Patents

Literature

63results about How to "High Hydrodenitrogenation Activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

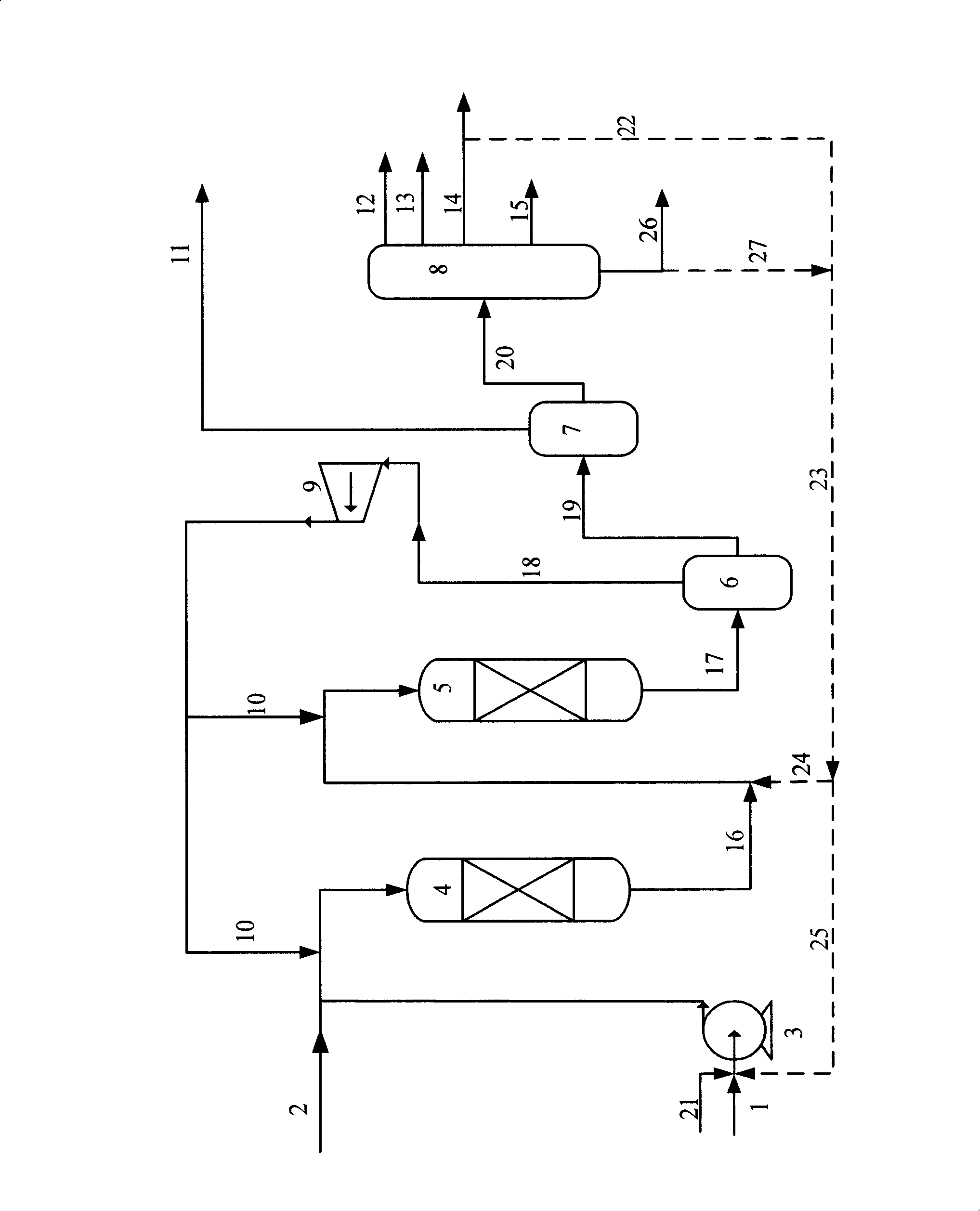

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn process of vulcanized catalyst

ActiveCN101088620AImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationChemistryThiram

