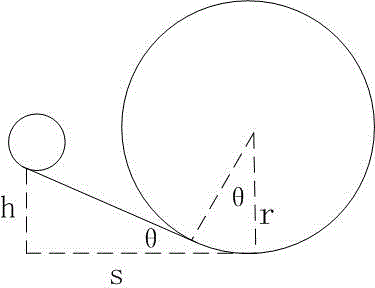

A bending machine with a d-axis guide

Owner:东莞市谊科数控科技有限公司

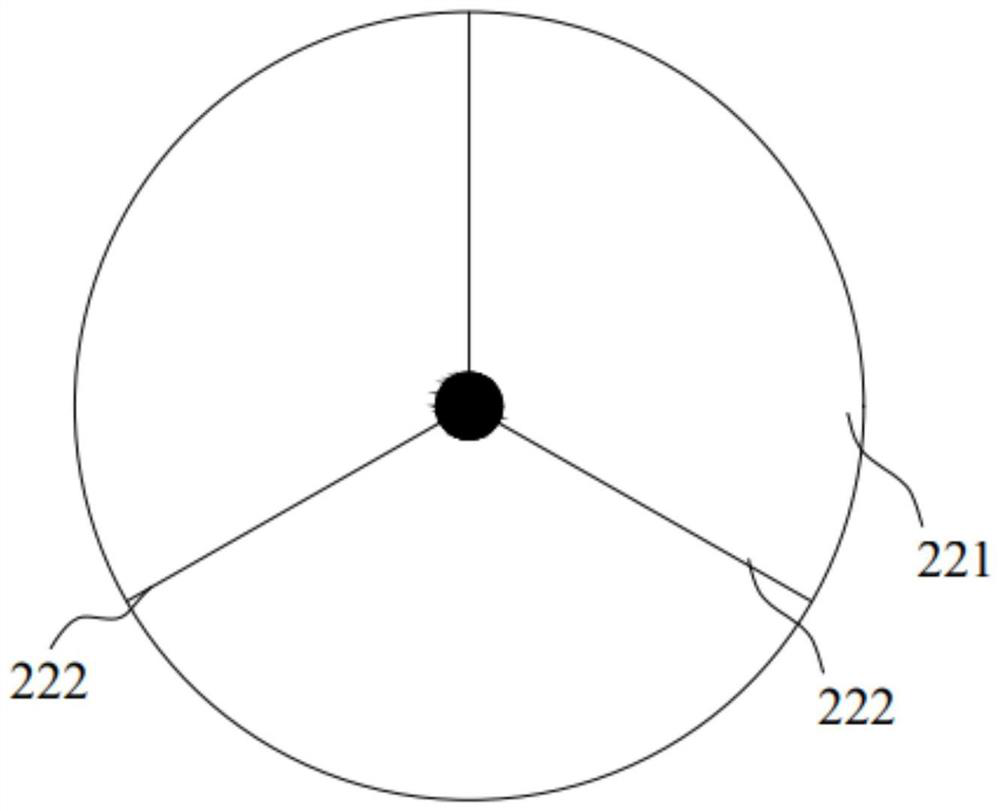

Device for preparing adjustable latex pillow

The invention discloses a device for preparing an adjustable latex pillow. The device for preparing the adjustable latex pillow comprises a bottom plate, wherein a material box is fixedly installed at the top of the bottom plate, a stirring shaft is arranged in the material box, three stirring rods are fixedly installed at the two sides of the stirring shaft at equal intervals, and bubble puncturing needles are fixedly installed on the six stirring rods; and a loading hopper, a motor and a conveying pump are fixedly installed at the top of the material box, and a first straight gear is fixedly installed at the output shaft end of the motor. The device for preparing the adjustable latex pillow is reasonable in design and high in practicability, materials can be conveniently and uniformly injected into a mold cavity, and material liquid can be uniformly diffused and automatically spread in the mold cavity, manual operation for spreading the material liquid in the mold cavity is not needed, so that the labor amount of workers is reduced, time and labor are saved, and the working efficiency is increased; and in the process of injecting the materials into the mold cavity, the six stirring rods are used for continuously stirring and uniformly mixing the latex material liquid and additives, and non-uniform mixing caused by precipitation or layering of the material liquid is avoided, so that the production quality for the rubber pillow is improved.

Owner:永康市东琦家居用品有限公司

Micro-adjusting injection molding device for processing earphone connectors

ActiveCN111976082AStay parallelAvoid compromising production qualityCoatingsMobile bearingEngineering

The invention discloses a micro-adjusting injection molding device for processing earphone connectors, and relates to the technical field of earphone connector injection molding. The micro-adjusting injection molding device for processing the earphone connectors comprises a bottom fixing plate, wherein an injection mold is fixedly installed at the upper end of the bottom fixing plate. According tothe device, when a cylindrical adjusting screw rotates, a moving bearing can move front and back on the outer circle of the cylindrical adjusting screw through the arrangement that the moving bearingis connected with the cylindrical adjusting screw in a threaded mode, the moving bearing moves to drive an annular moving sleeve to move, and the annular moving sleeve drives a ring-shaped limit sleeve to move front and back through a rectangular connecting rod to adjust the position of the ring-shaped limit sleeve, so that earphones corresponding to different lengths of metal plugs can adjust the supporting point position of the ring-shaped limit sleeve during injection molding, so as to ensure that the metal plugs are always kept in parallel states, the situation of tilting, affecting the production quality, when the metal plugs are connected to injection positions.

