Mulching film prepared by utilizing rice straw and preparation method thereof

A technology of rice straw and mulch, which is applied in the fields of application, cultivation, textiles and papermaking, etc. It can solve the problems that affect the large-scale use of mulch, easy to break, and poor strength and toughness of the mulch, so as to achieve less impurities, reduce environmental pollution, and improve fertility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

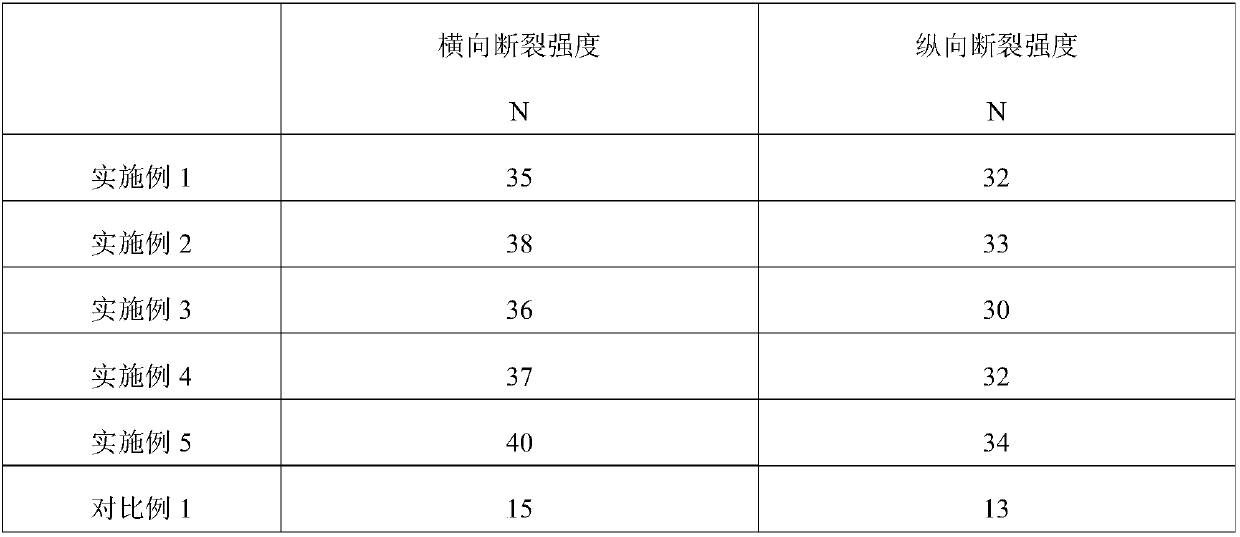

Examples

Embodiment 1

[0049] A mulch film prepared from rice stalks, comprising the following components according to weight percentage:

[0050]Rice straw fiber 70%, waste silk fiber 18%, bio-organic fertilizer 1%, polyvinyl alcohol 6%, corn starch 2%, glycerin 1%, sorbitol fatty acid ester 1%, mineral 0.2%.

[0051] The mineral is dry powder of deep underground water; the dry powder is prepared by heating deep underground water at 260° C. for 10 minutes to evaporate water.

[0052] A method for preparing a mulch film prepared from rice stalks, comprising the following steps:

[0053] S1. Rice straw fiber preparation:

[0054] 1) Straw pretreatment:

[0055] Washing and chopping rice straw into short stems with a length of 2 to 5 cm, adding to an ethanol aqueous solution for pretreatment for 2 hours at a treatment temperature of 180° C., and then drying; the ethanol concentration in the ethanol aqueous solution is 60%.

[0056] 2) Cellulose dissolution:

[0057] The 1-allyl-3-methylimidazolium...

Embodiment 2

[0067] A mulch film prepared from rice stalks, comprising the following components according to weight percentage:

[0068] Rice straw fiber 70%, waste silk fiber 18%, bio-organic fertilizer 1%, polyvinyl alcohol 6.8%, corn starch 2%, glycerin 1%, sorbitol fatty acid ester 1%, mineral 0.2%, insecticide 0.8 %.

[0069] The insecticide is a neonicotinoid insecticide.

[0070] The preparation method is the same as in Example 1.

Embodiment 3

[0072] A mulch film prepared from rice stalks, comprising the following components according to weight percentage:

[0073] Rice straw fiber 70%, waste silk fiber 18%, bio-organic fertilizer 1%, polyvinyl alcohol 6.8%, corn starch 1%, glycerin 1%, sorbitol fatty acid ester 1%, mineral 0.2%, glyoxal Joint agent 1%.

[0074] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com