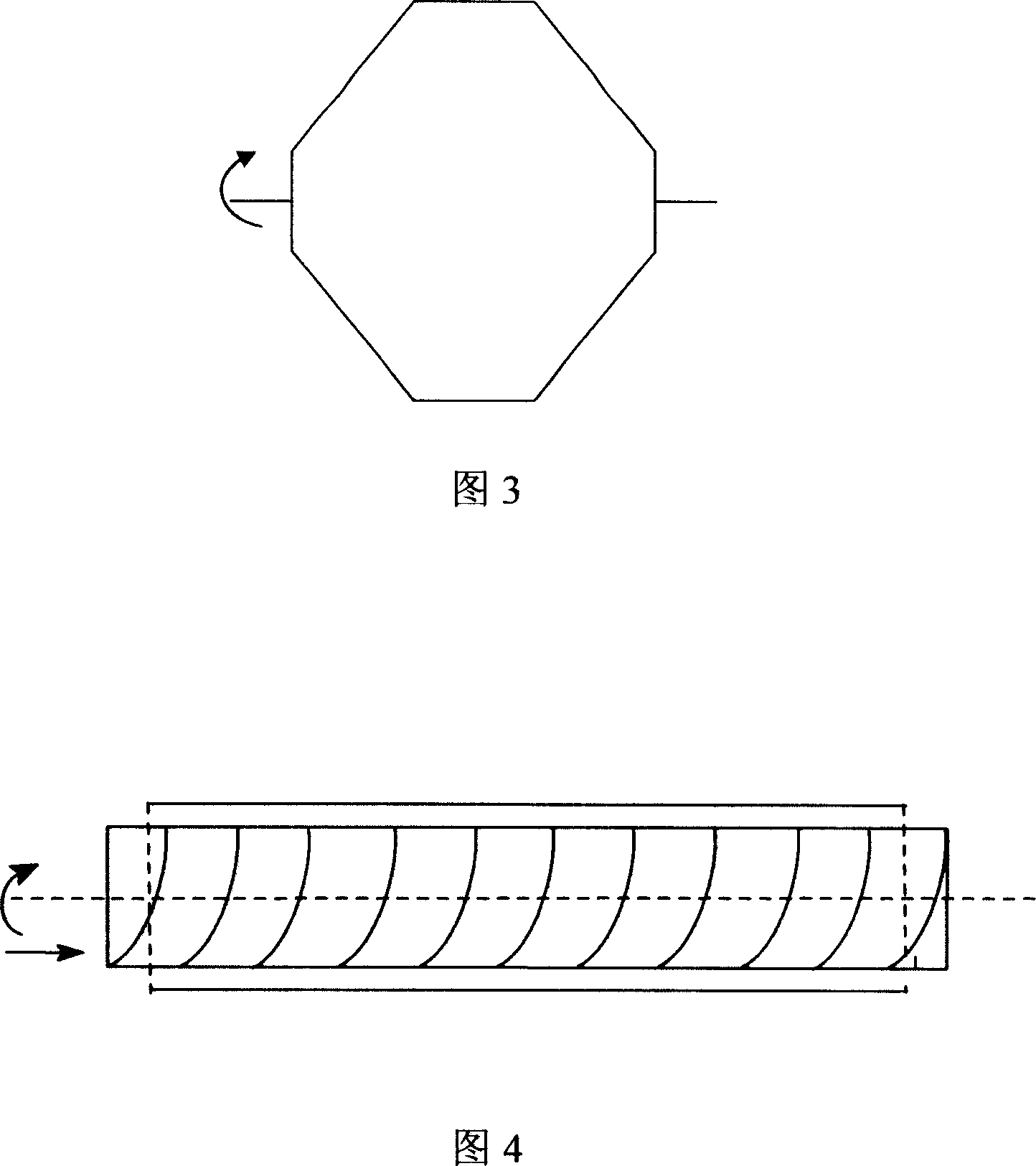

The present invention relates preparation process of vulcanized catalyst. During the preparation process, thiram in 0.5-25 wt% of the catalyst, sulfur element in 30-150 % of the theoretic sulfur demand of the catalyst and organic solvent in 0.1-50 wt% of the catalyst are first introduced into the catalyst in oxide state, and the catalyst is then heat treated in dynamic heating apparatus. The catalyst has raised sulfur holding rate, smooth heat release, shortened vulcanizing period and raised production efficiency. The method of the present invention may be used in the treatment of various kinds of hydrogenating catalyst before application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for producing gasoline blending component with high octane value

ActiveCN103184073ASimple processEasy to operateHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineReaction zone