Owner:湖北省迈尔森科技有限公司

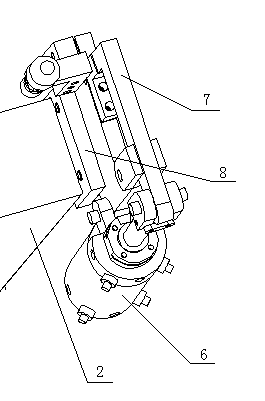

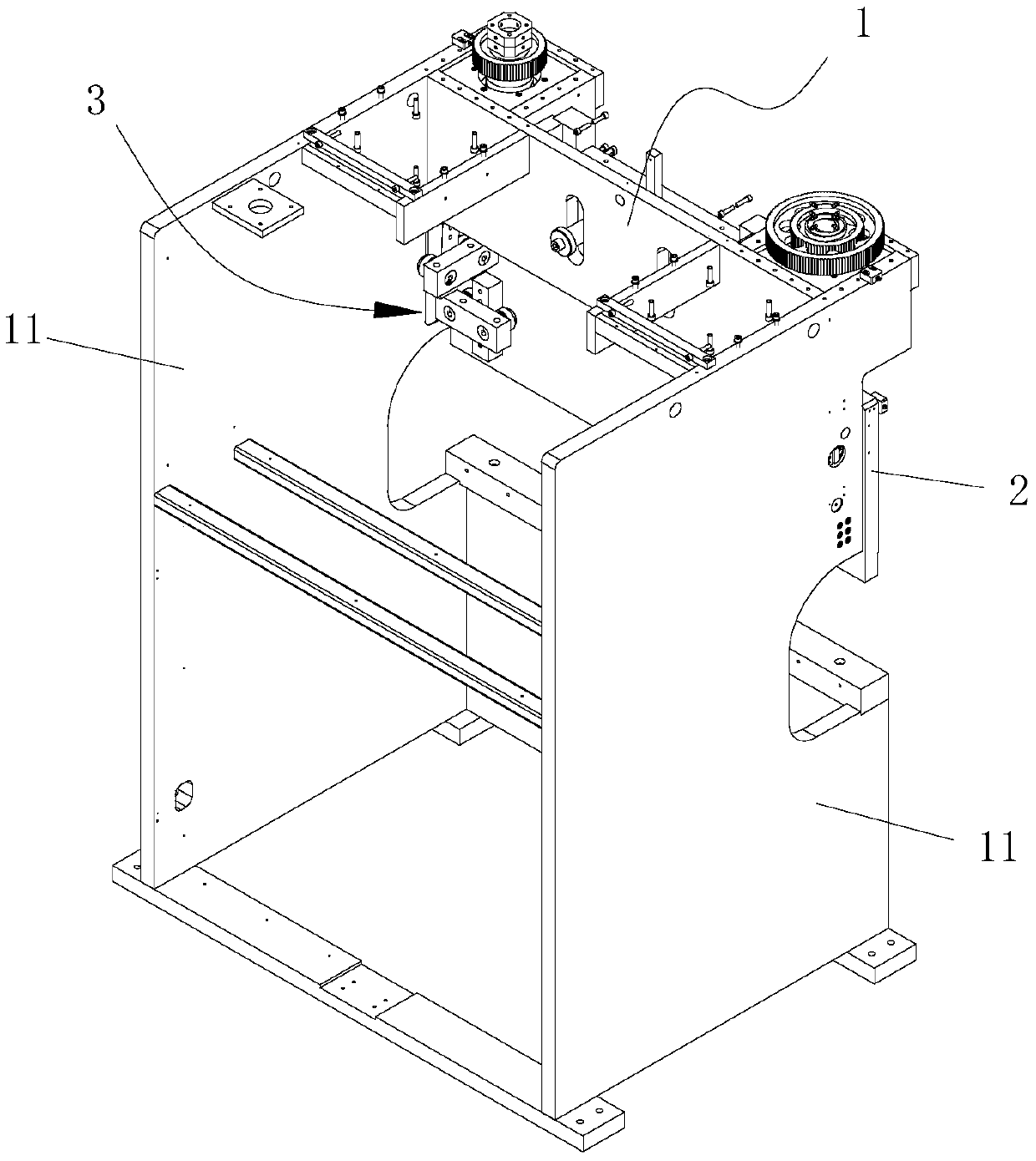

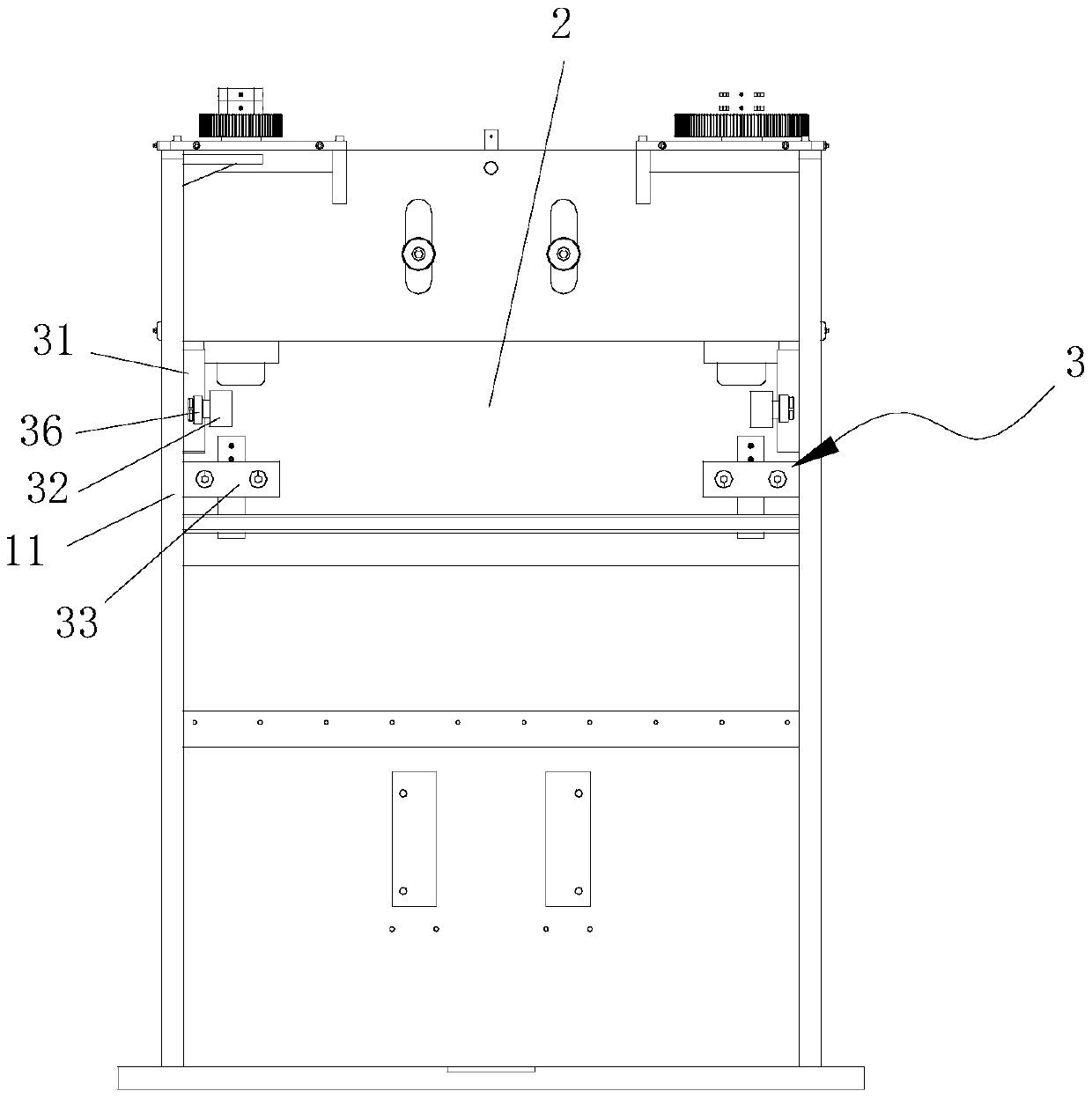

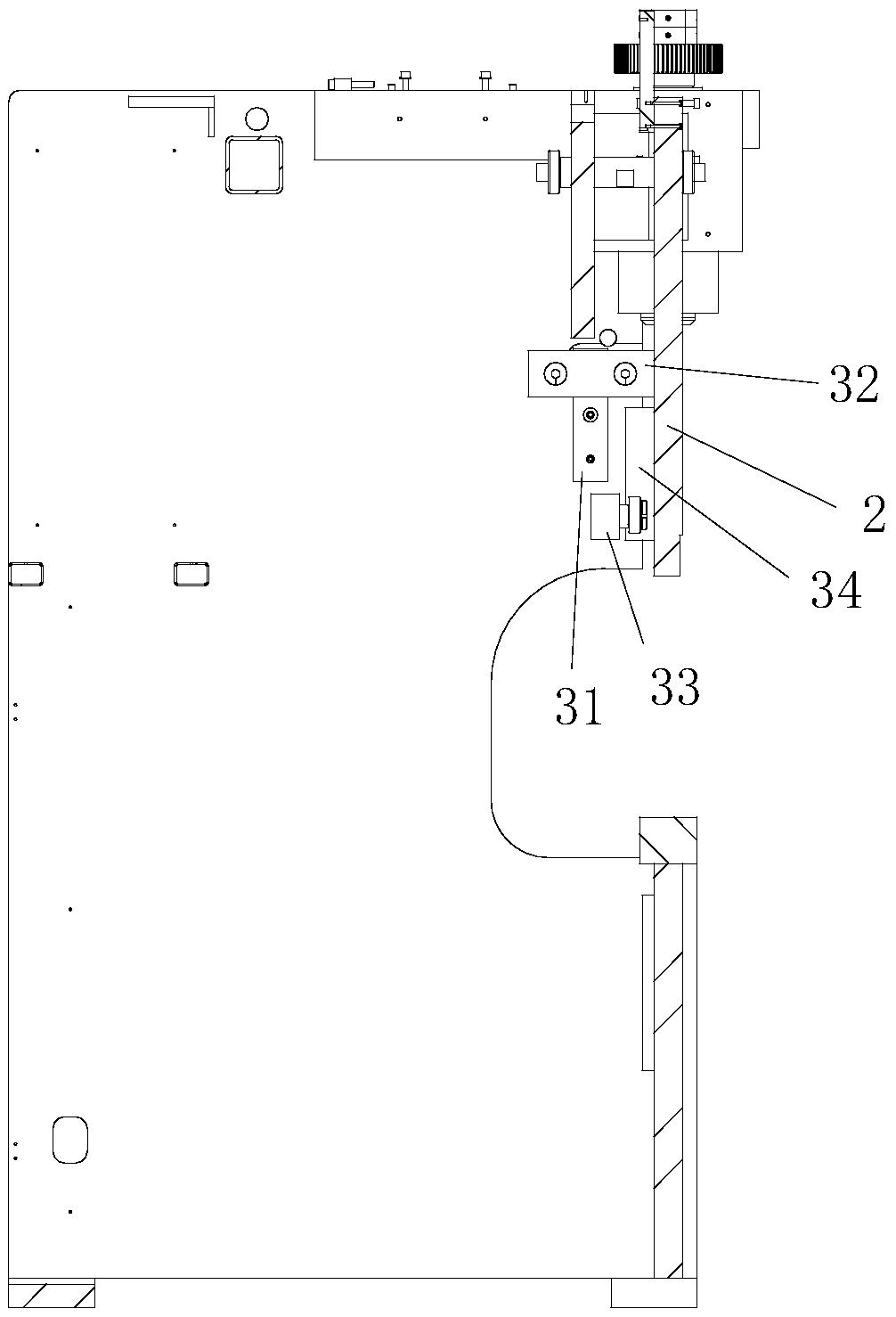

Bending machine with D-axis guide devices

The invention discloses a bending machine with D-axis guide devices. The bending machine comprises a machine frame. An upper working table is arranged on the front face of the machine frame. The D-axis guide devices are arranged between the two sides of the upper working table and side plates of the machine frame. Each D-axis guide device comprises a first guide fixed block, a first guide movable block, a second guide fixed block and a second guide movable block, wherein the first guide fixed block is longitudinally installed on the corresponding side plate of the machine frame of the bending machine, the first guide movable block and the first guide fixed block are perpendicular to each other and installed on the upper working table, the first guide movable block is provided with a first guide eccentric shaft and a first guide wheel, the second guide movable block is longitudinally installed on the upper working table, the second guide fixed block and the second guide movable block are perpendicular to each other and installed on the corresponding side plate of the machine frame of the bending machine, and the second guide fixed block is provided with a second guide eccentric shaft and a second guide wheel. The bending machine is simple in structure, convenient to install and maintain, smooth in sliding, strong in bearing capacity, long in service life and capable of ensuring perpendicularity of the upper working table.

