Patents

Literature

225results about How to "Meet different production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

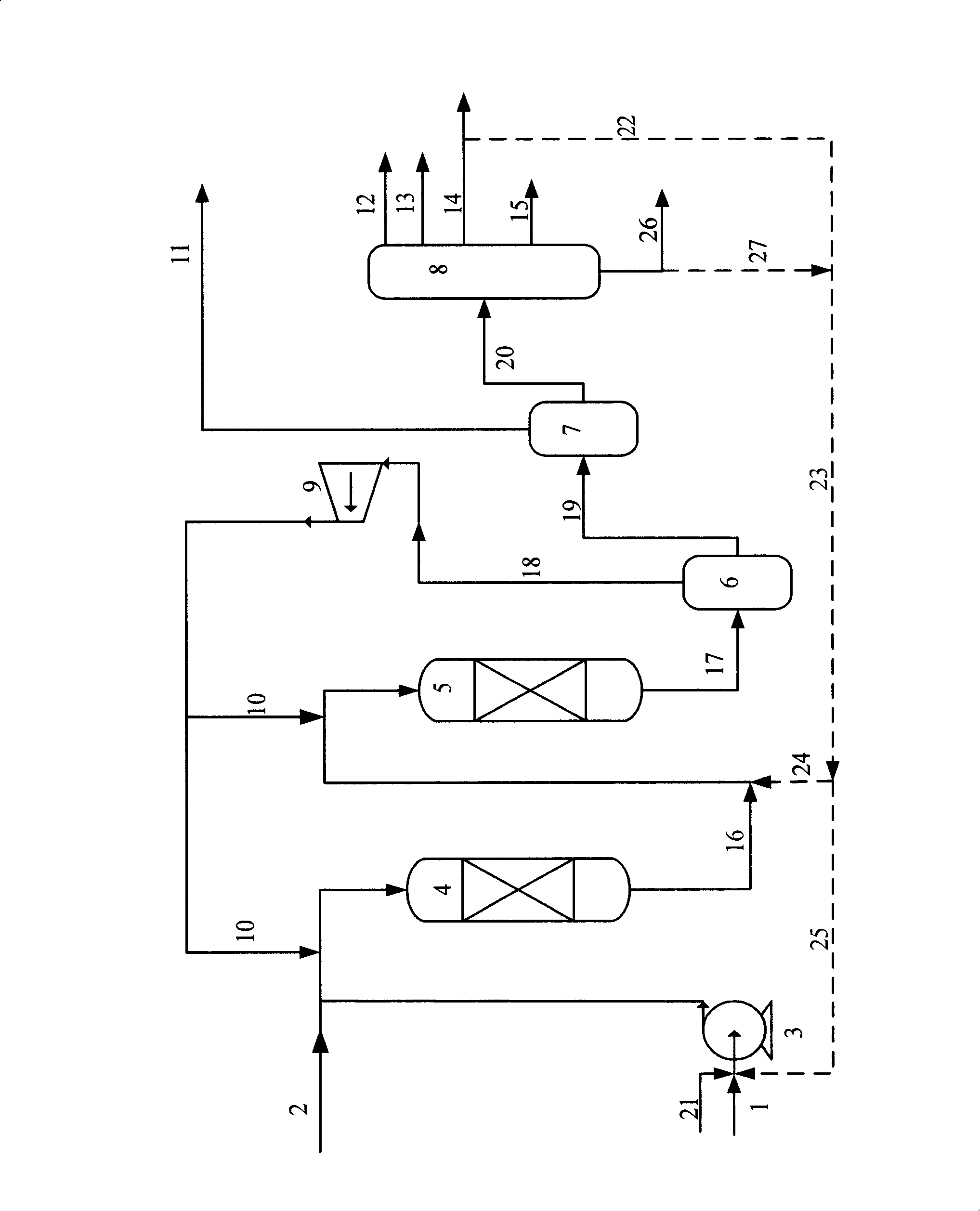

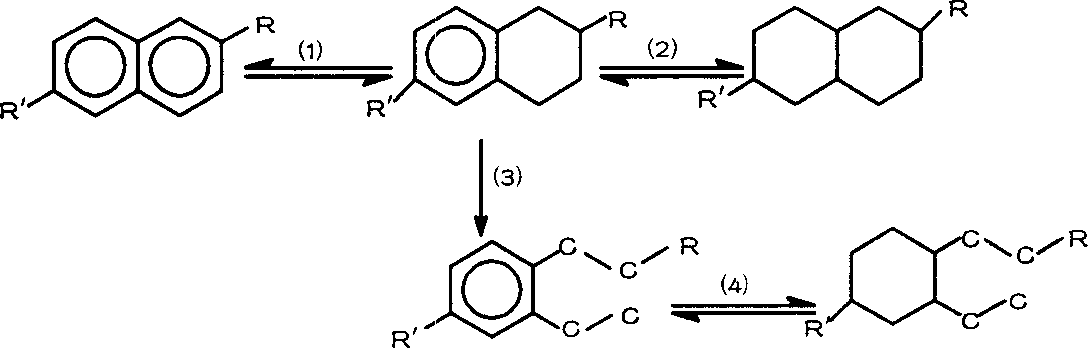

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

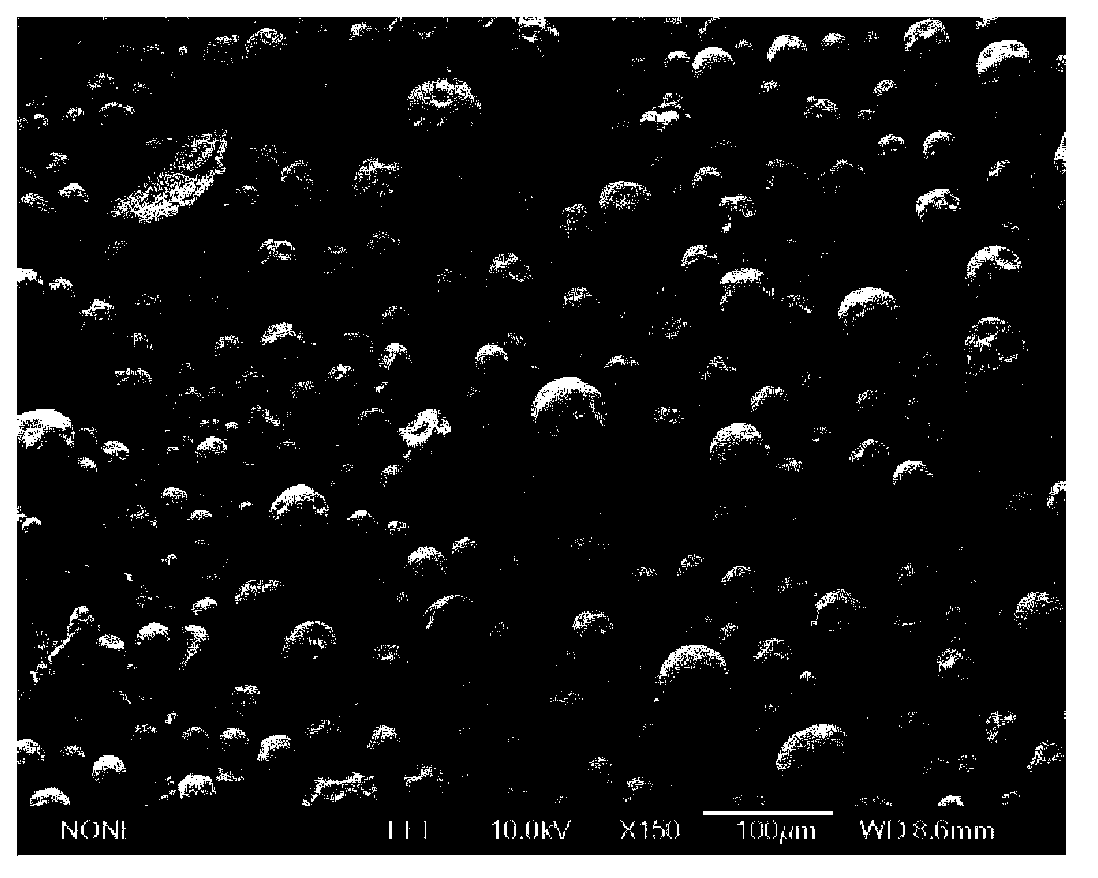

High-strength polysaccharide aerogel microsphere, and preparation method and application thereof

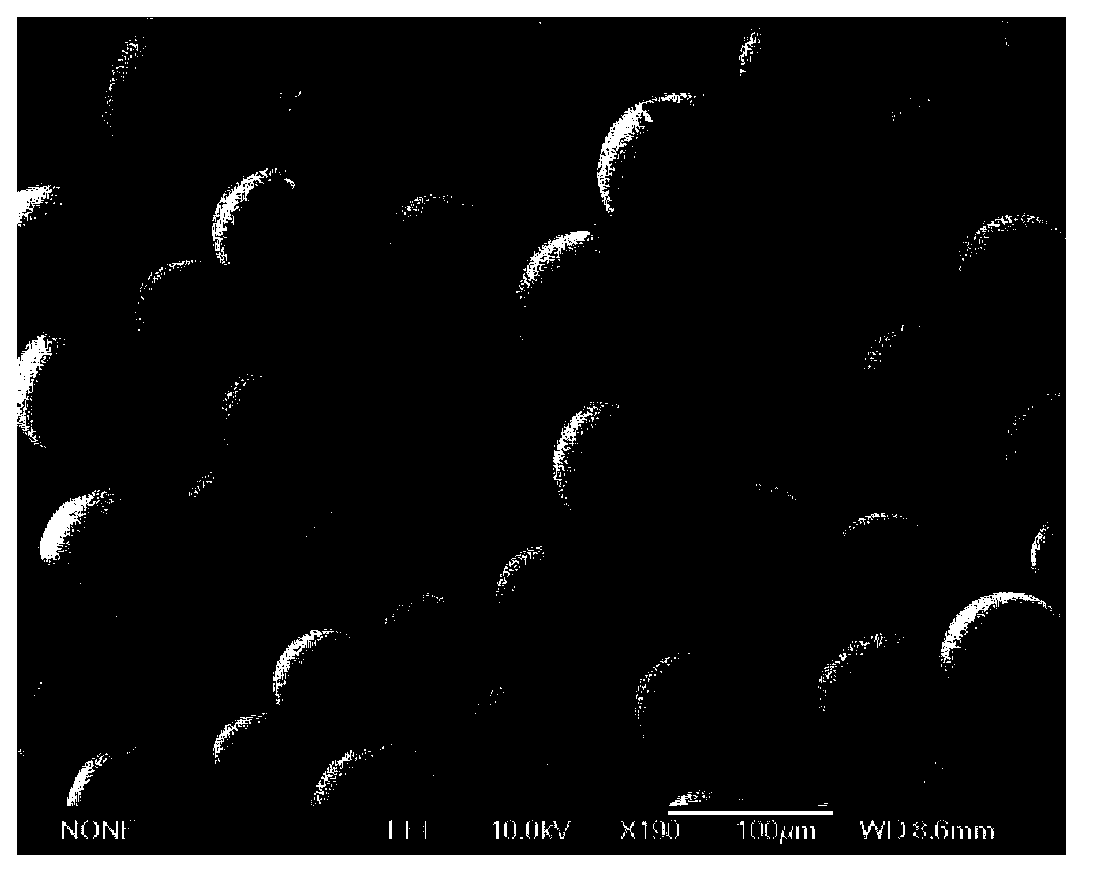

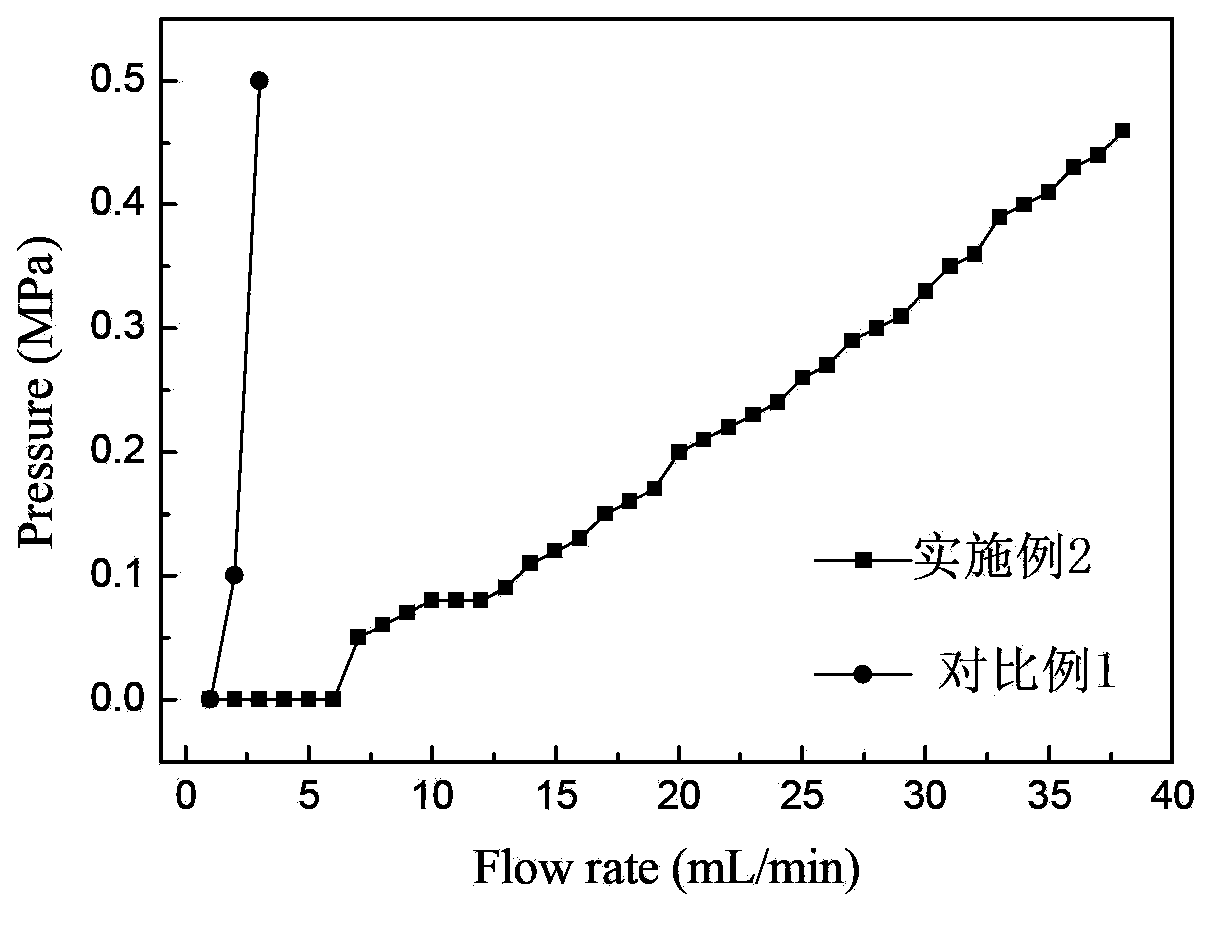

ActiveCN103769057AHigh strengthHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesChromatographic separationCross-link

The invention discloses a high-strength polysaccharide aerogel microsphere, and a preparation method of the high-strength polysaccharide aerogel microsphere, which are mainly used in the field of chromatographic separation. According to the preparation method, firstly a difunctional cross-linking agent is used to modify a polysaccharide material, then the polysaccharide material is mixed with a material not modified, and the mixture is emulsified into a sphere, and activated at the later stage to achieve crosslinking in the microsphere. The modified polysaccharide chain forms a covalent cross-linking bond in an aerogel fiber bundle and between the aerogel fiber bundles, so that the mechanical strength of the aerogel microsphere is greatly improved; the polysaccharide chain not modified contains a large quantity of hydroxide radicals so as to be good for the formation of a hydrogen bond in the gelation process and play a role of skeleton supporting, then a macropore network structure formed through aerogel solidification is kept, and the shrinkage and the deformation of the microsphere are effectively avoided. The aerogel microsphere not only has an excellent property of the natural polysaccharide, but also has a remarkable advantage on the skeleton rigidity and operation flow rate, and is therefore an ideal industrial chromatographic separation filler.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

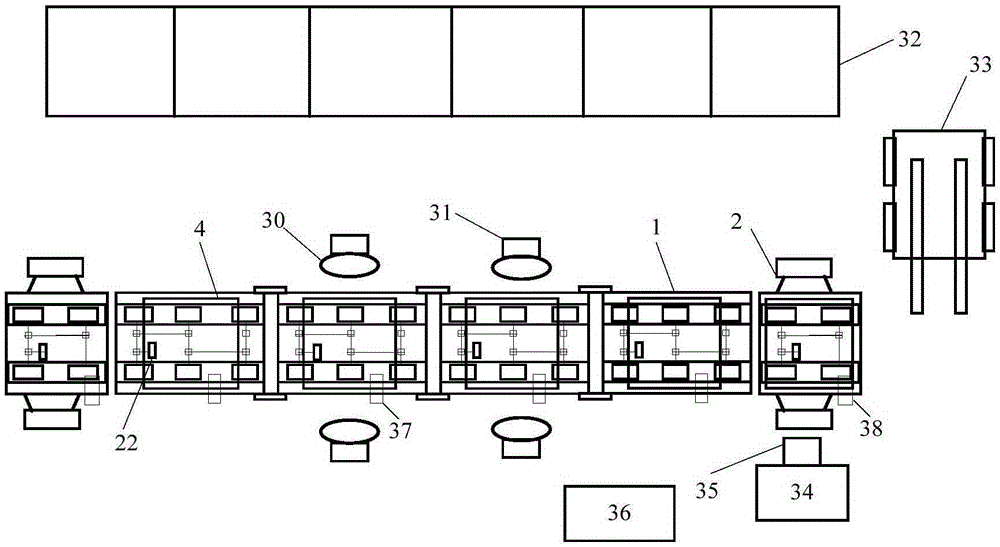

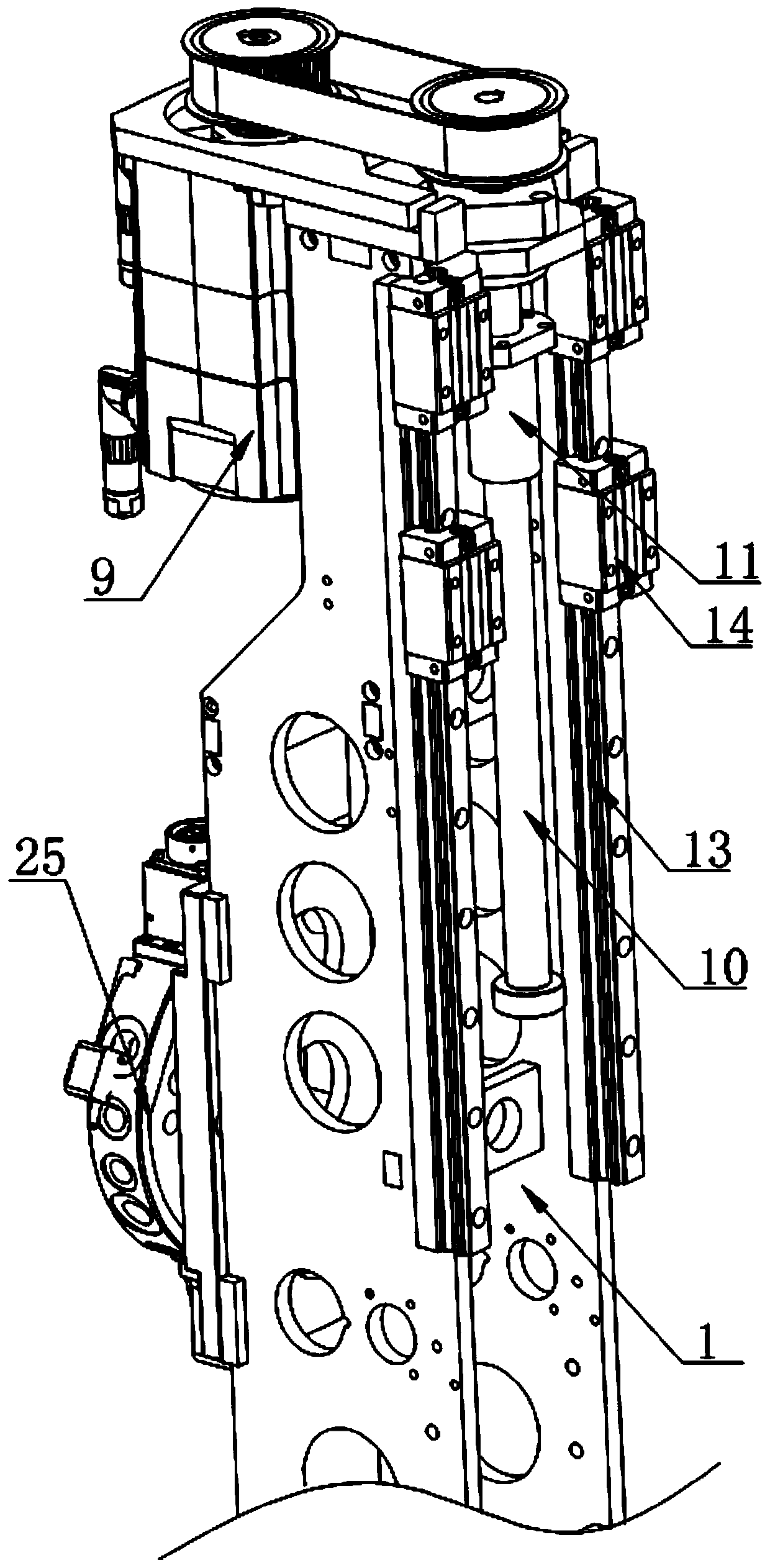

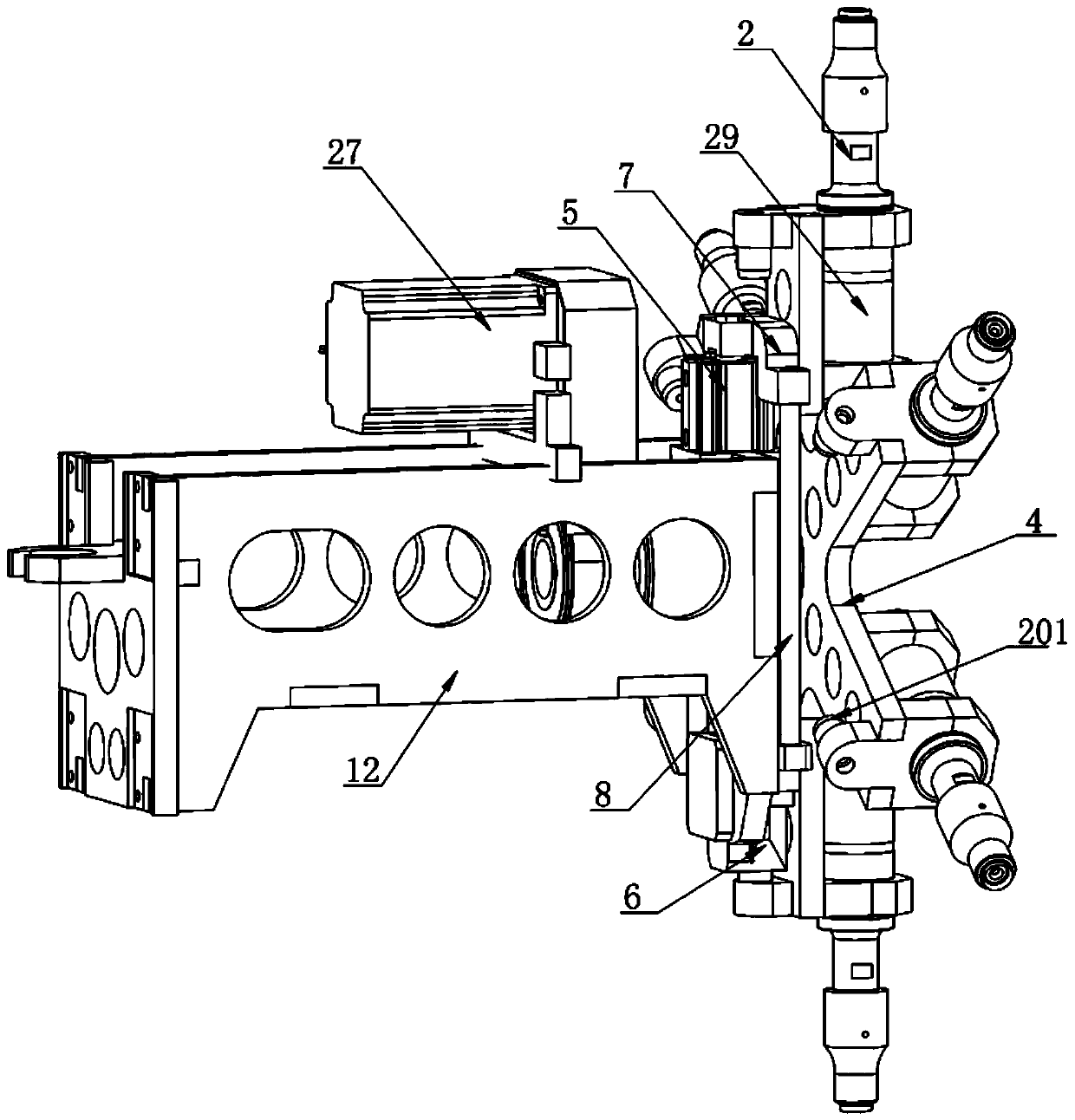

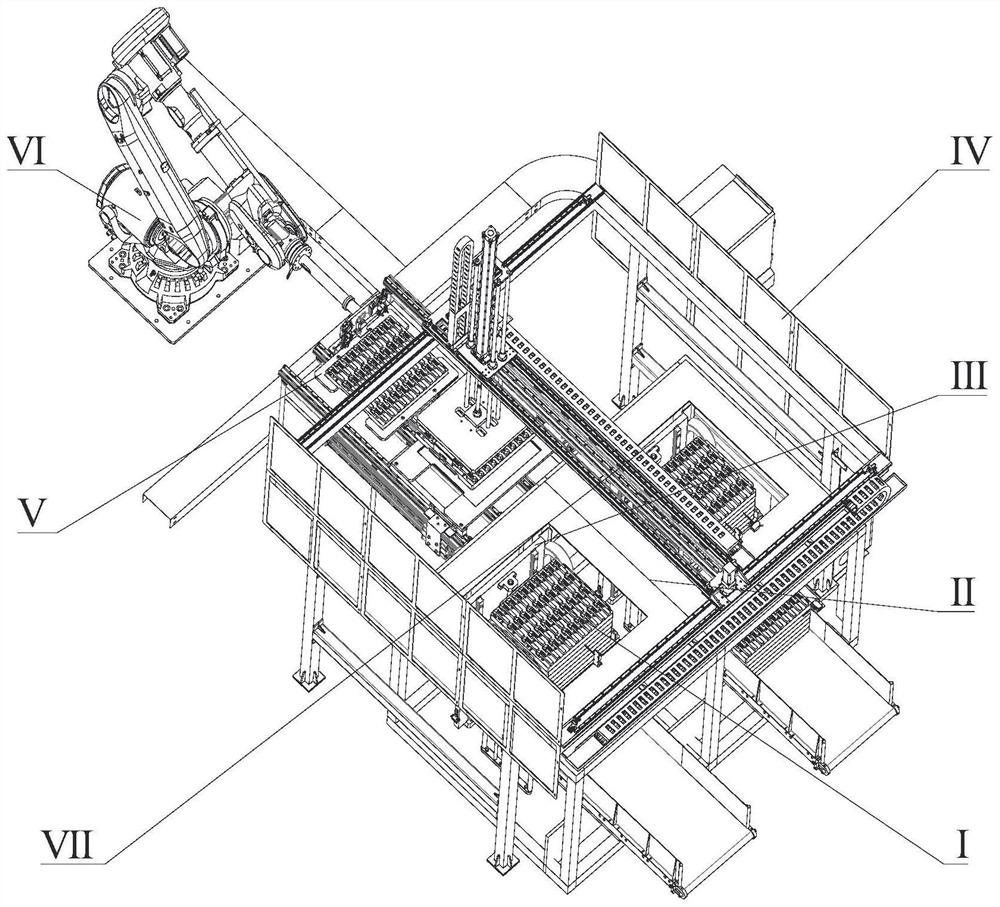

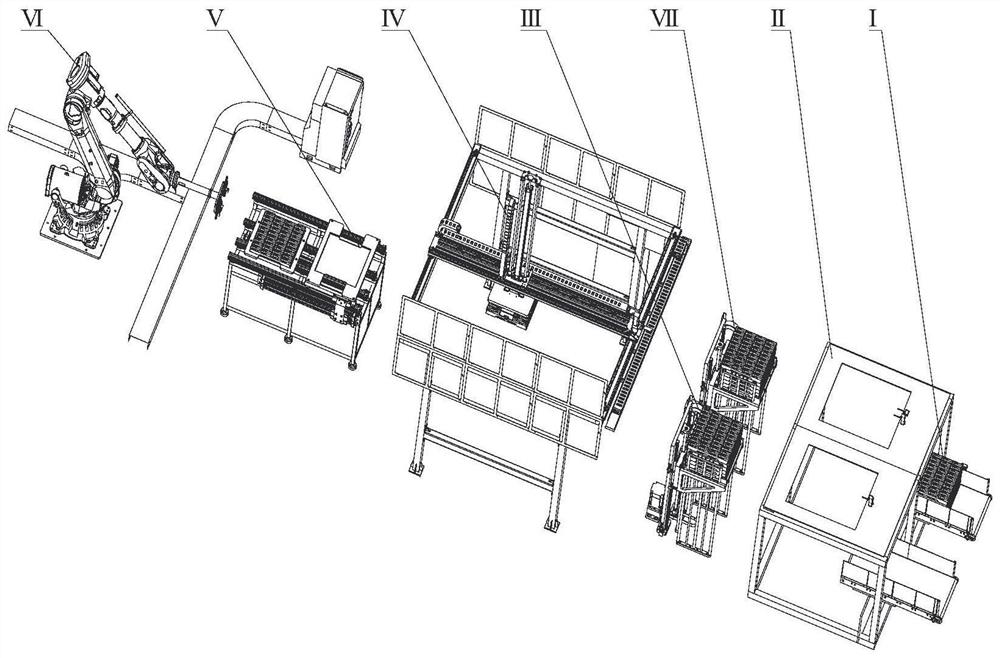

Reconfigurable automatic flexible welding production platform and operation method thereof

ActiveCN105252180ATo achieve high flexibility requirementsProduction task production capacity coordinationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRe design

The invention discloses a reconfigurable automatic flexible welding production platform and an operation method thereof. The reconfigurable automatic flexible welding production platform comprises a production line main body, an accompanying platform, an accompanying fixture, a lifting mechanism, welding robots, a welding robot control center, a fixture transfer trolley, a fixture base and a production platform control center, wherein the accompanying platform can move on a line body; the accompanying clamp is positioned on the accompanying platform; the lifting mechanism is positioned on two sections of the line body; the welding robots are positioned at the two sides of a line body welding station; the welding robot control center controls movement of the welding robots and welding action of a fixed welding gun; the transfer trolley is responsible for replacing a fixture; the fixture base stores fixtures for producing different kinds of assemblies; the production platform control center controls movement of the whole production platform, wherein the movement comprises operation of a welding production line main body and operation of the lifting mechanism, so that high-flexibility requirements of automatic welding production for various small assembly components are reached, and production capacity is re-designed for realizing coordination of production tasks and production capacity.