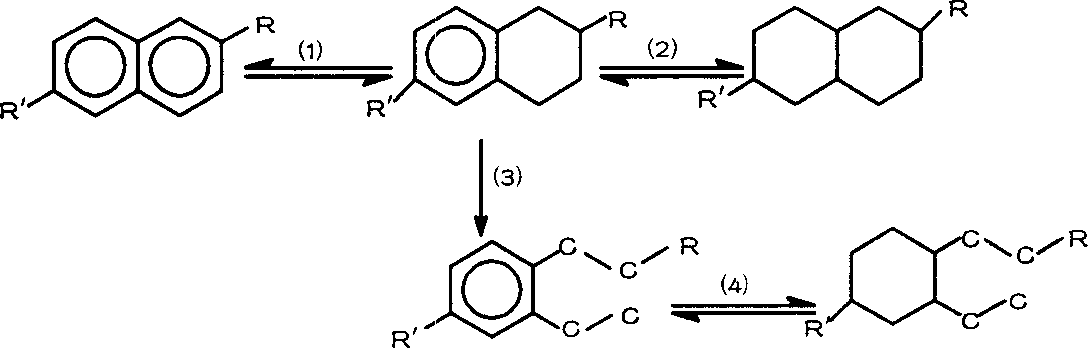

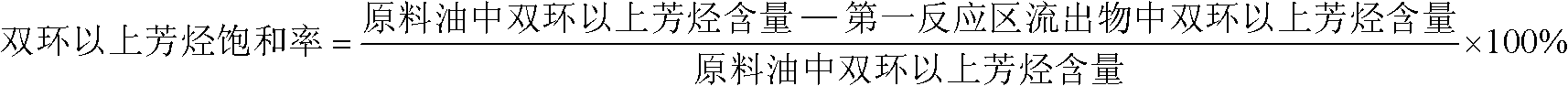

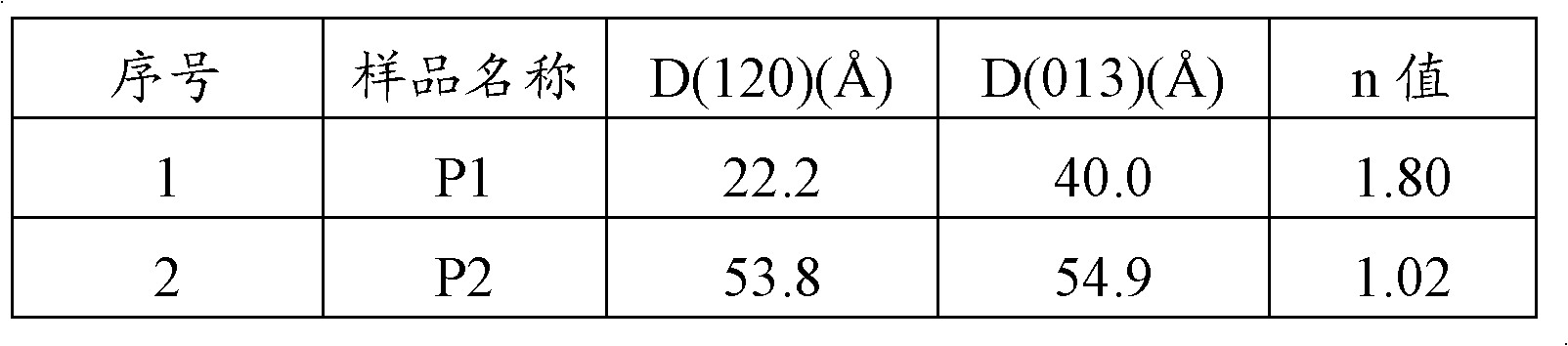

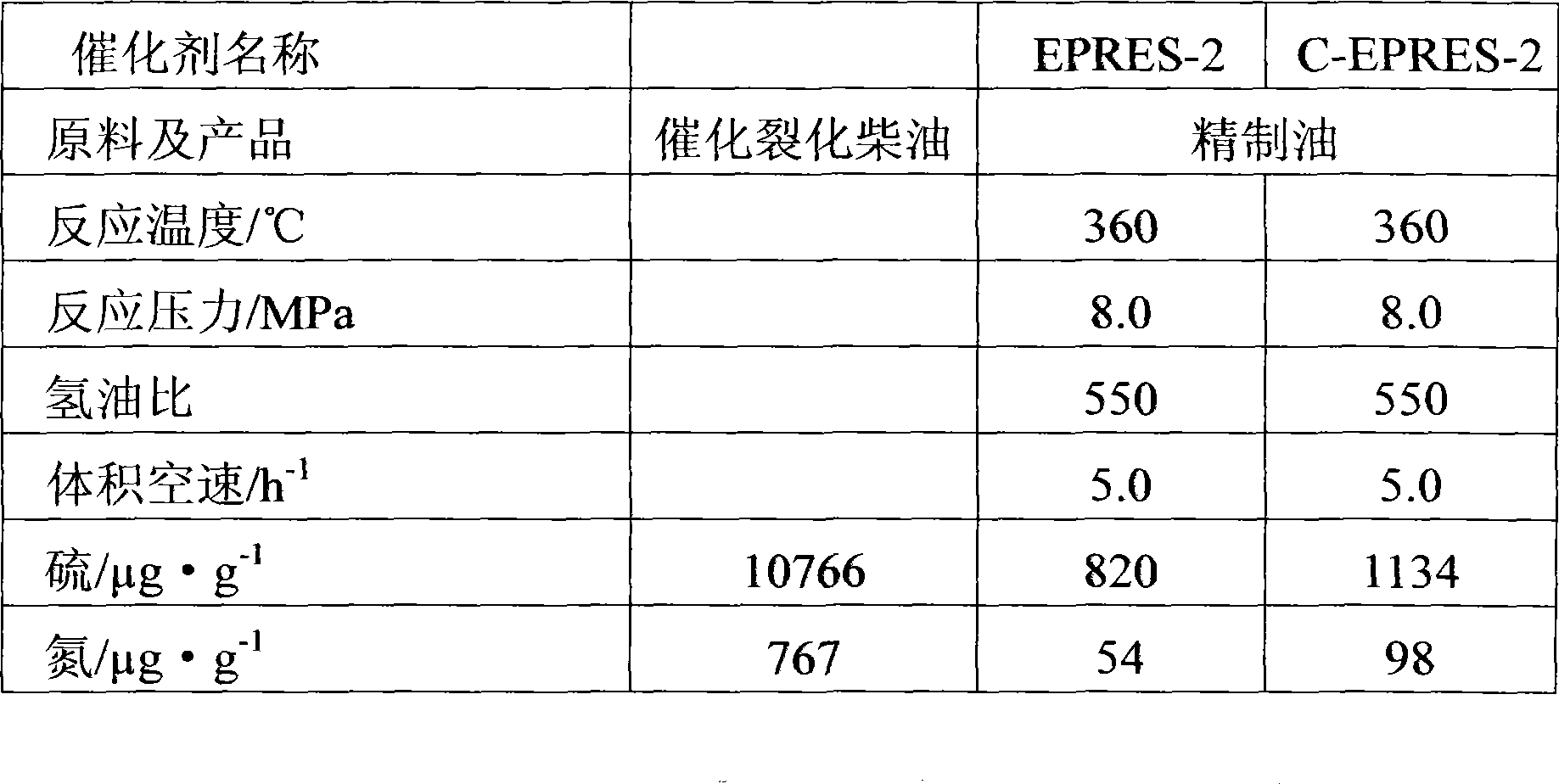

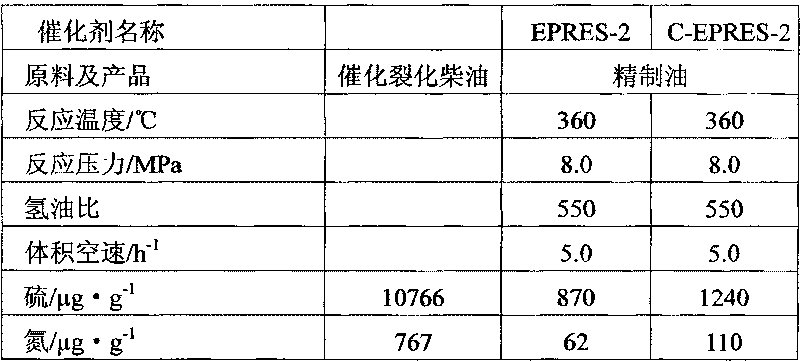

The invention relates to a hyfrocracking method for producing a gasoline blending component with a high octane value. The hyfrocracking method controls aromatic saturation depth in a first reaction zone, that is, compared with a diesel oil raw oil, a saturation rate of aromatics with two or more aromatic rings in reaction effluent in the first reaction zone is over 60%, the content of monocyclic aromatics is increased to over 40 mass% on basis of liquid components of the reaction effluent in the first reaction zone; and at the same time, organic nitrogen content in feeding materials of a second reaction zone is no higher than 10 [mu]g.g<-1>. The method for controlling the aromatic saturation depth of a hydrofining section and reinforcing hydro-denitrification activity of a hydrofining catalyst, gasoline fractions with sulfur content less than 50 [mu]g / g and a research octane number higher than 90 can be produced from inferior diesel fractions with high content of the aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method before application of hydrogenation catalyst

ActiveCN1861257AImprove sulfur retentionHigh activityCatalyst activation/preparationRefining to eliminate hetero atomsOrganic solventOxidation state

A process for treating the hydrocatalyst before it is used features that the organic solvent and sulfur-contained substance are introduced to the oxidation-state hydrocatalyst for higher activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

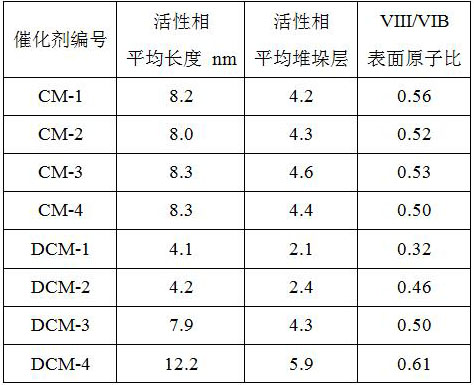

Catalyst for hydro-denitrification of inferior heavy distillate oil and preparation method and application of catalyst

ActiveCN103212432AGood dispersionImprove vulcanization effectMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveVulcanization

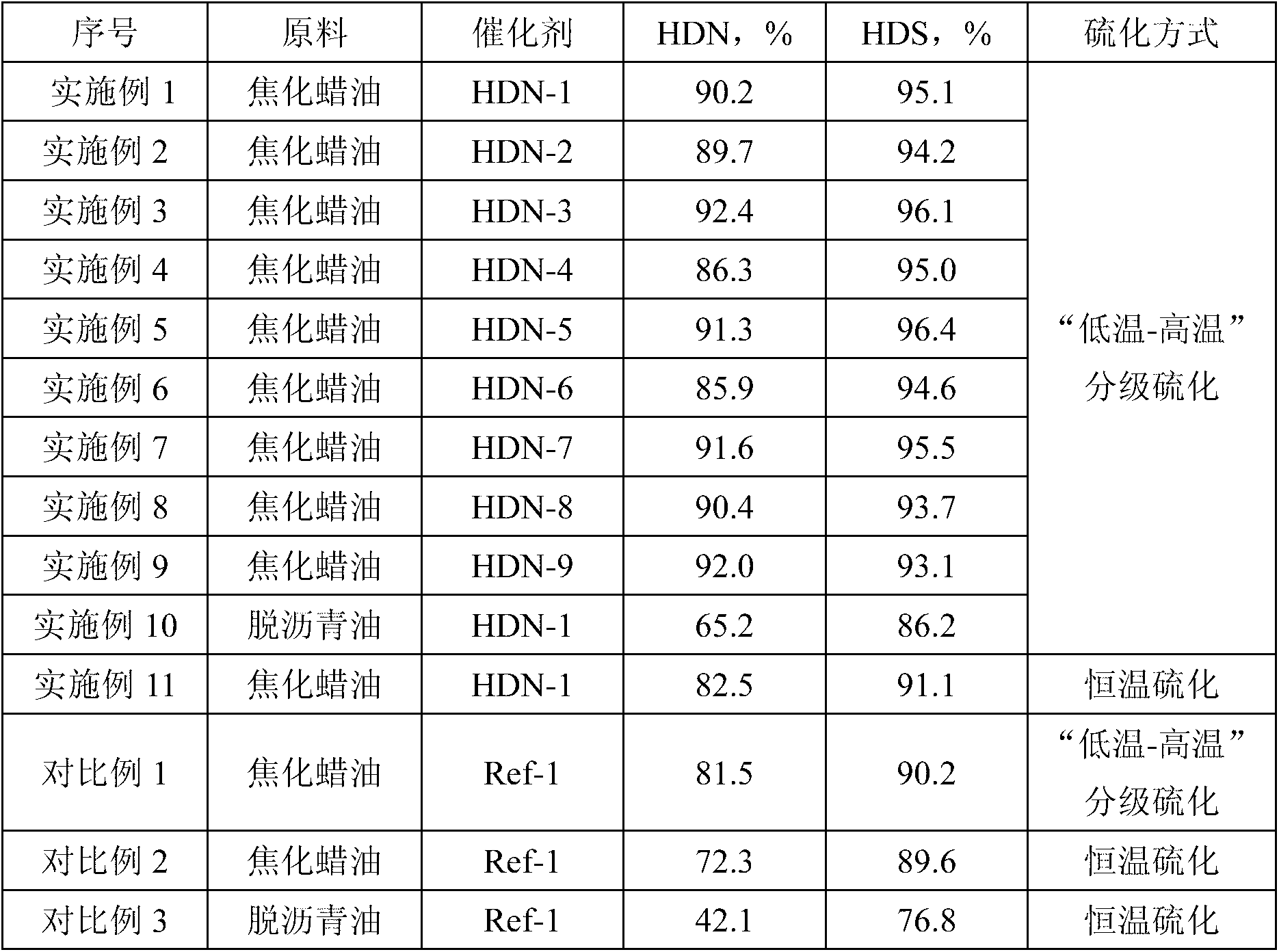

The invention provides a catalyst for hydro-denitrification of inferior heavy distillate oil and a preparation method and application of the catalyst. The preparation method comprises the following steps of: performing surface acid treatment on aluminum oxide and an HY molecular sieve separately; mechanically compounding the aluminum oxide subjected to the acid treatment and the HY molecular sieve subjected to the acid treatment into a carrier; dipping steeping liquid containing catalyst active components to load the catalyst active components; and drying to obtain the catalyst for hydro-denitrification of heavy distillate oil. In the carrier, the content of the HY molecular sieve subjected to the acid treatment is 5 to 20 percent, the active components comprise Mo and / or W, and Co and / or Ni, the steeping liquid also comprises a complexing agent, the Mo and / or W oxide content of the catalyst is 10 to 30 percent, and the Co and / or Ni oxide content of the catalyst is 1 to 10 percent. The catalyst has the characteristics of reasonable acidic distribution, a large number of active metal stacking piles and complete metal vulcanization, has a high hydro-denitrification activity to the inferior heavy distillate oil, and has high hydro-desulfurization performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydrogenation catalyst processing method