Owner:东莞市谊科数控科技有限公司

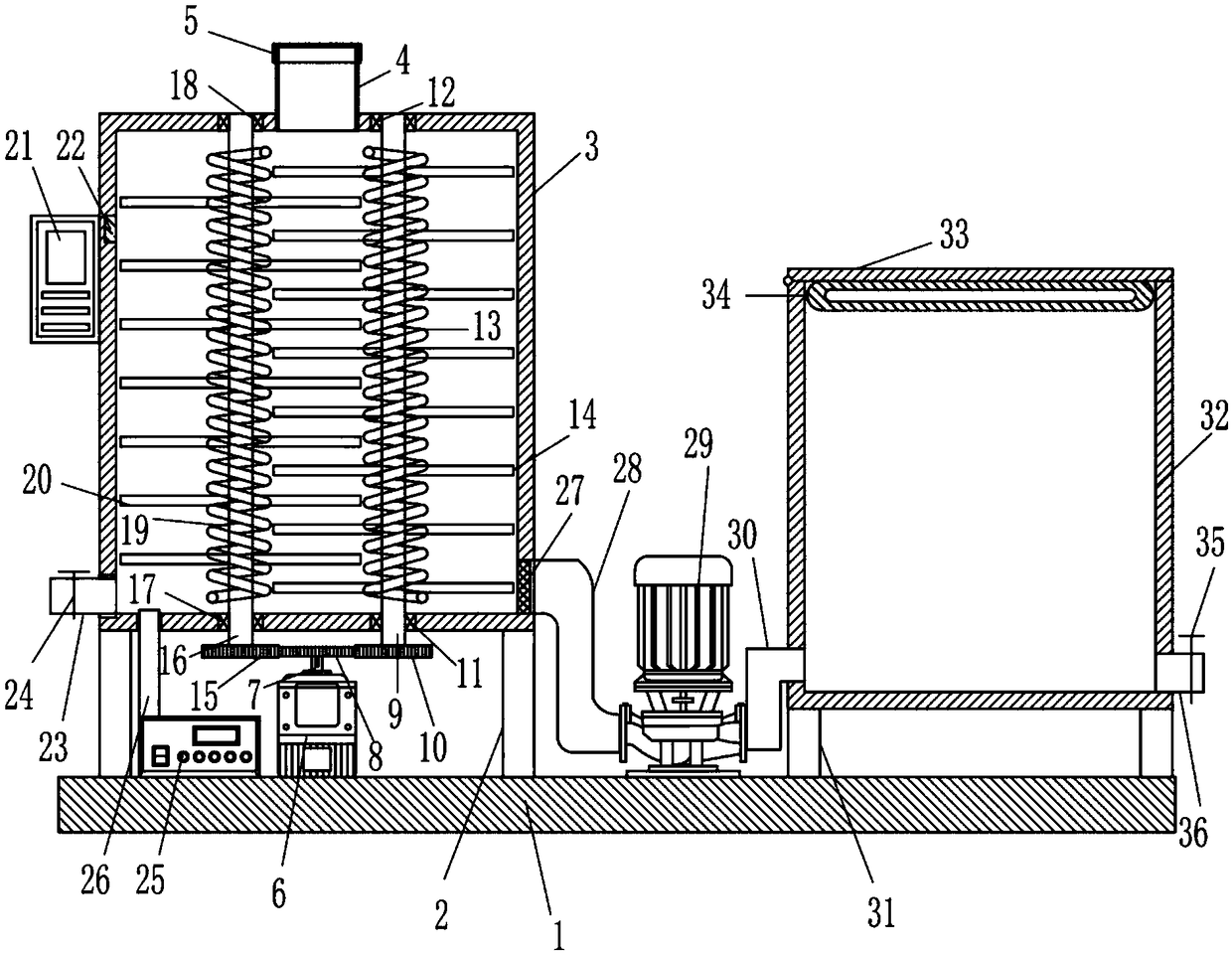

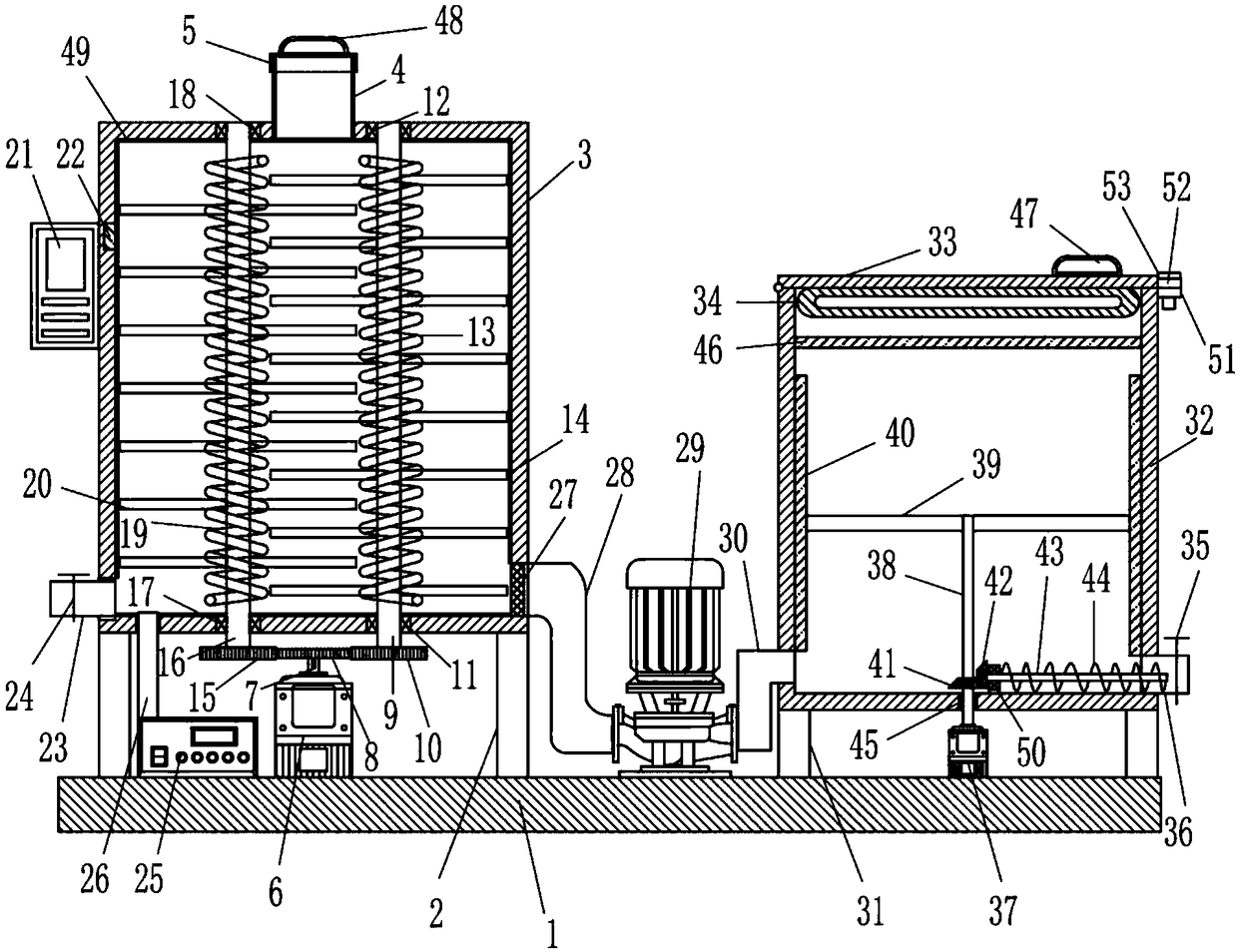

A thick-walled stainless steel tube vertical induction heating equipment

ActiveCN112333866BAvoid damageAvoid compromising production qualityInduction heating apparatusEngineeringSS - Stainless steel

The invention relates to a vertical induction heating device of a thick-walled stainless steel tube. An installation seat is installed horizontally and symmetrically in the middle position of the installation box; a lift is vertically fixed and installed on the upper surface of the installation seat; the top of the installation box is connected to the upper part of the installation seat. A guide column is installed vertically between the surfaces; a slide plate is installed on the guide column; a top rod is installed vertically in the middle of the upper surface of the slide plate; a heat insulation board is sleeved and installed on the outer side wall of the lower end of the top rod; the installation box An oil cylinder is installed horizontally on the upper surface of the left side; a telescopic rod is installed horizontally at the front end of the oil cylinder; a push plate is fixedly installed at the front end of the telescopic rod; the upper surface of the installation box is evenly spaced and processed with support blocks; the upper surface of the support block is provided with A storage board; the bottom surface of the storage board is provided with a chute matched with the support block; the invention can provide a thick-walled stainless steel tube vertical induction heating equipment with fast heating speed, good heat preservation effect and guaranteed production quality.

Owner:京港工业炉科技(苏州)有限公司

Adjusting roller device for glue-free film laminating machine

ActiveCN104309257AFlexible speed adjustmentAvoid compromising production qualityLaminationLamination apparatusWrinkle skinBall screw

The invention discloses an adjusting roller device for a glue-free film laminating machine. The device comprises a thermo-compression device and an adjusting roller device, wherein the thermo-compression device comprises a hot steel roller and a rubber roller which are oppositely arranged; the surface of the hot steel roller is closely attached to the surface of the rubber roller; a heating device is arranged inside the