Patents

Literature

63 results about "Ni oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite catalyst used for reforming hydrogen prodn. using methane and water vapor as raw material, preparing process and use

ActiveCN1903431AFacilitated releasePromote absorptionHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

A composite catalyst for preparing hydrogen by reforming the CO2 adsorbed and intensified methane vapor is proportionally prepared from CaO, NiO and Al2O3 as carrier. It features that the heat generated by reaction between calcium oxide and CO2 is used to promote said reforming reaction. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

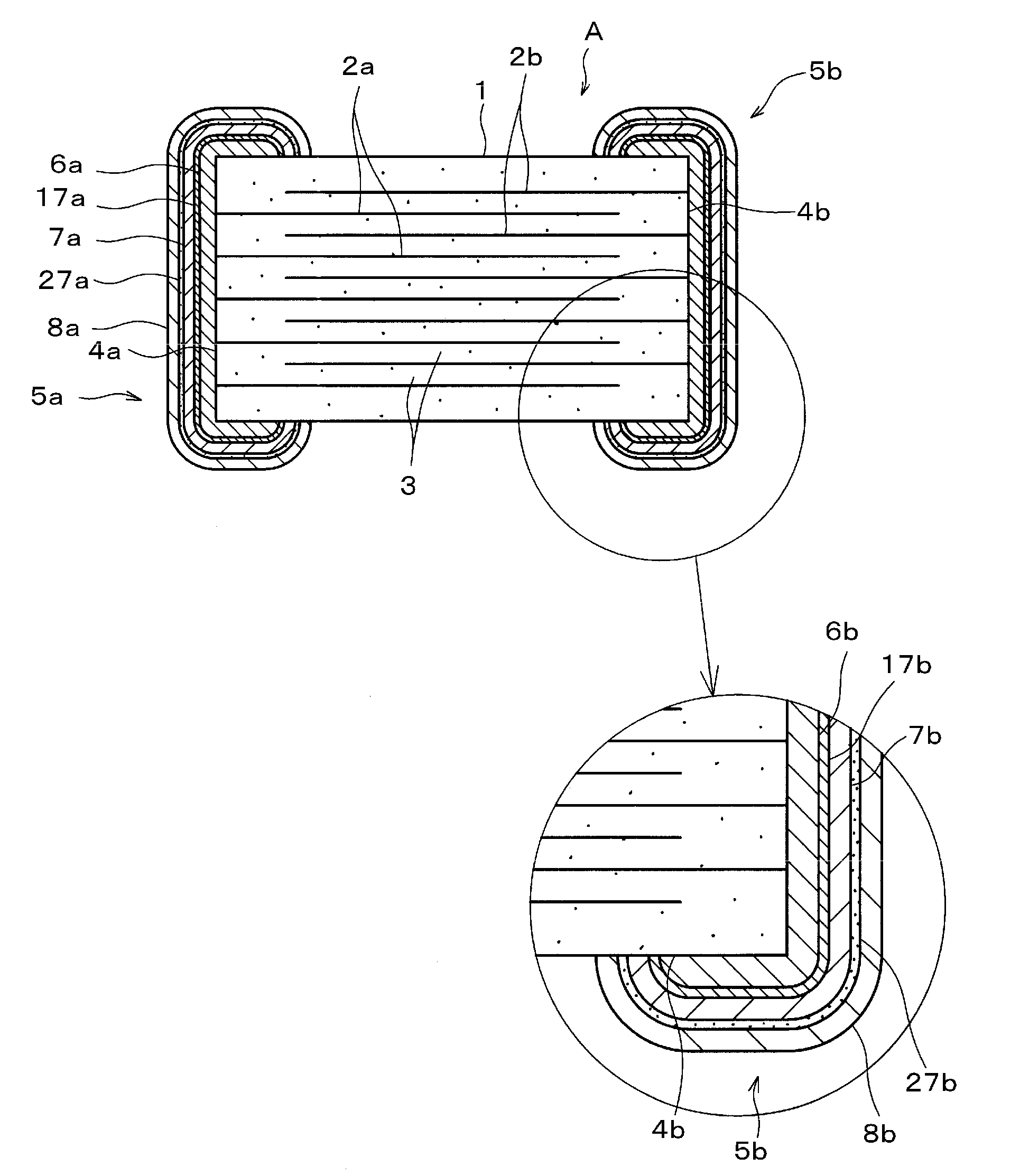

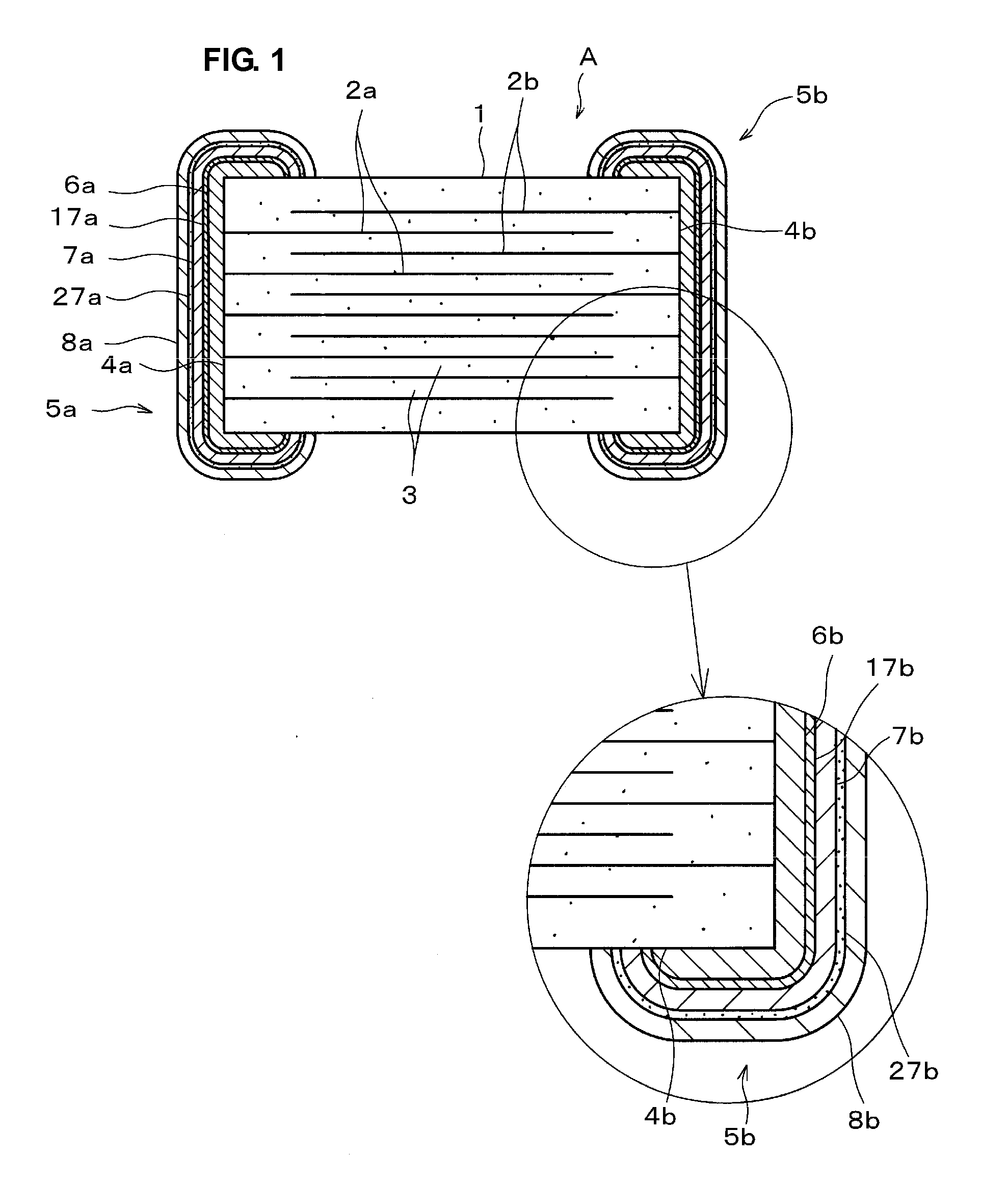

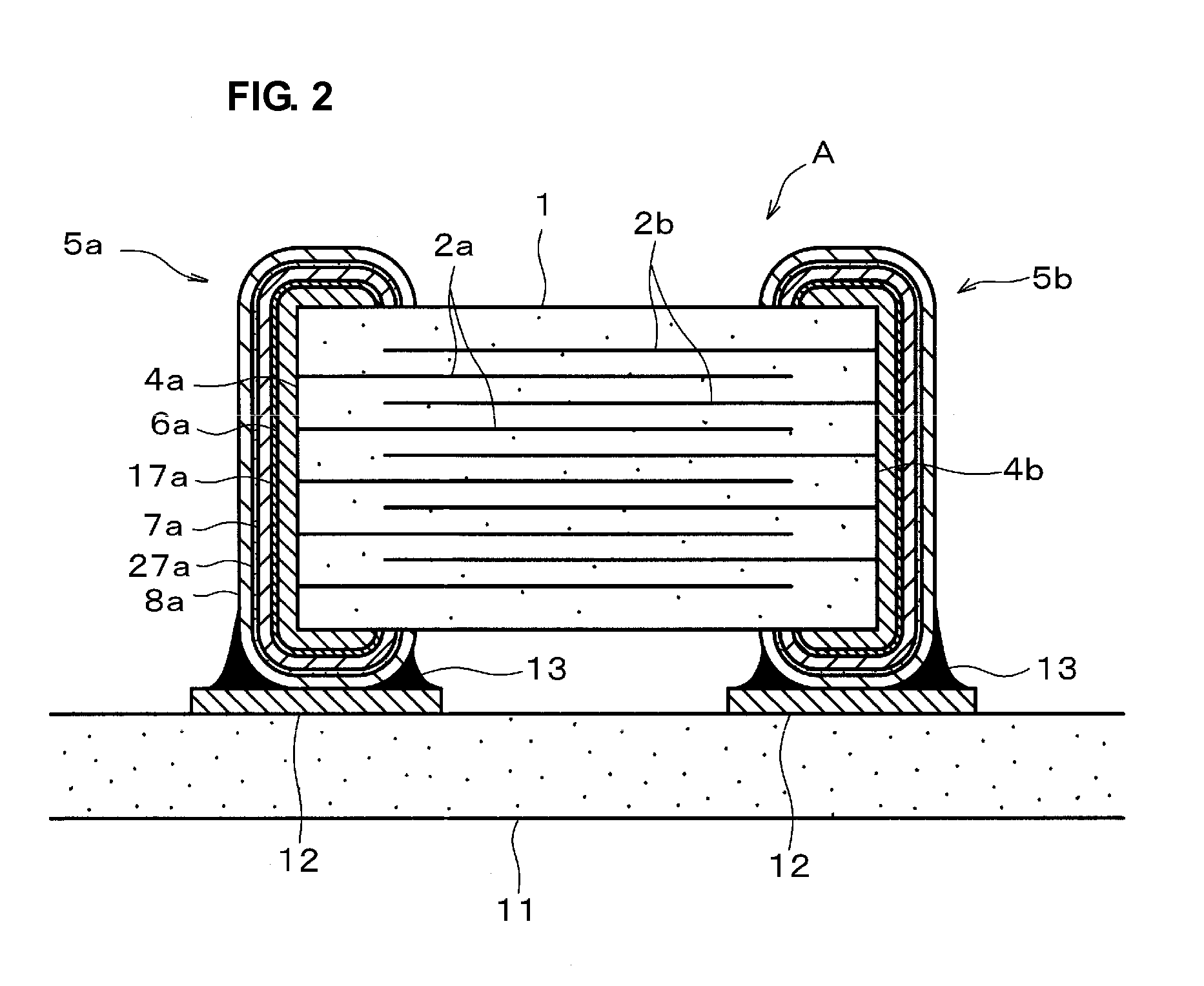

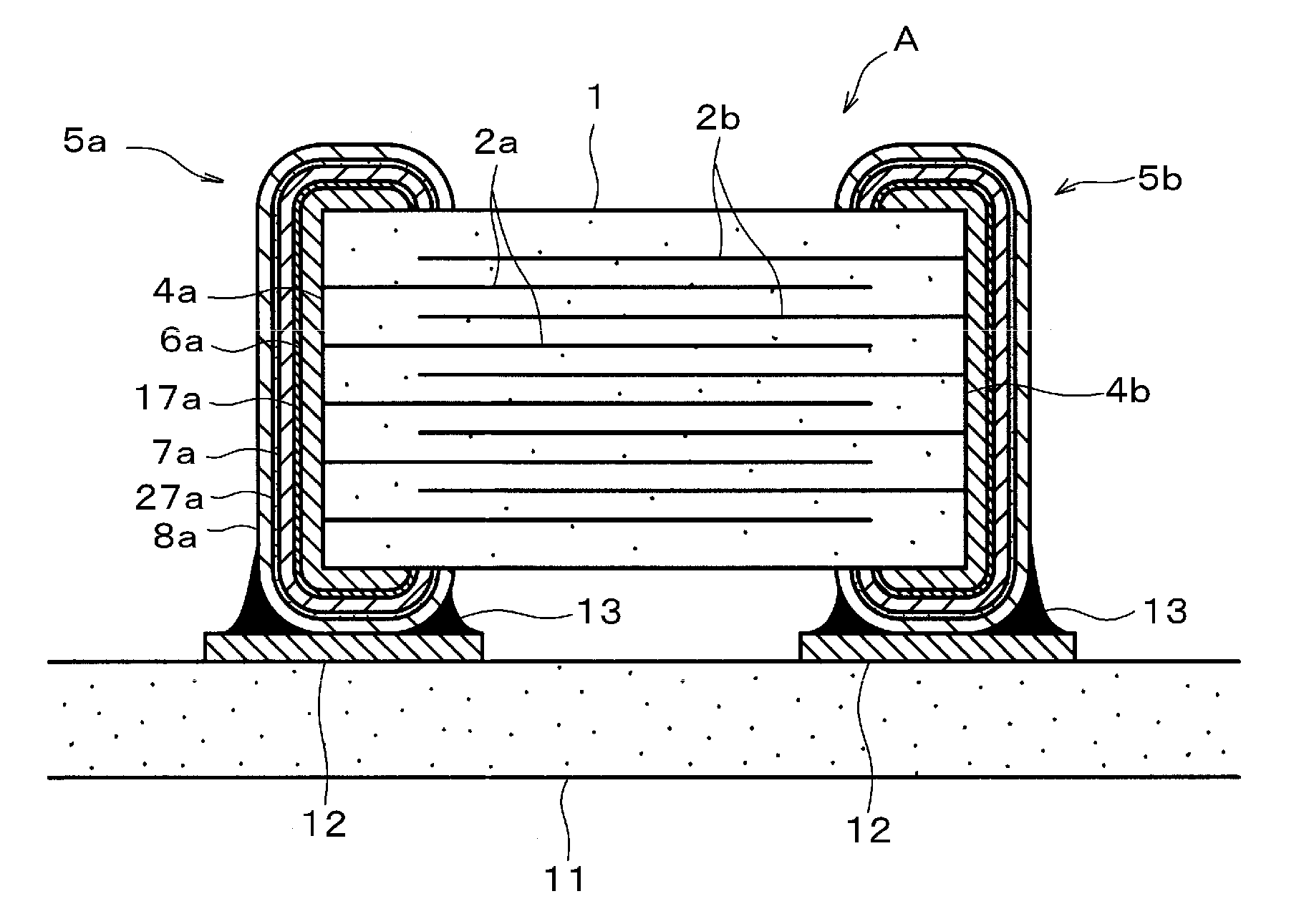

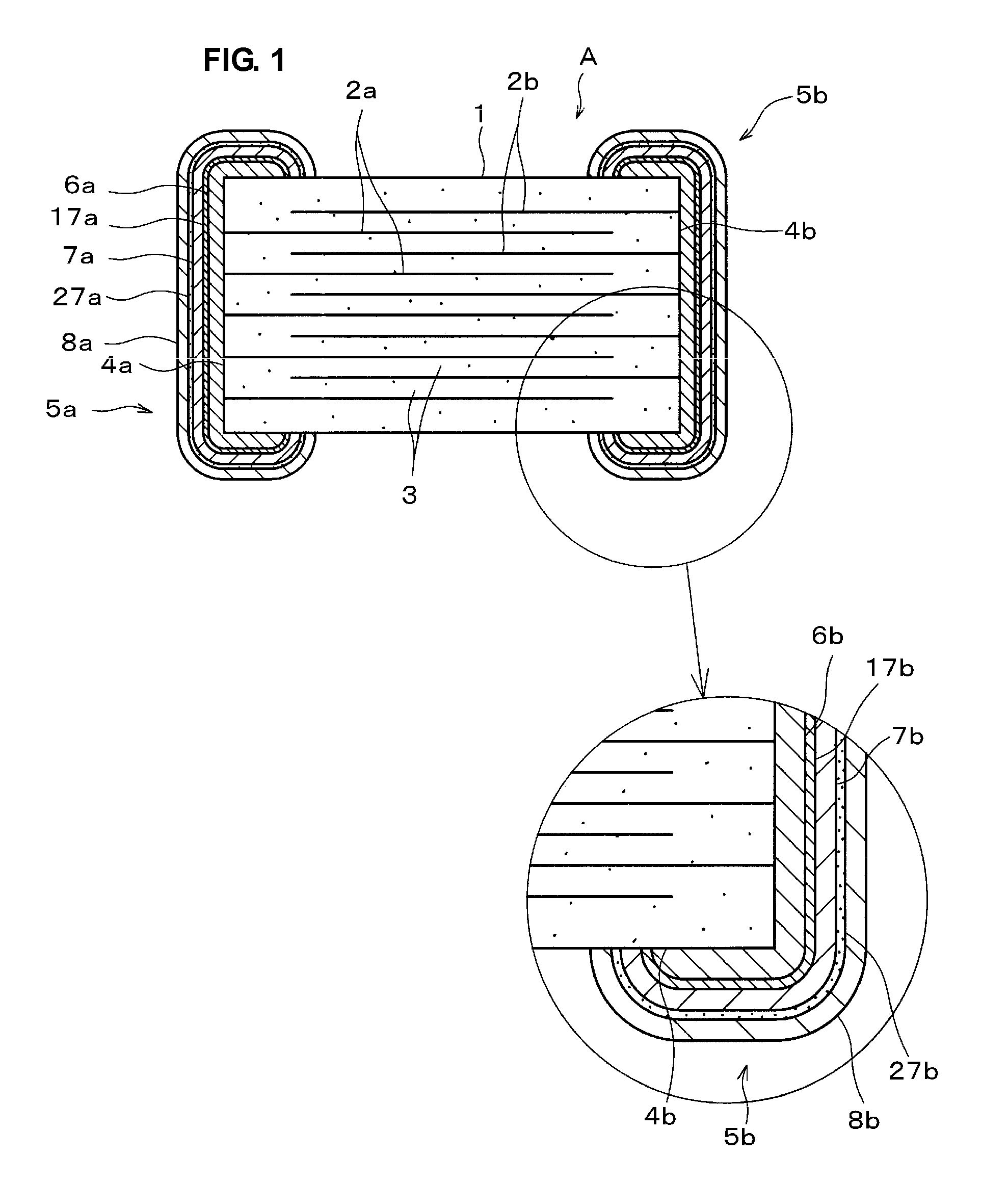

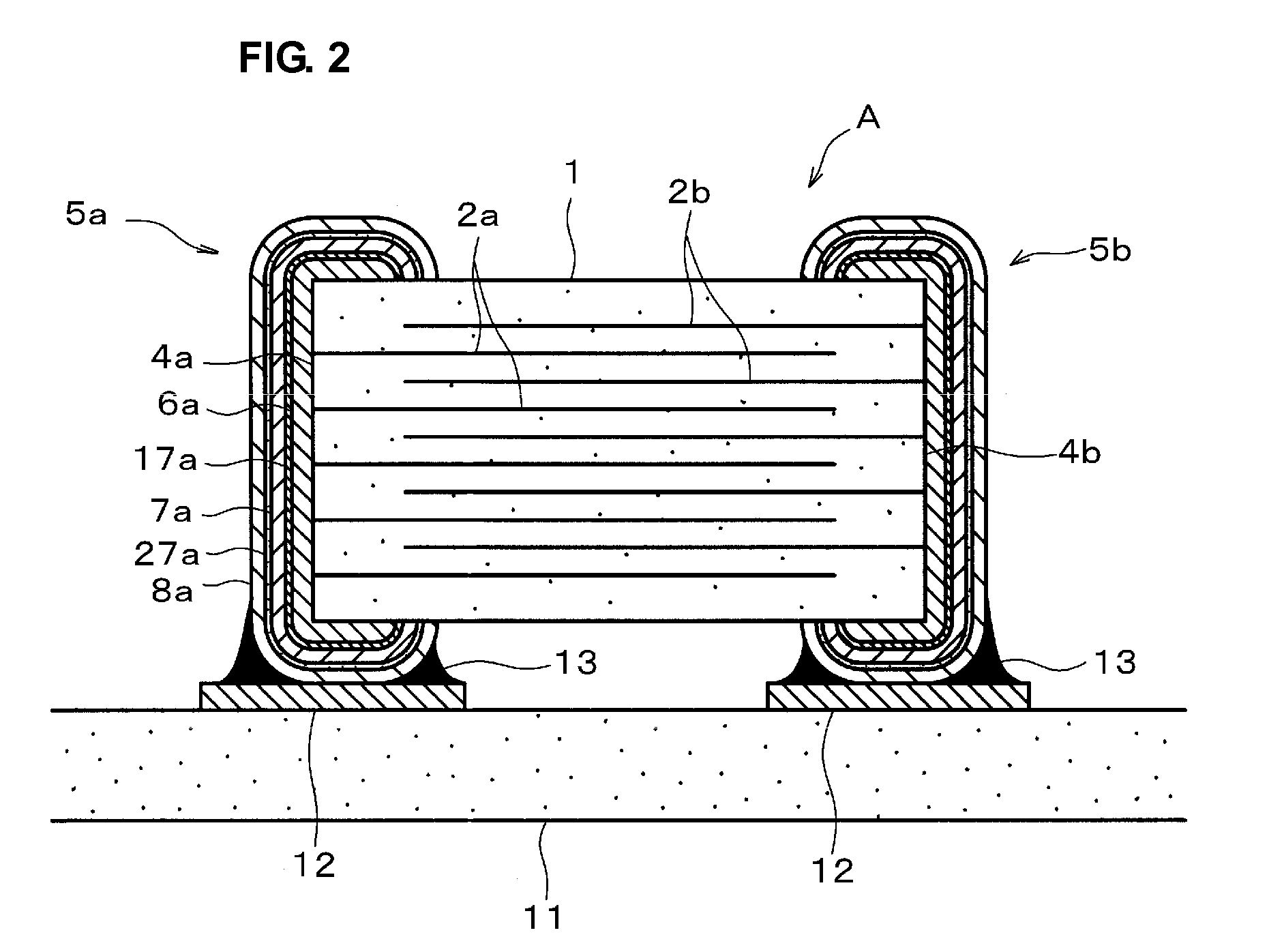

Electronic component, mounting structure of electronic component, and process for producing electronic component

ActiveUS20080118721A1Satisfactory solderabilityFixed capacitor dielectricPrinted electric component incorporationHigh humiditySolderability

Owner:MURATA MFG CO LTD

Glass ceramic coating produced on metal carrier and its producing method

InactiveCN1899997AImprove ductilityNot easy to fall offCatalyst carriersCatalyst protectionCopper oxideAluminium oxide

The present invention belongs to the field of automobile tail gas purifying technology, and is especially glass ceramic coating on metal or alloy carrier of automobile tail gas purifying treater and its preparation process. The oxides of the glass coating include silica in 25-65 wt% and boron oxide in 5.0-27 wt%, except the mixture of other 3-9 oxides selected from 17 kinds of oxides, including sodium oxide, potassium oxide, lithium oxide, aluminum oxide, calcium oxide, etc. The glass coating on the metal carrier can raise the mechanical strength and reaction activity of the catalyst effectively, and this results in saving in active component and lowered cost.