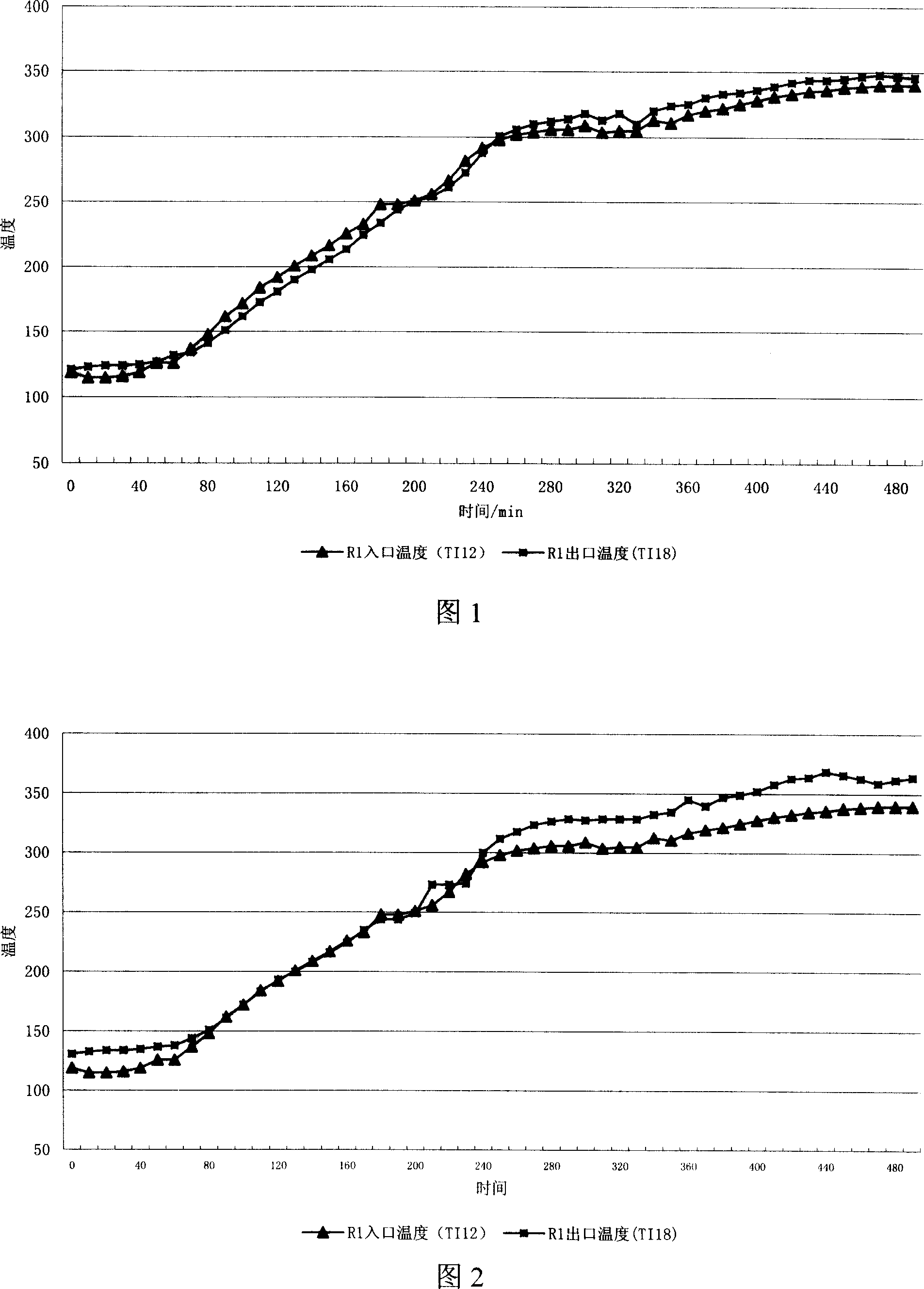

ActiveCN101417245AImprove vulcanization effectImprove hydrogenation reaction performanceMolecular sieve catalystsCatalyst activation/preparationOrganic solventWater vapor

The invention relates to a processing method used for a hydrogenation catalyst, comprising the detailed process as follows: the catalyst carrier is dipped in catalyst active metal component and dried to certain water content; subsequently, organic solvent and elemental sulfur are introduced; and finally, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the water contained in the catalyst adjusts the interaction of the sulfur and the active composition of the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method before using hydrogenation catalyst

ActiveCN101417246AEasy to useIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventWater vapor

The invention relates to a processing method before the application of hydrogenation catalyst, comprising the detailed process as follows: organic solvent, elemental sulfur and water are introduced in oxidated hydrogenation catalyst; subsequently, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the added water adjusts the interaction of the sulfur and the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

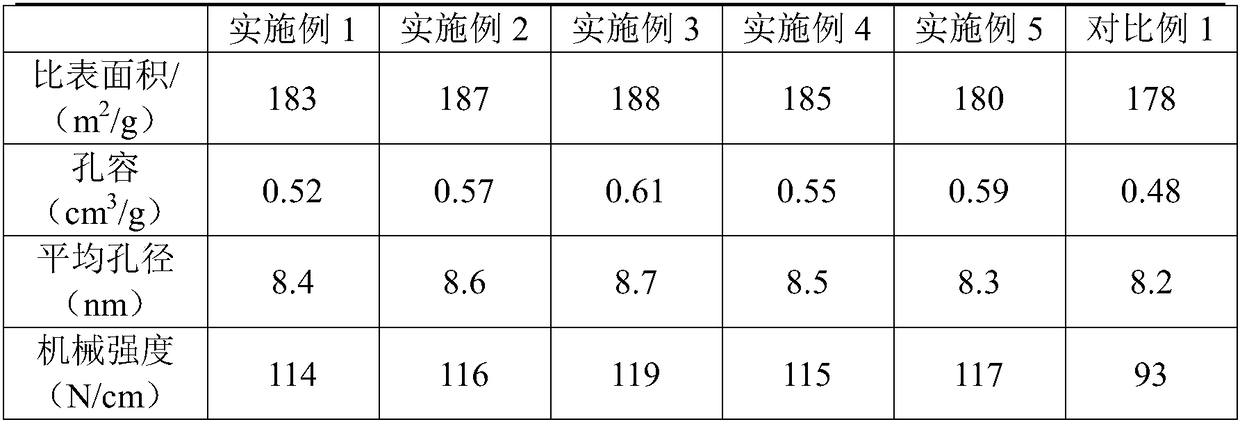

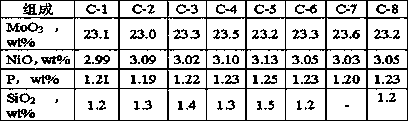

Hydrotreatment catalyst, and preparation method and application thereof

ActiveCN107442129AHigh Hydrodenitrogenation ActivityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEngineering

The invention discloses a hydrotreatment catalyst, and a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing a modified alumina-based carrier by sequentially or simultaneously introducing water-soluble silicon oil and / or a soluble aid into an alumina-based carrier and then carrying out heat treatment; and (2) impregnating the modified alumina-based carrier prepared in the step (1) with group VIB and group VIII active metal components, introducing an organic additive at the same time and carrying out drying without roasting so as to obtain the eventual hydrotreatment catalyst. The method can adjust the distribution of an acid center and a hydrogenation active center to make the acid center and the hydrogenation active center coordinate with each other, thereby improving the comprehensive performance of the hydrotreatment catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of modified aluminium oxide-based carrier

ActiveCN105709712AImprove coordinationDistribution facilitates regulationPhysical/chemical process catalystsRefining to eliminate hetero atomsPtru catalystHydrogen treatment

The invention discloses a preparation method of a modified aluminium oxide-based carrier. The preparation method comprises following steps: water soluble silicone oil and a soluble aluminum-containing compound are introduced into an aluminium oxide-based carrier successively or simultaneously, and the modified aluminium oxide-based carrier is obtained via heat treatment. The preparation method is capable of adjusting distribution of acid centers and hydrogenation active centers, achieving coordination effects, and improving catalyst performance; and the modified aluminium oxide-based carrier is suitable to be taken as a hydrogenation catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon hydroprocessing technique

ActiveCN101148607AImprove performanceImprove vulcanization effectRefining to eliminate hetero atomsAmount of substanceOrganic solvent

The present invention relates to hydrocarbon hydrotreating process including the steps of loading catalyst into the reactor, activating, reaction, etc. The hydrotreating catalyst contains thiram matter in 0.5-25 wt% of the catalyst, simple substance sulfur in the amount of 30-150 % of the theoretical sulfur demand of the catalyst, and organic solvent in 0.1-50 wt% of the catalyst. The hydrotreating catalyst with the common action of thiram matter, sulfur and organic solvent has high sulfur holding rate in activation, less concentrated heat release, lowered temperature rise in the catalyst bed and high activity. It may be applied in various kinds of hydrocarbon hydrotreating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method used for preparing hydrogenation catalyst

ActiveCN105709763AImprove coordinationEasy to useMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystHydrogen treatment