hot steel roller; the adjusting roller device is arranged at the film feeding end of the thermo-compression device, and comprises an alternating current motor and a connecting shaft connected to an output shaft of the alternating current motor; a speed reducer is arranged on the connecting shaft, and is used for respectively driving a ball screw to rotate; the ball screw is connected with an adjusting aluminum roller, and is used for controlling lifting of the adjusting aluminum roller. According to the adjusting roller device, the speed of film laminating can be flexibly adjusted under the situation that temperature and pressure are not variable, the adjusting aluminum roller can move smoothly, film feeding smoothness can be guaranteed, wrinkles influencing production quality can be avoided, a flattening mechanism is capable of flattening wrinkles which are generated in film lamination and caused by speed changes of the hot steel roller, cooling is carried out quickly, and yield is increased.

Owner:广东山河实业有限公司

A kind of waterborne polyurethane adhesive production line and its tackifier preparation method

ActiveCN108854645BImprove the mixing effectQuality improvementRotary stirring mixersTransportation and packagingProduction linePolymer science

The invention discloses that the production line frame of a polyurethane adhesive production line is equipped with a material storage classification mechanism for raw material storage and classification, an automatic allocation mechanism for quantitative allocation of raw materials, and a forming mixing drum. The forming mixing drum is connected with a The forming and distributing components of the forming materials are quantitatively discharged, and the inside of the forming mixing drum is automatically mixed and stirred by an electric stirring mechanism. There are several main barrels and several secondary barrels on the production line frame, and a method for preparing a tackifier for water-based polyurethane adhesives is also disclosed, including the following steps: S100, raw material preparation and pretreatment; S200, raw material Mixing and stirring; S300, adding auxiliary materials; S400, degassing and cooling molding, mixing materials through combined heating and combined stirring methods to avoid uneven local reactions and effectively improve product quality.