Owner:JILIN UNIV

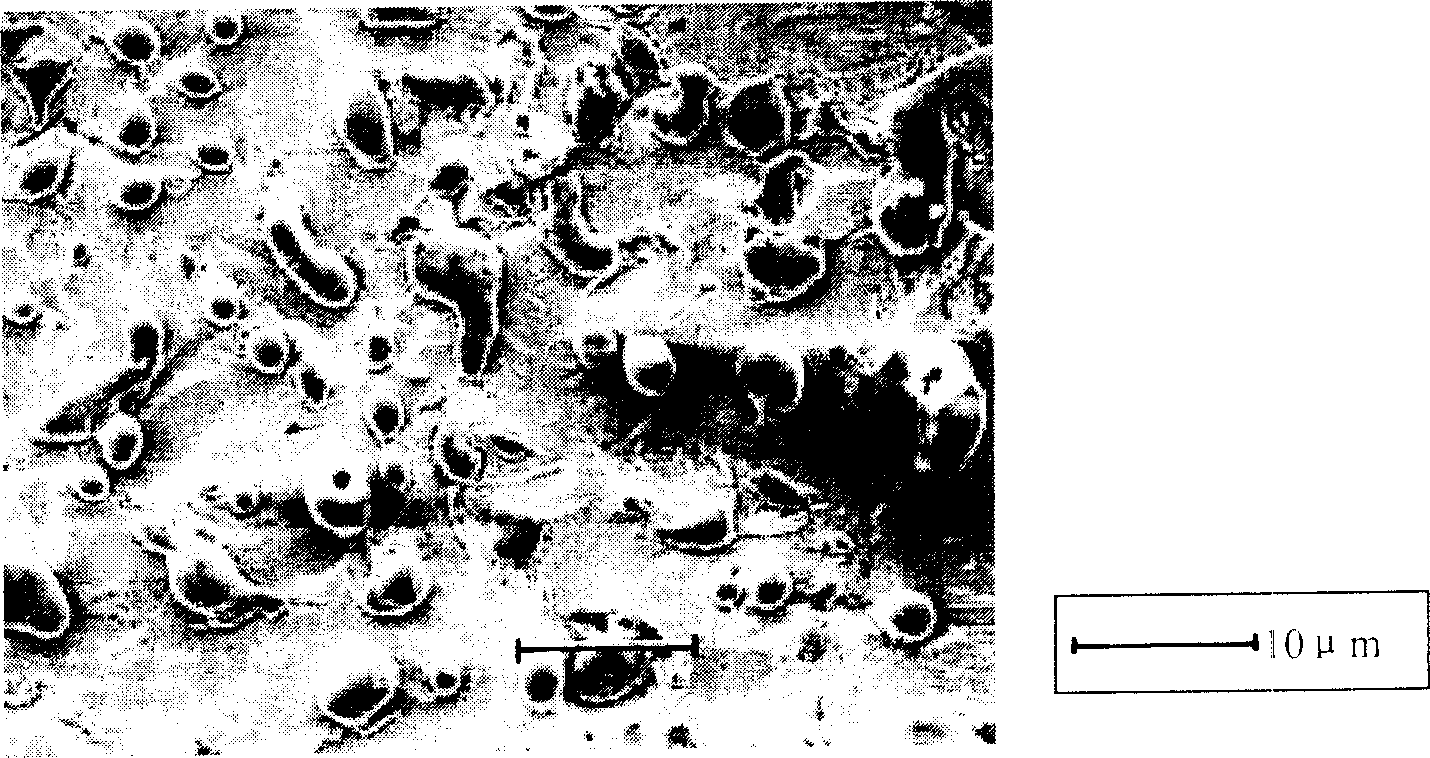

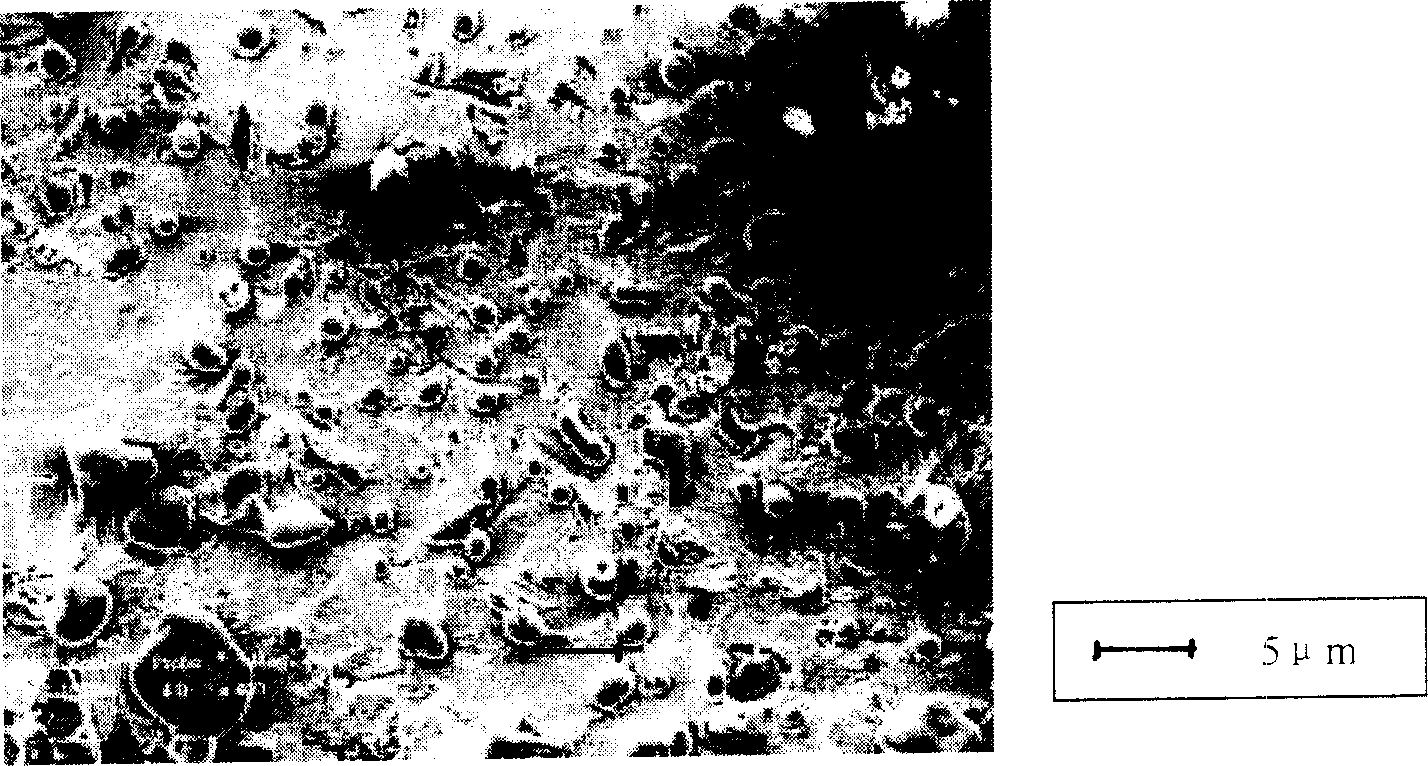

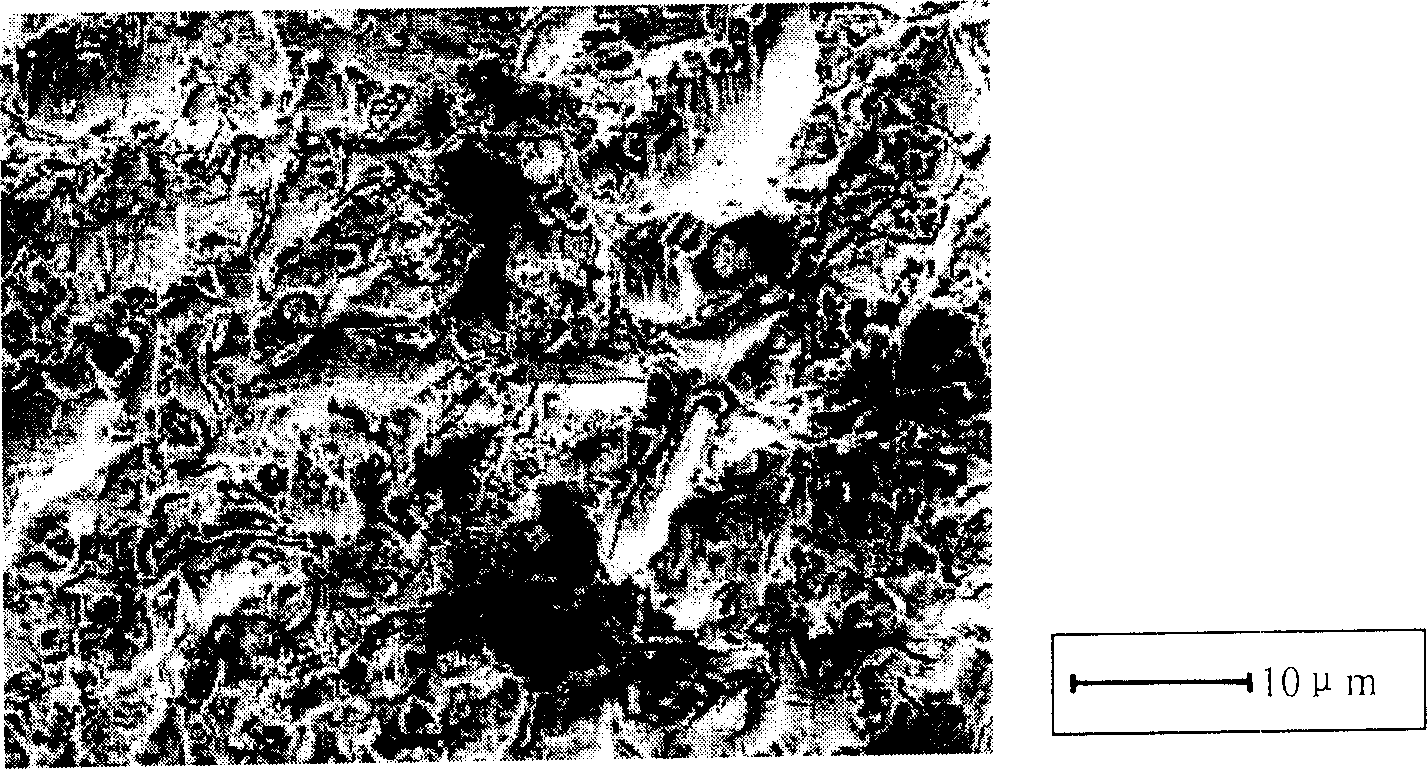

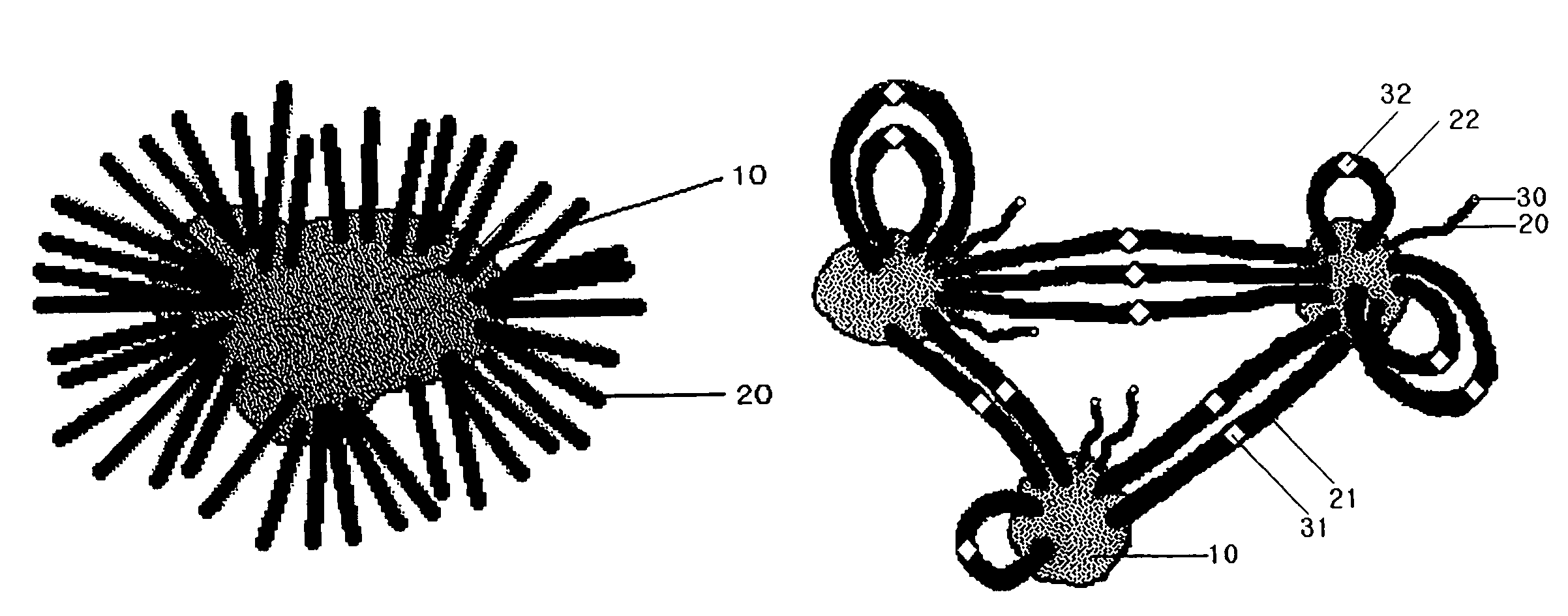

