A kind of waterborne polyurethane adhesive production line and its tackifier preparation method

A technology of polyurethane adhesive and water-based polyurethane, applied in polyurea/polyurethane adhesives, adhesives, chemical instruments and methods, etc., can solve problems such as failure to meet requirements, low heat utilization rate, and affect product quality, and achieve easy Accurate control, improved heating effect, faster mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

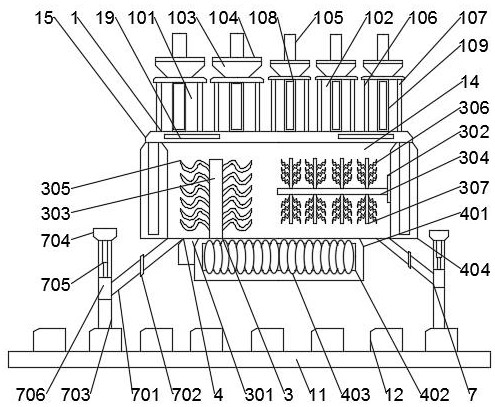

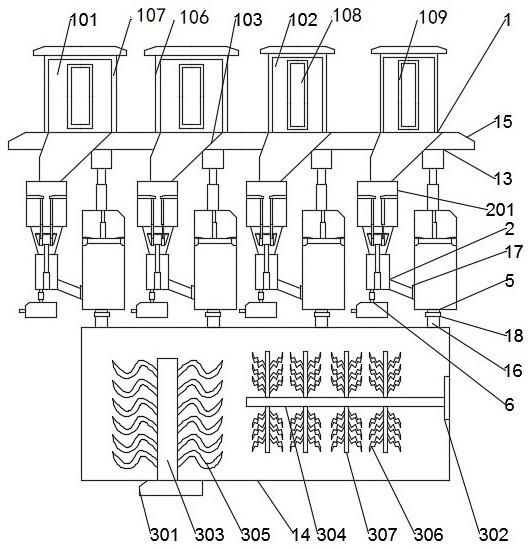

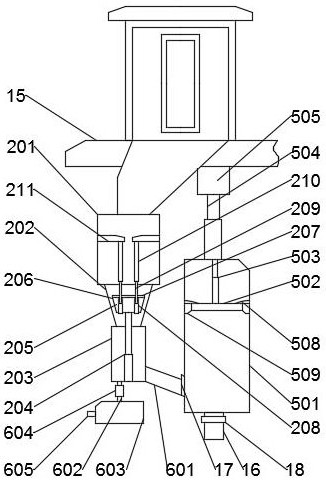

[0046] Such as Figure 1 to Figure 8 As shown, the present invention provides a water-based polyurethane adhesive production line, on the production line frame 15 of the polyurethane adhesive production line, a material storage classification mechanism 1 for raw material storage and classification is installed, and the automatic allocation of quantitative allocation of raw materials Mechanism 13 and forming mixing drum 14, the forming mixing drum 14 is connected with forming material dispensing assembly 7 for quantitatively discharging molding materials, and the storage and sorting mechanism 1 includes several main material drums 101 installed on the production line frame 15 and several secondary barrels 102, the main barrel 101 and the top of the secondary barrel 102 are connected with a guide hopper 103, and the bottom ends of the main barrel 101 and the secondary barrel 102 are connected with the forming mixing drum 14, through the storage The material classification mechan...

Embodiment 2

[0084] A formulation of an environment-friendly water-based polyurethane adhesive, which comprises the following raw materials in parts by weight:

[0085] 10 parts of aromatic isocyanate, 5 parts of polyester polyol, 10 parts of polyether polyol, 2 parts of catalyst, 15 parts of dimethylformamide solvent, 3 parts of dimethylol propionic acid, 1 part of acetone, 5 parts of polyisocyanate , 6 parts of silicone solvent, 4 parts of epoxy resin, 10 parts of fluoroalkyl polymer emulsion, 1 part of sealing agent, and 8 parts of tackifier.

[0086] A formulation of an environment-friendly water-based polyurethane adhesive, which comprises the following raw materials in parts by weight:

[0087] 15 parts of aromatic isocyanate, 10 parts of polyester polyol, 15 parts of polyether polyol, 4 parts of catalyst, 20 parts of dimethylformamide solvent, 6 parts of dimethylol propionic acid, 2 parts of acetone, 7 parts of polyisocyanate , 8 parts of silicone solvent, 6 parts of epoxy resin, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com