Owner:莆田市东升涂料有限公司

Adjusting roller device for glueless laminating machine

ActiveCN104309257BFlexible speed adjustmentAvoid compromising production qualityLaminationLamination apparatusWrinkle skinBall screw

The invention discloses an adjusting roller device for a glue-free film laminating machine. The device comprises a thermo-compression device and an adjusting roller device, wherein the thermo-compression device comprises a hot steel roller and a rubber roller which are oppositely arranged; the surface of the hot steel roller is closely attached to the surface of the rubber roller; a heating device is arranged inside the hot steel roller; the adjusting roller device is arranged at the film feeding end of the thermo-compression device, and comprises an alternating current motor and a connecting shaft connected to an output shaft of the alternating current motor; a speed reducer is arranged on the connecting shaft, and is used for respectively driving a ball screw to rotate; the ball screw is connected with an adjusting aluminum roller, and is used for controlling lifting of the adjusting aluminum roller. According to the adjusting roller device, the speed of film laminating can be flexibly adjusted under the situation that temperature and pressure are not variable, the adjusting aluminum roller can move smoothly, film feeding smoothness can be guaranteed, wrinkles influencing production quality can be avoided, a flattening mechanism is capable of flattening wrinkles which are generated in film lamination and caused by speed changes of the hot steel roller, cooling is carried out quickly, and yield is increased.

Owner:广东山河实业有限公司

Portable type valve pipe fitting production device

The invention provides a portable type valve pipe fitting production device which comprises a machine head and a rack, wherein the rack comprises a support frame and a working table, the structure is simple, the design is reasonable, later maintenance and replacement are facilitated, fixed connection is realized by an adjustment block and a second fixing block when the machine head is mounted, the fixation effect is better, the accuracy performance is improved, and a displacement phenomenon of the machine head during working is avoided to affect the product production quality; at the same time, a main shaft end is connected with a rear end cover through an inclined transition part into an integral structure, and the stress is more uniform and the stress effect is better when the inclination angle alpha of the inclined transition part is 80 degrees, a pipe body damage phenomenon cannot be caused when the device doesn't work, the working efficiency is improved, and manufacturers' requirements can be well met.

