Material pulverizer for precise screening

A pulverizer and material technology, which is applied to mixers with rotating stirring devices, mixers, grain processing, etc., can solve the problem of complete separation of difficult particles, and achieve good practical effects, simple operation, and precise control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

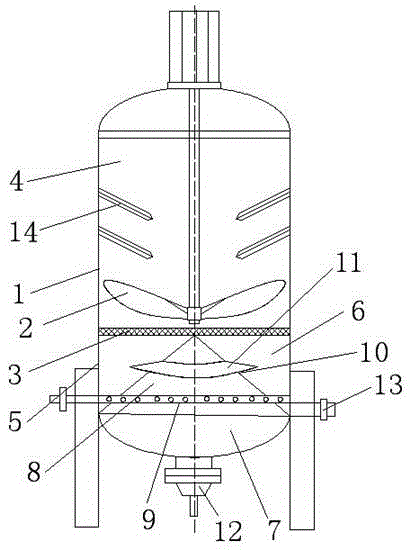

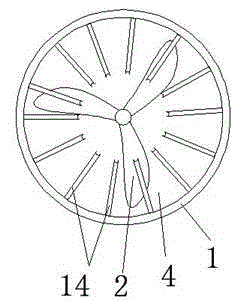

[0014] Example 1: Such as figure 1 and 2 Shown is a material pulverizer for precise screening, the material pulverizer is a cylindrical shell 1, the inside of the shell 1 is provided with a stirring paddle 2, and the middle part of the shell 1 is provided with a separating Screen 3, the separation screen 3 separates the housing 1 into an upper crushing bin 4 and a lower secondary separation bin 5, the stirring paddle 2 is arranged on the upper part of the separation screen 3, and the separation The bottom of the screen 3 is provided with a conical deflector 8, the inside of the deflector 8 is a light material collection tank 7, and the outside of the deflector 8 is a heavy material collection tank 6, the deflector 8 The middle part is provided with a feeding port 10, and a circle of blast pipeline 9 is provided on the pulverizer shell 1 below the heavy material collecting tank 6, and a circle of material blocking is provided above the feeding port 10. plate 11.

Embodiment 2

[0015] Example 2: Such as figure 1 As shown, the bottom of the housing 1 is provided with a light material collection port 12 connected to the light material collection tank 7, and the side of the housing 1 is provided with a heavy material collection port 13 connected to the heavy material collection tank 6; The two different collection ports 12 and 13 facilitate the collection of small particle solid materials of different weights or volumes, and the operation is simple and convenient, saving time and effort.

Embodiment 3

[0016] Example 3: Such as figure 1 and 2 As shown, a plurality of cutting blades 14 are evenly distributed on the shells 1 of different heights in the crushing bin 4; the stirring paddle 2 cannot completely crush the large-particle solid material into small particles during the stirring process, so the stirring paddle 2 and the The combined action of the cutting blade 14 further improves the crushing effect of solid materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com