Owner:YANGZHOU XINLIAN AUTO PARTS +1

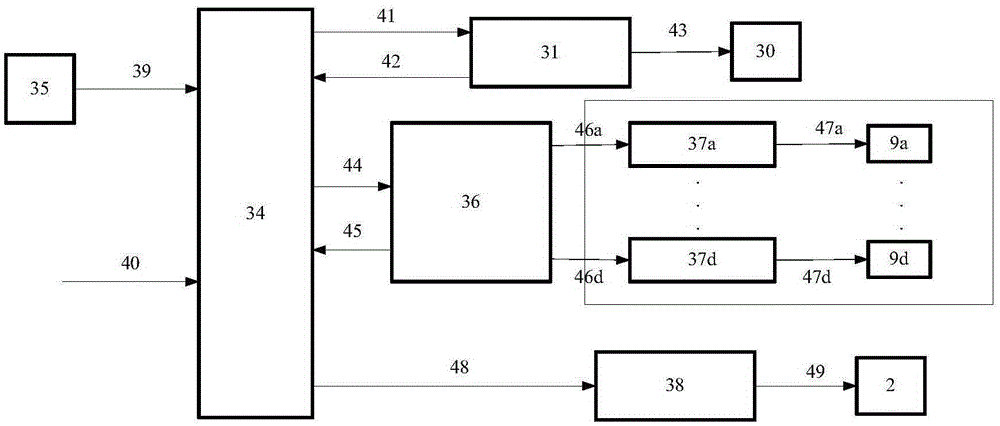

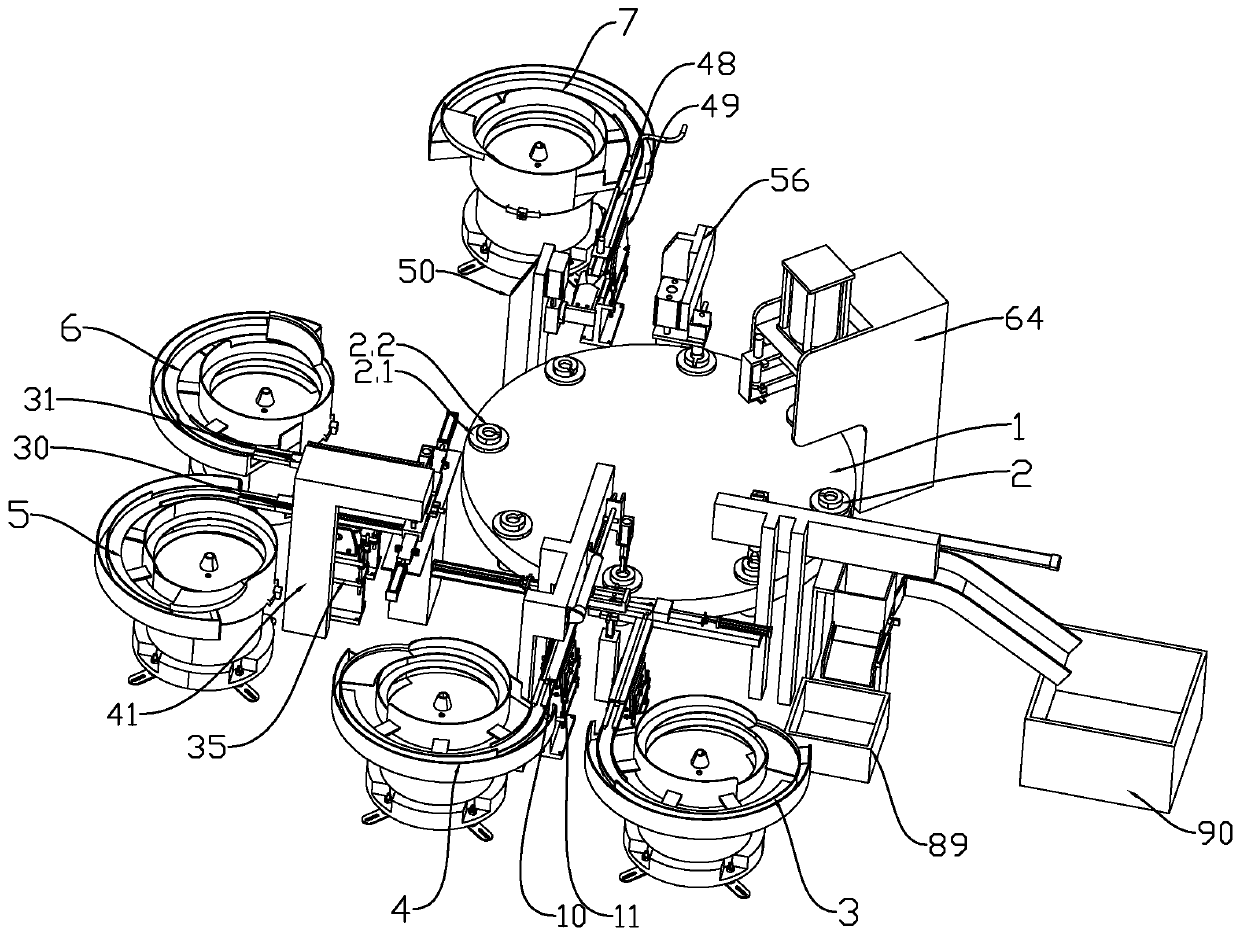

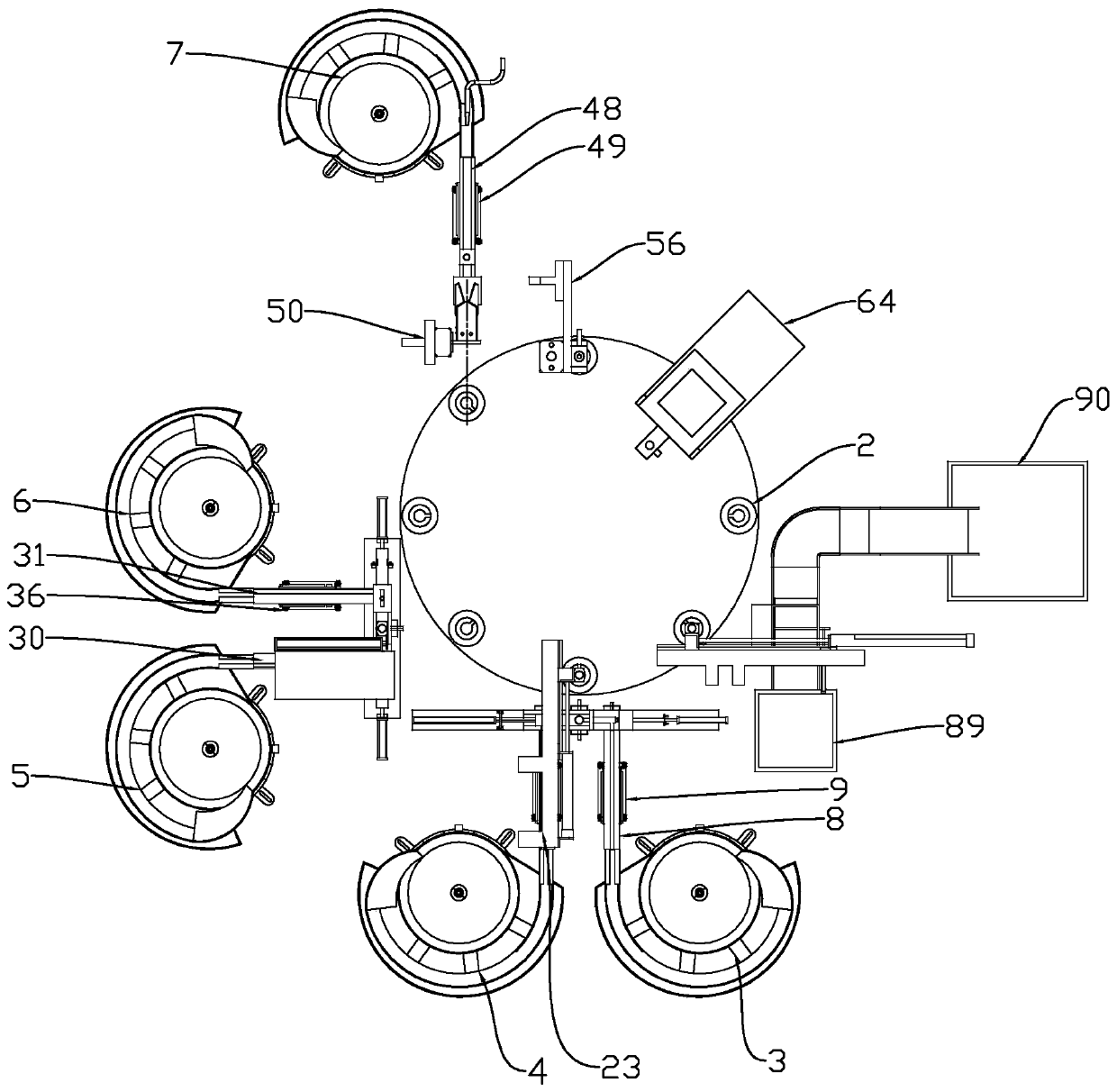

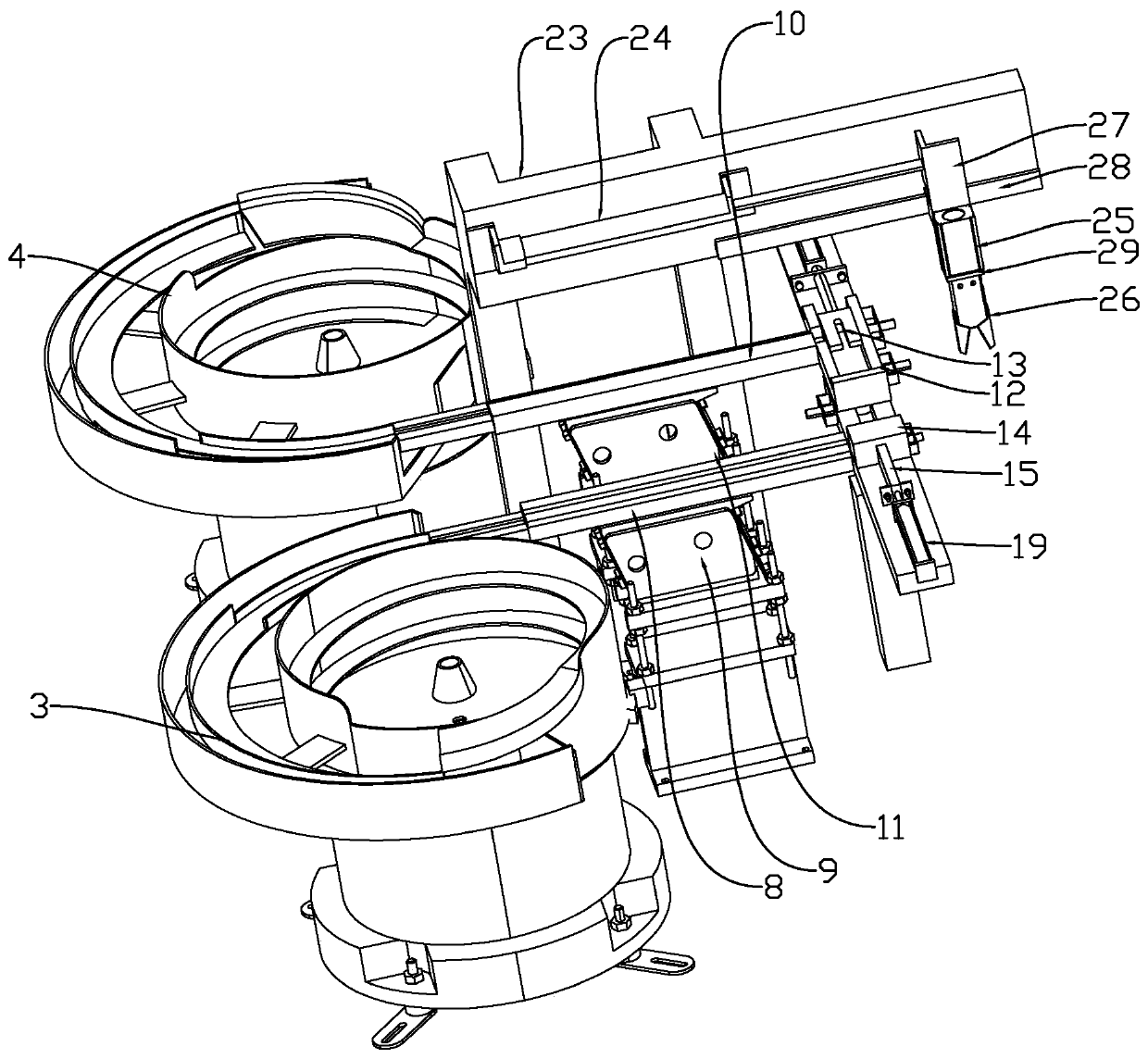

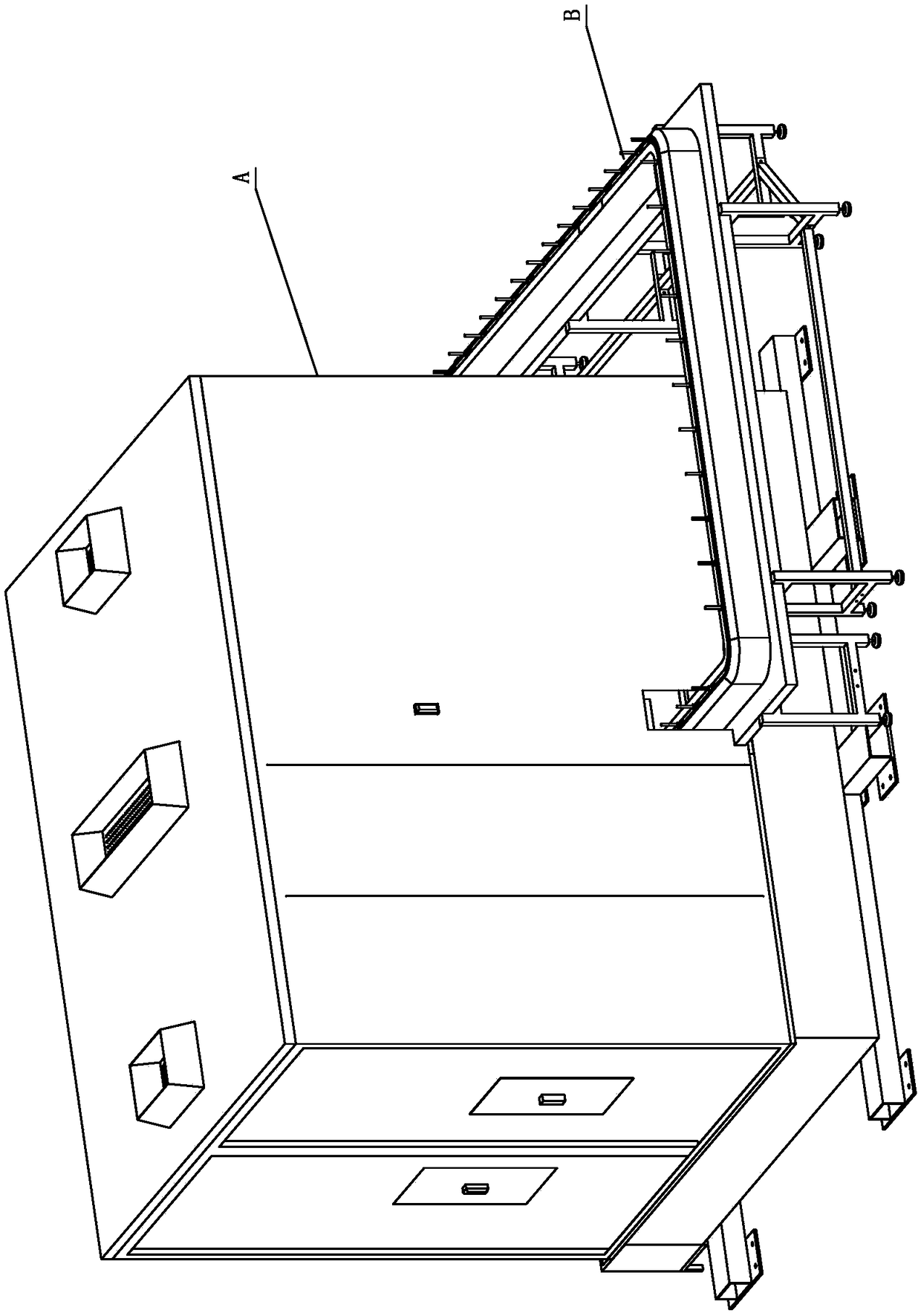

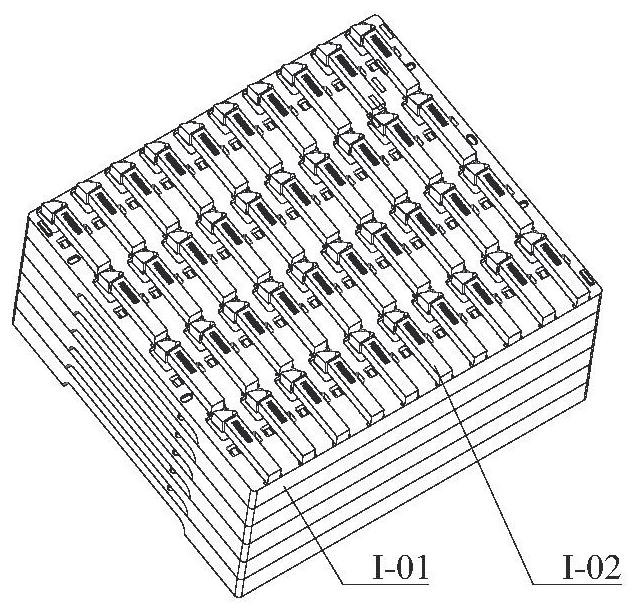

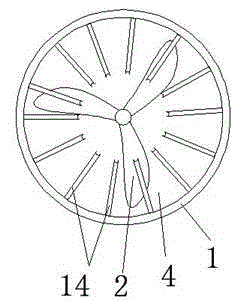

Multi-station rotary disc type automatic assembly production line of combined roller

PendingCN110919361AReduce chanceReduce production areaAssembly machinesMetal working apparatusProduction lineEngineering

The invention relates to a combined roller and particularly relates to a multi-station rotary disc type automatic assembly production line of the combined roller. The combined roller comprises a rotary disc, a bolt feeding mechanism, a bearing feeding mechanism, a gasket feeding mechanism, a clamping ring feeding mechanism, a press fitting mechanism and a rotary disc discharging mechanism, whereinthe rotary disc is connected with a rotation driving mechanism, the rotation driving mechanism can drive the rotary disc to rotate, the bolt feeding mechanism, the bearing feeding mechanism, the gasket feeding mechanism, the clamping ring feeding mechanism, the press fitting mechanism and the rotary disc discharging mechanism are sequentially arranged on the periphery of the rotary disc, and bearing seats are arranged at area positions, facing the bolt feeding mechanism, the gasket feeding mechanism, the clamping ring feeding mechanism, the press fitting mechanism and the rotary disc discharging mechanism, of an upper face of the rotary disc respectively. The combined roller is advantaged that the conveying mechanism and the assembling mechanism of all parts of a combined roller are distributed along the rotary disc, so the combined roller is continuously and automatically assembled in a relatively concentrated area, the occupied production area is small, and production cost is reduced.

Owner:无锡阿尔法精密机械制造有限公司

Water-dispersible transparent astaxanthin emulsion and preparation method

ActiveCN105832569AImprove solubilityGood dispersionOrganic active ingredientsCosmetic preparationsSolubilityDispersity

The invention belongs to dosage form technology of functional additives, and particularly relates to a water-dispersible transparent astaxanthin emulsion and a preparation method. The astaxanthin emulsion comprises an oil phase, a water phase and an emulsifier, the oil phase is an astaxanthin solution and comprises astaxanthin and a solvent, mass-volume concentration of the astaxanthin solution is 1-30 mg / mL, the water phase is water or a mixture of glycerin and water, the solvent is edible oil, a volume ratio of the oil phase to the emulsifier is 1:3:3:1, and a volume ratio of the water phase to mixed liquid of the oil phase and the emulsifier is greater than or equal to 1:9. The preparation method includes: preparing the oil phase, preparing the water phase, and preparing the emulsion. The water-dispersible astaxanthin emulsion has high solubility and water dispersity, bioavailability of the water-dispersible astaxanthin emulsion is improved, and various physiological active functions of the water-dispersible astaxanthin emulsion are brought into effective play.

Owner:CHINA AGRI UNIV

Fur printing technology

InactiveCN102108640AMeet different production needsTanning treatmentDyeing processChemical reactionSheep skin

The invention discloses a fur printing technology, which is characterized by comprising the following steps of: 1) selecting materials; 2) pretreating raw hide, namely treating the fur by using formaldehyde, and bleaching needle or discoloring; 3) dyeing a bottom color, namely performing brush dyeing or dip dyeing to obtain a color similar to the bottom color of the fur to be imitated; 4) printing, namely smoothening the hair by using a brush, printing a center color, printing the black color on the excircle, uniformly scraping and drying; 5) desizing; and 6) rolling saw dust, namely adding the saw dust, a brightener and the like into a drum for rolling the fur, so that the fur is loosened, brightened and subjected to float color removal. By the technical process that color patterns are formed on the fur through physic-chemical reaction by using dyes or coatings by means of a printing plate, patterns of animals or plants such as leopard cats, leopards, tigers and the like can be imitated on raw rabbit skins, beaver rabbit skins, kidskins, sheared sheep skins and the like, and the skins can be used for manufacturing collars, hats, clothes, edgings and the like.