Owner:YANGZHONG VALVE FACTORY CO LTD

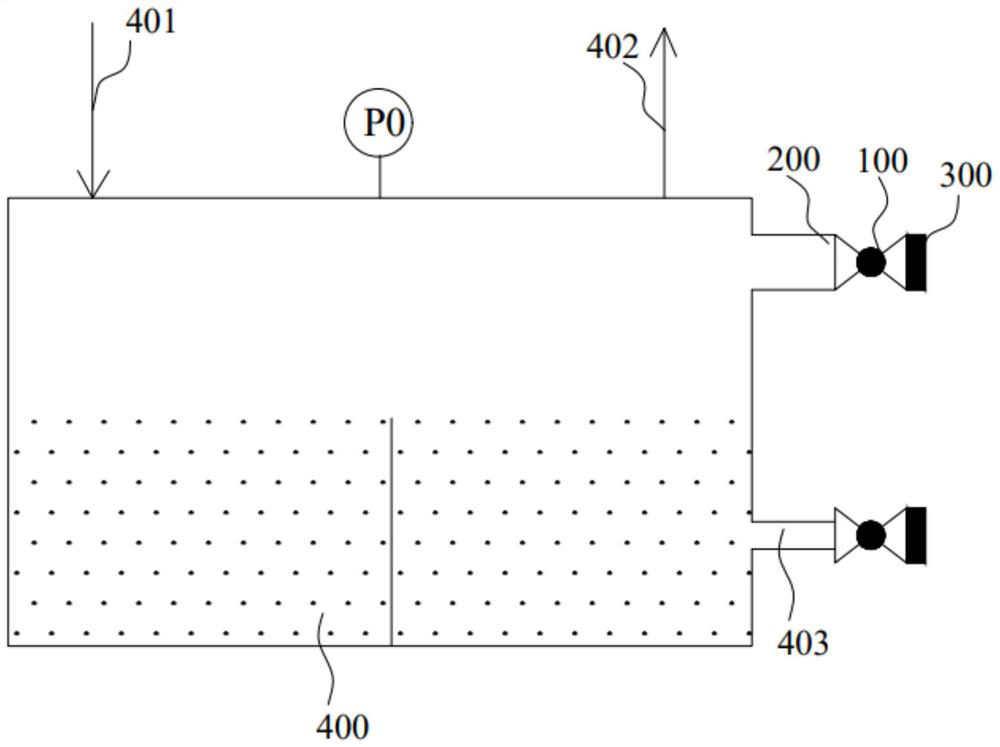

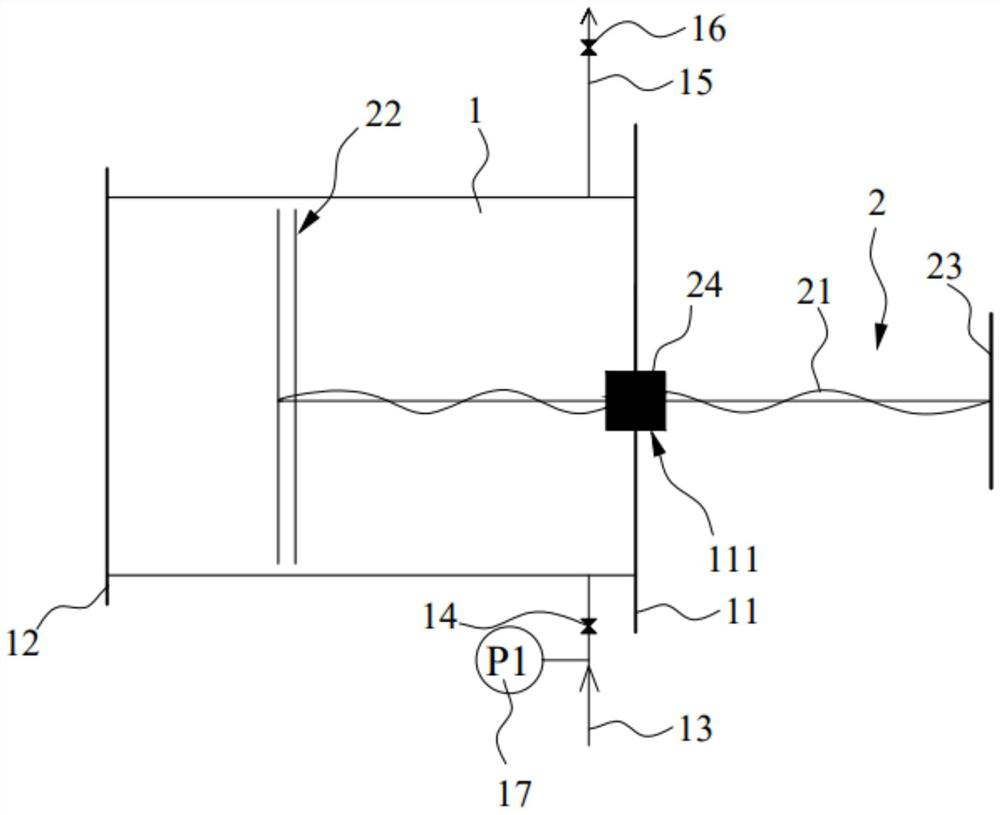

Online cleaning device and online cleaning method for liquid level meter of vacuum pump separation tank

PendingCN114850146APrevent metering distortionEasy to operateHollow article cleaningMachines/enginesEngineeringControl valves

The invention belongs to the technical field of vacuum pumps, and discloses an online cleaning device and an online cleaning method for a liquid level meter of a vacuum pump separating tank, and the online cleaning device for the liquid level meter of the vacuum pump separating tank comprises a cleaning cylinder and a movable scraper assembly; one end of the cleaning cylinder is open, the other end of the cleaning cylinder is provided with a bottom plate with a guide hole, the opening is provided with a connecting piece used for being connected with a liquidometer guide pipe valve, and the cleaning cylinder is provided with a water inlet pipe used for inflow of cleaning water and a first control valve arranged on the water inlet pipe; the movable scraper assembly comprises a rotating rod and a scraper structure, one end of the rotating rod rotatably penetrates through the guide hole, the other end of the rotating rod is fixedly connected with the scraper structure, and the scraper structure is used for rotating and propelling to penetrate through the guide pipe valve and clean the inner wall of the guide pipe. According to the online cleaning device for the liquid level meter of the vacuum pump separating tank, the guide pipe can be cleaned online, the pump does not need to be stopped, the liquid level meter is prevented from being distorted, and the production efficiency is prevented from being influenced; according to the online cleaning method, the device is applied to online cleaning of the guide pipe, the cleaning steps are simple, and the cleaning efficiency is high.