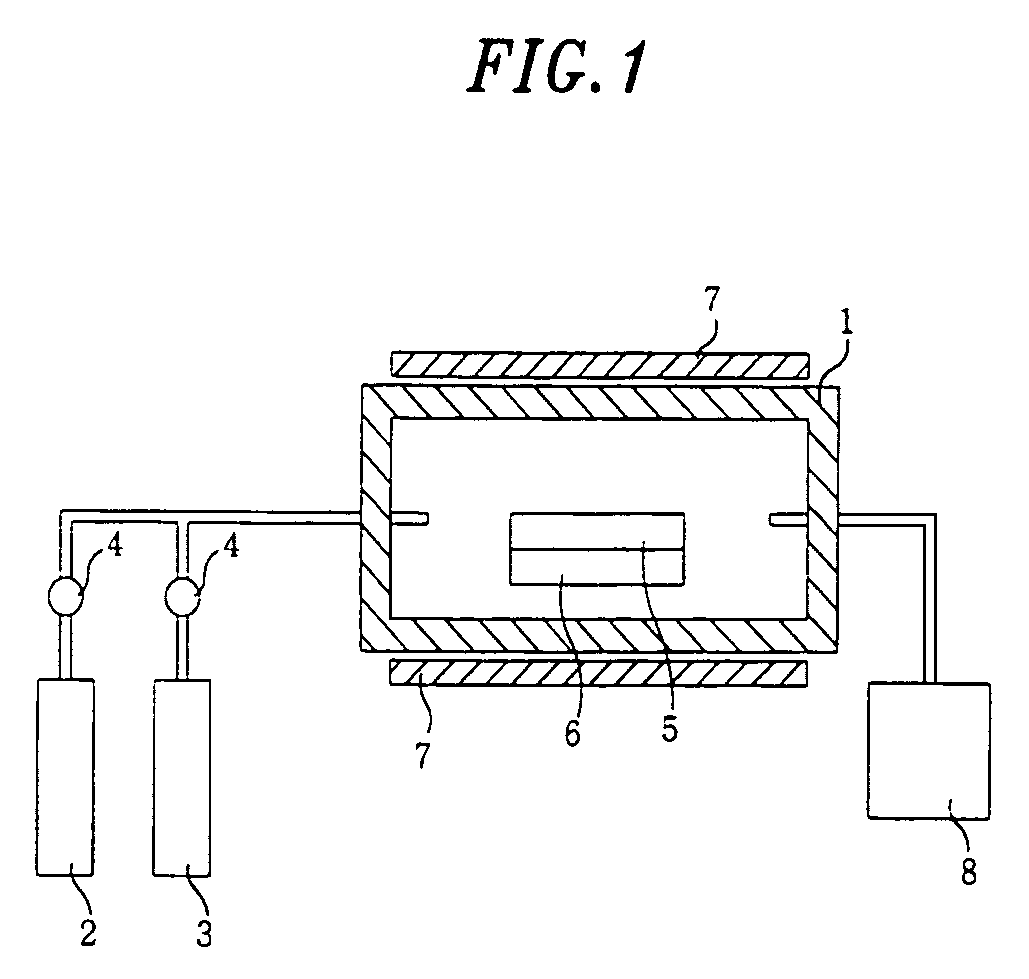

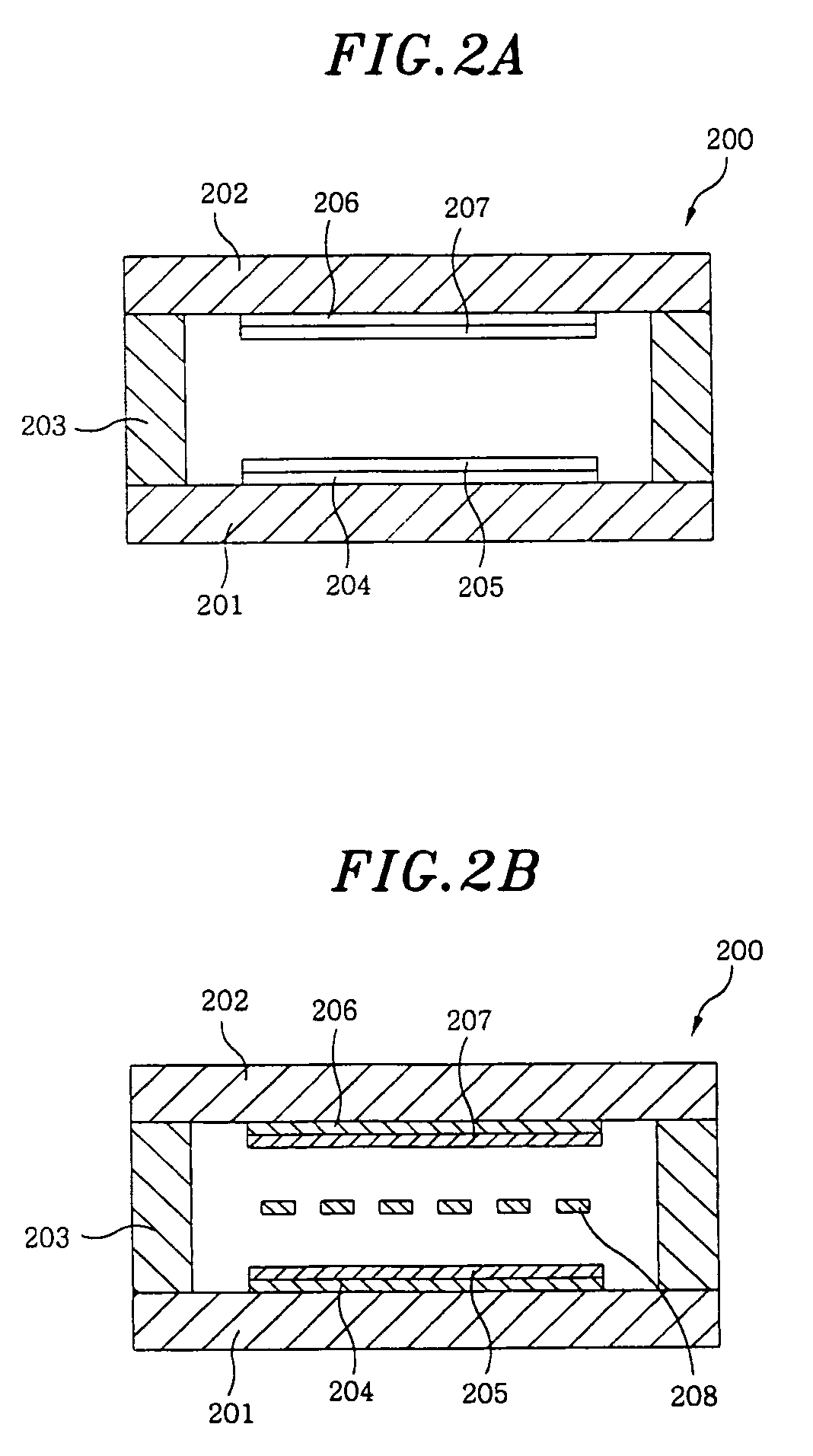

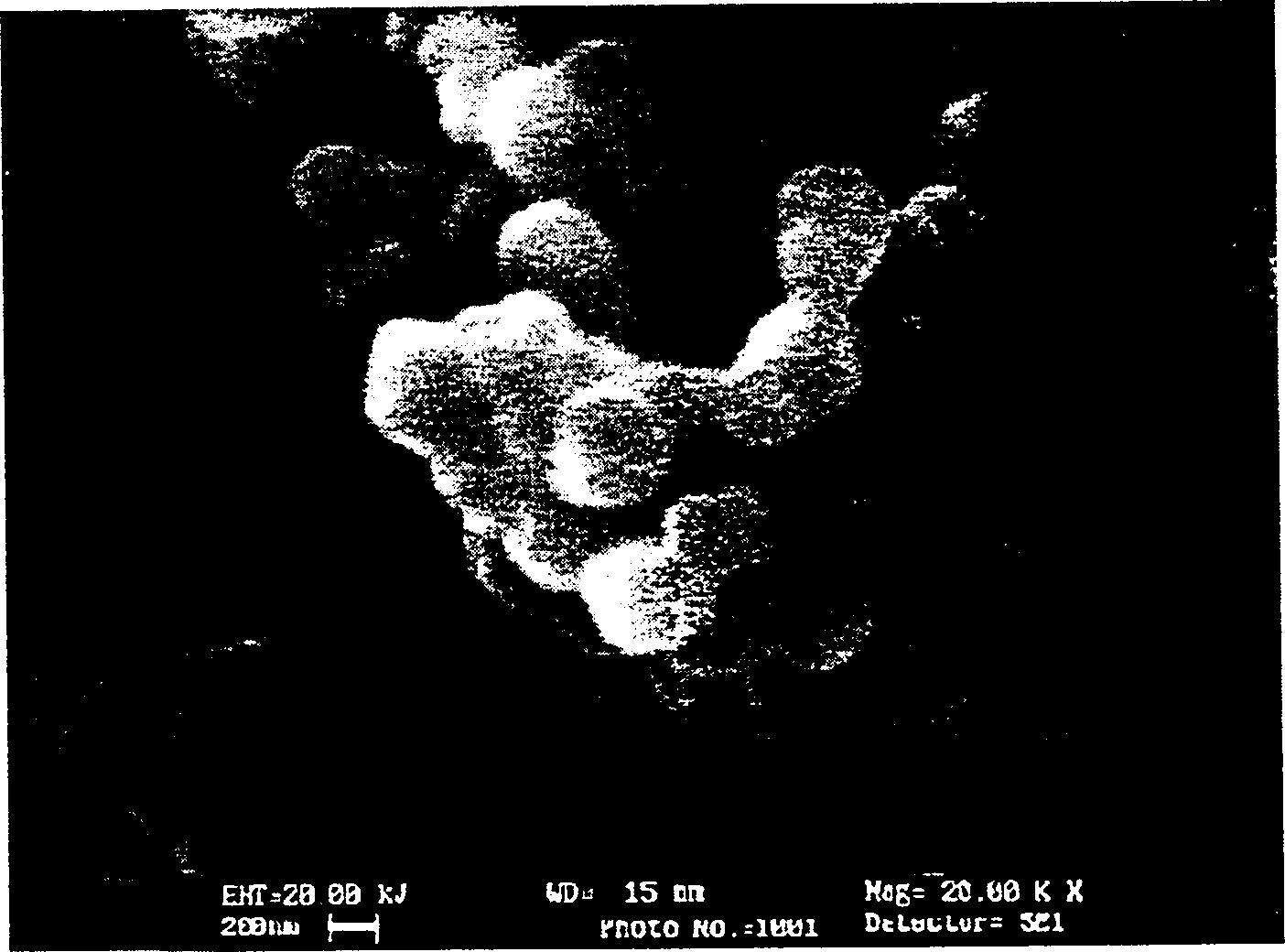

Carbon substance and method for manufacturing the same, electron emission element and composite materials

InactiveUS7239073B2Improve adhesionMaterial nanotechnologyDischarge tube luminescnet screensProduct gasElectron