Owner:HUASI HLDG CO LTD

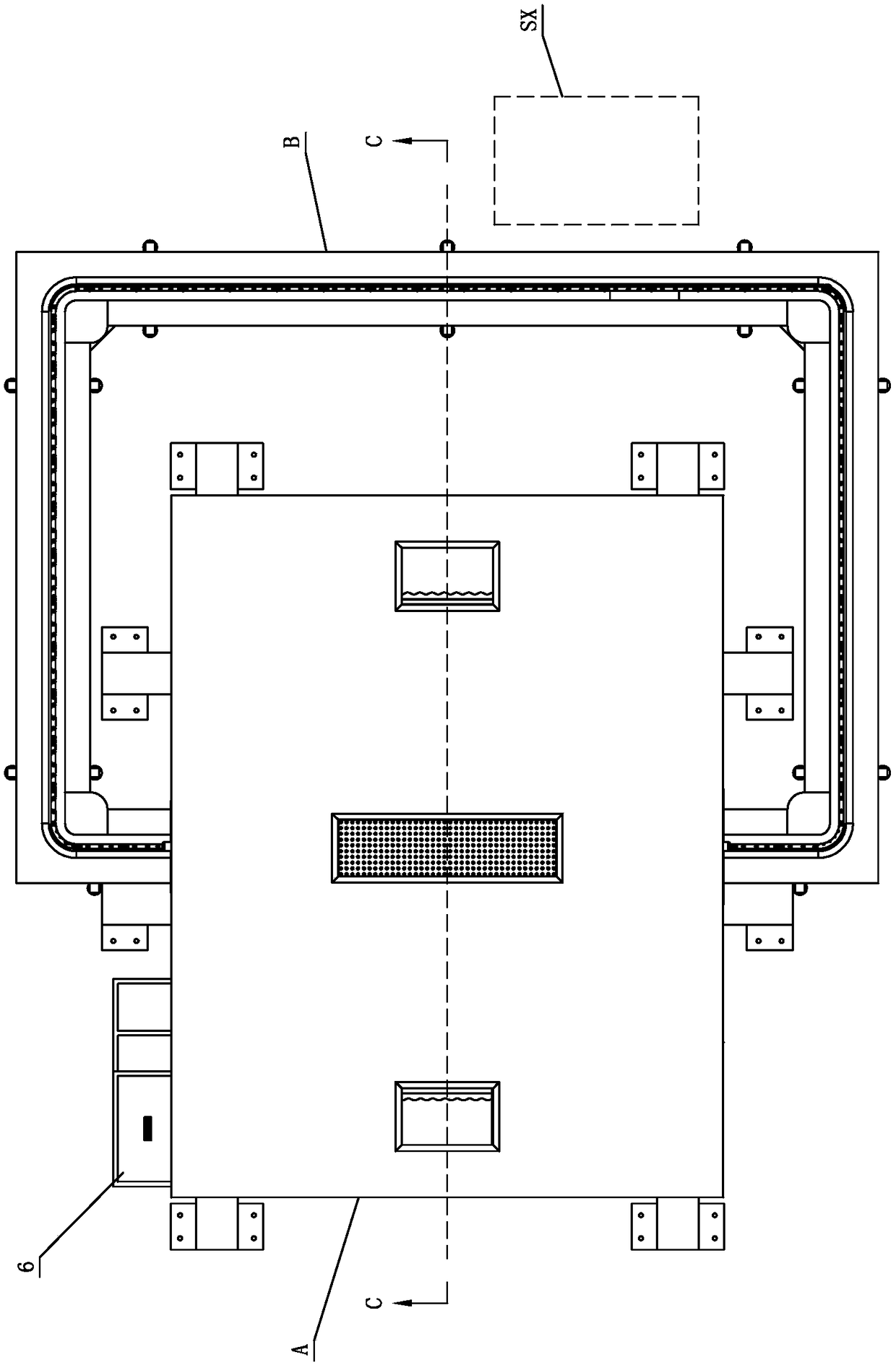

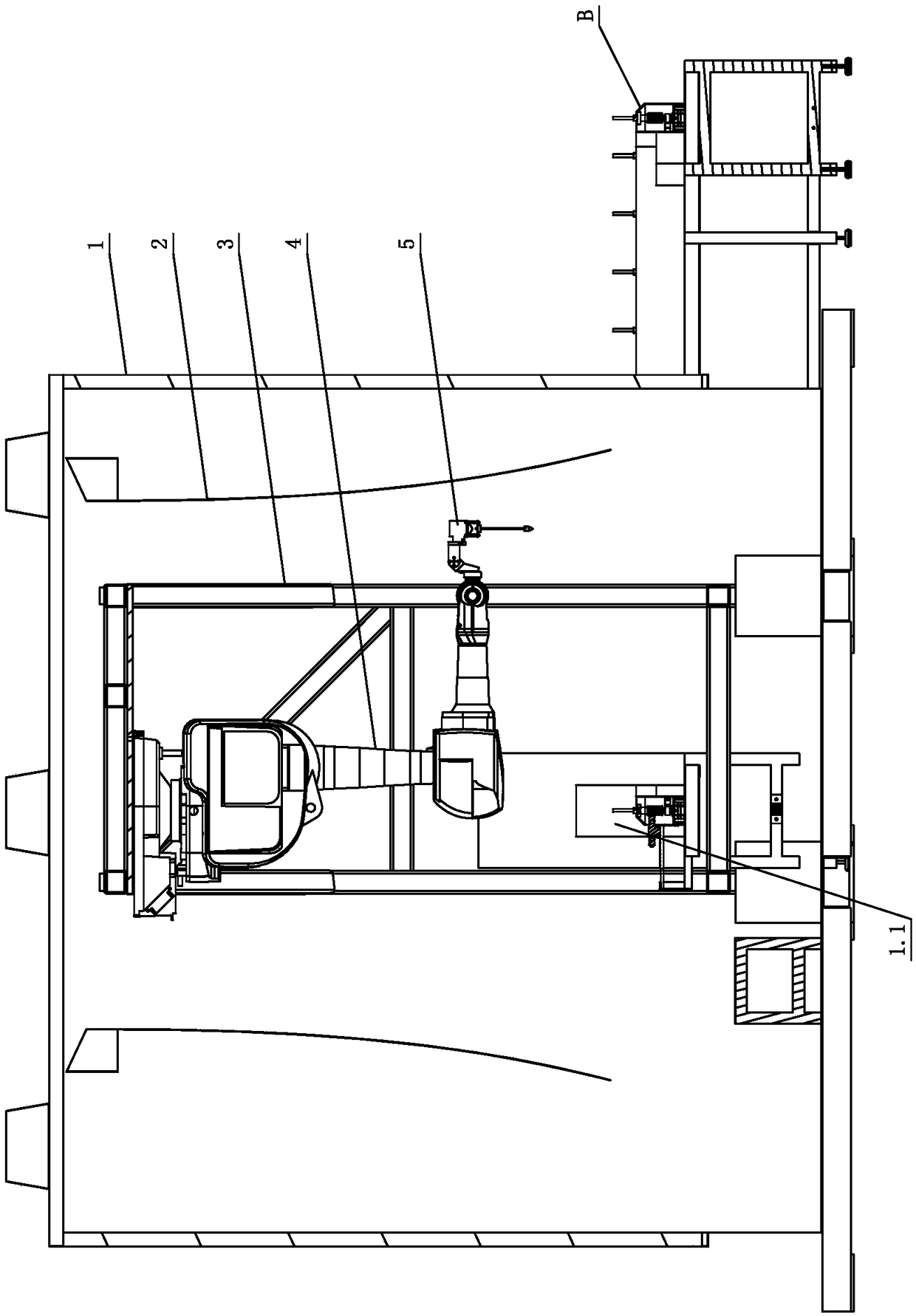

Automatic spraying line for golf club head

The invention relates to an automatic spraying line for a golf club head. The automatic spraying line comprises spraying equipment and conveying equipment, wherein at least one spraying equipment is arranged along the conveying equipment; the conveying equipment is annually arranged and penetrates through at least one spraying equipment; the spraying equipment comprises a water curtain cabinet, asupporting portal frame and a multi-shaft robot, the supporting portal frame and the multi-shaft robot are covered with the water curtain cabinet, the multi-shaft robot is arranged on the supporting portal frame in an upside down manner, and a spraying gun is arranged on the multi-shaft robot; and the conveying equipment comprises a conveying mechanism and a plurality of club head tool assemblies,the conveying mechanism comprises a conveying strip and a conveying driving assembly, the conveying belt is annularly arranged, the conveying driving assembly is used for driving the conveying stripto work, the conveying strip penetrates through the water curtain cabinet through a conveying opening in the water curtain cabinet, the multi-shaft robot is located above the conveying strip which penetrates through the inner side of the water curtain cabinet, and the club head tool assemblies are distributed on the conveying strip. The automatic spraying line is simple and reasonable in structure, high in degree of automation and spraying efficiency, good in spraying quality, high in finished rate and applicable to multiple spraying procedures, and the clean working environment is guaranteed.

Owner:GUANGDONG LXD ROBOTICS CO LTD

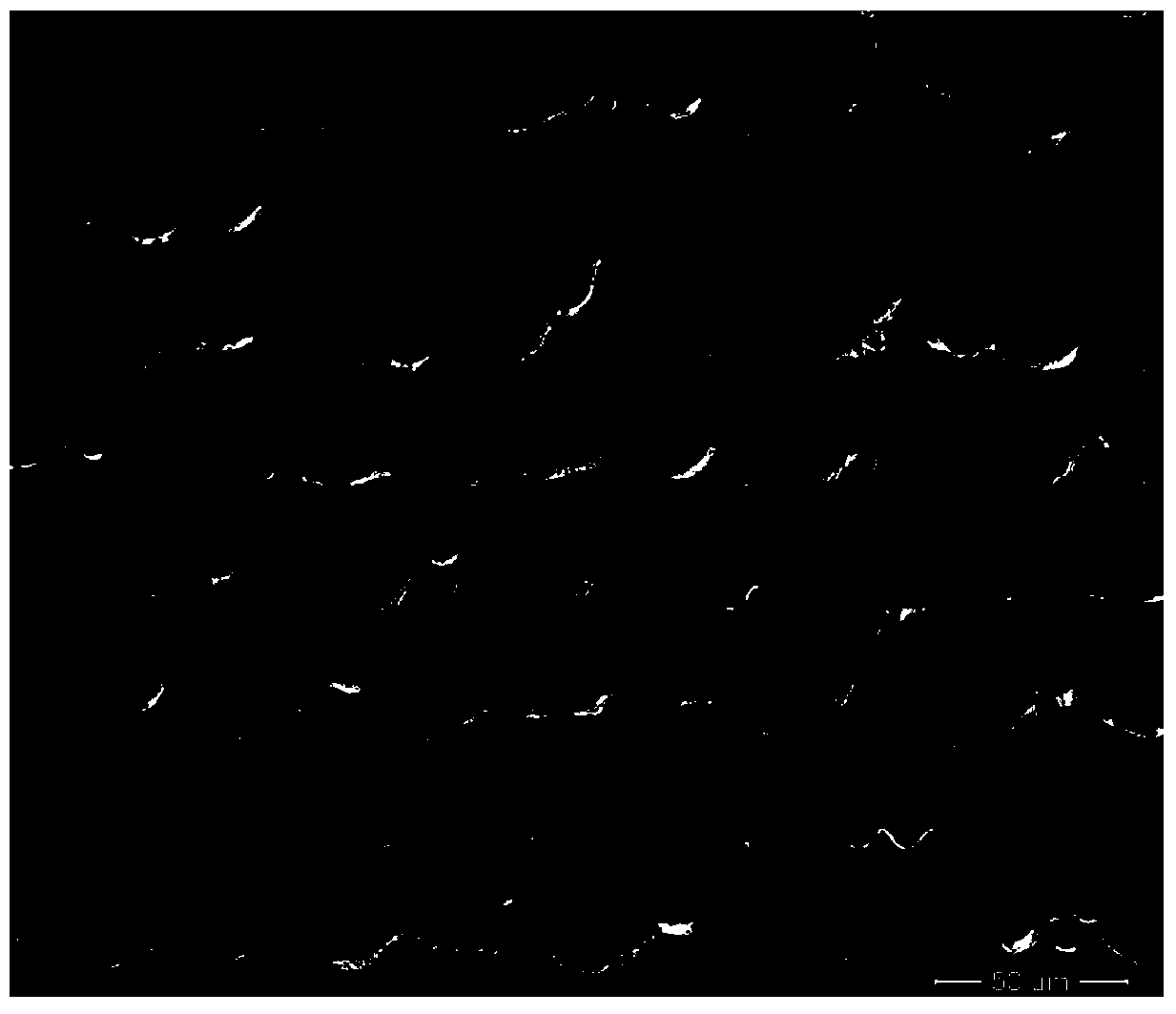

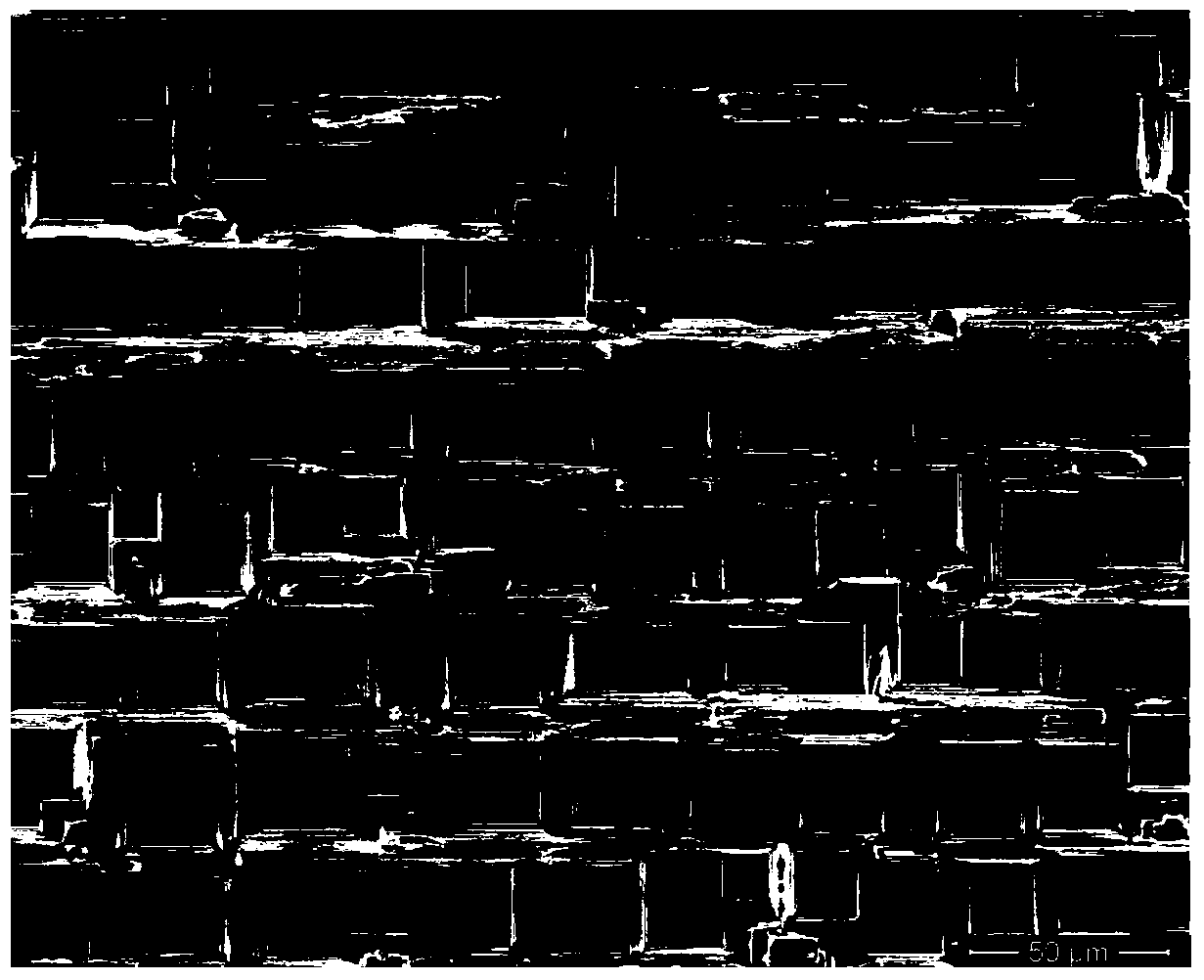

Laser chemical order controllable preparation method of monocrystalline silicon inverted pyramid suede

InactiveCN103426736ASimple manufacturing processEasy to operateSemiconductor/solid-state device manufacturingPicosecond laserLaser scanning

The invention discloses a laser chemical order controllable preparation method of a monocrystalline silicon inverted pyramid suede. The laser chemical order controllable preparation method comprises the following steps of 1 performing laser scanning, tapping and positioning, namely utilizing software to draw a required felting graph (computer aided design (CAD) drawing), performing the scanning and the tapping on the surface of a cleaned silicon wafer through picoseconds laser according to the graph to form a micron-sized inverted-cone-shaped suede with evenly-distributed holes; 2 performing acid washing of the poroid suede, firstly using hydrogen fluoride (HF) to perform the acid washing and then using distilled water to perform the washing; 3 performing acid washing of a poroid suede layer, firstly using the HF to perform acid washing and then using ultrapure water to perform washing; 4 preparing the inverted pyramid suede, namely placing a sample subjected to the acid washing into a prepared alkaline solution to perform heating in water bath so as to prepare the micron-sized inverted pyramid suede. A preparing and mask-removing process is omitted and replaced by a laser scanning and tapping technology, and the size and the shape of a felting region can be customized through the software (CAD). The monocrystalline silicon inverted pyramid suede has excellent reflection-reducing effect on a 400-700nm wave band with intensive solar spectrum photons, and the reflection rate reaches up to 5%.

Owner:BEIJING UNIV OF TECH

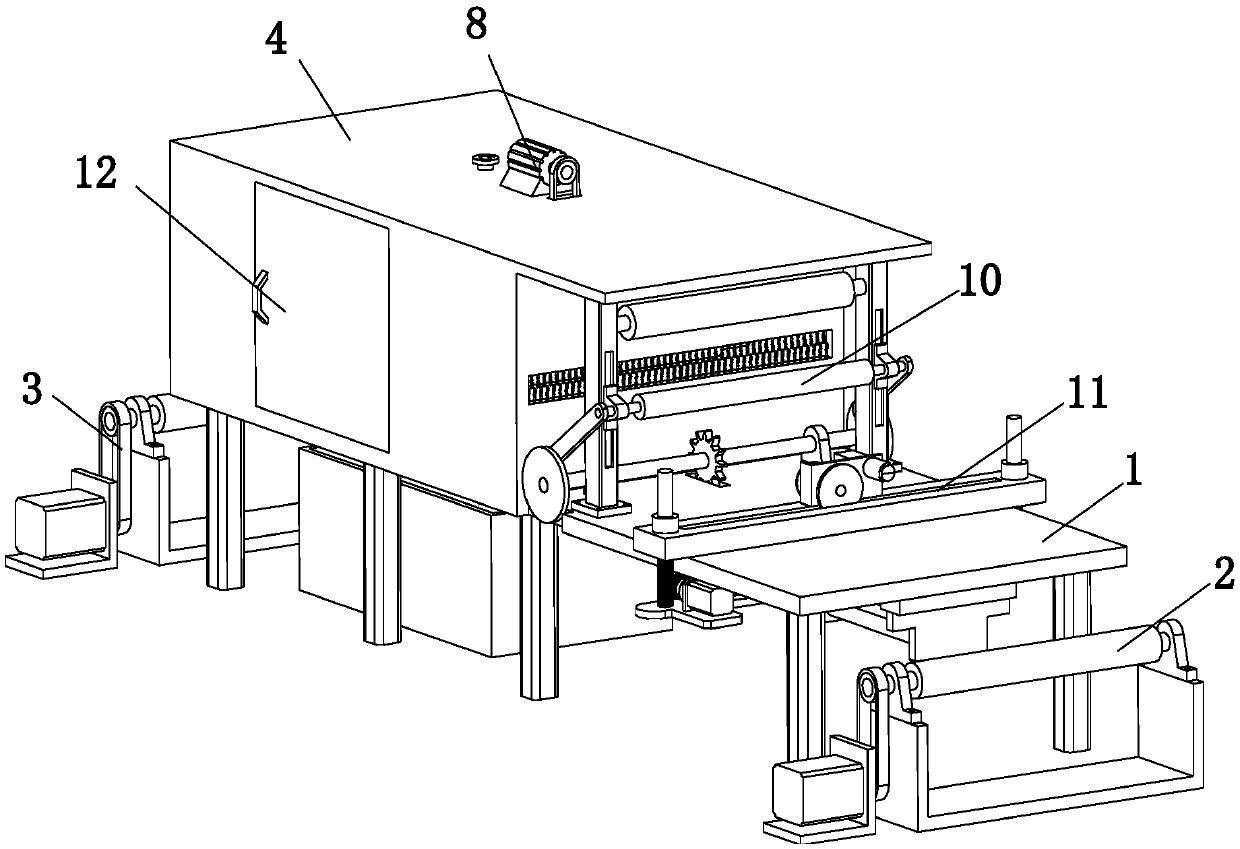

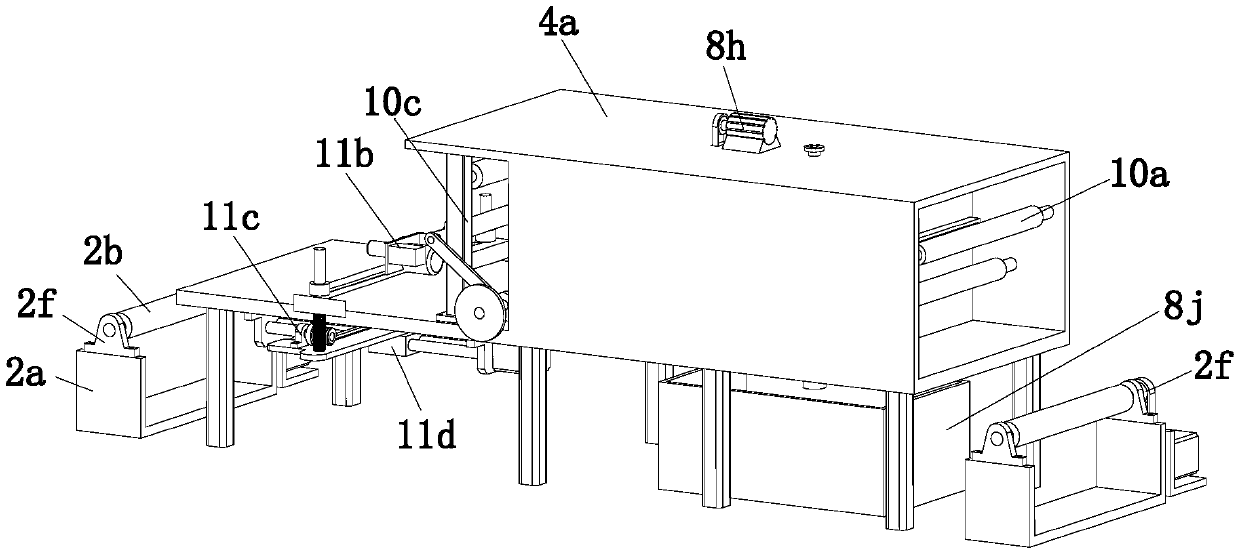

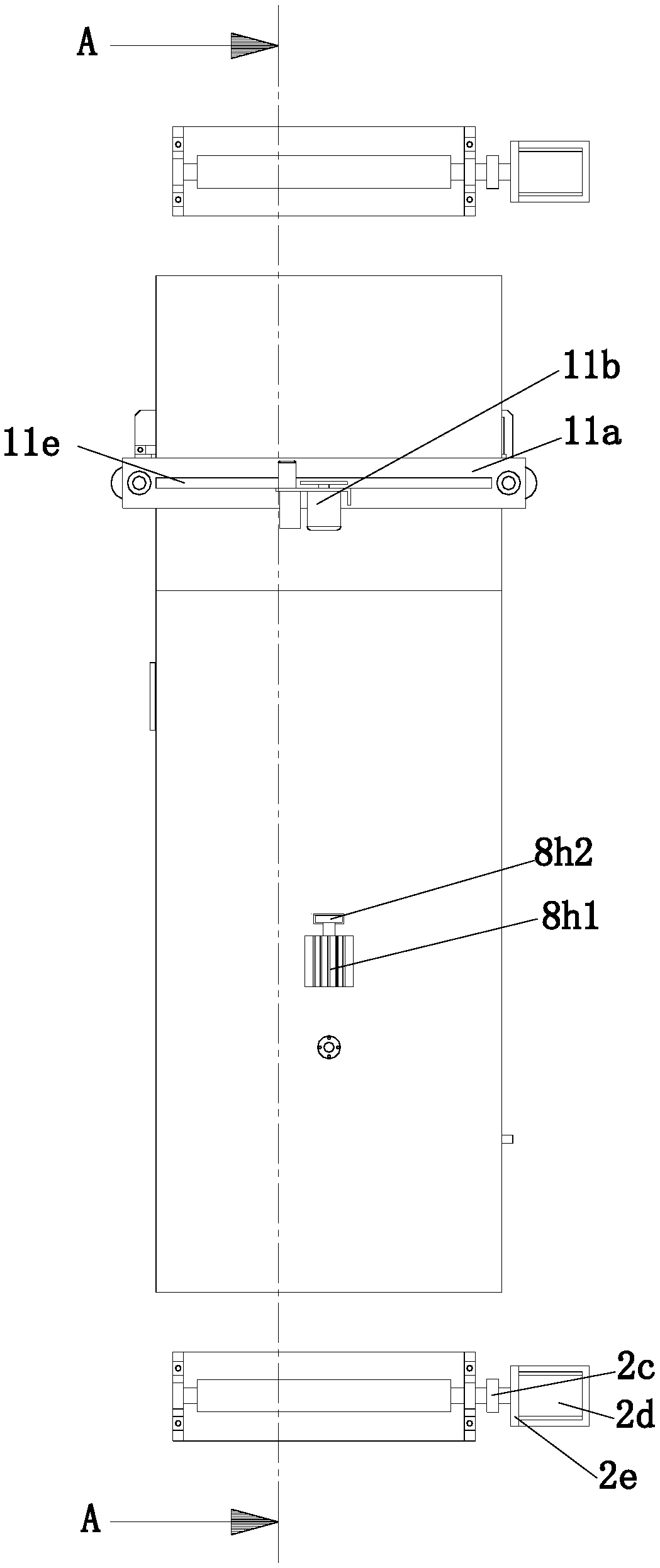

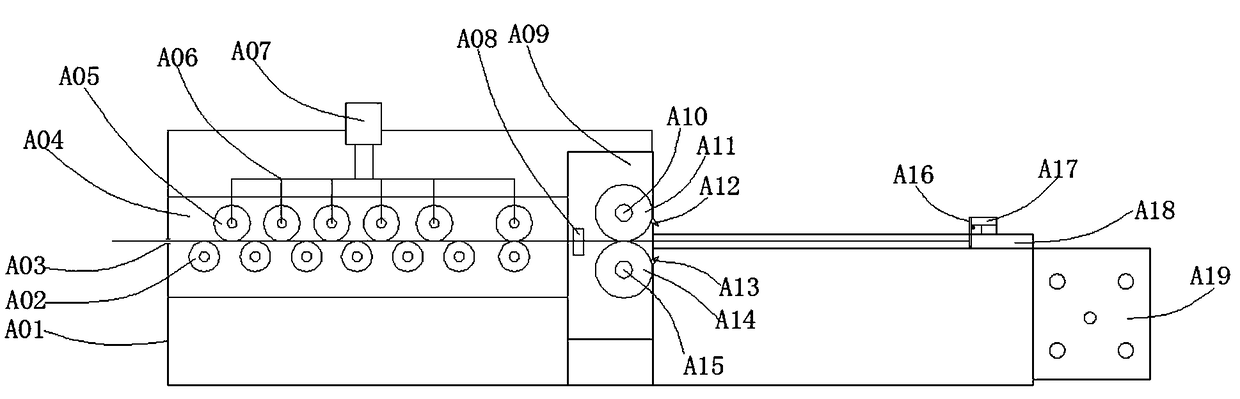

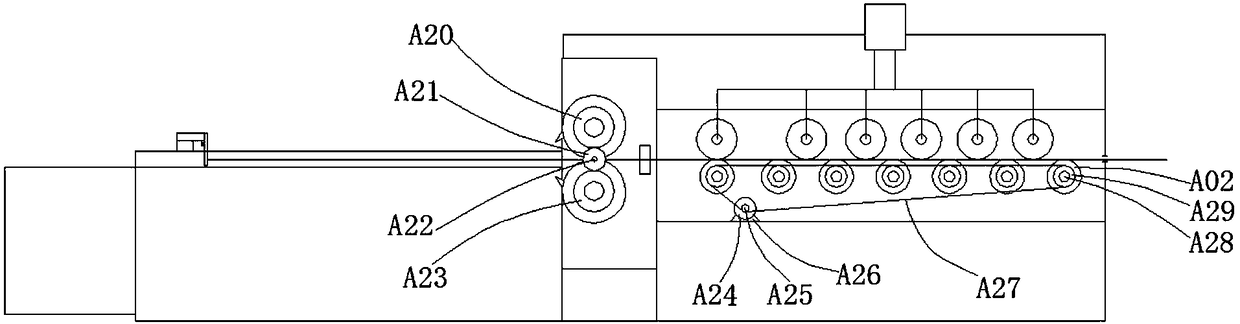

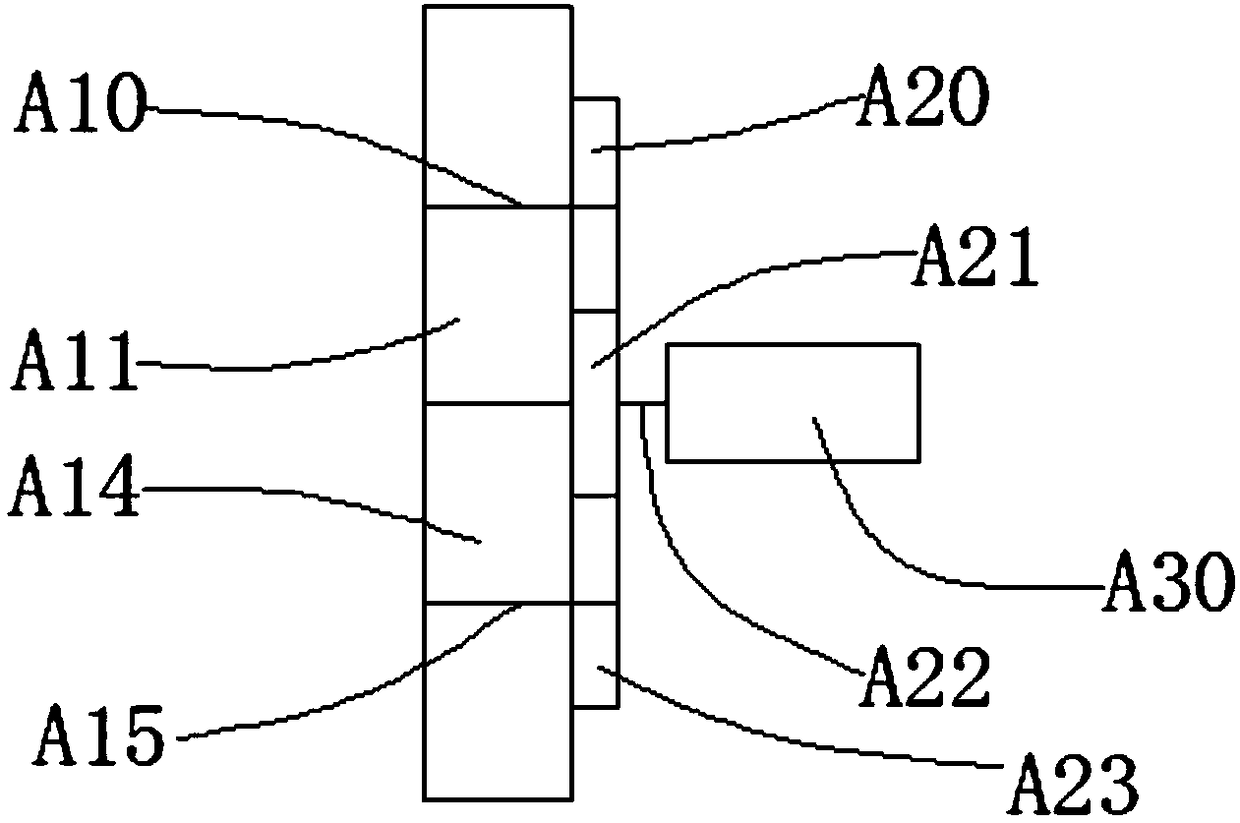

Work method of integrated processing equipment for textile fabric

InactiveCN109629158AReduce manufacturing costIncrease productivityMechanical cleaningPressure cleaningEngineeringIntegrated processing

The invention discloses a work method of integrated processing equipment for textile fabric, and belongs to the field of textile mechanical equipment. The processing equipment comprises a workbench, adischarging device and a rolling device. A supporting frame fixedly connected with the workbench is arranged at the top of the workbench, a first containing cavity, a second containing cavity and a third containing cavity can be formed by the supporting frame and the workbench, a washing device is arranged in the first containing cavity, a hot air blowing set is arranged in the second containingcavity, and a traction device and a cloth cut-off device are arranged on the workbench. A side door plate is arranged on the side wall of the supporting frame, the traction device comprises a first guide assembly, a second guide assembly and an adjusting guide assembly, and the first guide assembly and the second guide assembly are identical in structure. According to the work method of the integrated processing equipment, by means of the discharging device, the traction guide device, the washing device, the hot air blowing device, the cloth cut-off device and the rolling device, automatic feeding, cleaning, dust removal, cutting off and rolling work of the fabric can be achieved, the production cost is greatly reduced, the production efficiency is greatly improved, and the therefore the overall practicality is improved.