Owner:SGIS SONGSHAN CO LTD

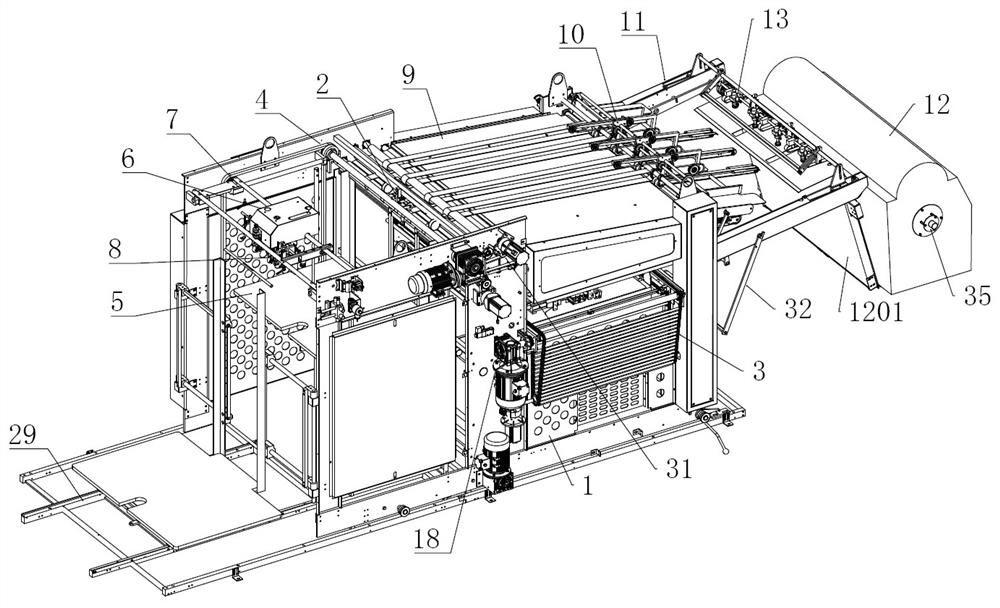

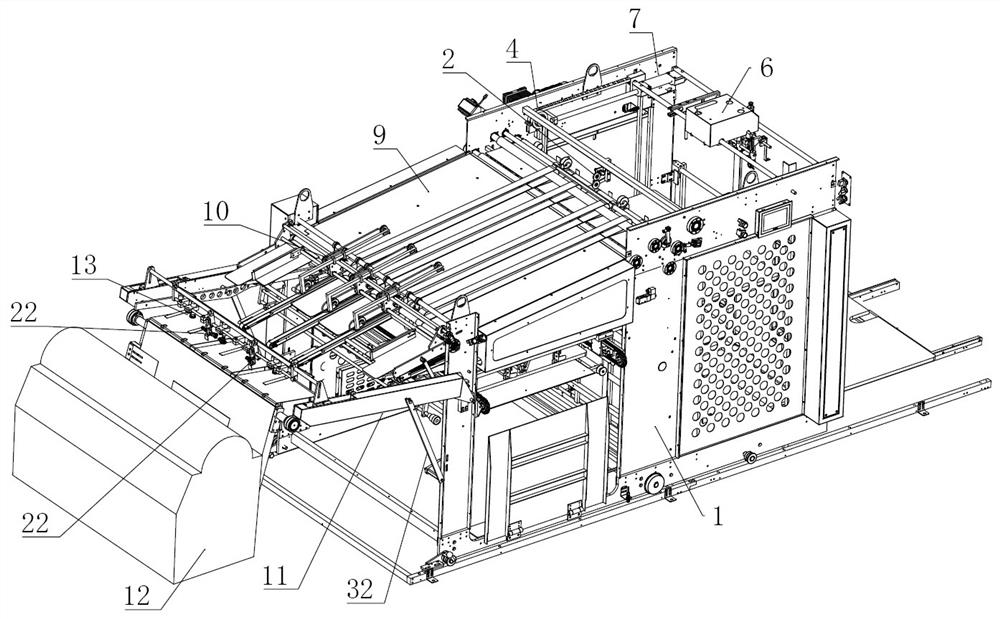

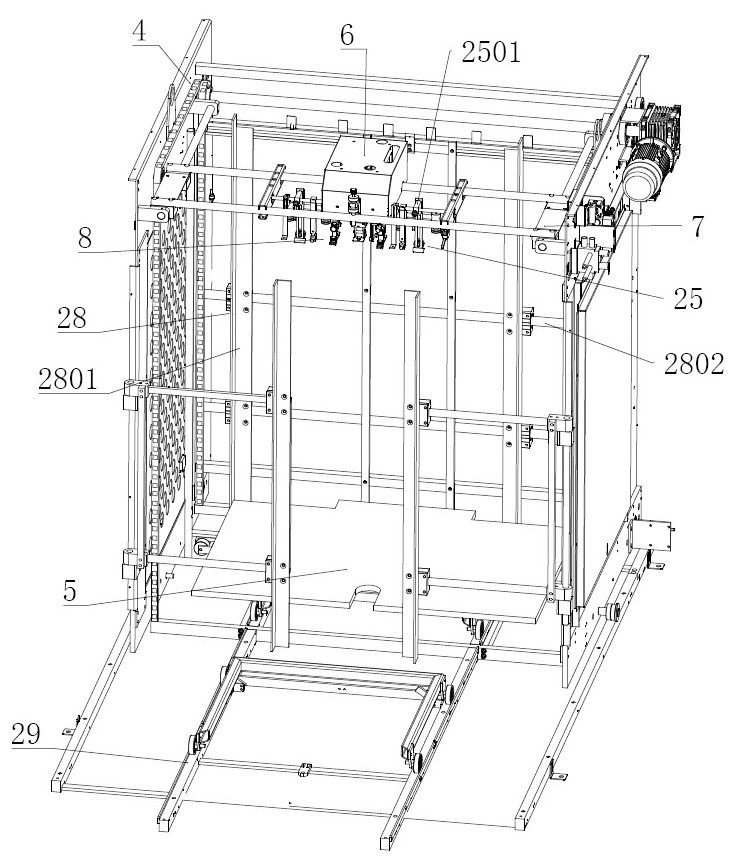

Automatic paper feeding and taking machine

ActiveCN114380085ARealize automatic feeding processReduce overlapPile receiversArticle feedersProcess engineeringIndustrial engineering

The invention relates to the technical field of paper feeding and taking equipment, and provides an automatic paper feeding and taking machine which comprises a rack, a paper feeding device is arranged at one end of the rack, the discharging end of the paper feeding device is connected with a paper number detection mechanism, and the discharging end of the paper number detection mechanism is connected with a paper conveying device. The discharging end of the paper conveying device is connected with a paper feeding device in linkage fit with the paper die-cutting machine, the rack is further provided with a paper taking device in linkage fit with the paper feeding device, and the paper taking device takes out paper die-cut by the paper die-cutting machine and places the paper on a paper collecting device. A paper temporary bearing mechanism used for collecting paper without shutdown is further arranged between the paper taking device and the paper collecting device. The automatic paper feeding and taking machine solves the problems that when an existing automatic paper feeding and taking machine is used, paper clamping and paper stacking are prone to occurring in the paper conveying process, shutdown operation is needed in the paper taking process, taking is inconvenient, and the production efficiency is affected.

Owner:潍坊强兴新达自动化设备有限公司

A plastic bag heat sealing device

ActiveCN109229609BAvoid compromising production qualityWrapper twisting/gatheringThermodynamicsElectric power

The invention discloses a plastic bag heat-sealing device. The plastic bag heat-sealing device structurally comprises heat dissipation openings, a base, a heat-sealing machine, a support, a workbenchand an operation panel; the heat dissipation openings are formed in the left side of the base, the heat dissipation openings and the base are integrated, and the heat-sealing machine is located over the workbench; by improving part structures of the equipment, a retractable assembly can be matched with a power supply control assembly when moving downward and thus provides a power supply for a heating mechanism, and the situations are avoided that the heat-sealing machine is in a working state all the time, so that a large amount of electric power waste is caused, accordingly, the service lifeof the equipment is shortened, and abrasion of the equipment is aggravated; meanwhile, during clamping, through cooperation of a pull-level mechanism and a plastic bag sealing and clamping mechanism,a plastic bag is pulled tightly, wrinkles on a seal of the plastic bag are removed, and accordingly the situation is avoided that the wrinkles of the plastic bag are pressed and folded together duringpress heat-sealing, so that the production quality of the equipment is influenced.

Owner:海宁易通包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com