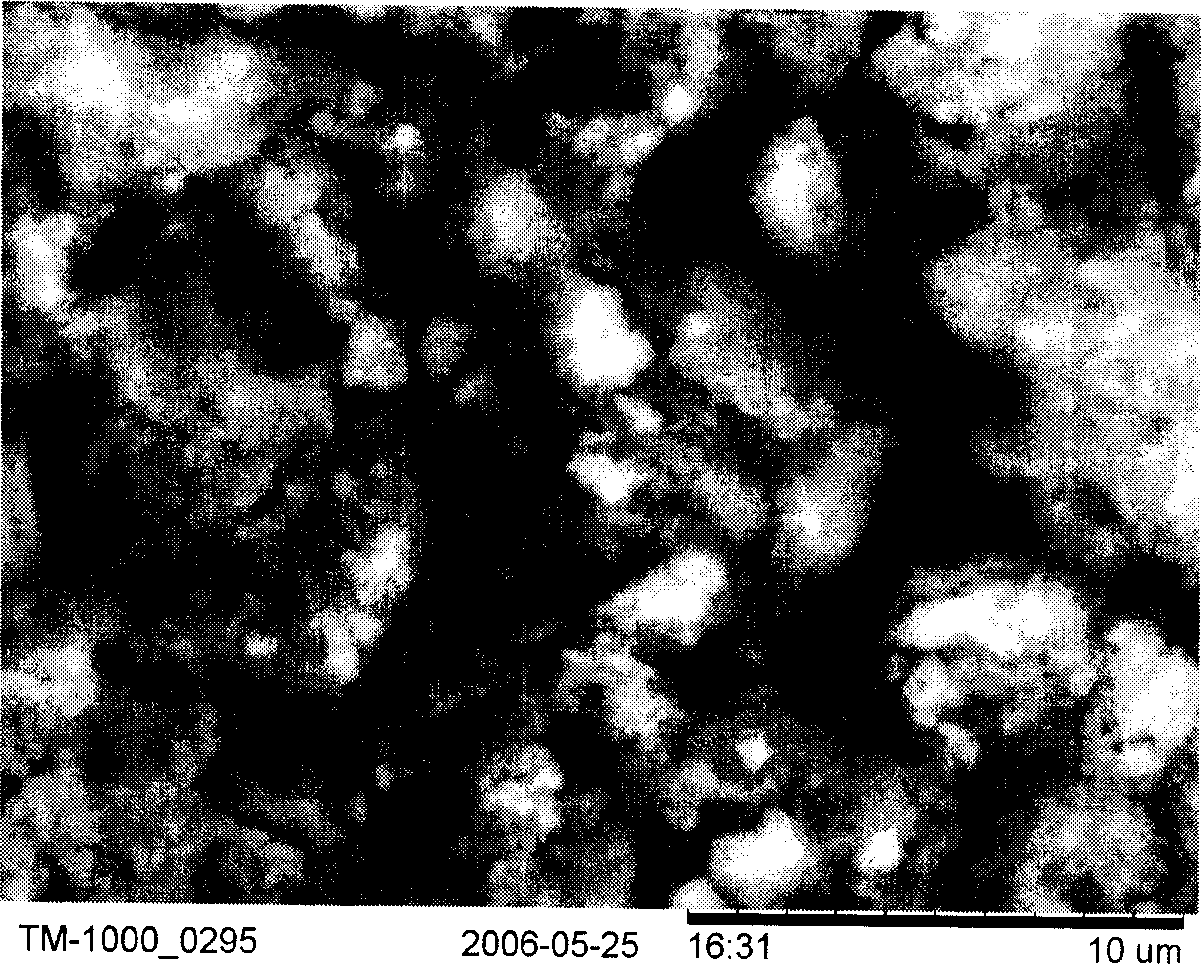

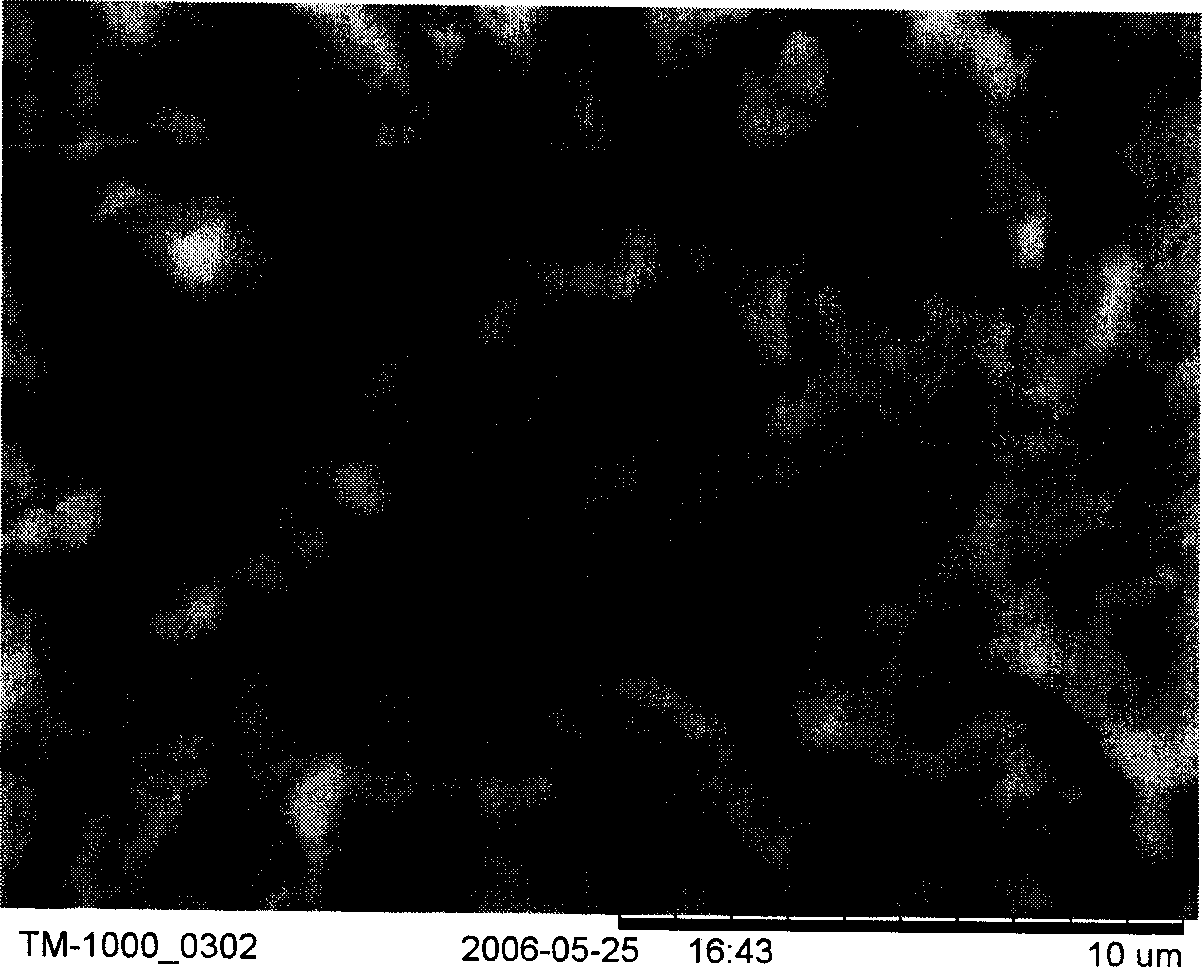

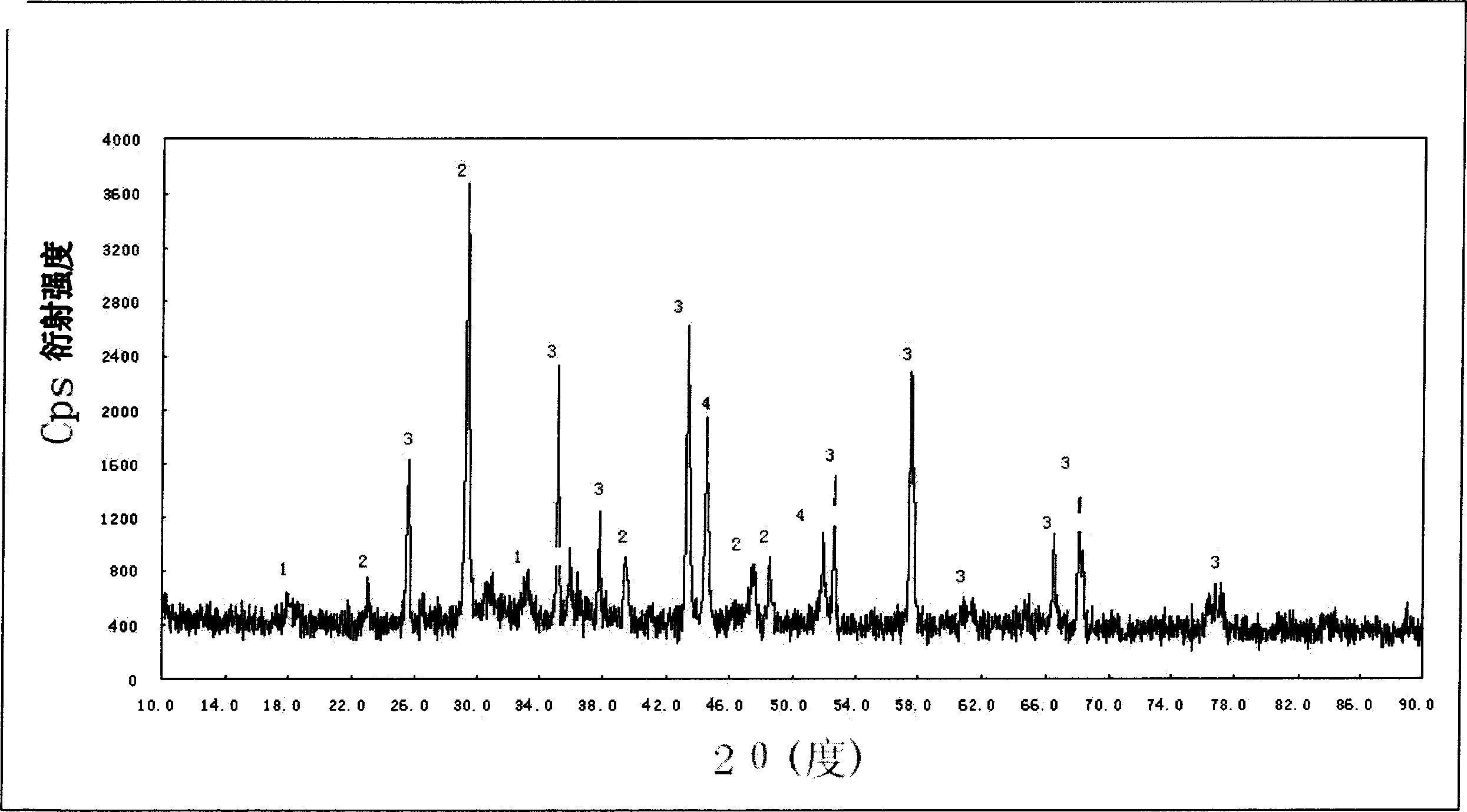

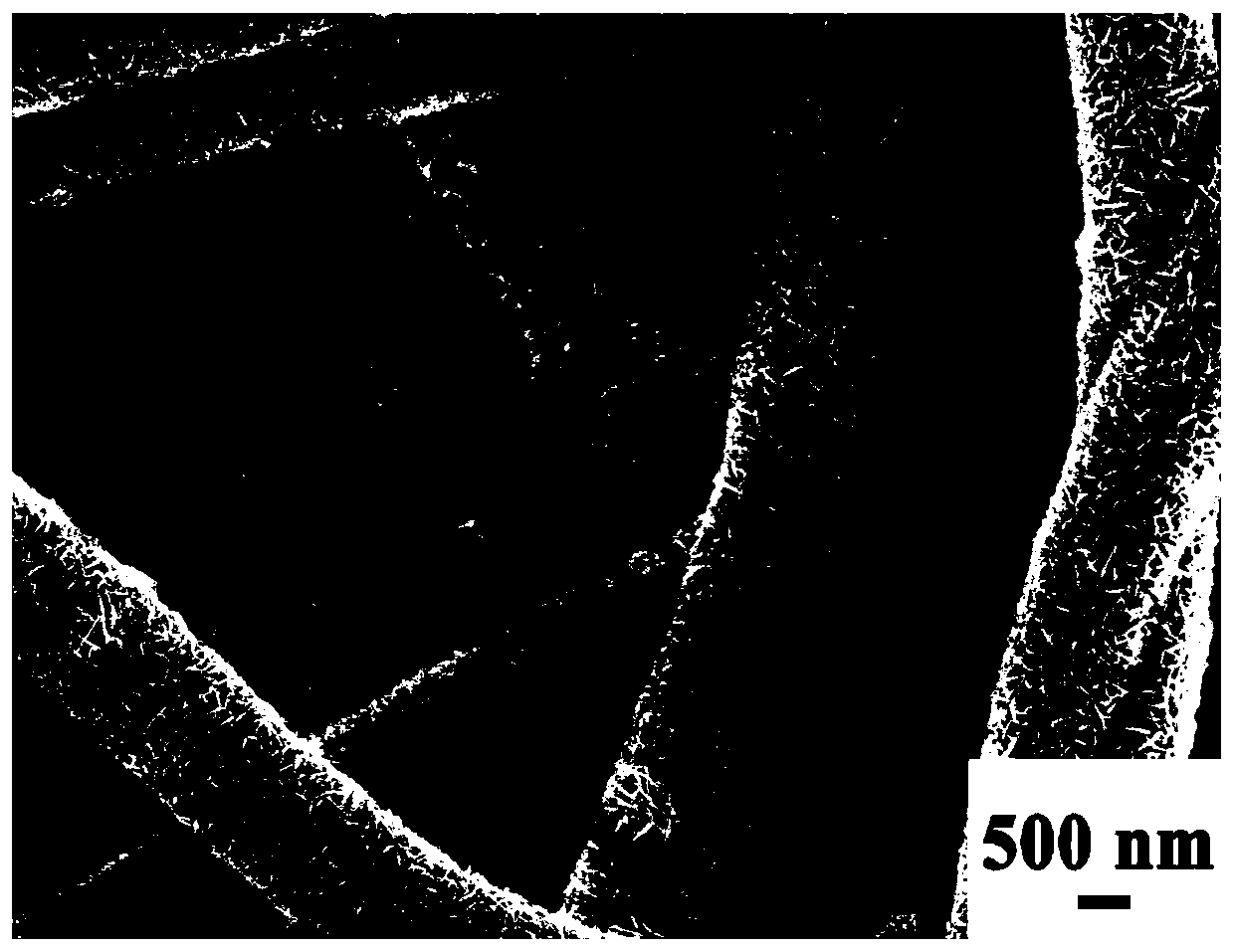

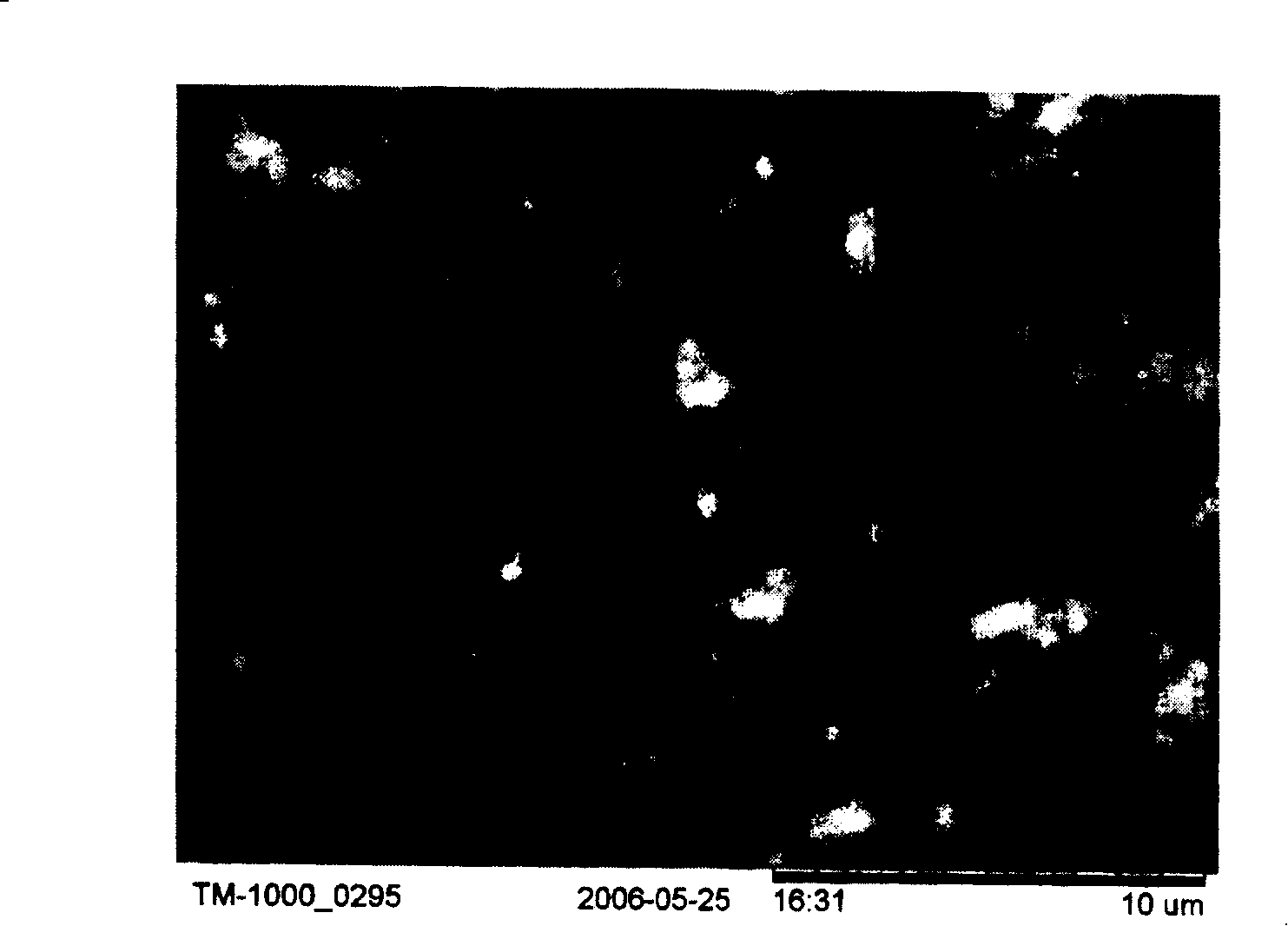

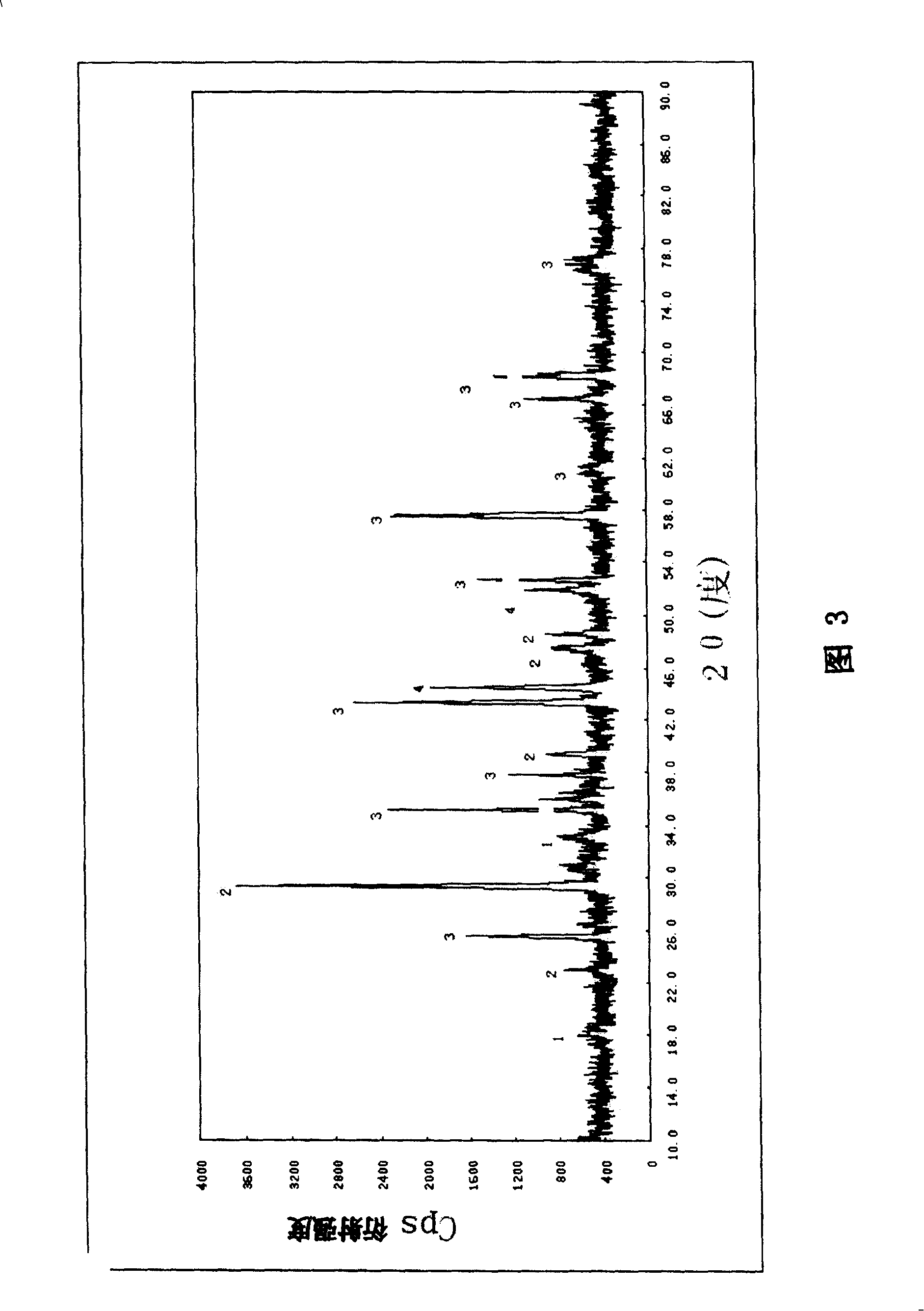

A carbon substance comprises a structure and line-shaped bodies, the structure having a size ranging from about 1 μm to about 100 μm and including carbon and a metal or a metallic oxide, and the line-shaped bodies having diameters smaller than about 200 nm and including carbon as a main component thereof and growing radially from a surface of the structure. A method for manufacturing the carbon substance uses a thermal decomposition of a source gas containing carbon in the vicinity of a catalyst, wherein the catalyst comprises a first and a second materials, the first material being Ni or a Ni oxide and the second material being In or an In oxide; and the thermal decomposition is performed at a temperature ranging from about 675° C. to about 750° C. An electron emission element uses the carbon substance as an electron emission material. A composite material includes the carbon substance in its matrix.