Owner:杭州富龙布艺有限公司

Method for preparing corn straw coarse feed by microbial beneficial living bacteria

InactiveCN104012787AGrowth inhibitionFor long-term storageFood processingAnimal feeding stuffBiotechnologyLactobacillus acidophilus

The invention relates to a method for preparing corn straw coarse feed by microbial beneficial living bacteria. The method comprises the steps of (1) preparing microbial strains: respectively feeding two strains of bacillus subtilis, one strain of lactobacillus acidophilus, one strain of lactobacillus bulgaricus and one strain of rhodopseudomonas palustris onto corresponding culture mediums, culturing, carrying out expanding propagation, and mixing 20g of bacillus subtilis, 20g of lactobacillus acidophilus, 20g of lactobacillus bulgaricus and 20g of rhodopseudomonas palustris for later use; preparing 100g of cellulase; (2) preparing corn straw: flattening the corn straw, and drawing into hair shape with a wire drawing machine for later use; (3) preparing the corn straw coarse feed: putting 1000g of prepared corn straw into a fermentation container, and evenly spraying 5g of cellulase onto the corn straw; diluting microorganism with well water, then spraying onto the corn straw, and fermenting in an airtight way for 7-10 days; taking out the product, drying and packaging to obtain the corn straw coarse feed. The method is simple in technology and short in fermentation period, and is capable of saving a great deal of grain; the prepared biological straw feed is good in palatability, high in lactic acid content and more in beneficial bacteria.

Owner:山西海洲生物科技有限公司

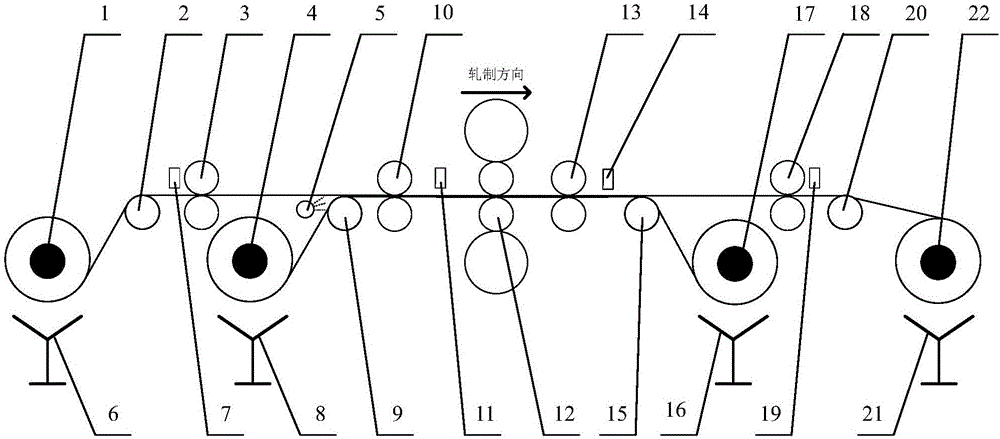

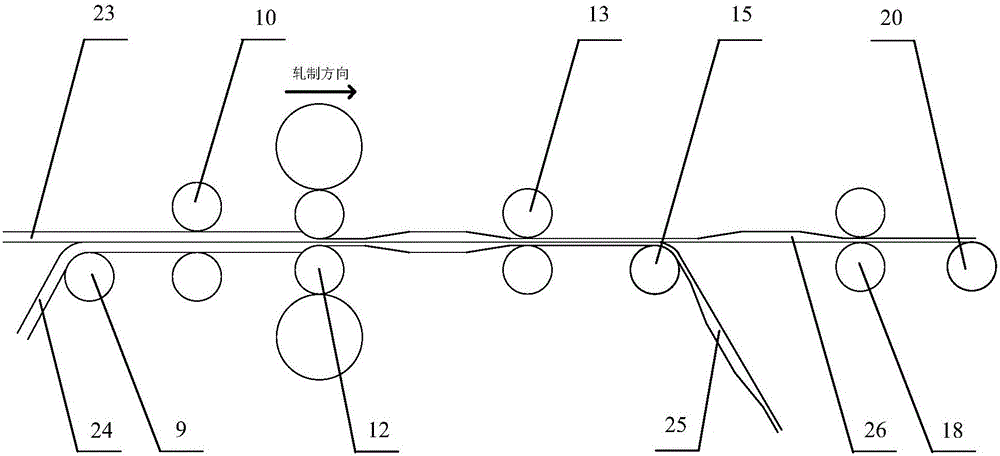

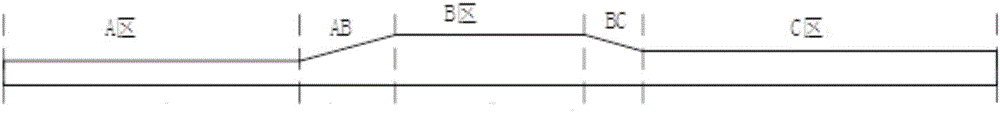

Rolling method for single-face periodically variable thickness plate strip materials

ActiveCN106513436AAchieve productionImprove rolling efficiencyTension/compression control deviceWork lubrication devicesVariable thicknessMetal

The invention disclose a rolling method for single-face periodically variable thickness plate strip materials, and belongs to the technical field of metal rolling. According to the method, double-strip synchronous variable-thickness ply rolling is conducted through two uncoilers and two coilers, that is, the two uncoilers and the two coilers are arranged on two sides of a rolling mill correspondingly. The rolling method includes the specific steps that (1) feeding is carried out, specifically, upper-layer raw plate strip materials and lower-layer raw plate strip materials are installed on the corresponding uncoilers; (2) strip penetrating is conducted, specifically, the upper-layer raw plate strip materials and the lower-layer raw plate strip materials are welded to guide strips of the corresponding coilers separately through guide strip movement and welding, so that strip penetrating is completed; (3) variable-thickness rolling is conducted, specifically, setting of rolling parameters and control over alignment, speed, thickness, tension and the like in the rolling process are included; and (4) the single-face periodically variable thickness plate strip materials are obtained and moved out. By the adoption of the method, rolling of the single-face periodically variable thickness plate strip materials and double-face periodically variable thickness plate strip materials can be realized, different production requirements are met, the rolling efficiency is greatly improved, and the production cost is lowered.

Owner:NORTHEASTERN UNIV

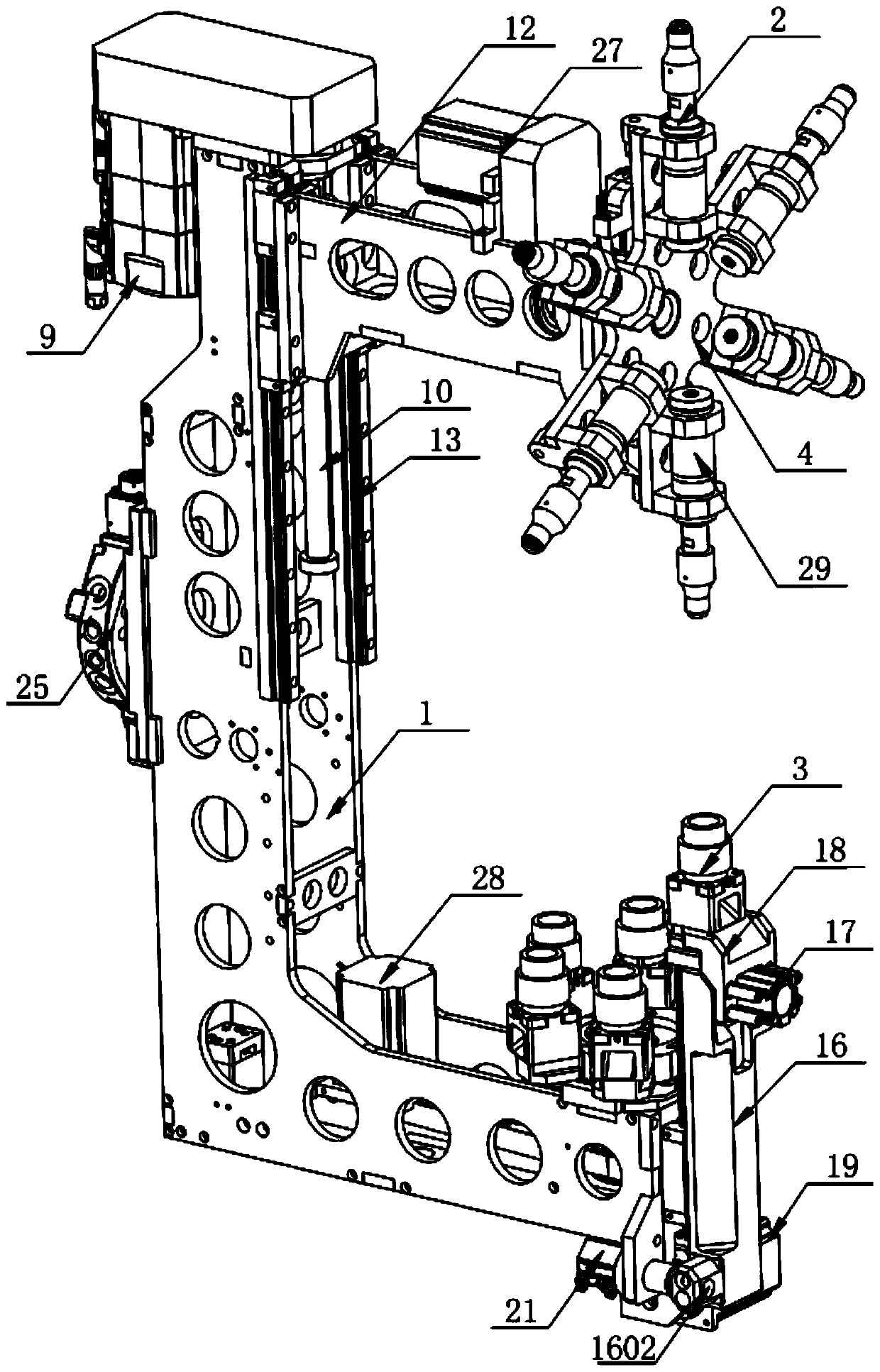

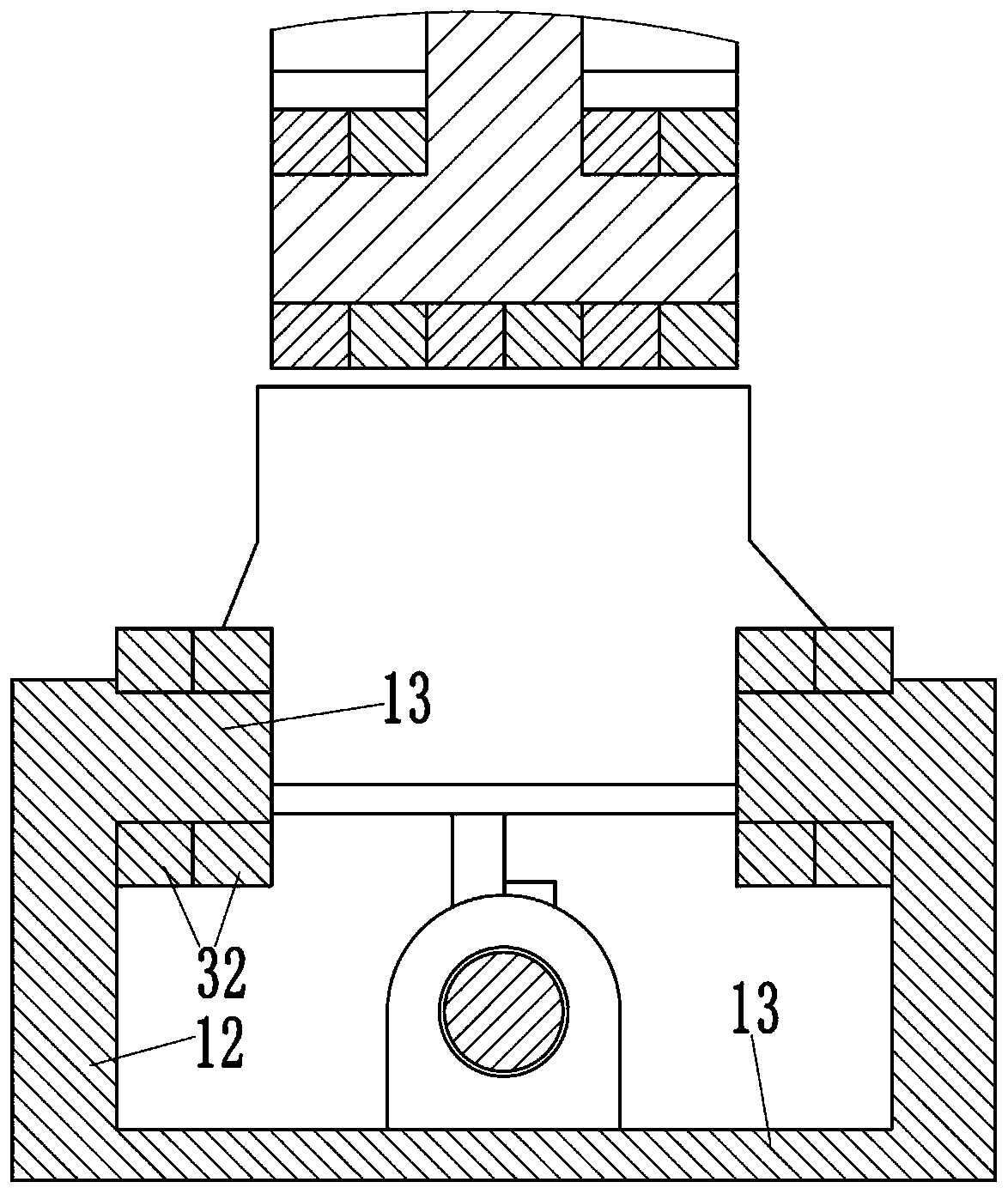

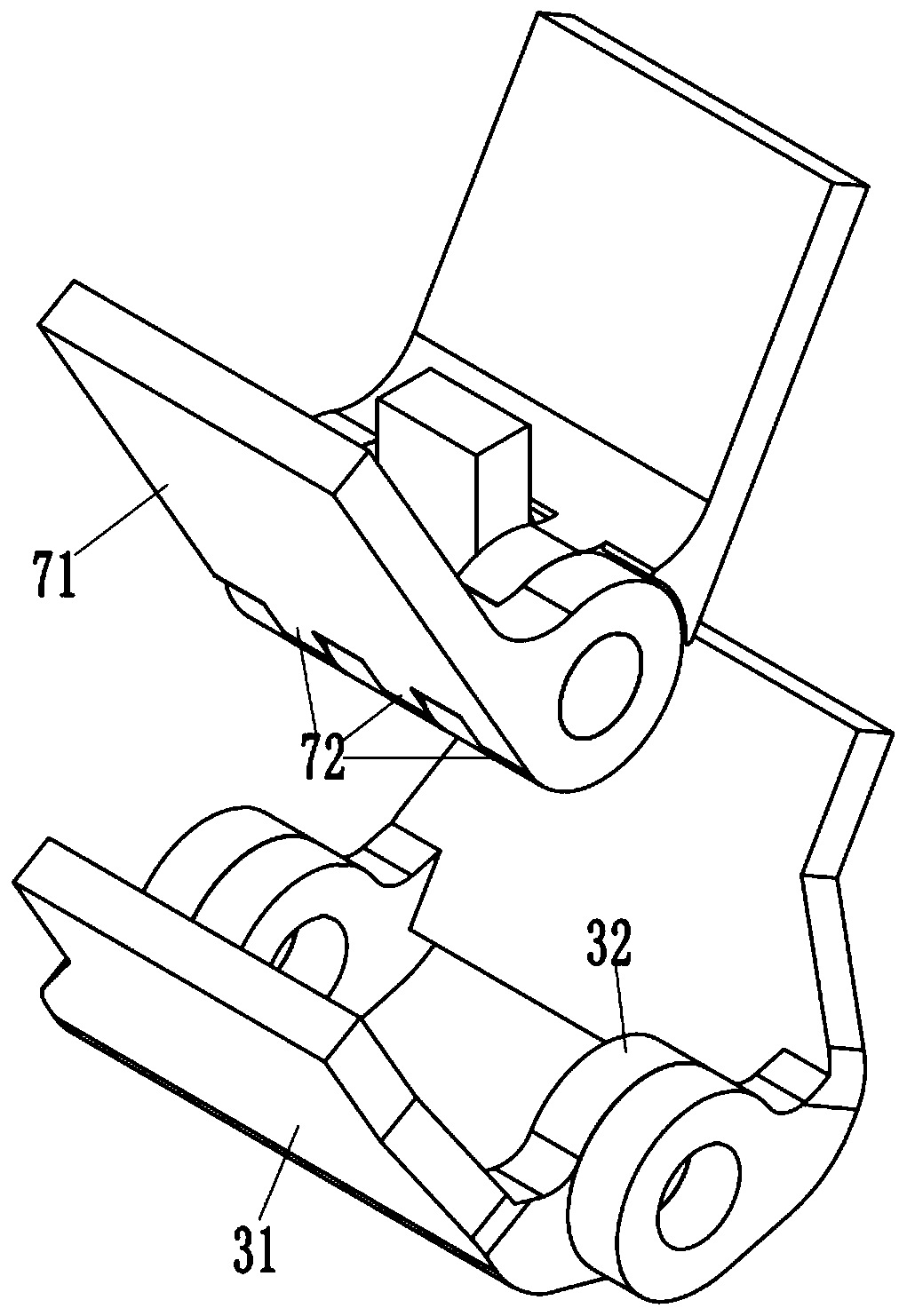

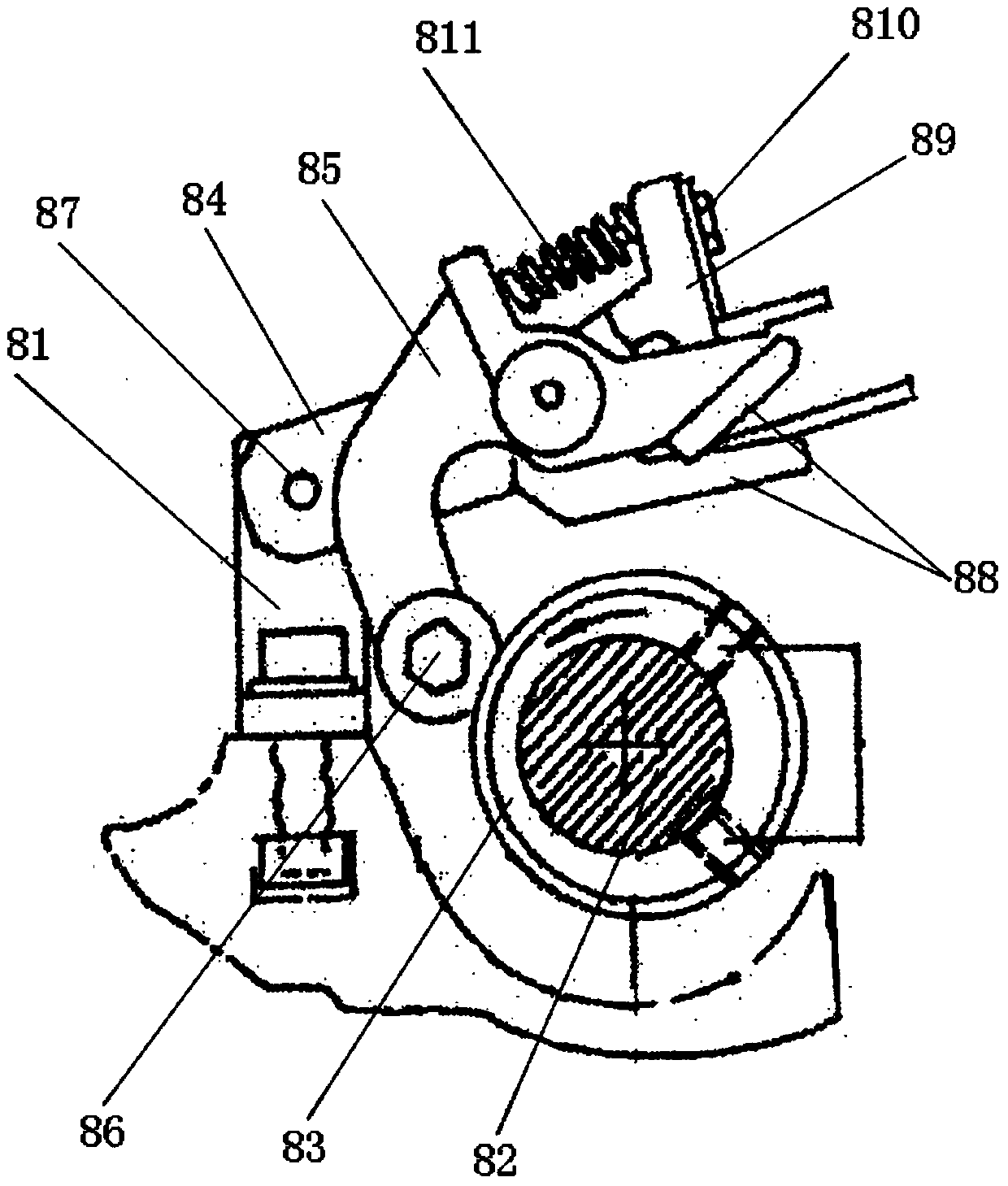

Six-head automatic switching punching module

ActiveCN110918762AMovement is stable and fastReduces problems with docking replacementsPerforating toolsVehicle componentsPunchingRobot hand

The invention provides a six-head automatic switching punching module. The punching module comprises a support body, an upper punching cutter mechanism and a lower punching cutter mechanism, wherein alifting driving mechanism is arranged on the upper part of the support body, the upper punching cutter mechanism is slidably arranged on the lifting driving mechanism, and the lower punching cutter mechanism is arranged on the lower part of the support body and opposite to the upper punching cutter mechanism in position; and during working, the lifting driving mechanism drives the upper punchingcutter mechanism to move downwards, and upper punching cutters on the upper punching cutter mechanism are matched with lower punching cutters on the lower punching cutter mechanism for punching. According to the six-head automatic switching punching module, the upper punching cutter mechanism and the lower punching cutter mechanism are arranged, and six cutters which correspond to one another andare matched and used are arranged on each of the upper punching cutter mechanism and the lower punching cutter mechanism so that cutters can be switched under the motion state of a manipulator, the problem of butt joint replacement of a robot in the production process is reduced, high-precision punching is achieved, and punching efficiency is improved.

Owner:余姚泰速自动化科技有限公司

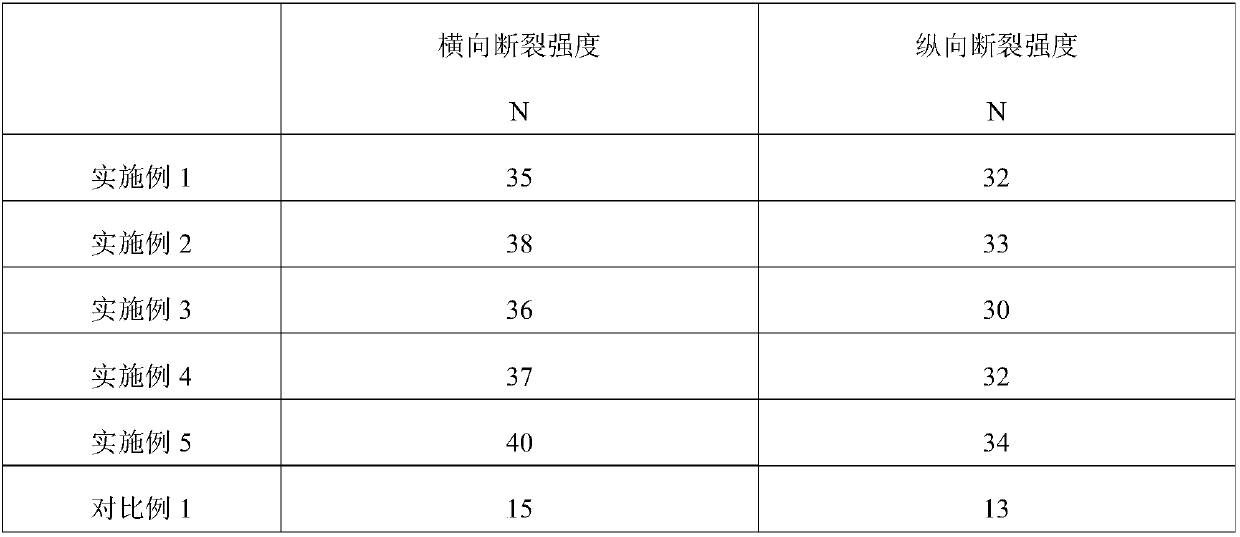

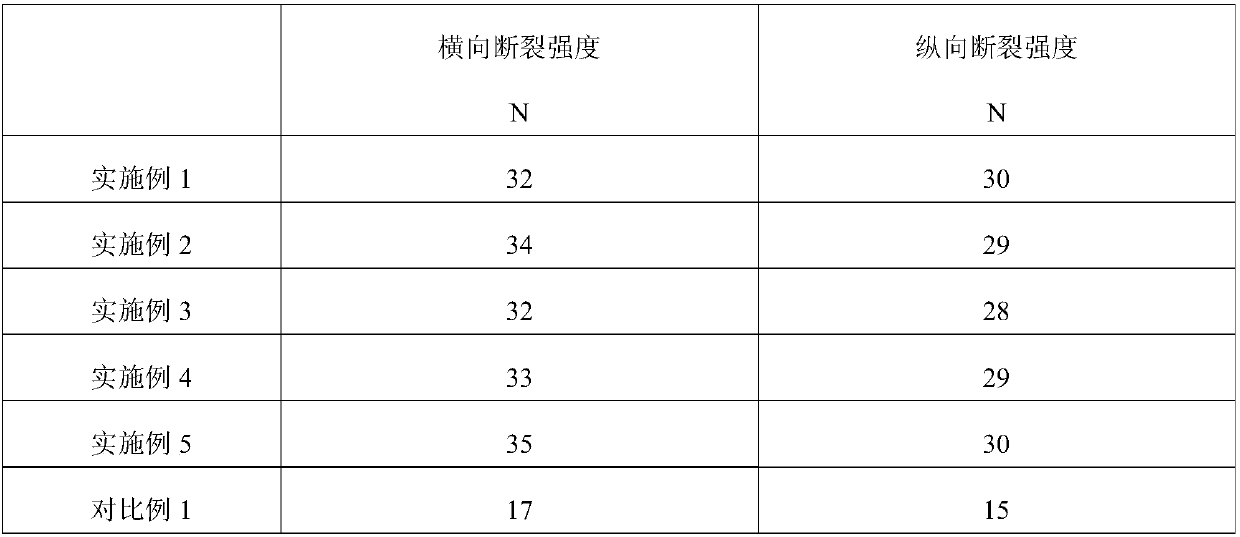

Mulching film prepared by utilizing rice straw and preparation method thereof

InactiveCN107915868AImprove mechanical propertiesIncreased Nitrogen and PotassiumCultivating equipmentsPaper material treatmentRice strawCorn starch

The invention provides a mulching film prepared by utilizing rice straw and a preparation method thereof and relates to the field of crop straw utilization. The mulching film comprises, by weight, 60-80% of rice straw fiber, 10-30% of waste silk fiber, 1-3% of biological organic fertilizer, 3-10% of polyvinyl alcohol, 1-5% of corn starch, 1-3% of glycerin, 1-3% of sorbitol fatty acid ester and 0.1-0.5% of mineral. The preparation method includes following steps: preparing the rice straw fiber; treating the waste silk fiber; performing nonwoven networking; bonding and curing. The mulching filmhas high strength and air permeability and is degradable, a lot of cellulose after degradation can play a role in improving soil, and utilization value is increased.

