Rolling method for single-face periodically variable thickness plate strip materials

A variable thickness and periodic technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as uneven welding edges, uneven placement of stamping dies, and impact on project quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

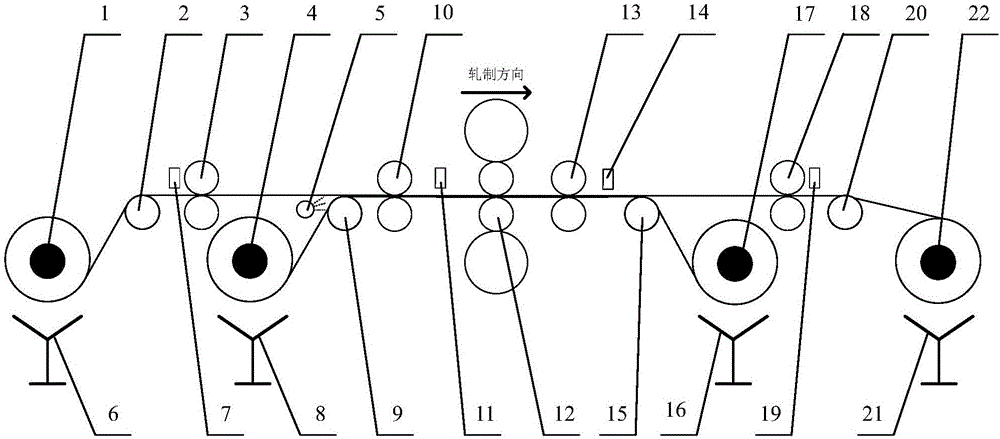

[0113] The rolling device used in this embodiment is as figure 1 As shown, the rolling device is sequentially provided with a first uncoiler 1, a first guide roll 2, a first pinch roll 3, a second uncoiler 4, a second guide roll 9, and a second pinch roll along the rolling direction. 10, four-high rolling mill 12, the third pinch roll 13, the third guide roll 15, the first coiler 17, the fourth pinch roll 18, the fourth guide roll 20 and the second coiler 22;

[0114] A first thickness gauge 7 is provided between the first guide roll 2 and the first pinch roll 3, a second thickness gauge 11 is provided between the second pinch roll 10 and the four-roll mill 12, and the third pinch roll A third thickness gauge 14 is provided between the roller 13 and the third guide roller 15, and a fourth thickness gauge 19 is provided between the fourth pinch roller 18 and the fourth guide roller 20;

[0115] Below the first uncoiler 1 is provided with a first loading car 6, below the second...

Embodiment 2

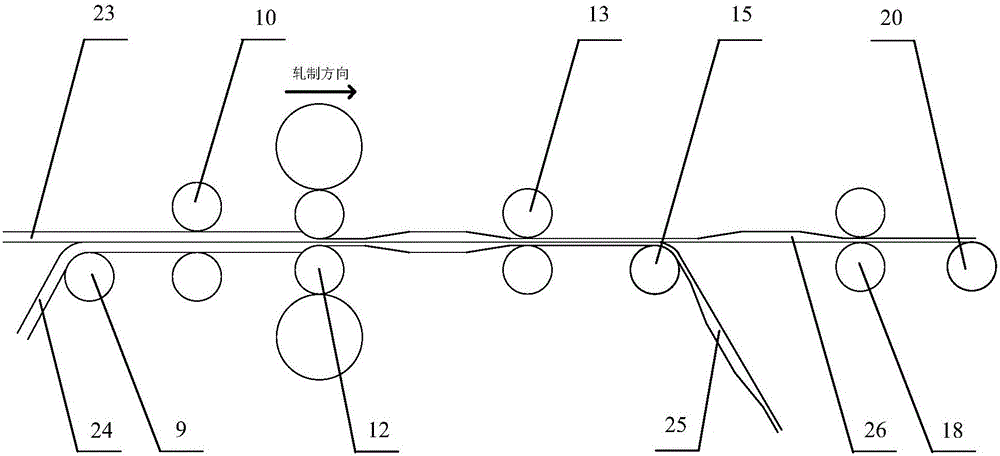

[0208] This embodiment is a method of rolling double-sided periodic side thickness plates and strips using a rolling device with double uncoilers and double coilers. The rolling device used is the same as that of Embodiment 1, the difference is that the rolling method Different, in the rolling process of the method of this embodiment, there is only one uncoiler and one coiler working under the working state, and the double-sided differential thick plate rolling of single coil strip is carried out; the other uncoiler and coiler In the state of material preparation, two groups of equipment are formed. The first group of equipment works, and the second group prepares materials. The specific group rolling method is:

[0209] The first group of equipment: the second loading car, the second uncoiler, the second guide roll, the second pinch roll, the second thickness gauge, four-roll mill, the third thickness gauge, the third pinch roll, the Three guide rollers, first coiler and firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com