The invention discloses a method used for preparing a hydrogenation catalyst. The method comprises steps of preparation of an aluminium oxide-based carrier containing silicon and magnesium, and loading of a hydrogenation active metal; in the step of preparation of the aluminium oxide-based carrier containing silicon and magnesium, water soluble silicone oil and a soluble magnesium-containing compound are introduced into an aluminium oxide-based carrier successively or simultaneously, and the aluminium oxide-based carrier containing silicon and magnesium is obtained via heat treatment. The method is capable of adjusting distribution of acid centers and hydrogenation active centers, achieving coordination effects, and improving comprehensive performance of the hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for hydrotreatment catalyst

ActiveCN107442126AHigh Hydrodenitrogenation ActivityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsWater solubleSilicone oil

The invention discloses a preparation method of a hydrotreatment catalyst. The preparation method comprises the following steps: preparing a carbon-containing modified alumina-based carrier; loading the carrier with hydrogenation active metal component by using an impregnation process; and carrying out drying to obtain the hydrotreatment catalyst. A preparation method for the carbon-containing modified alumina-based carrier comprises the following steps: sequentially or simultaneously introducing water-soluble silicon oil, a soluble aid and a carbon precursor into an alumina-based carrier and carrying out heat treatment so as to obtain the carbon-containing modified alumina-based carrier. The method can adjust the distribution of an acid center and a hydrogenation active center to make the acid center and the hydrogenation active center coordinate with each other, thereby improving the comprehensive performance of the hydrotreatment catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing catalytic reforming raw material

ActiveCN100448951CHigh Hydrodenitrogenation ActivityReduce contentRefining to eliminate hetero atomsCatalytic reformingNaphtha

The invention is a method for producing catalytic reforming raw material, cutting secondary gasoline raw material into light gasoline fraction, medium gasoline fraction and heavy gasoline fraction, where the medium gasoline fraction, optional virgin naphtha and hydrogen gas contact with first hydrofining catalyst to make alkene saturated reaction, the resultant effluent is not separated but directly contacts with second hydrofining catalyst to make hydrodesulfurization and hydro- denitrogenation reactions, and the extracted hydrogen-enriched gas is recycled and the extracted liquid enters a distillation dehydrating tower and is purified to obtain naphtha. And it can process secondary gasoline with high sulfur, nitrogen and alkene contents, and provides qualified raw material with sulfur and nitrogen contents both less than 0.5 mug / g for catalytic reforming.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of aluminium oxide-based carrier containing silicon and magnesium

ActiveCN105709850AHigh Hydrodenitrogenation ActivityCatalyst carriersRefining to eliminate hetero atomsAluminium oxidesMaterials science

The invention discloses a preparation method of an aluminium oxide-based carrier containing silicon and magnesium. The preparation method comprises following steps: water soluble silicone oil and a soluble magnesium-containing compound are introduced into an aluminium oxide-based carrier successively or simultaneously, and the aluminium oxide-based carrier containing silicon and magnesium is obtained via heat treatment. The preparation method is capable of adjusting distribution of acid centers and hydrogenation active centers, achieving coordination effects, and improving catalyst performance; and the modified aluminium oxide-based carrier is suitable to be taken as a hydrogenation catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mild hydrogenation purifying method for coal direct liquefaction oil

InactiveCN101311246AImprove economyHigh Hydrodenitrogenation ActivityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesChemistryNaphtha

The invention relates to a mild hydrogenation extraction method for direct coal liquefaction oil, which comprises: blending the direct coal liquefaction oil with hydrogen to put into a steady hydrogenation reactor, carrying out desulfurization, denitrification, olefin saturation and aromatics saturation reaction under the action of a hydrotreating catalyst, separating and distilling the reaction product to obtain naphtha cut and diesel distillate, blending the obtained diesel distillate with the hydrogen, putting the mixture into a hydrogenation modification reactor to contact and react with a hydrogenation modification catalyst, separating and distilling the reaction product to obtain the diesel product. The method provided by the invention effectively combines a steady hydrogenation unit with a hydrogenation modification unit, and can product the diesel product with more than 45 of cetane number. The method has the advantages of mild operation condition, simple process, low investment, and low operation expense.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrogenation catalyst

ActiveCN105709788AReasonable acidity and acidity distributionImprove performanceCatalyst carriersRefining to eliminate hetero atomsAluminium oxidesMaterials science

The invention discloses a preparation method of a hydrogenation catalyst. The preparation method comprises steps of preparation of a modified aluminium oxide-based carrier, and loading of a hydrogenation active metal; in the step of preparation of the modified aluminium oxide-based carrier, water soluble silicone oil and a soluble zirconium-containing compound are introduced into an aluminium oxide-based carrier successively or simultaneously, and the modified aluminium oxide-based carrier is obtained via heat treatment. The preparation method is capable of adjusting distribution of acid centers and hydrogenation active centers, achieving coordination effects, and improving comprehensive performance of the hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon hydroprocessing technique

ActiveCN101148608AEasy to makeSuitable for large-scale useRefining to eliminate hetero atomsOrganic solventSulfur

The present invention relates to hydrocarbon hydrotreating process including the steps of loading catalyst into the reactor, activating, reaction, etc. The hydrotreating catalyst contains organic nitrogen compound in 0.5-20 wt% of the catalyst, simple substance sulfur in the amount of 30-150 % of the theoretical sulfur demand of the catalyst, and organic solvent in 0.1-50 wt% of the catalyst. The hydrotreating catalyst with the common action of organic nitrogen compound, sulfur and organic solvent has high sulfur holding rate in activation, less concentrated heat release, lowered temperature rise in the catalyst bed and high activity. It may be applied in various kinds of hydrocarbon hydrotreating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method used for preparing hydrogenation catalyst

ActiveCN105709761AImprove coordinationDistribution facilitates regulationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystHydrogen treatment

The invention discloses a method used for preparing a hydrogenation catalyst. The method comprises steps of preparation of an aluminium oxide-based carrier containing silicon and boron, and loading of a hydrogenation active metal; in the step of preparation of the aluminium oxide-based carrier containing silicon and boron, water soluble silicone oil and a soluble boron-containing compound are introduced into an aluminium oxide-based carrier successively or simultaneously, and the aluminium oxide-based carrier containing silicon and boron is obtained via heat treatment. The method is capable of adjusting distribution of acid centers and hydrogenation active centers, achieving coordination effects, and improving comprehensive performance of the hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal tar hydrodenitrification catalyst and preparation method thereof

InactiveCN108906118AAvoid the problem of difficult complete conversion to sulfideHigh activityMolecular sieve catalystsHydrocarbon oils refiningNitrogenDry basis

The invention discloses a coal tar hydrodenitrification catalyst and a preparation method thereof. The coal tar hydrodenitrification catalyst includes active ingredients, an auxiliary and a carrier. The active ingredients include the following components in parts by weight: 13-15 parts of tungsten trisulfide, 5-8 parts of nickel oxide and 3-4 parts of molybdenum trisulfide; the auxiliary includesthe following components in parts by weight: in terms of elementary substance, 1-2 parts of phosphorus, and 1-4 parts of fluorine; and the carrier includes the following components in parts by weight:in terms of the dry basis of the carrier, 45-55 parts of alumina, 5-10 parts of H[beta] zeolite and 10-15 parts of titanium dioxide. The beneficial effects of the present invention are that the catalyst has excellent activity for hydrodenitrification of coal tar.