Owner:柳州市柳科科技有限公司

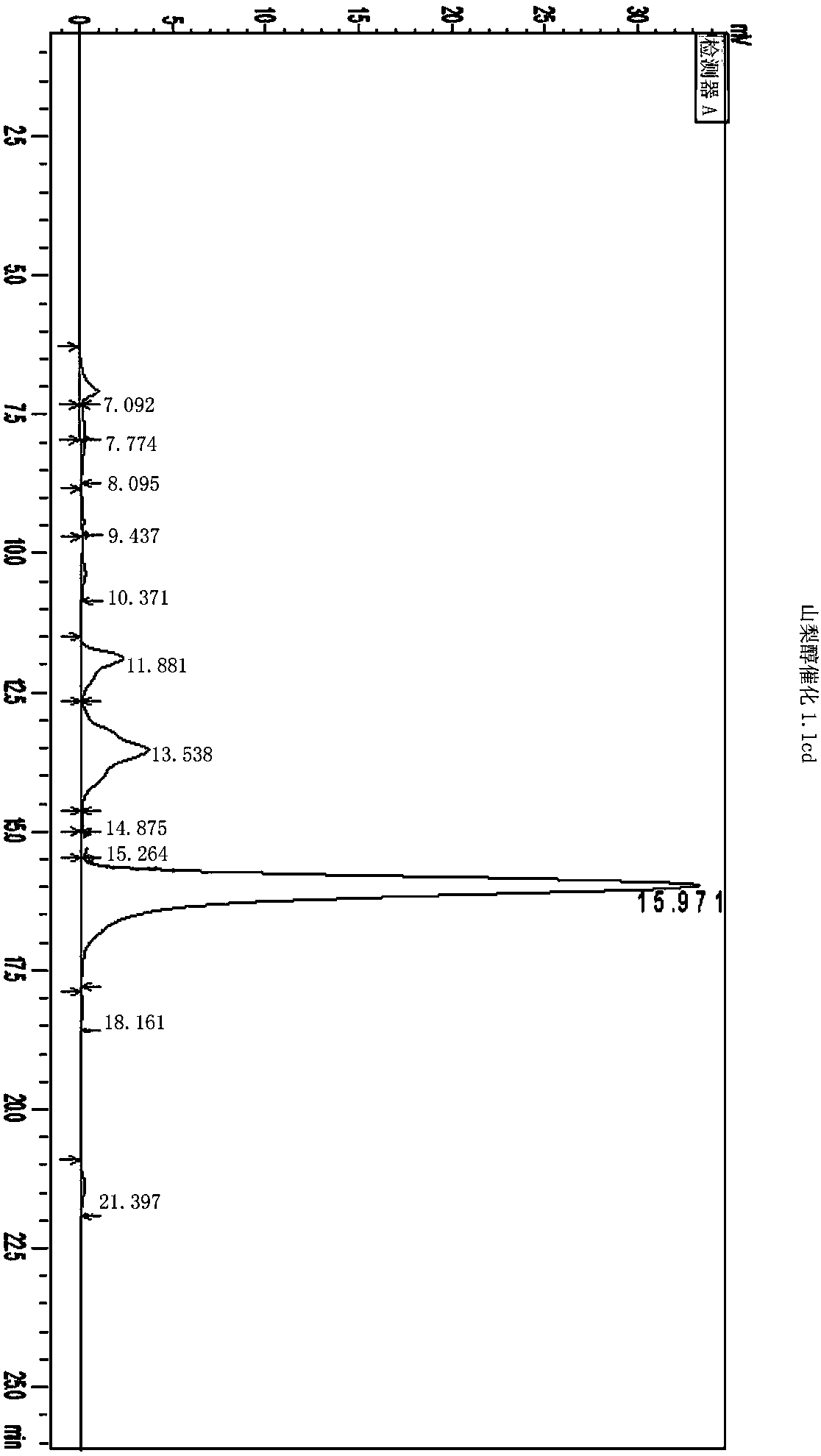

Isosorbide preparation method

ActiveCN108117560AStable transformationLower conditionsOrganic chemistryMolecular sievePhysical chemistry

The invention discloses an isosorbide preparation method. The method comprises the following steps: 1) adding a phosphorus modified HZSM-5 molecular sieve into a sorbitol solution, and carrying out adehydration reaction to obtain a solid-liquid mixture; 2) filtering the solid-liquid mixture so as to obtain the filtrate; 3) performing actived carbon decoloration on the filtrate, and filtering again so as to obtain the filtrate; 4) performing ion exchange on the filtrate by virtue of D301 anion resins, 001*7 cation resins and D301 anion resins respectively so as to obtain ion exchange liquid; 5) concentrating the ion exchange liquid into Brix being 75-90%, and performing primary cooling crystallization; and centrifuging to obtain a crude isosorbide crystal; and 6) adding water into the crude isosorbide crystal, heating and dissolving to enable the Brix to be 70-85%, performing secondary cooling crystallization, centrifuging and drying, thereby obtaining the product isosorbide crystal. Compared with the prior art, the method disclosed by the invention has the advantages that the isosorbide produced by the method is high in yield, the number of by-products is few and the stability ishigh, so that the isosorbide preparation process is simplified, and the cost is reduced.

Owner:FUTASTE PHARM CO LTD

Toughened alumina ceramic mobile phone backboard and preparation method thereof

The invention relates to a toughened alumina ceramic mobile phone backboard and a preparation method thereof. The toughened alumina ceramic mobile phone backboard is prepared from the following components: doped toughening component, doped color changing component, graphene and high purity Al2O3; wherein each component accounting for the total mass percentage of materials is as follow: 12 to 25% of doped toughening component, 0.25 to 1% of graphene, 1.25 to 4.25% of doped color changing component, and the balance of high purity Al2O3; wherein, the doped toughening component is ZrO2; the dopedcolor changing component is one, two or three of high purity Fe2O3, high purity CoO , high purity MnO2, high purity NiO. The fracture toughness of the alumina ceramic material can reach 4.75 MPam <1 / 2>, and is 35% higher than that of a conventional Al 2 O 3 based ceramic, and the wave permeability is 80 to 87%.

Owner:HEBEI UNIV OF TECH

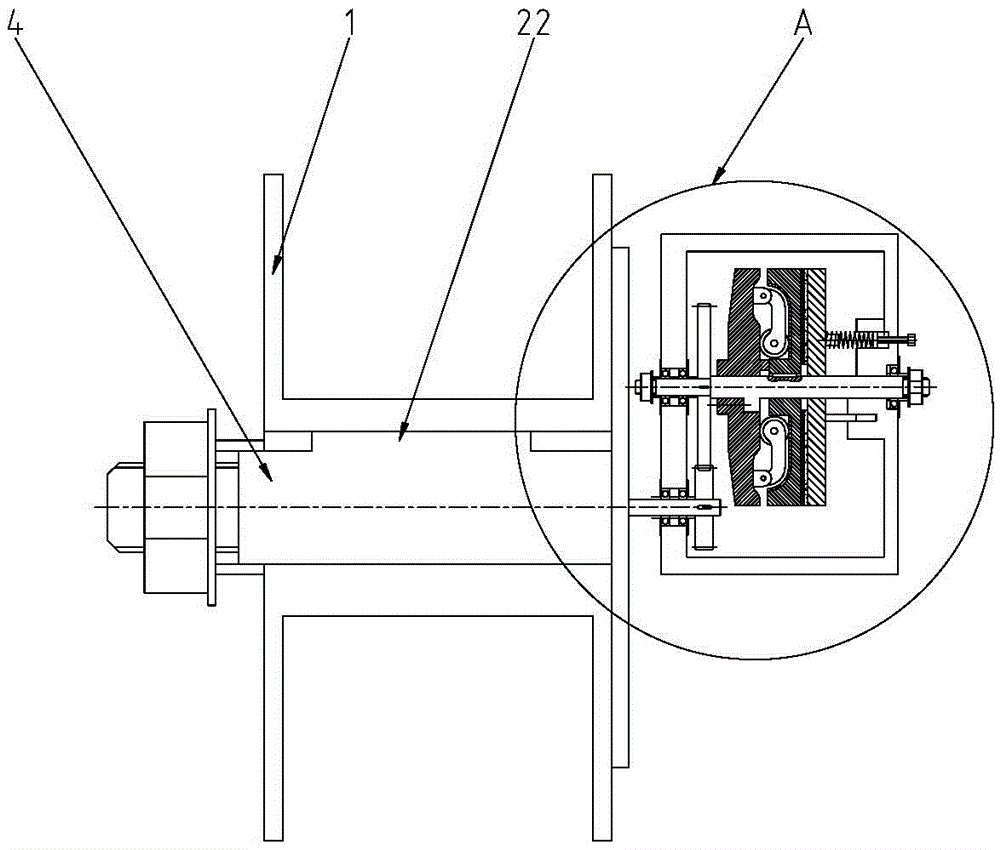

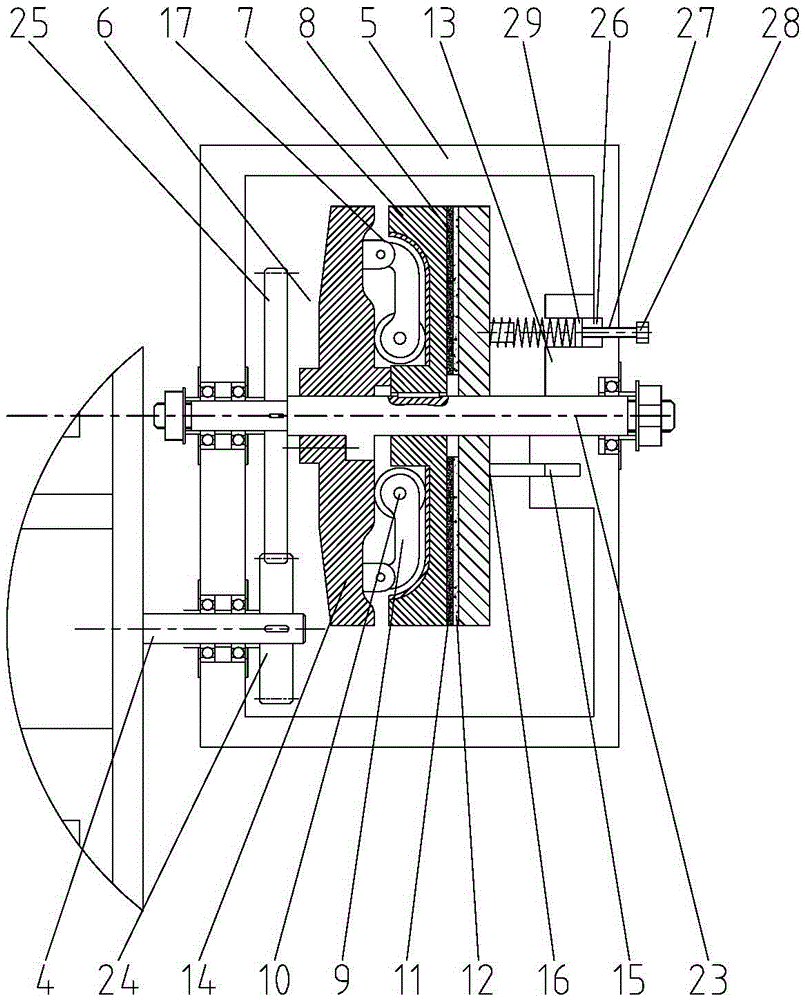

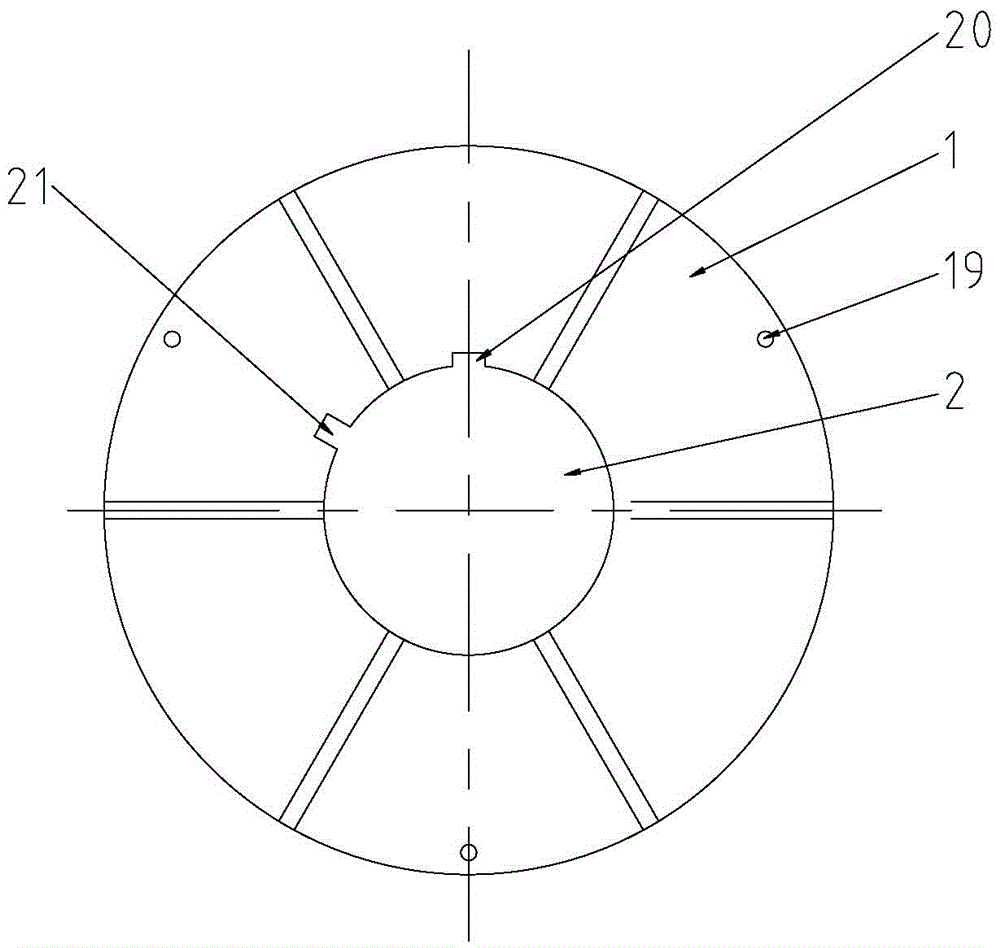

Adjustable self-adaptive wire spool system

InactiveCN105819271AIncrease frictionOvercome external forcesFilament handlingGear transmissionSelf adaptive

An adjustable self-adaptive wire spool system comprises a wire spool body. The wire spool body is provided with a center through hole. The peripheral wall of the wire spool body is provided with a wire winding groove. A winding shaft is arranged in the center through hole in a sleeved mode. A self-adaptive friction mechanism is mounted on the winding shaft and comprises a shell. A rotary shaft is arranged in the shell. A gear transmission mechanism is arranged between the rotary shaft and the winding shaft. The shell is further internally provided with a rotary arm disk, a friction disk I and a friction disk II. Rotary arm mechanisms are annularly and evenly distributed on the side face of the side, facing the friction disk I, of the rotary arm disk. Each rotary arm mechanism comprises a rotary arm located in the radial direction of the rotary arm disk, and one end of each rotary arm is in hinged connection with the rotary arm disk. Friction surfaces matched with each other are arranged between the friction disk I and the friction disk II. A spring and a sliding guide mechanism are arranged between the friction disk II and the shell. The shell is provided with a groove used for mounting of the spring. The bottom of the groove is provided with an adjusting mechanism used for adjusting pre-pressure exerted on the friction disk II by the spring.

Owner:CHONGQING CITY SOUTH FLAME RETARDANT WIRE & CABLE CO LTD

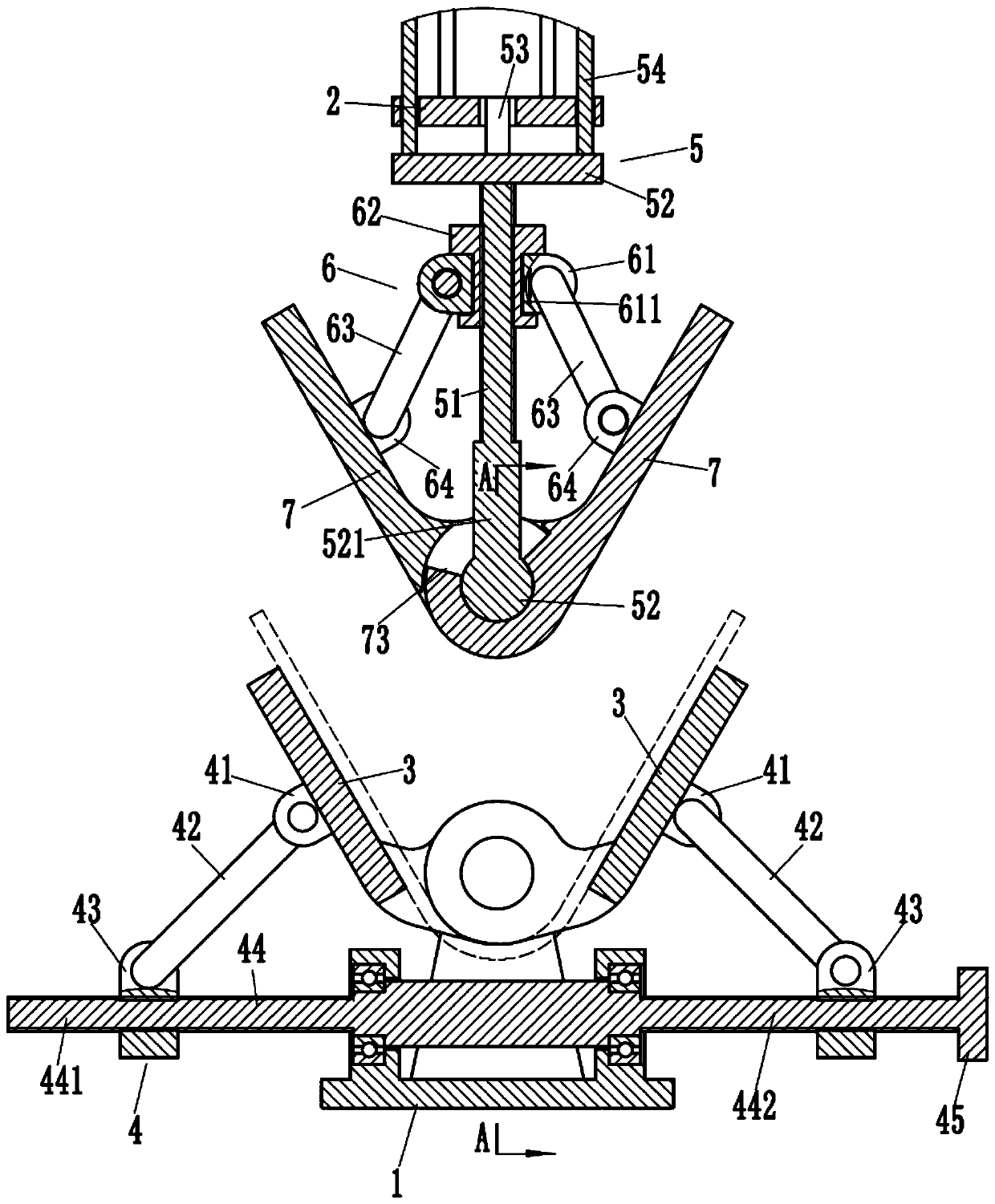

Hardware product angle folding device with adjustable angle folding angle

The invention discloses a hardware product angle folding device with an adjustable angle folding angle. The hardware product angle folding device comprises a base and a fixing plate which are fixed toa rack, wherein two lower die plates which are arranged in a left-right central symmetry manner are hinged to the base; the two lower die plates are arranged in a V shape and are provided with firstangle adjusting devices; the fixing plate is provided with a stamping part; the stamping part comprises a vertically-arranged stamping rod; a hinge shaft arranged in the front-back direction is fixedto the lower end of the stamping rod; two upper die plates which are arranged in a left-right central symmetry manner are hinged to the hinge shaft; and the two upper die plates are arranged in a V shape and are provided with second angle adjusting devices. According to the hardware product angle folding device, by adjusting the angle between the two upper die plates and the angle between the twolower die plates, a hardware product can be folded into different angles, and different production requirements are met.

Owner:SHENZHEN SENSELEADER TECH DEV CO LTD

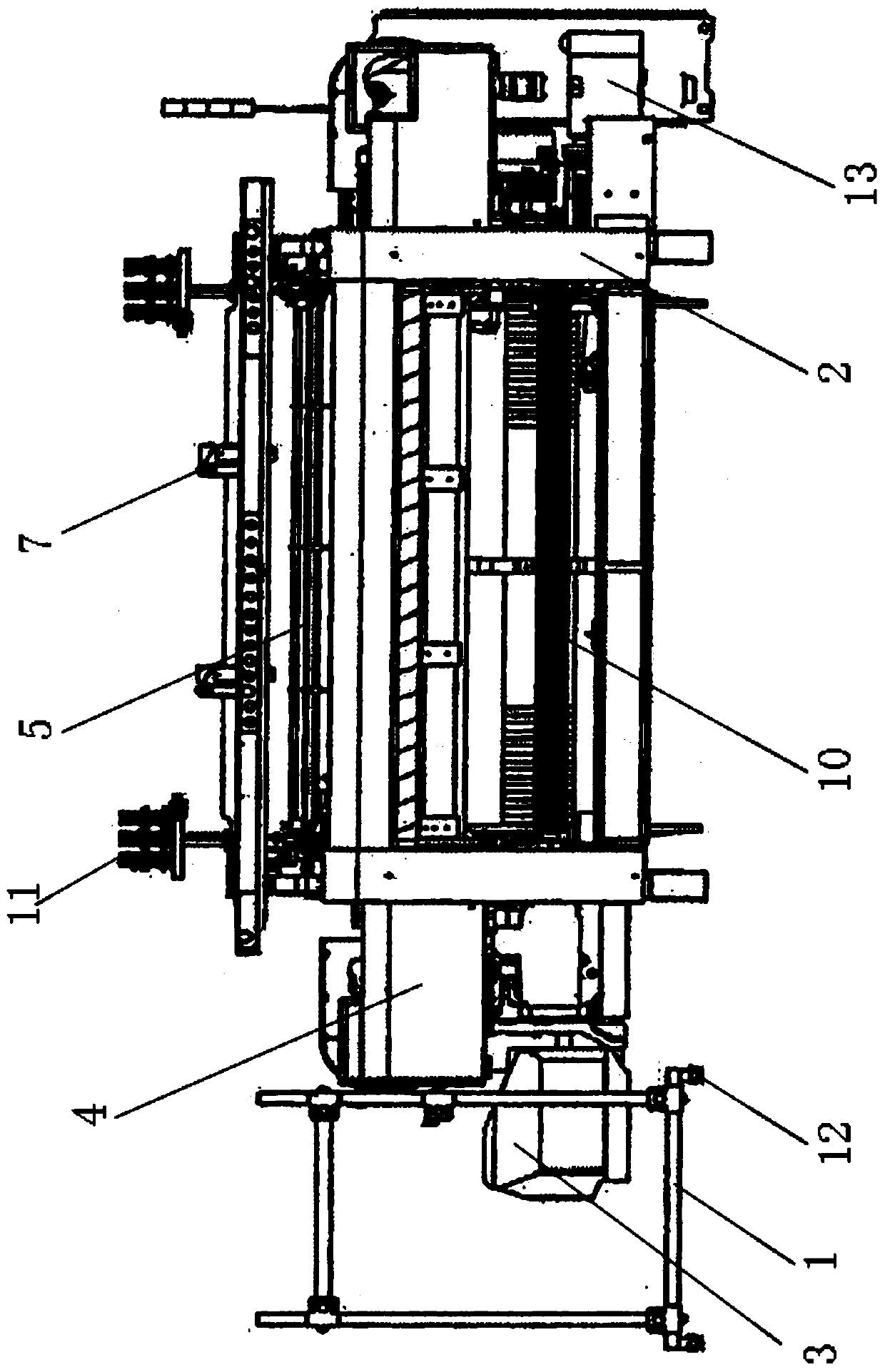

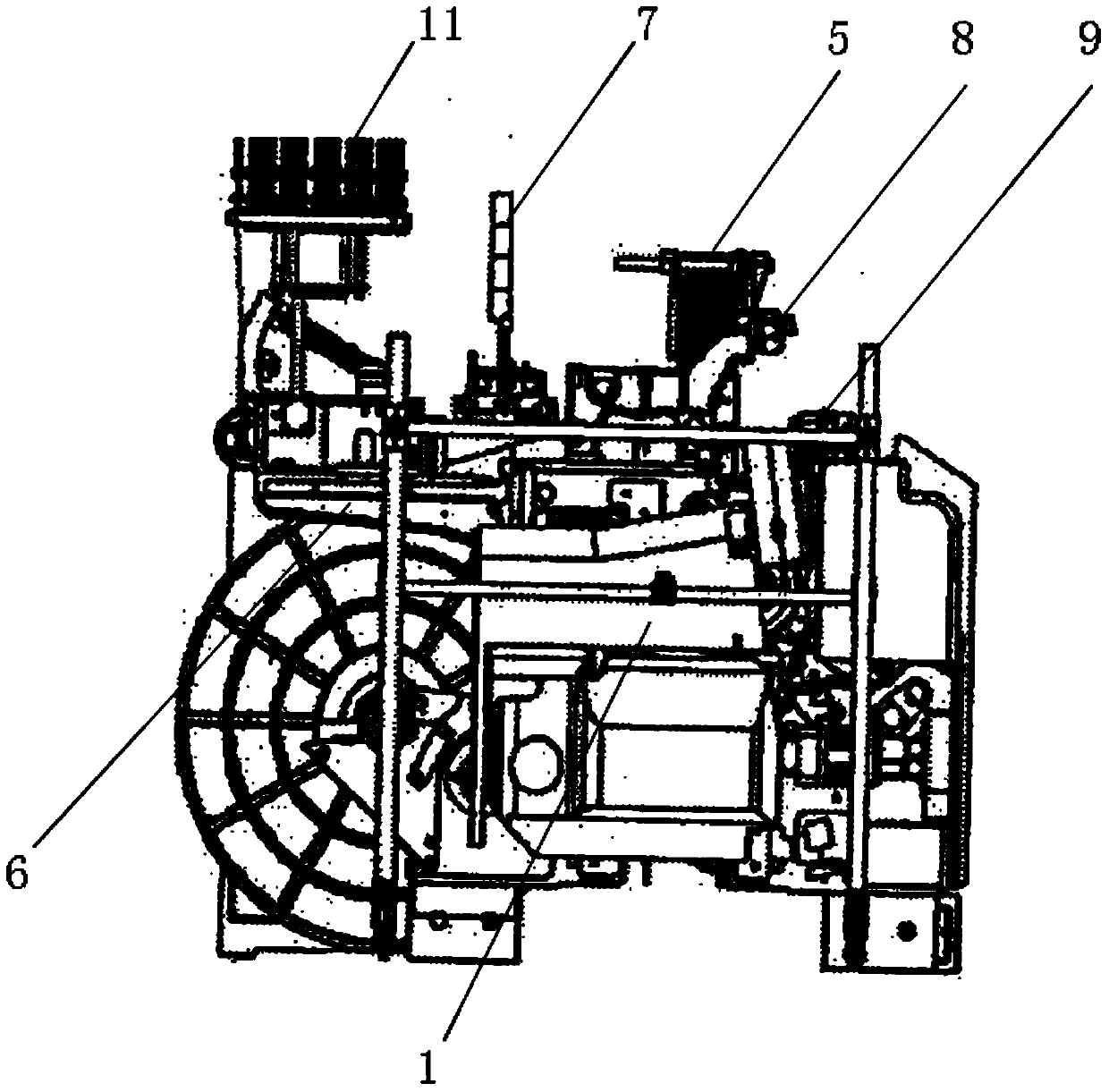

High-speed rapier loom

ActiveCN103993409AMeet different production needsQuality improvementLoomsAuxillary apparatusStructural engineeringMechanical engineering

The invention relates to a high-speed rapier loom. The high-speed rapier loom comprises a weft frame, a rack, an opening mechanism, a weft insertion box, a beating-up mechanism, a warp frame, a heald frame, a selvedge scissor mechanism, a temple structure, a take-up mechanism and selvedge creels, wherein the weft frame is arranged on one side of the rack; the opening mechanism and the weft insertion box are installed on one side of the rack; the beating-up mechanism, the heald frame, the selvedge scissor mechanism and the temple structure are respectively installed above the rack, and the temple structure, the selvedge scissor mechanism, the beating-up mechanism and the heald frame are sequentially arranged from front to back; the warp frame is connected to the rear portion of the rack; the take-up mechanism is installed underneath the rack; the selvedge creels are installed on the two sides of the warp frame. The high-speed rapier loom has the advantages that operation is convenient, warp tension is convenient to adjust, and the high-speed rapier loom can ascend and descend in the vertical direction and guide slitter edges.

