Coal tar hydrodenitrification catalyst and preparation method thereof

A hydrogenation denitrification and catalyst technology, applied in the field of coal tar, can solve the problems of strong interaction force, difficult sulfide of active components, affecting catalyst activity, etc., and achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

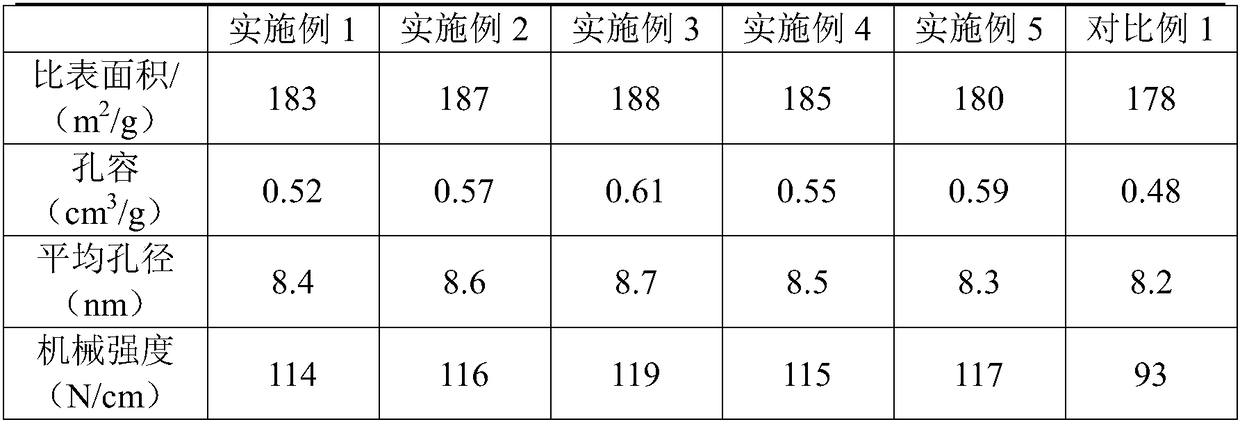

Examples

Embodiment 1

[0034] A coal tar hydrogenation denitrification catalyst, including active components, additives and carriers, the active components include the following components in parts by weight: 15 parts of tungsten trisulfide, 8 parts of nickel oxide and 4 parts of molybdenum trisulfide; The components include the following parts by weight: calculated as simple substances, 1 part of phosphorus and 4 parts of fluorine; the carrier includes the following components by weight: calculated on a dry basis of the carrier, 47 parts of alumina, 10 parts of Hβ molecular sieve, and 15 parts of titanium dioxide .

Embodiment 2

[0036] A coal tar hydrogenation denitrogenation catalyst, including active components, additives and carriers, the active components include the following components in parts by weight: 14 parts of tungsten trisulfide, 5 parts of nickel oxide and 3 parts of molybdenum trisulfide; The components include the following parts by weight: calculated as simple substances, 2 parts of phosphorus and 3 parts of fluorine; the carrier includes the following components by weight: calculated on a dry basis of the carrier, 52 parts of alumina, 5 parts of Hβ molecular sieve, and 10 parts of titanium dioxide .

Embodiment 3

[0038] A coal tar hydrogenation denitrification catalyst, including active components, additives and carriers, the active components include the following components in parts by weight: 13 parts of tungsten trisulfide, 6 parts of nickel oxide and 3 parts of molybdenum trisulfide; The components include the following parts by weight: calculated as simple substances, 1 part of phosphorus and 2 parts of fluorine; the carrier includes the following components by weight: calculated on a dry basis of the carrier, 55 parts of alumina, 6 parts of Hβ molecular sieve, and 12 parts of titanium dioxide .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com