Owner:宁波敬业控股集团有限公司

Preparation method of hydrogenation catalyst

ActiveCN105709762AImprove coordinationDistribution facilitates regulationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystHydrogen treatment

The invention discloses a preparation method of a hydrogenation catalyst. The preparation method comprises a step of preparation of the modified aluminium oxide-based carrier, and a step of loading of hydrogenation active metals. According to the preparation method, water soluble silicone oil and a soluble aluminum-containing compound are introduced into an aluminium oxide-based carrier successively or simultaneously, and the modified aluminium oxide-based carrier is obtained via heat treatment. The preparation method is capable of adjusting distribution of acid centers and hydrogenation active centers, achieving coordination effects, and improving comprehensive performance of the hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating catalyst as well as preparation method and application thereof

InactiveCN111318292AHigh Hydrodenitrogenation ActivityHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystMetallurgy

The invention discloses a hydrotreating catalyst as well as a preparation method and application thereof. The preparation method of the catalyst comprises the following steps: (1) introducing modifiedsilicone oil into an alumina carrier, drying and roasting to obtain a modified alumina carrier; and (2) dipping the modified alumina carrier prepared in the step (1) in an active metal component dipping solution containing a trihydroxymethyl compound, and drying and roasting after dipping to obtain the final hydrotreating catalyst. The catalyst not only has high stability of a class I active center catalyst, but also has high activity of a class II active center catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of aluminium oxide-based carrier containing silicon and boron

ActiveCN105709851AHigh Hydrodenitrogenation ActivityCatalyst carriersPtru catalystHydrogen treatment

The invention discloses a preparation method of an aluminium oxide-based carrier containing silicon and boron. The preparation method comprises following steps: water soluble silicone oil and a soluble boron-containing compound are introduced into an aluminium oxide-based carrier successively or simultaneously, and the aluminium oxide-based carrier containing silicon and boron is obtained via heat treatment. The preparation method is capable of adjusting distribution of acid centers and hydrogenation active centers, achieving coordination effects, and improving catalyst performance; and the modified aluminium oxide-based carrier is suitable to be taken as a hydrogenation catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfide catalyst for hydrogenation desulfurization and denitrogenation and its preparation process and use

InactiveCN100348700CThe synthesis method is simpleLower synthesis costPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrodesulfurizationReaction temperature

The preparation method for HDSN sulfide catalyst comprises: mixing element precursor from VIB and VIII family with S-contained precursor, adding reducer to produce the sulfide contained VIB and VIII elements at given temperature; separating nano particle from reaction system, drying, and hot processing in inert / sulfidization atmosphere. This product has activity 4-5 times than the industrial product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrodenitrification catalyst as well as preparation method and application thereof

ActiveCN114433233AImprove the coordination effectFit closelyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a hydrodenitrification catalyst as well as a preparation method and application thereof. The catalyst comprises a carrier, a molybdenum element and a group VIII metal element, at least part of the molybdenum element exists in the catalyst in the form of carbonyl molybdenum, at least part of the group VIII metal element exists in the catalyst in the form of a group VIII metal complex, and a complexing agent is a compound containing a nitrogen element and lone pair electrons. The hydrodenitrogenation catalyst is used in a heavy oil hydrotreating process, can deeply remove nitrogen-containing compounds in residual oil, and has good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenating catalyst composition and preparation process thereof

ActiveCN100360231CSolve the problem of concentrated heat releaseImprove vulcanization effectPhysical/chemical process catalystsRefining to eliminate hetero atomsOrganic solventSulfur

This invention relates to the compound of hydro catalyst and its preparation method. The compound contains the hydro catalyst, the organic nitrogen compound the content of which is 0.5-20%, the sulfur element which is composed of 30-150% sulfur demand of the hydro catalyst and the organic solution the weight of which is 0.1-50% of the catalyst. The preparation processes is leading-in the demanded mater when the hydro catalyst is oxide. This hydro catalyst compound can improve the sulfur holding ratio of the catalyst which is activated, and slow up the concentrate heat release, decrease the elevated temperature of the catalyst bed, and increase the activity of the catalyst through the lead-in organic nitrogen, sulfur and organic solution. This invention can be applied to the treatment processes of any hydro catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of treating hydrogenation catalyst before application

ActiveCN101088616BImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic solvent

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodenitrification catalyst as well as preparation method and application thereof

ActiveCN114643070AFavorable for hydrogenation saturationWell formedHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystActive agent

The invention discloses a hydrodenitrification catalyst as well as a preparation method and application thereof. The catalyst comprises a carrier, a molybdenum element, a group VIII metal element, an electronic auxiliary agent and a surfactant, at least part of the molybdenum element exists in the catalyst in the form of phosphomolybdenum blue, and the electronic auxiliary agent is a soluble nitrogen-containing compound containing lone pair electrons. And the surfactant is one or more of long-chain fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether, polyoxyethylene fatty acid ester, polyoxyethylene alkylamine, polyoxyethylene alkylolamides and polyether. The hydrodenitrogenation catalyst is used in a heavy oil hydrotreating process, can deeply remove nitrogen-containing compounds in heavy oil, and has good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