Owner:SHAOXING TEXTILE MACHINERY GRP

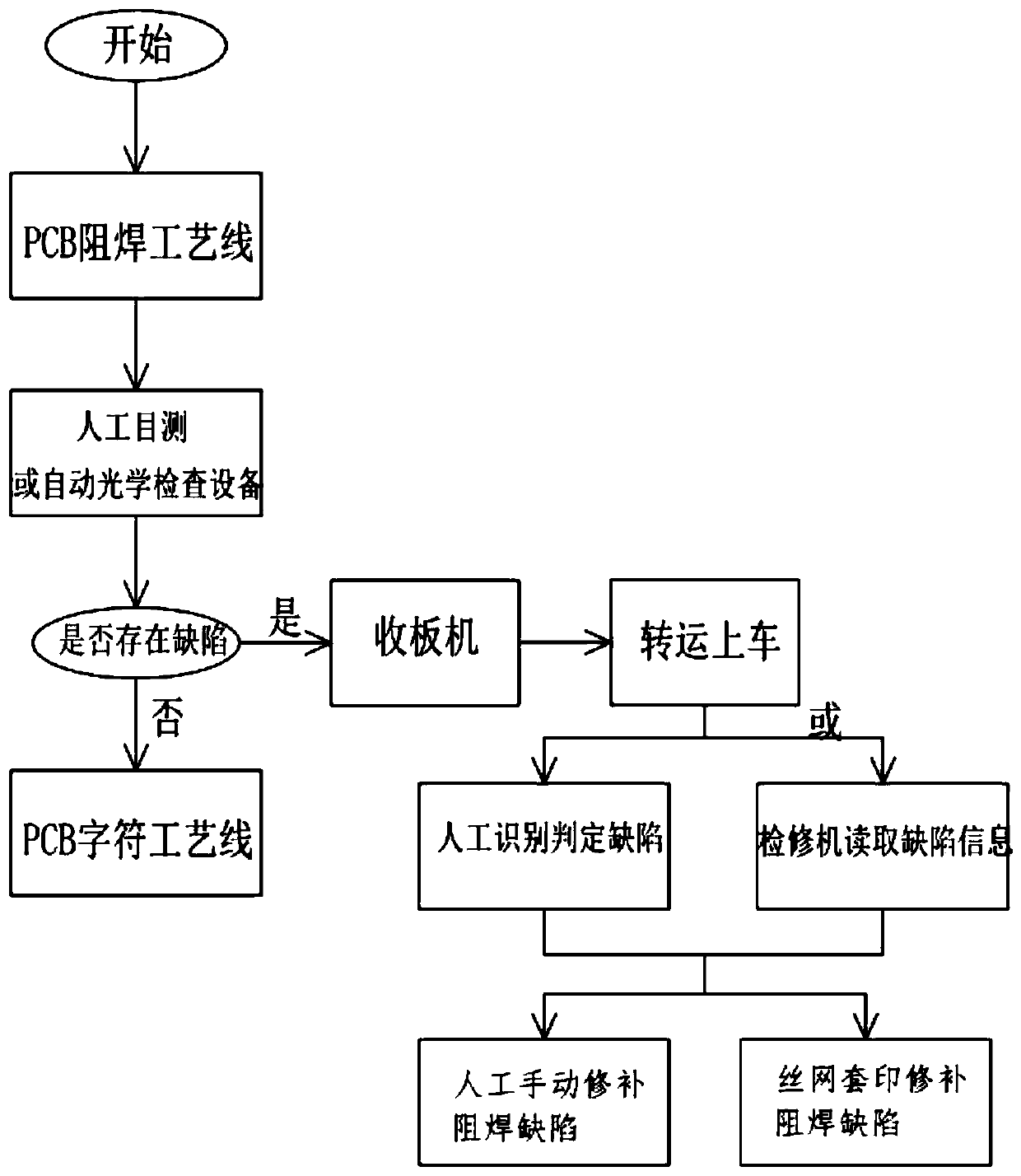

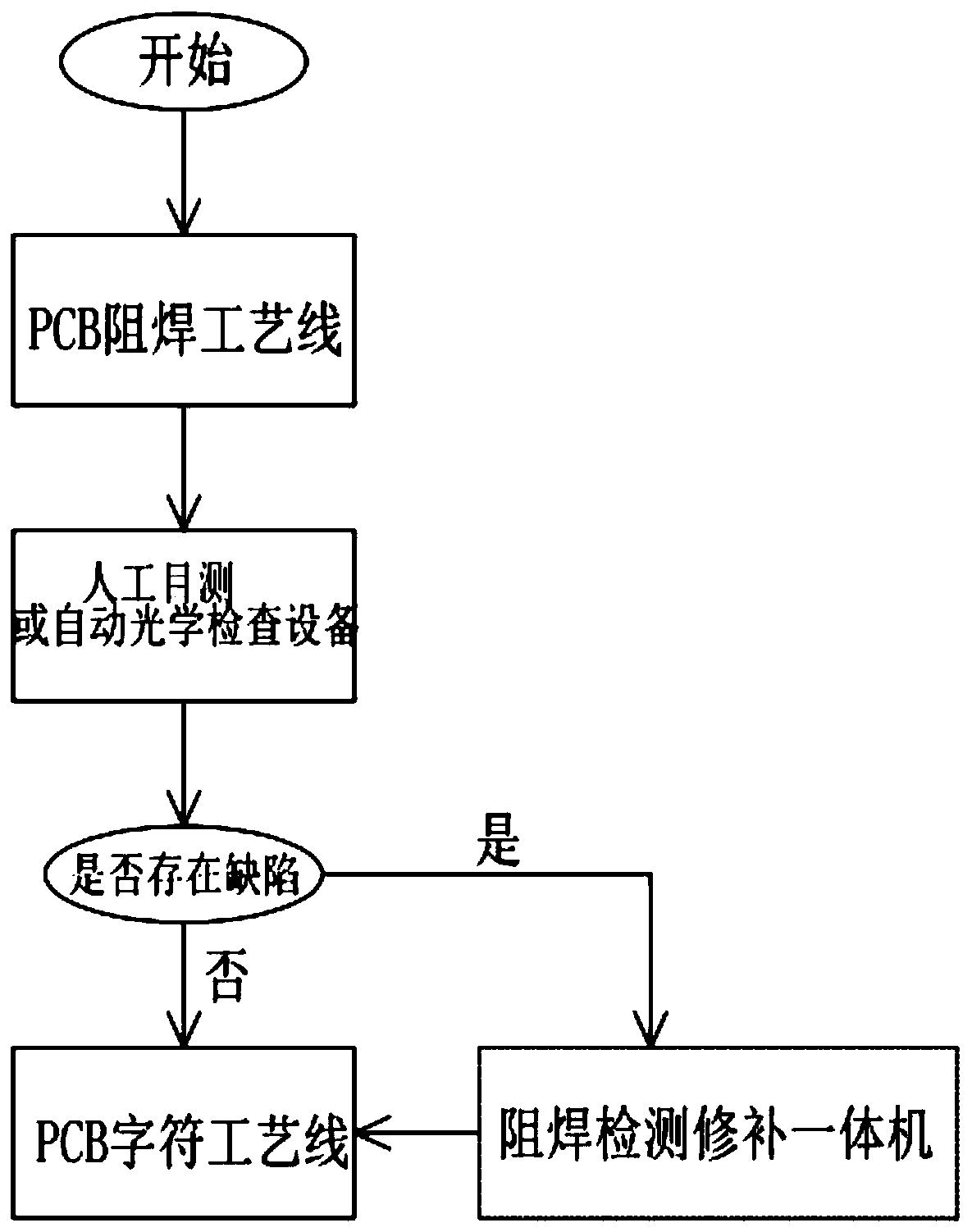

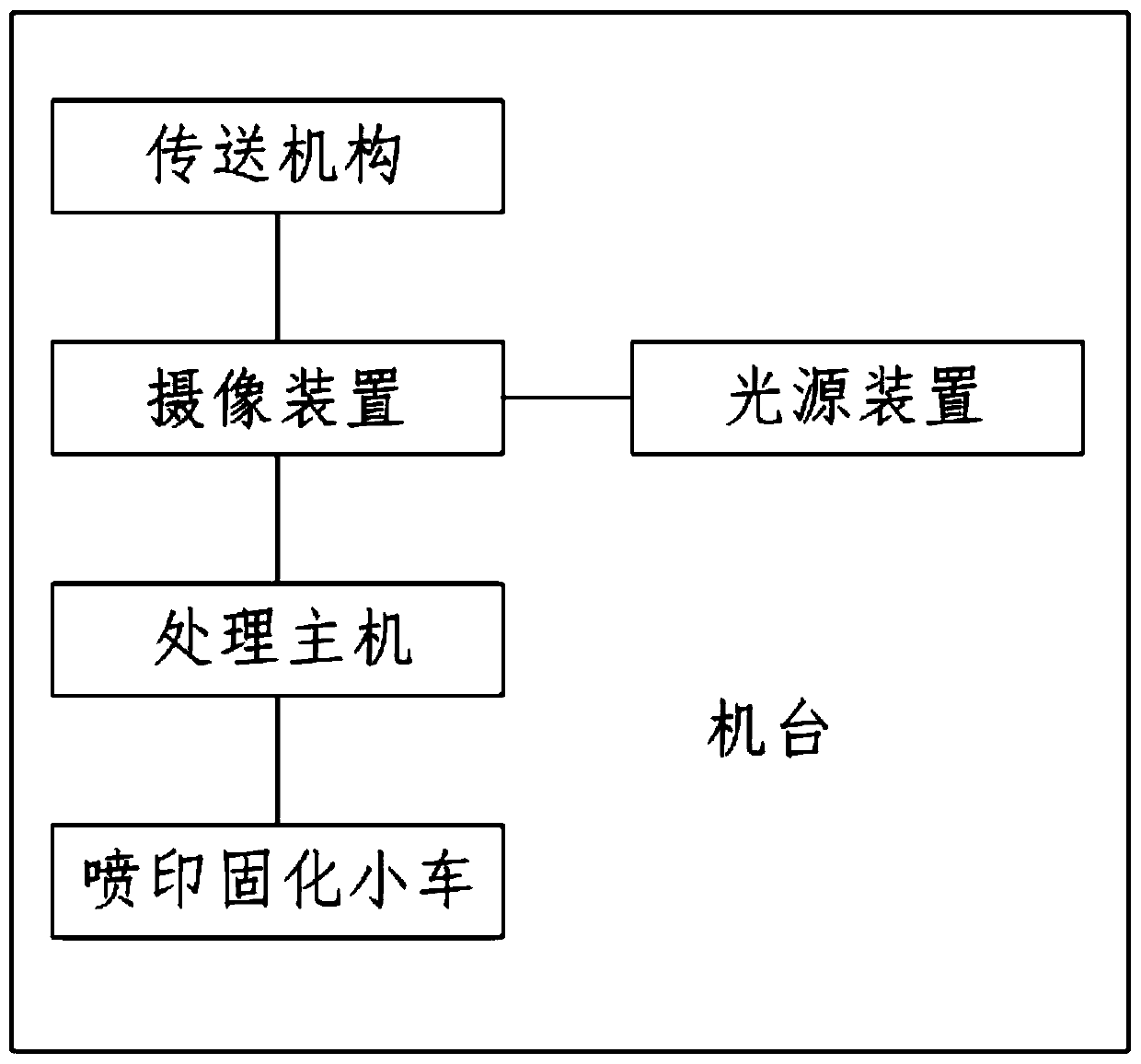

PCB solder resist detection and repair all-in-one machine and technology method

ActiveCN110678003AImprove work efficiencyImprove accuracyMaterial analysis by optical meansPrinted circuits repair/correctingManufacturing technologyPrinted circuit board

The invention relates to the printed circuit board manufacturing technology field and especially relates to a PCB solder resist detection and repair all-in-one machine and a technology method. A camera device is used for scanning and photographing a surface of a PCB to obtain an identifiable pattern. An automatic optical detection device is used for automatically identifying and judging defects ofthe PCB, determining defect positions and outputting solder resist defect patterns corresponding to the defect positions. And specific defect area identification, extraction and integration can be performed in time according to the solder resist defect patterns, a corresponding defect repair pattern of the whole PCB is generated, and a piezoelectric ceramic jet printing and curing device adopts apiezoelectric ceramic jet printing technology to repair a solder resist defect. Compared with the prior art, by using the PCB solder resist detection and repair all-in-one machine and the technologymethod of the invention, uncertainty caused by manual operation is overcome, working accuracy is effectively improved, a production process is shortened, manpower and equipment cost are saved, the solder resist defects caused by various reasons can be repaired, and practical and flexible performance is achieved.

Owner:선전진신테크놀로지컴퍼니리미티드

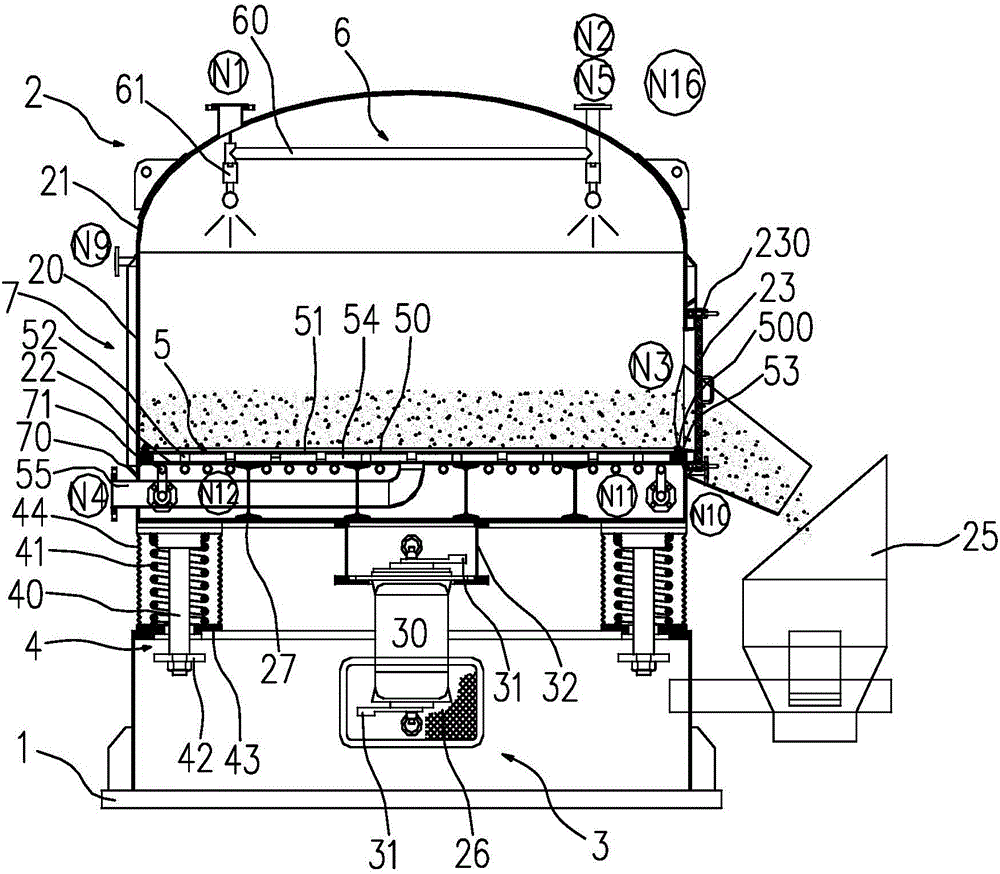

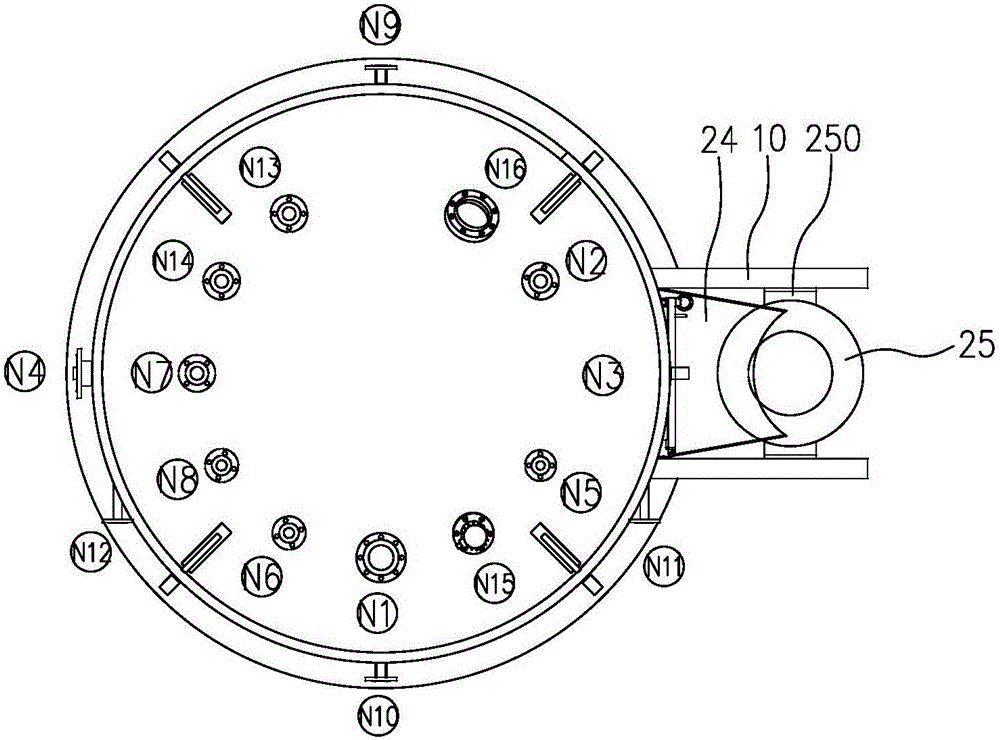

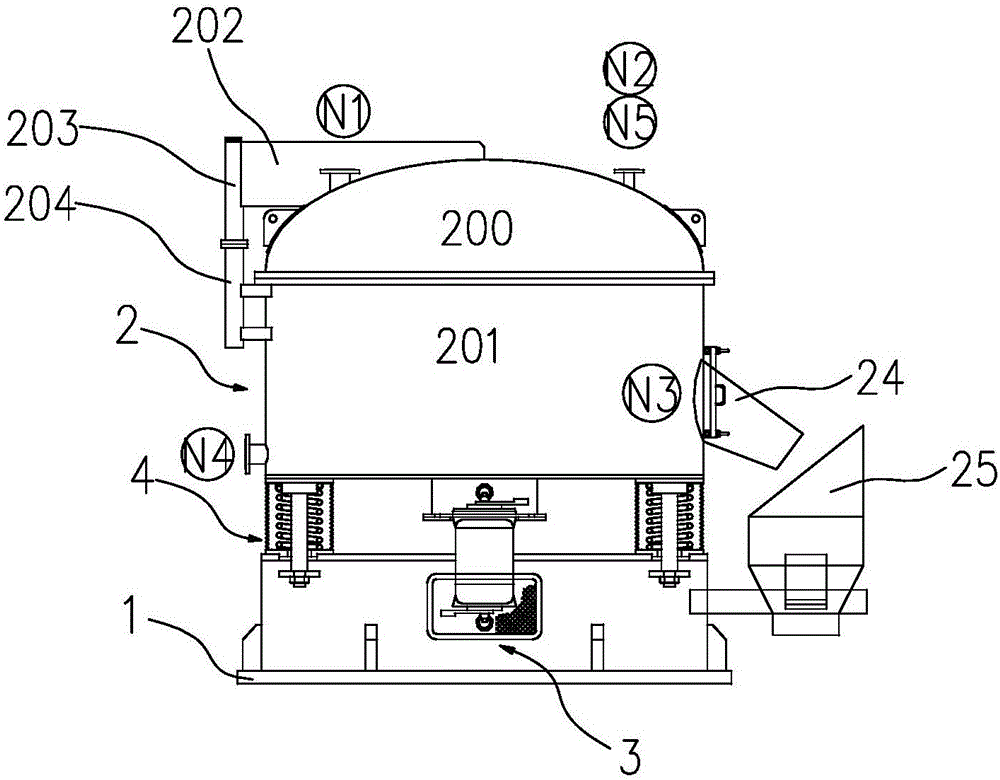

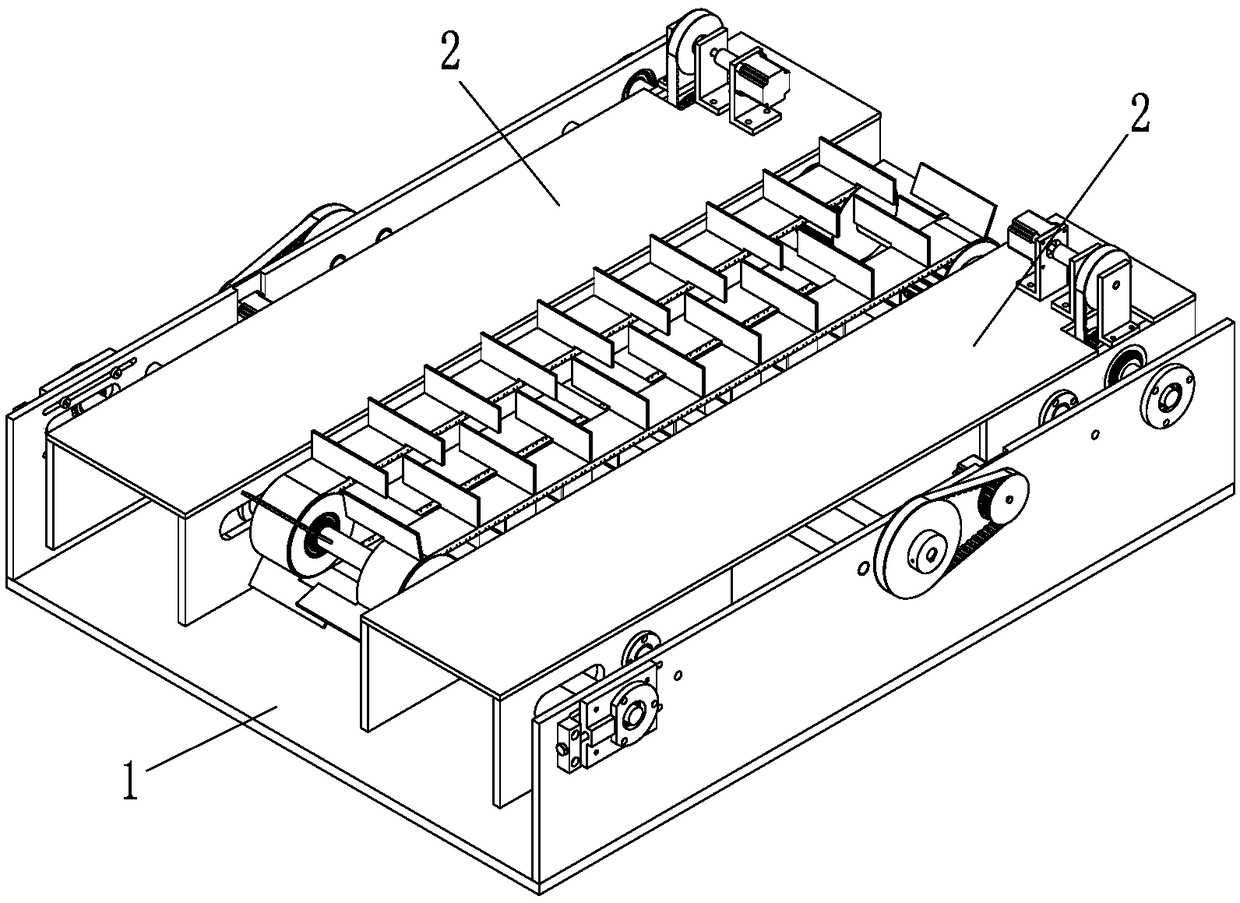

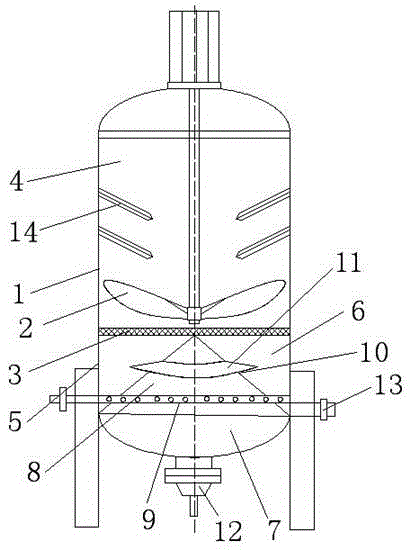

Rotary vibrating type filtering, washing and drying machine

InactiveCN104998452AMeet processing needsStructural integrity maintainedStationary filtering element filtersElastomerEngineering

The invention discloses a rotary vibrating type filtering, washing and drying machine. The machine comprises a barrel which forms a closed cavity except an inlet and an outlet, the lower side of the closed barrel is provided with a base, and a machine body further comprises a rotary vibrating device arranged at the bottom of the closed barrel. The rotary vibrating device comprises a vibrating motor and eccentric flail blocks which are installed at the upper end and the lower end of the vibrating motor, and the eccentric flail blocks convert the rotation motion of the vibrating motor into the horizontal, vertical and oblique three-dimensional motion; the bottom of the closed barrel is evenly provided with a series of elastomers in the circumferential direction, and the closed barrel and the base are mutually connected into a whole through the elastomers; the interior of the closed barrel is further provided with a filtering device and a washing device, and the outer surface of the closed barrel is further provided with a drying device in an attached mode.According to the rotary vibrating type filtering, washing and drying machine, operation is stable, the structure is more optimized, the material processing effect is improved, and energy is saved.

Owner:HEFEI GENERAL MACHINERY RES INST

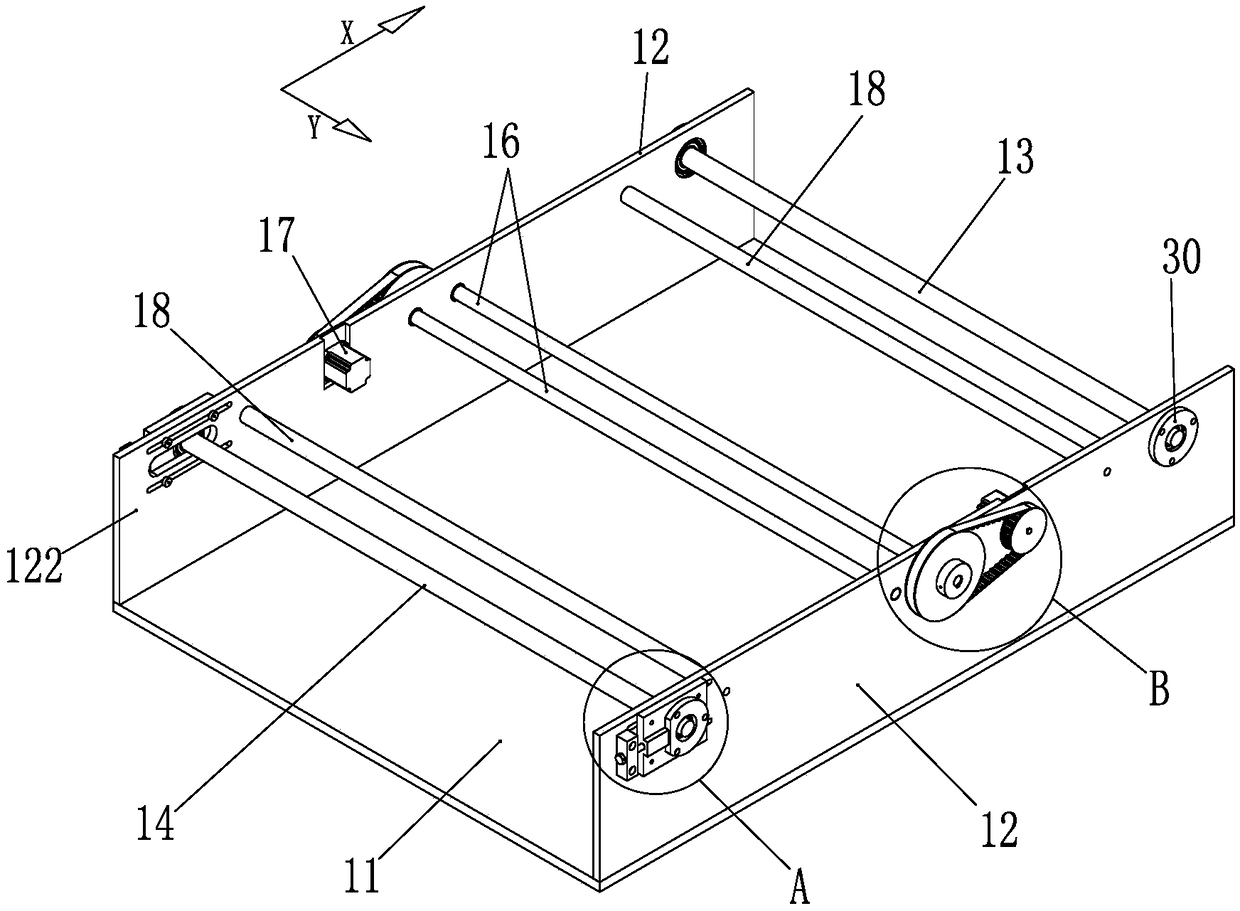

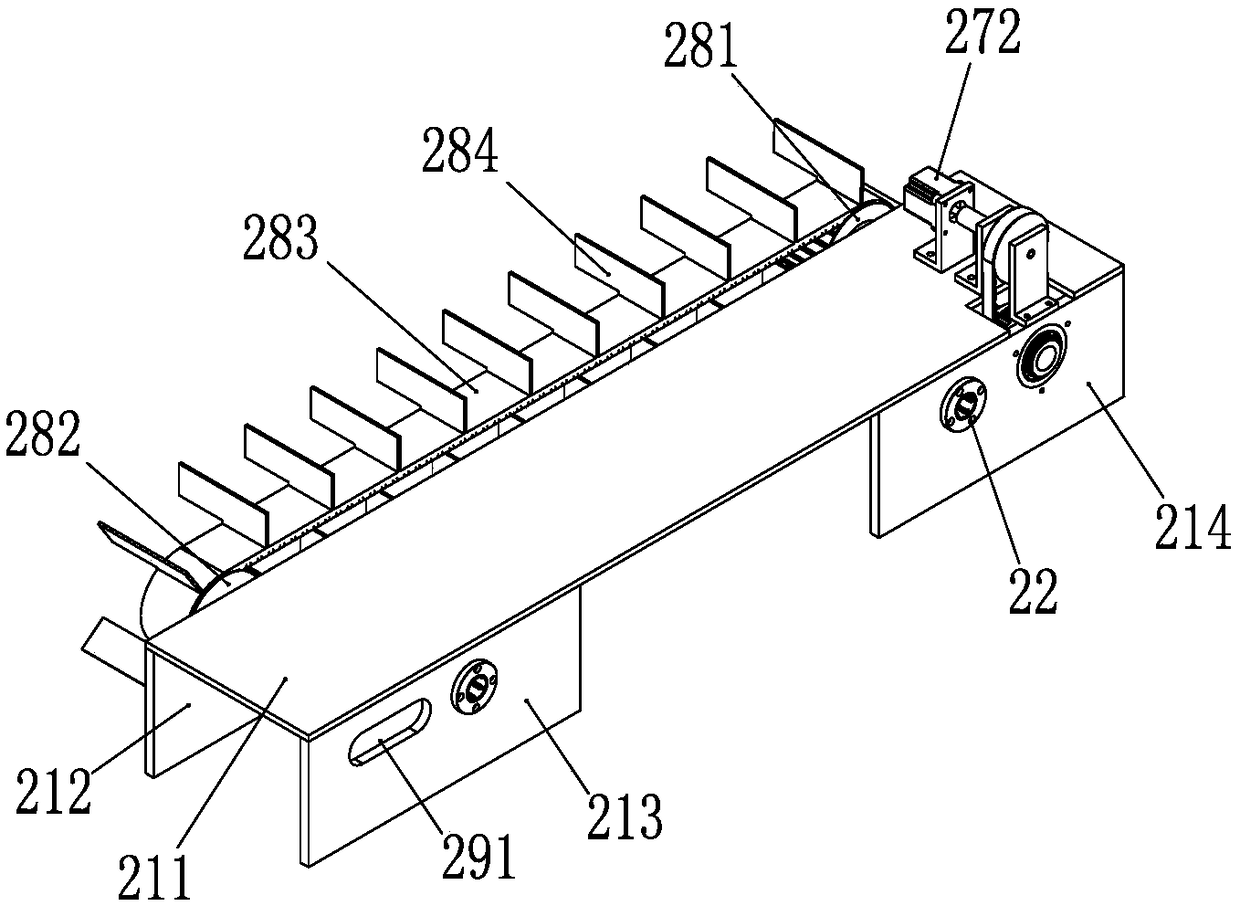

Multi-box-type box packing machine conveying device

ActiveCN109264115AMeet different production needsIncrease productivityConveyorsPackagingDrive wheelEngineering

The invention relates to a box packing machine, and aims to provide a multi-box-type box packing machine conveying device which has the advantages that the device is simple to operate, high in conveying efficiency and applicable to various box types. The multi-box-type box packing machine conveying device is characterized in that the device comprises a working platform, two movable platforms, synchronous belt mechanisms and an adjusting mechanism, the two movable platforms are arranged on the working platform, synchronous belt mechanisms are arranged on the movable platforms, the adjusting mechanism is used for adjusting the distance between the two movable platforms, a driving wheel shaft and a driven wheel shaft are arranged on two sides of the working platform along the length directionof the working platform and parallel to the width direction of the working platform, a plurality of guide rods are parallel to the driving wheel shaft, and the two movable platforms are arranged on two sides of the working platform along the width direction of the working platform.

Owner:ZHEJIANG SCI-TECH UNIV

Automatic tray feeding system and using method

ActiveCN111942841AReliable shippingReduce manual intervention timeConveyorsSemiconductor/solid-state device manufacturingRobot handEngineering

The invention discloses an automatic tray feeding system and a using method, solves the problems of low tray automation degree and more manual intervention in the prior art, has the beneficial effectof liberating manual labor, and adopts the specific scheme that the automatic tray feeding system comprises a tray stacking assembly body, a tray lifting platform, a tray grabbing and releasing platform and a feeding table. The tray stacking assembly body comprises at least one layer of trays, the trays are arranged in a stacked manner, and each tray is provided with a plurality of positioning grooves for limiting the positions of the materials; the tray lifting platform is supported by a rack, the tray lifting platform comprises a tray supporting table, and the tray supporting table is connected with a lifting mechanism; the tray grabbing and releasing platform is supported by the rack, a working area of the tray grabbing and releasing platform covers a tray input module, the tray grabbing and releasing platform comprises a manipulator, the manipulator is connected with a multi-dimensional movement mechanism, and the manipulator can be opened to clamp the trays in the tray stacking assembly body; and the feeding table comprises a tray containing plate, the tray containing plate is provided with grooves used for arrangement of the trays, and the tray containing plate is connected with a linear driving mechanism.

Owner:NINGBO SANHAN ALLOY MATERIAL CO LTD +1

Pellosil activate fluid and applications thereof for extracting nucleic acid

InactiveCN101338312AImprove bindingImprove uniformitySugar derivativesSugar derivatives preparationSilicon membraneActivation technique

The invention belongs to the technical field of nucleic acid extraction, in particular to a silicon membrane activation liquor and an application thereof. The invention aims at providing a method for carrying out processing on the silicon membrane; an activation technique can be adopted to increase the combining force of the silicon membrane and the nucleic acid; besides, the combining force thereof has excellent uniformity and stability. The invention improves the biological utilizing degree of the nucleic acid and better exerts the function for extracting the nucleic acid of the invention; besides, the silicon membrane is coated inside an activator by the method, thus isolating the contact with the outside environment; therefore, the character is more stable and the application range thereof is enlarged so as to meet different production demands.

Owner:TIANGEN BIOTECH BEIJING

Construction reinforcement machining device and application method thereof

The invention provides a construction reinforcement machining device and an application method thereof. The construction reinforcement machining device comprises a first bracket, a straightening machine and a shearing machine; the straightening machine is arranged at one end of the first bracket; the straightening machine comprises a traction wheel, a feed port, a pressing wheel, a second bracket,a hydraulic cylinder, a first motor, a driving chain wheel, a bracket, a chain, a fourth shaft and a driven chain wheel; and the shearing machine is arranged at the middle part of the first bracket.The construction reinforcement machining device adopts integral design of straightening and shearing; after reinforcements are straightened by the straightening machine, the reinforcements enter a receiving frame of the shearing machine through a positioning hole; and the position of a travel switch is set according to a needed length, so that the straightened reinforcements are shorn off according to the needed length, the repeated carrying operation in reinforcement machining is reduced, the production time and the labor amount are saved, the production efficiency is improved, and the production cost is reduced.

Owner:浙江聚光交通设施有限公司

Mulching film prepared from corn straws and preparation method thereof

InactiveCN107936304AImprove mechanical propertiesSimple structurePaper material treatmentPlant protective coveringsFiberCellulose

The invention provides a mulching film prepared from corn straws and a preparation method thereof and relates to the field of utilization of crop straws. The mulching film provided by the invention isprepared from the following components in percentage by weight: 60 to 80 percent of corn straw fibers, 10 to 30 percent of waste cotton fibers, 1 to 3 percent of biological organic fertilizer, 3 to 10 percent of polyvinyl alcohol, 1 to 5 percent of corn starch, 1 to 3 percent of glycerol, 1 to 3 percent of sorbitol fatty acid ester and 0.05 to 0.5 percent of a crosslinking agent. The preparationmethod comprises the following steps: preparing the corn straw fibers, treating the waste cotton fibers, carrying out non-woven net formation, and bonding and curing. The mulching film provided by theinvention has relatively good strength and air permeability and can be degraded; after the mulching film is degraded, a lot of cellulose can have the effect of improving soil and the utilization value is improved.

Owner:柳州市柳科科技有限公司

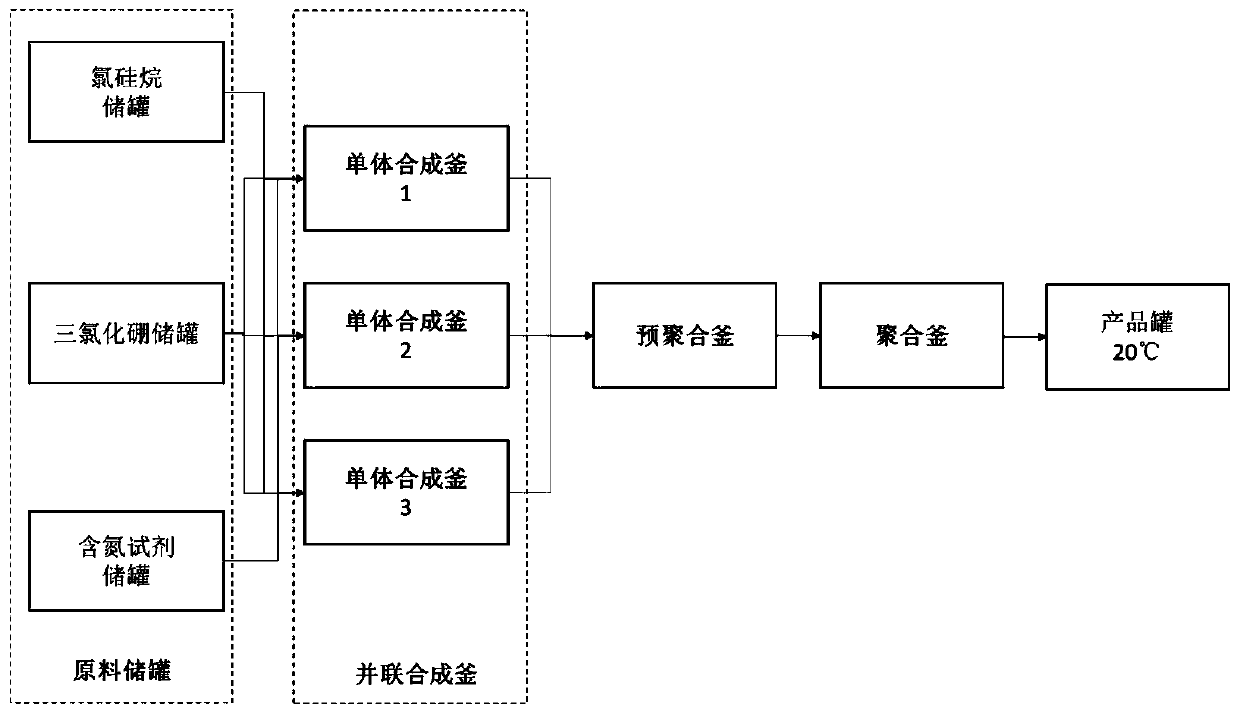

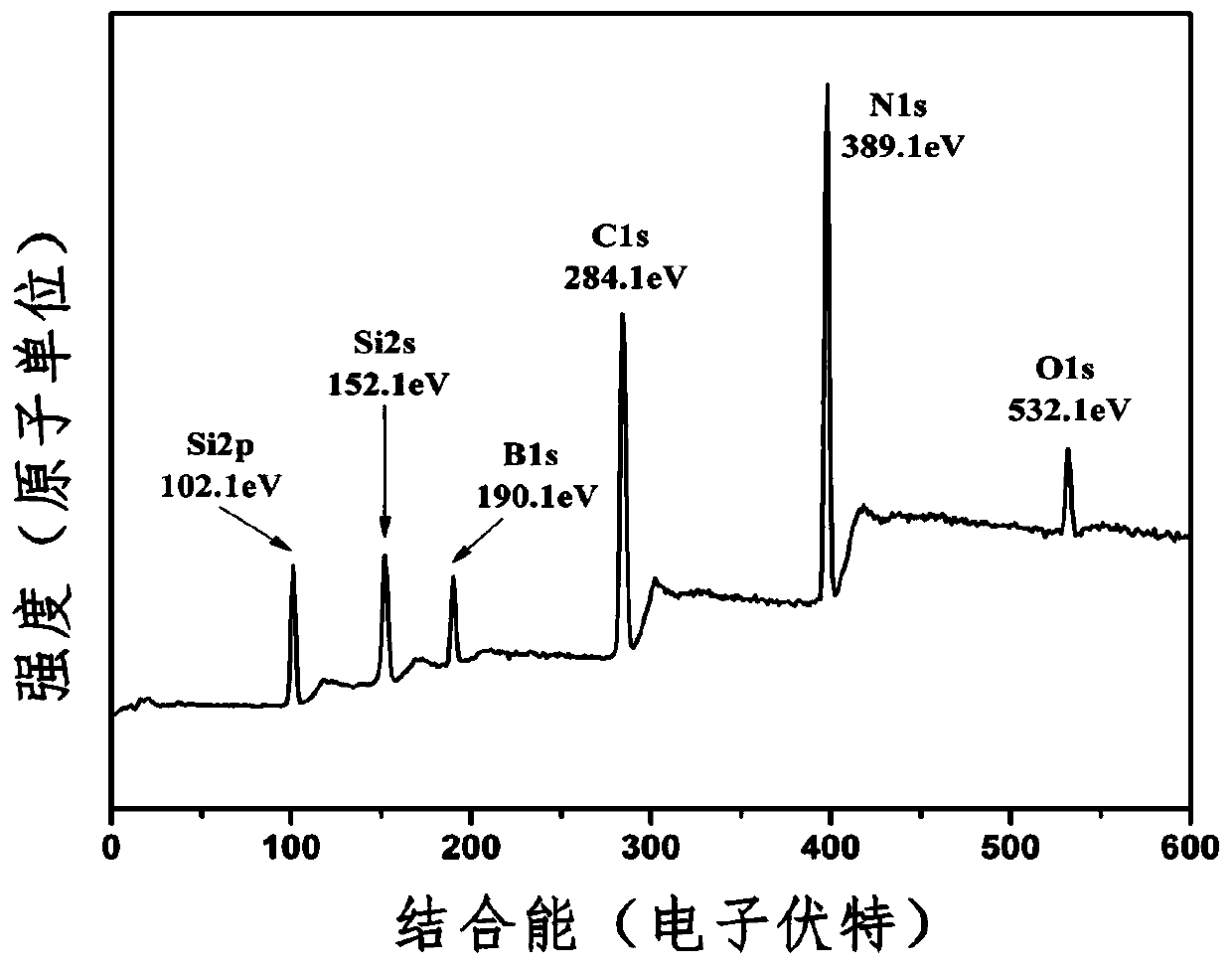

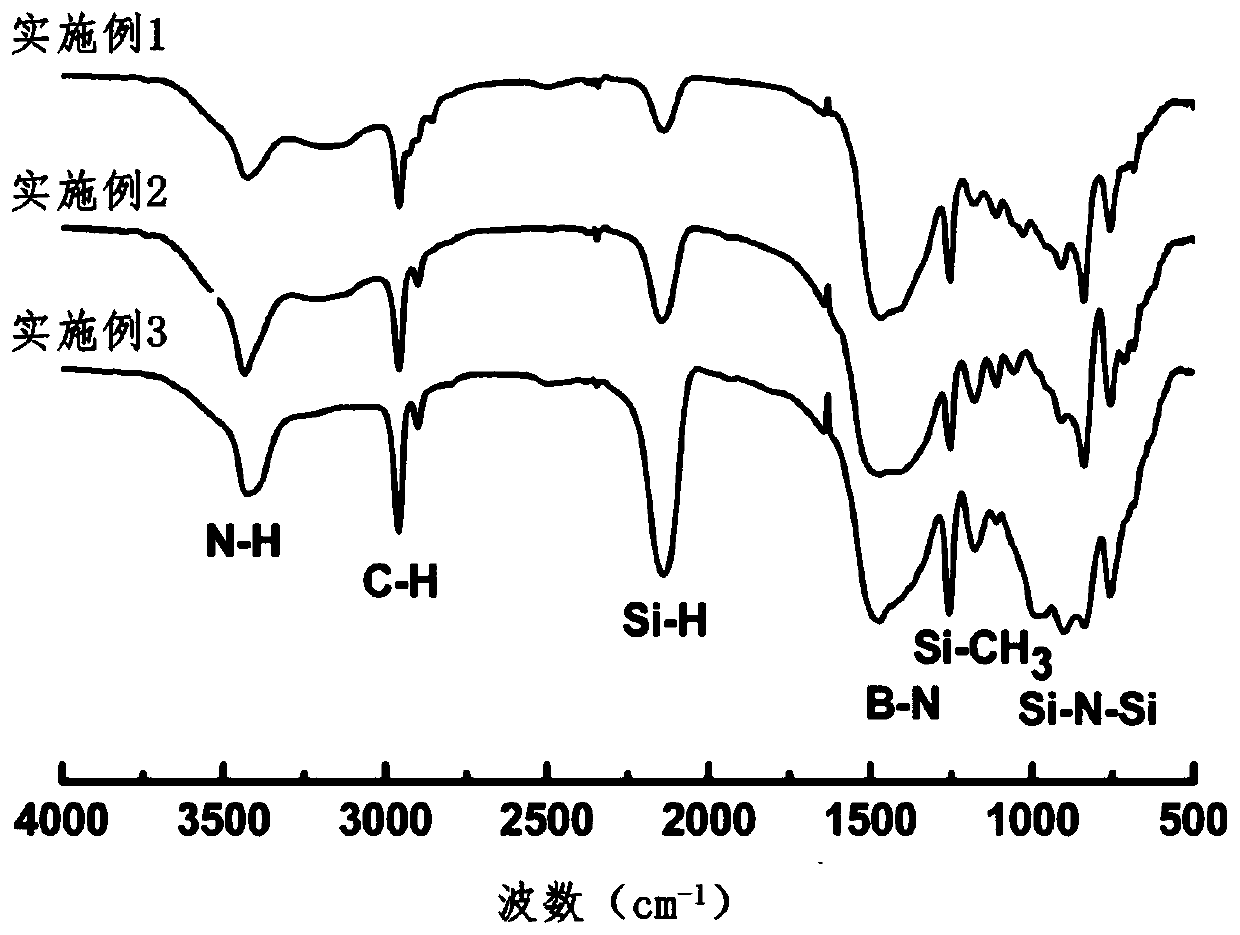

Series-parallel synthesis method of polyborosilazane

The invention discloses a series-parallel synthesis method of polyborosilazane. The series-parallel synthesis method is a method for synthesizing the polyborosilazane through serial connection by using a plurality of monomer synthesis kettles, pre-polymerization kettles and polymerization kettles which are connected in parallel. The method includes the steps that raw materials are prepared and mixed, monomers are synthesized, and pre-polymerization, polymerization, collection and cooling are carried out to obtain a polyborosilazane product. Compared with the prior art, the series-parallel synthesis method of the polyborosilazane greatly improves the production efficiency through step-by-step continuous reaction, and is suitable for large-scale production.

Owner:NAT UNIV OF DEFENSE TECH

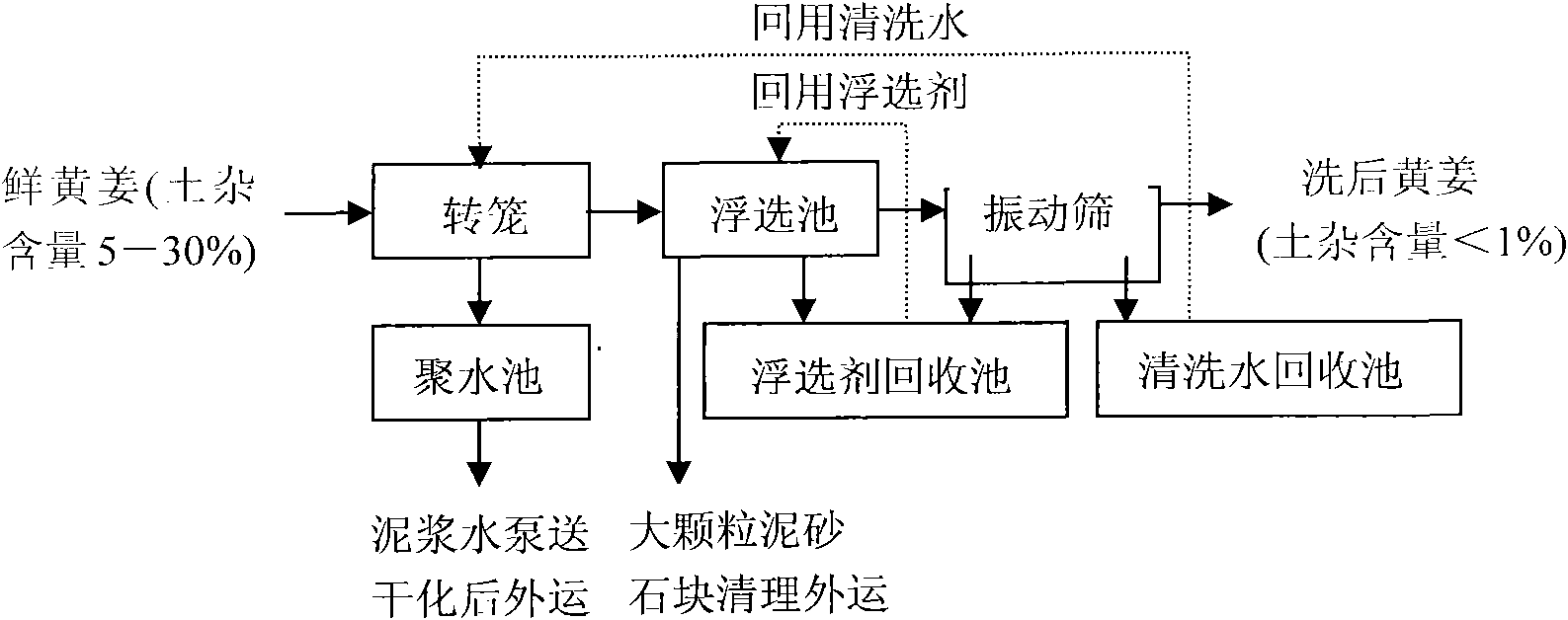

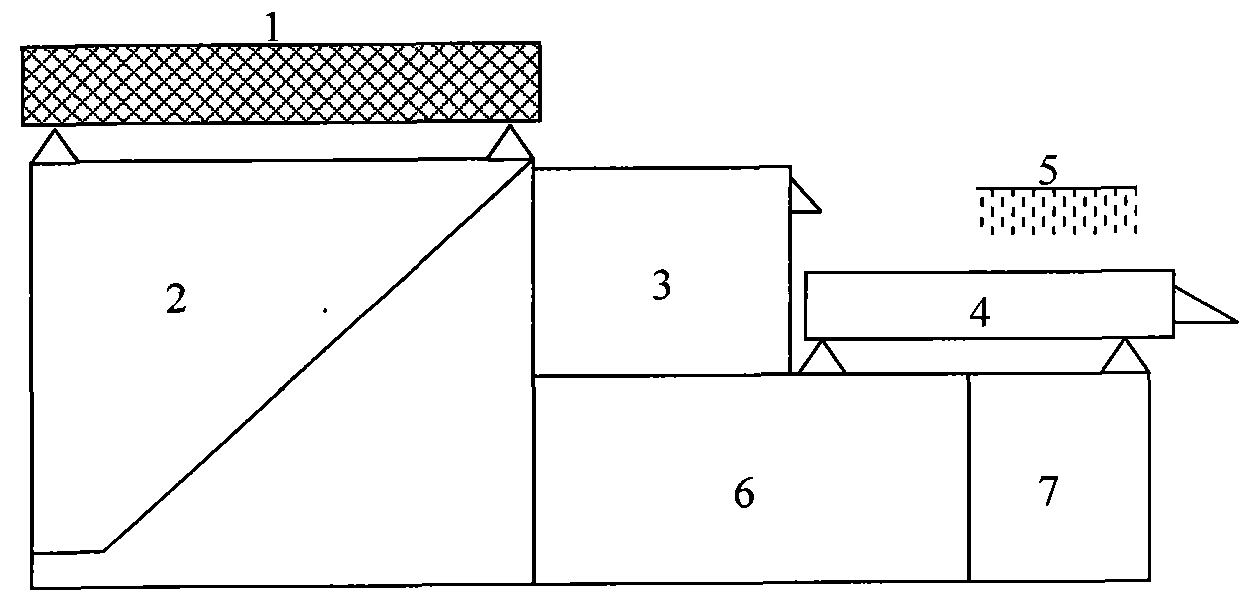

Method for removing soil and impurities from fresh yellow ginger

The invention provides a method for removing soil and impurities from fresh yellow ginger. The method comprises the following steps of: (1) firstly feeding the fresh yellow ginger to a rotating cage, and spraying water flow by two stages to the surface of the yellow ginger by a pressurizing spraying head so as to uniformly clean the yellow ginger; (2) removing smaller-grained sludge in the fresh yellow ginger during the rotating cage cleaning process, pumping the sludge to a sludge drying pool by a sludge pump after the separated sludge settles to a catchment pool with a cone bottom, and conveying the cleaned yellow ginger to a flotation tank under the rotation of the rotating cage; (3) conveying the yellow ginger to the flotation tank holding 20-40% calcium chloride solution or 5-25% sodium chloride solution to remove most of large-grained sludge and stones, and simultaneously further removing fine soil and impurities; (4) feeding the yellow ginger suspended on the surface of a flotation agent into a vibration screen through the overflow port of the flotation tank, cleaning the flotation agent on the surface of the yellow ginger, and conveying the cleaned yellow ginger to a disintegrator by the vibration screen; and (5) discharging the flotation agent in the flotation tank to a recovering tank, and cleaning and transporting the large-grained sludge and stones settled at the bottom of the flotation tank by adopting an artificial cleaning method. By adopting the treating process, the soil and impurities in the fresh yellow ginger can be effectively removed, particularly large-grained stones and irony impurities.