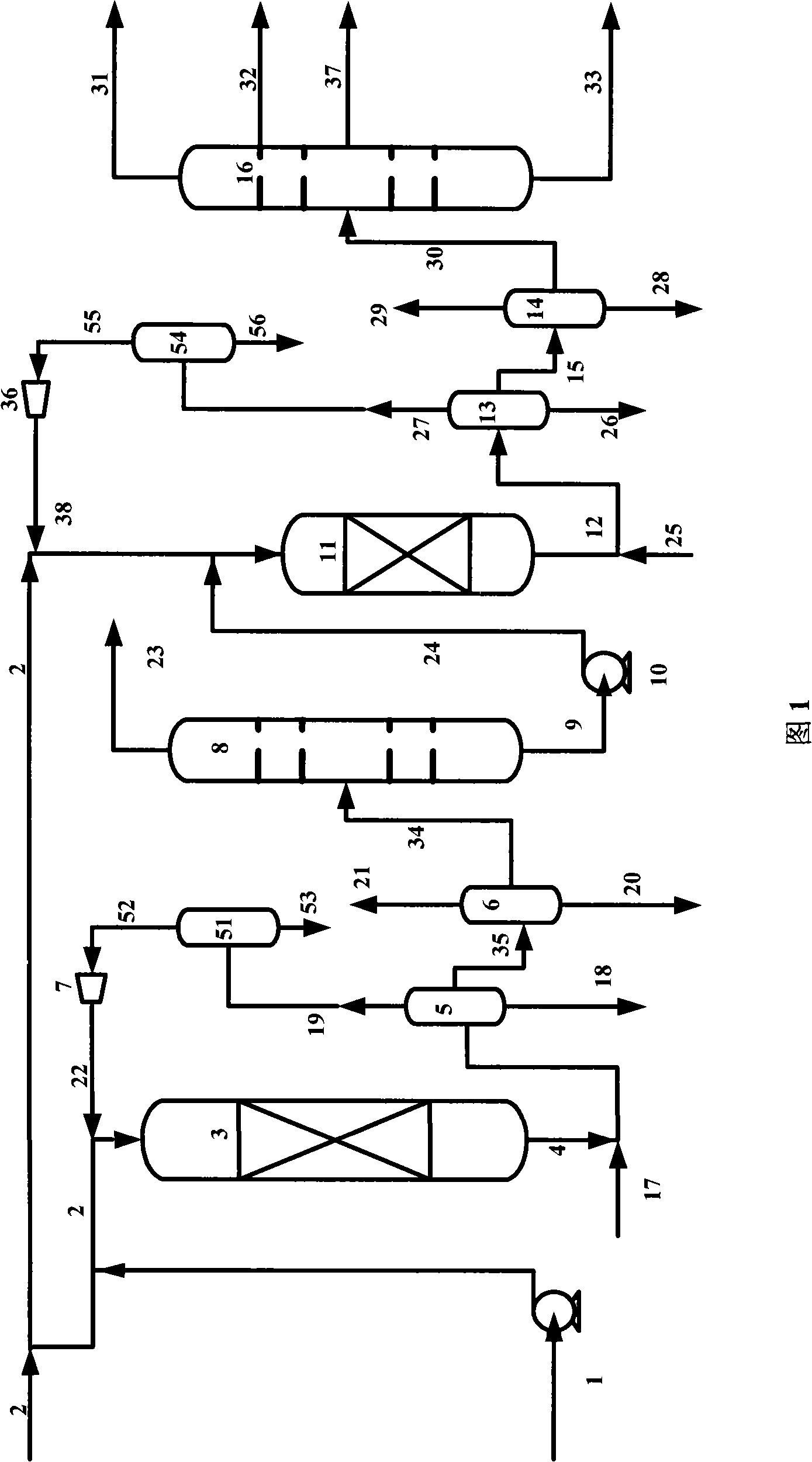

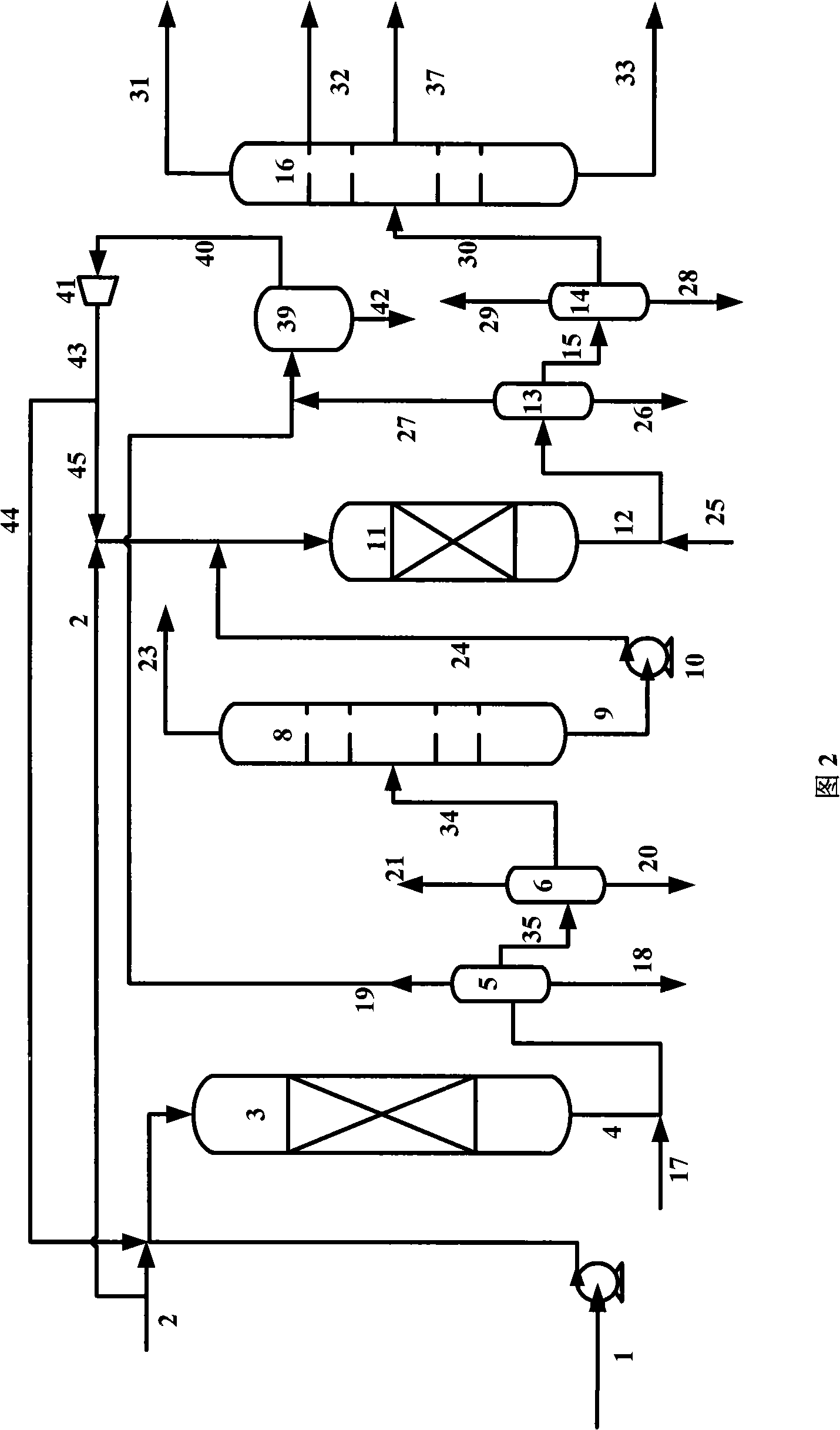

Hydrocarbons hydrocracking technique

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com