Owner:竹溪创艺皂素有限公司

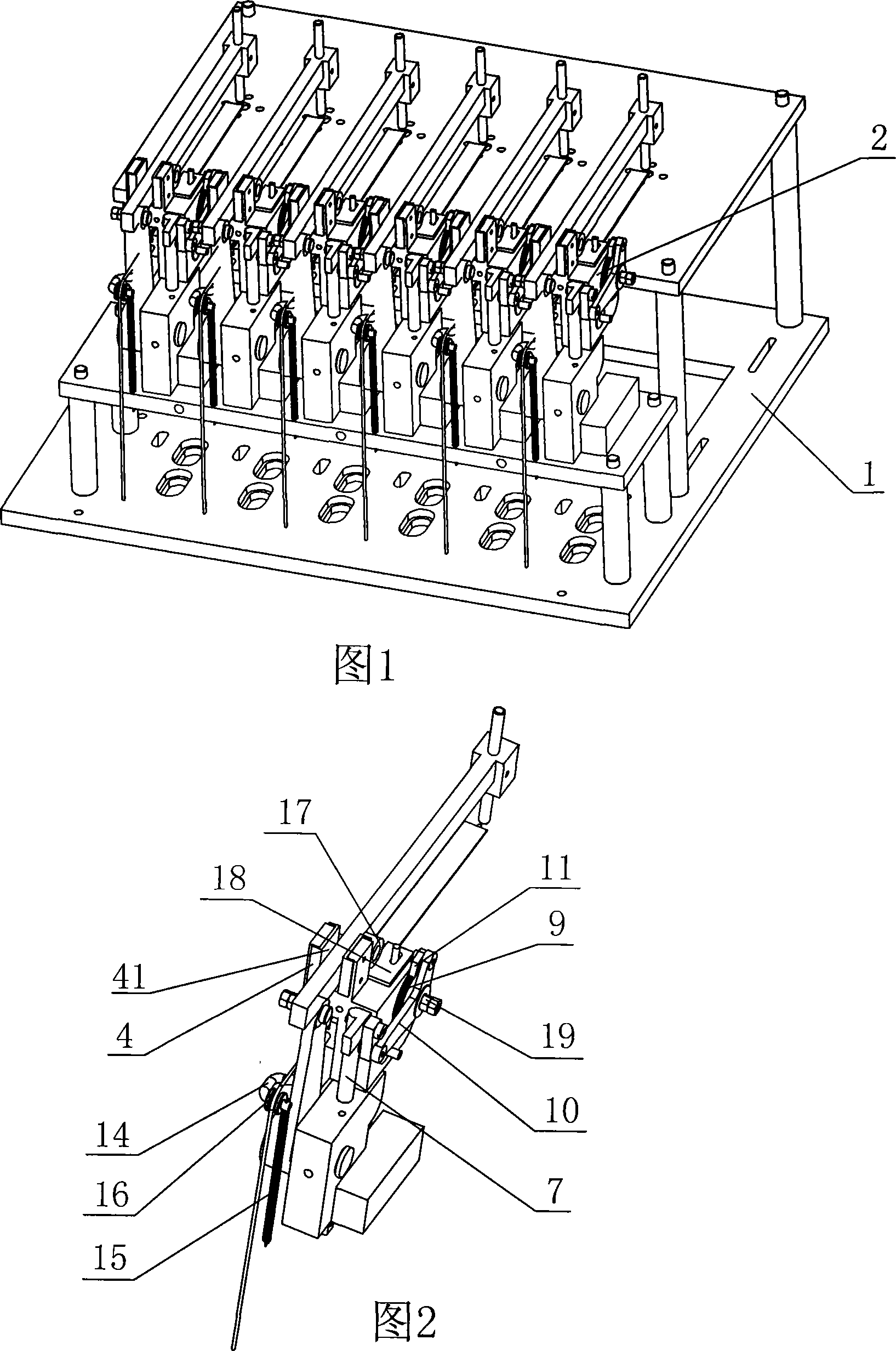

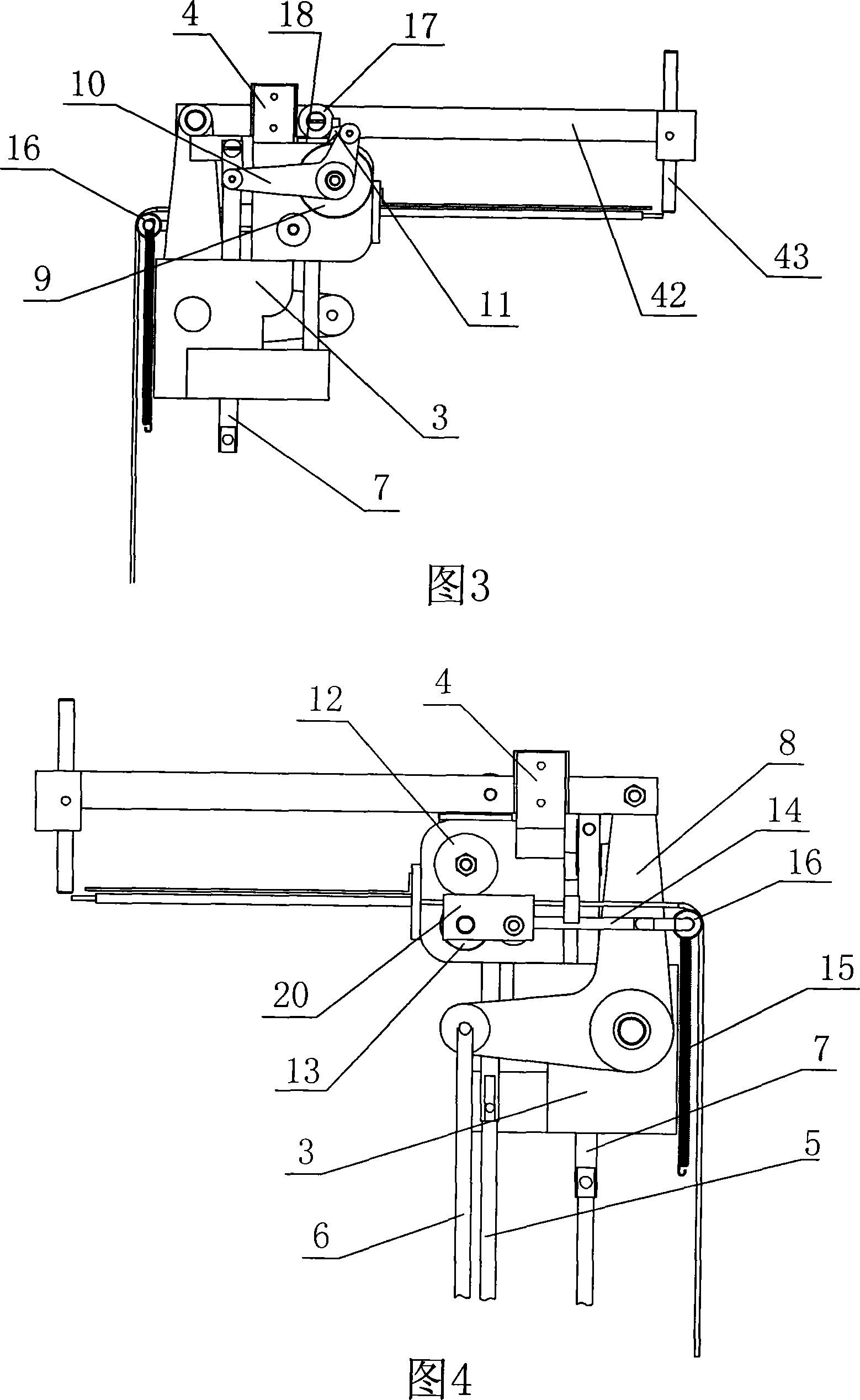

Wire lead solder device for screw energy conserving lamp assembling production

InactiveCN101219496ANo wasteHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesEdison screwOxidation resistant

The invention discloses a lead solder device applied to assembly production of edison screw energy saving lamps, which is characterized in that the invention comprises at least one soldering tin mechanism arranged on a work station platform. The soldering tin mechanism comprises a base and a first cylinder ejector pin. The base is coupled with a rocker arm; one end of the rocker arm is coupled with a second cylinder ejector pin and the other end with a cantilever. The end of the cantilever is vertically arranged with a welding head, the first cylinder ejector pin goes through the base and is apically grafted at the lower part of the cantilever and the base is provided with a solder wire delivery mechanism. The invention has the advantages that the welding head is made of oxidation-resistant and corrosion resistant pontil which does not need replacing frequently, the work station platform can be provided with a plurality of soldering tin mechanism parallel to meet different production demand, the structure of the whole device is simple, the working efficiency can be improved at least one time and operators can be reduced at least by half.

Owner:ANHUI SUNSHINE LIGHTING APPLIANCE CO LTD

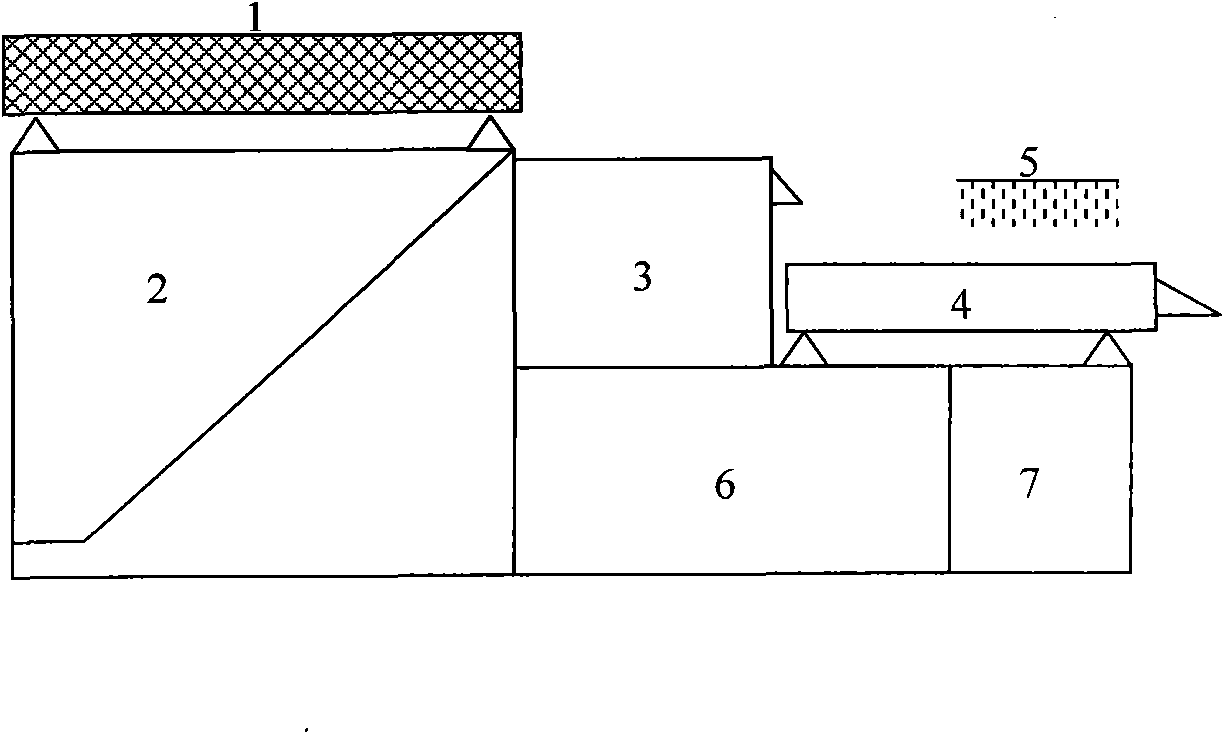

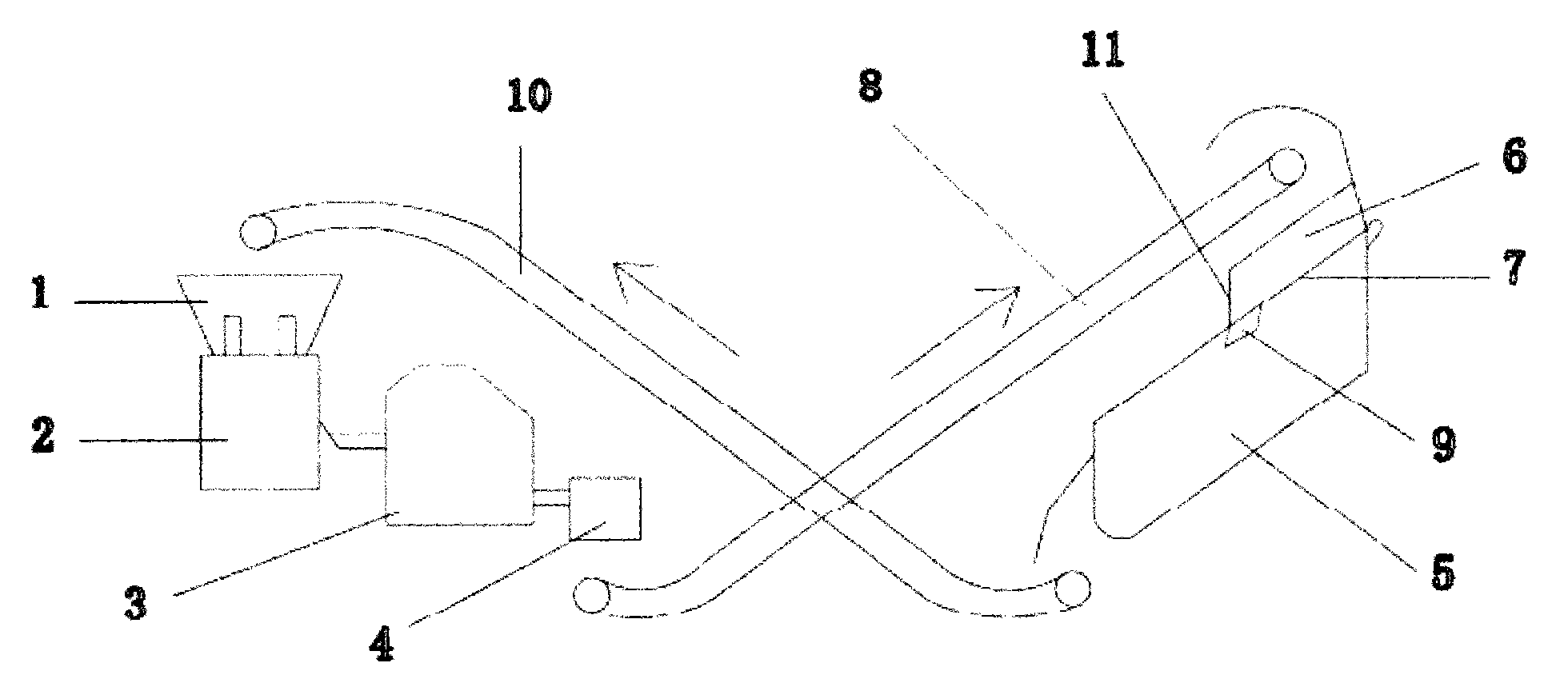

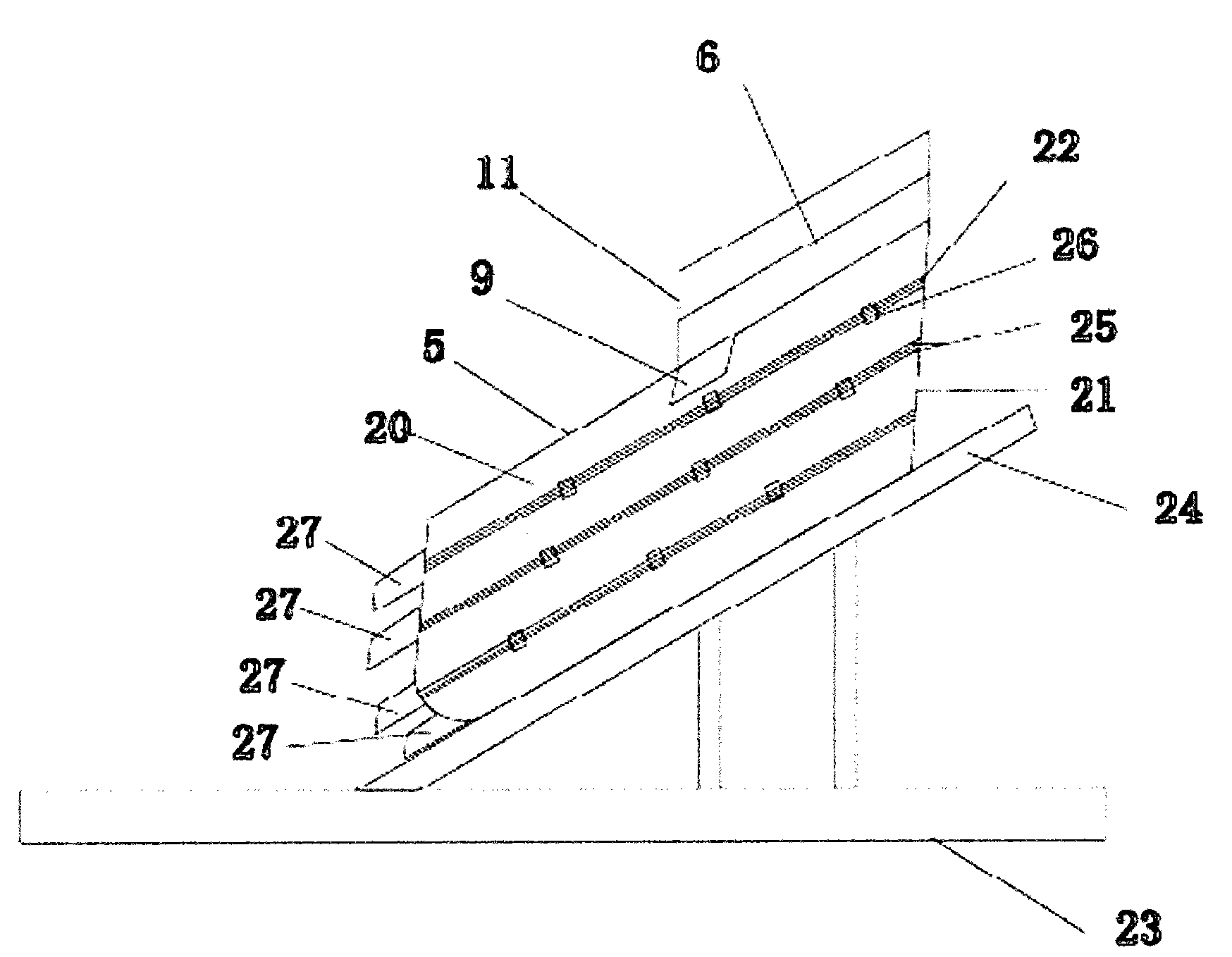

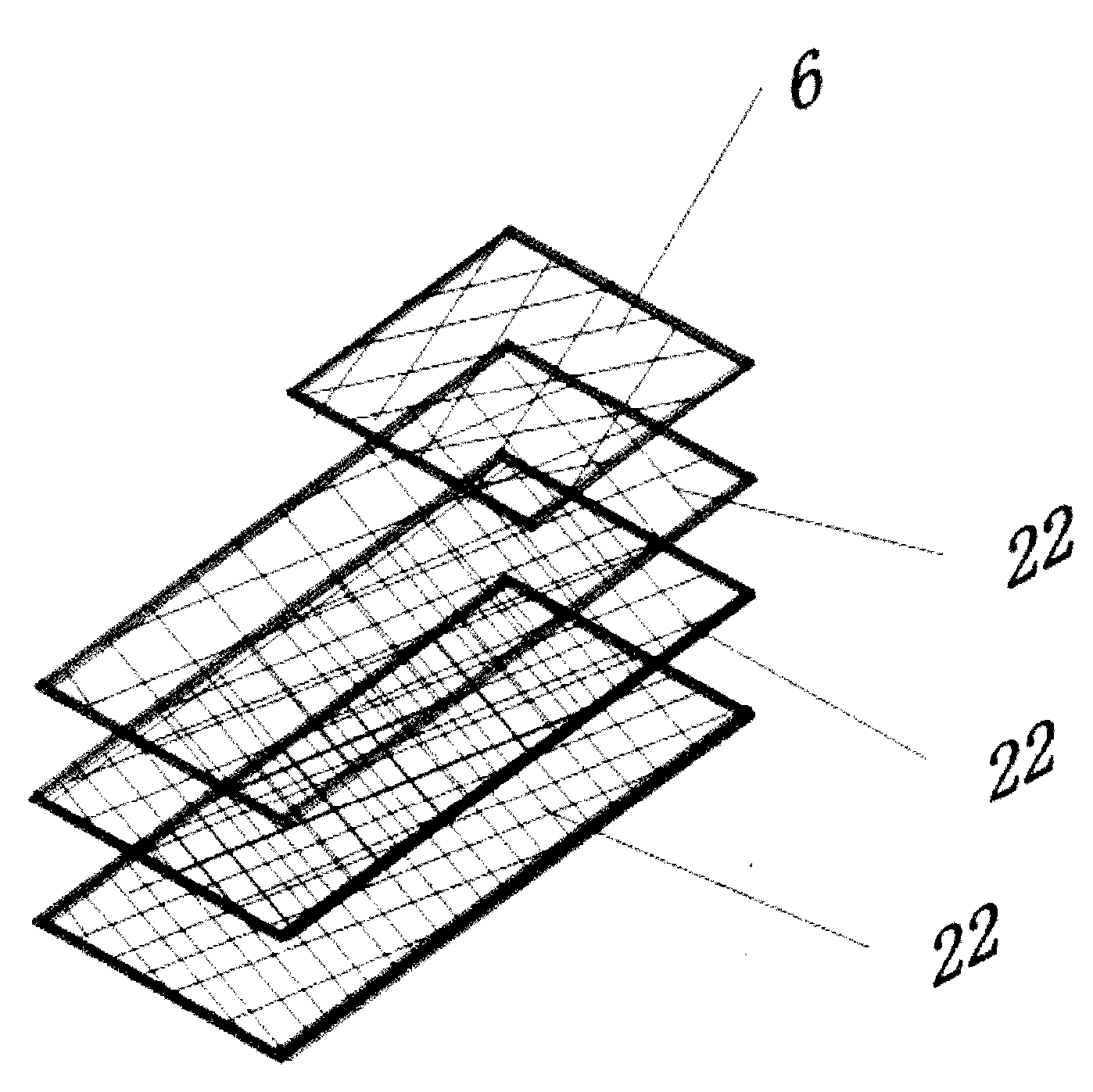

Equipment for producing brick-making sand by use of construction waste with separation light materials

The invention discloses equipment for producing brick-making sand by use of construction waste with separation light materials, which is used for solving the problem of pollution caused by light materials mixed in the raw materials for producing construction sand by use of construction waste. The equipment comprises a bin (1), a vibrating feeder (2), a crusher (3), a self-unloading iron remover (4), a vibrating sieve (5) and a sorting device (6), wherein the sorting device (6) is a wear-resistant separating sieve of which the sieve pore diameter is 7-10cm; the sorting device (6) is mounted at the upper part of a feed port (7) of the vibrating sieve (5) and shares a drive device with the vibrating sieve (5); a baffle (11) is arranged on the side surface of the upper part of the feed port (7); and an impurity conveying belt is arranged below a waste port (9) of the sorting device (6). According to the equipment disclosed by the invention, the sorting device and the vibrating sieve share a drive device; the particles fall onto the vibrating sieve under the vibration effect so as to be sieved, light impurities are output from the waste port, and over 80% of the light impurities in the construction waste can be removed; the treated construction waste is used for producing the construction bricks and sand; and the cost of the raw materials is low, and the economic benefits are high.

Owner:DALI ZHAOPING BUILDING WASTE

Material pulverizer for precise screening

InactiveCN104689895AImprove slipEasy separationRotary stirring mixersTransportation and packagingAir volumeStructural engineering

The invention discloses a material pulverizer for precise screening. The material pulverizer is a cylindrical shell, a separating screening mesh is arranged in the middle of the shell, the shell is divided by the separating screening mesh into an upper smashing bin and a lower secondary separating bin, a conical flow guide plate is arranged on the lower portion of the separating screening mesh, a light material collecting tank is arranged on the inner side of the flow guide plate, a heavy material collecting tank is arranged on the outer side of the flow guide plate, a feeding opening is formed in the middle of the flow guide plate, a circle of blower pipeline is arranged at the position, below the heavy material collecting tank, of the shell of the pulverizer, and a circle of material blocking baffles is arranged above the feeding opening. According to the material pulverizer, smashed small particle solid materials are screened and separated again through the conical flow guide plate and the blower pipeline under the dual action of gravity and airflow, the separating range of the solid materials is controlled by regulating and controlling the air outlet quantity, control is precise, and different production needs of the solid materials of different weights or sizes are met.

Owner:米勇龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com