Owner:FUTABA CORPORATION

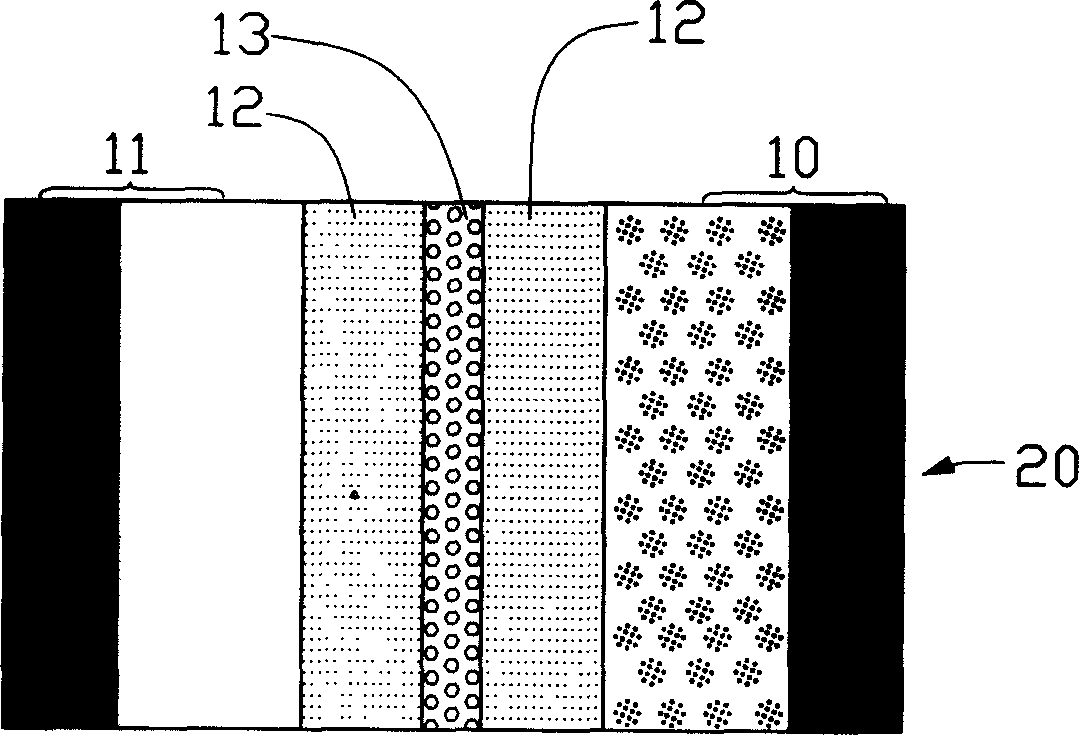

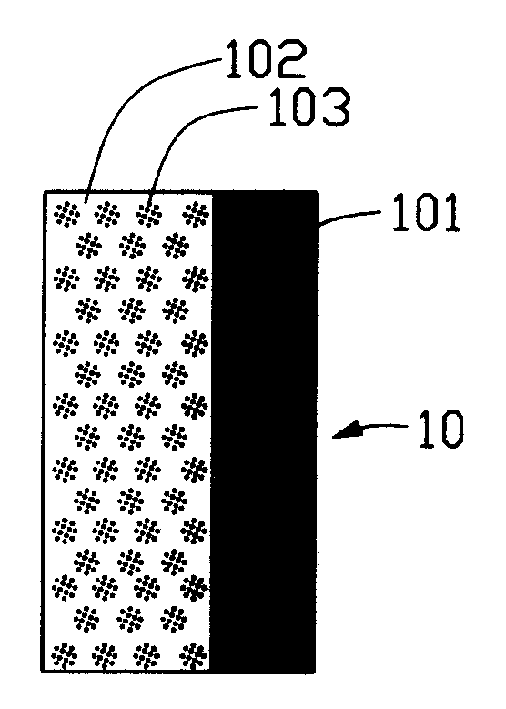

Electronic component, mounting structure of electronic component

ActiveUS7719852B2Satisfactory solderabilityFixed capacitor dielectricPrinted electric component incorporationHigh humiditySolderability

A high-reliability electronic component without reduction in insulation resistance under high-temperature and high-humidity conditions has satisfactory solderability of external electrodes. The electronic component includes a main body and external electrodes disposed on surfaces of the main body, the external electrodes include underlying electrode layers each containing a metal, alloy layers each disposed on the corresponding underlying electrode layer, Ni plating layers each disposed on the corresponding alloy layer, Ni oxide layers each disposed on the corresponding Ni plating layers, and upper plating layers each disposed on the corresponding Ni oxide layer, each Ni oxide layer having a thickness of about 150 nm or less, and each Ni plating layer having an average particle size of Ni particles of about 2 μm or more. To form the Ni plating layers having reduced grain boundaries, heat treatment is performed at about 500° C. to about 900° C. inclusive in a reducing atmosphere having an oxygen concentration of about 100 ppm or less.

Owner:MURATA MFG CO LTD

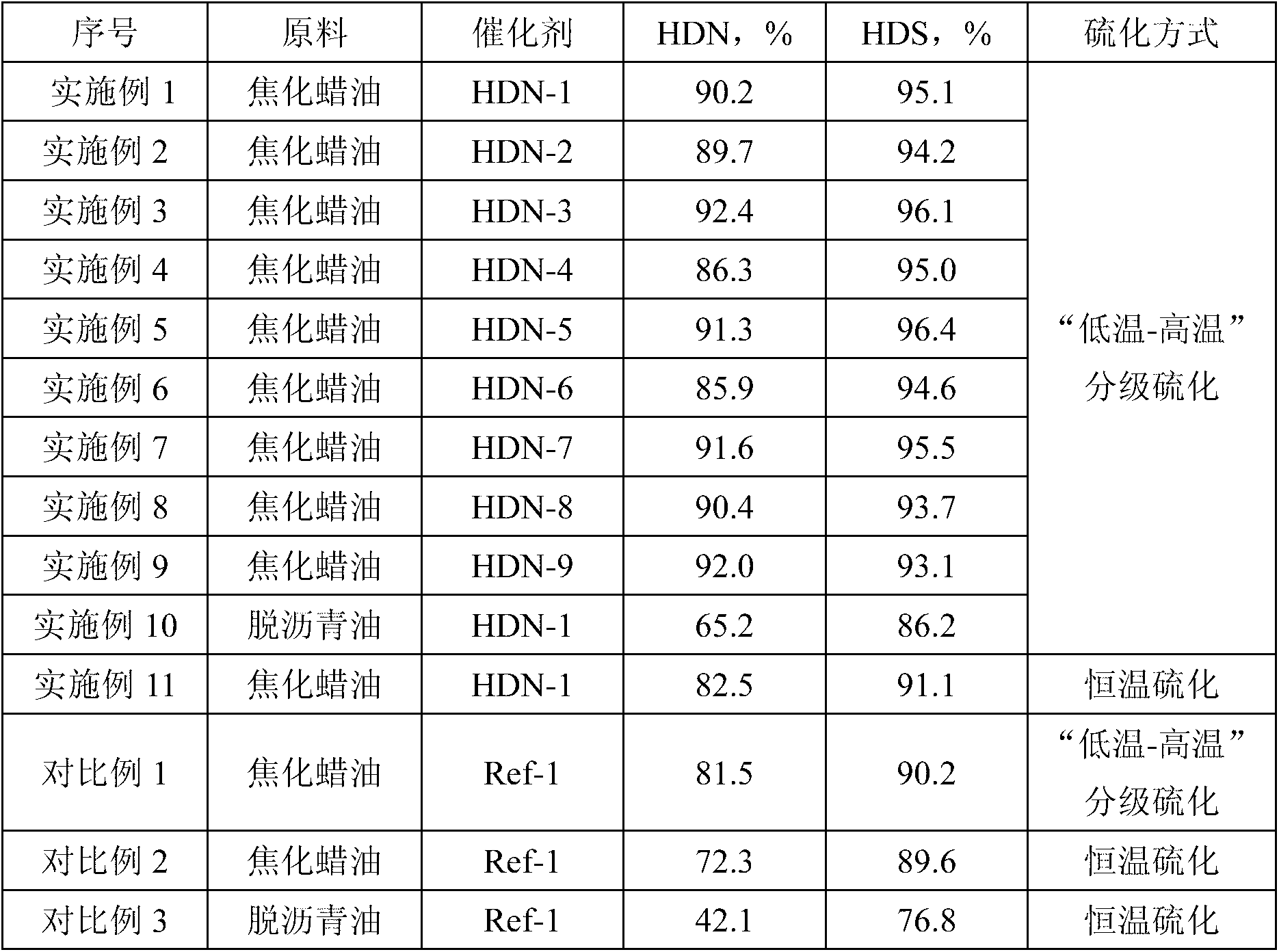

Catalyst for hydro-denitrification of inferior heavy distillate oil and preparation method and application of catalyst

ActiveCN103212432AGood dispersionImprove vulcanization effectMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveVulcanization

The invention provides a catalyst for hydro-denitrification of inferior heavy distillate oil and a preparation method and application of the catalyst. The preparation method comprises the following steps of: performing surface acid treatment on aluminum oxide and an HY molecular sieve separately; mechanically compounding the aluminum oxide subjected to the acid treatment and the HY molecular sieve subjected to the acid treatment into a carrier; dipping steeping liquid containing catalyst active components to load the catalyst active components; and drying to obtain the catalyst for hydro-denitrification of heavy distillate oil. In the carrier, the content of the HY molecular sieve subjected to the acid treatment is 5 to 20 percent, the active components comprise Mo and / or W, and Co and / or Ni, the steeping liquid also comprises a complexing agent, the Mo and / or W oxide content of the catalyst is 10 to 30 percent, and the Co and / or Ni oxide content of the catalyst is 1 to 10 percent. The catalyst has the characteristics of reasonable acidic distribution, a large number of active metal stacking piles and complete metal vulcanization, has a high hydro-denitrification activity to the inferior heavy distillate oil, and has high hydro-desulfurization performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

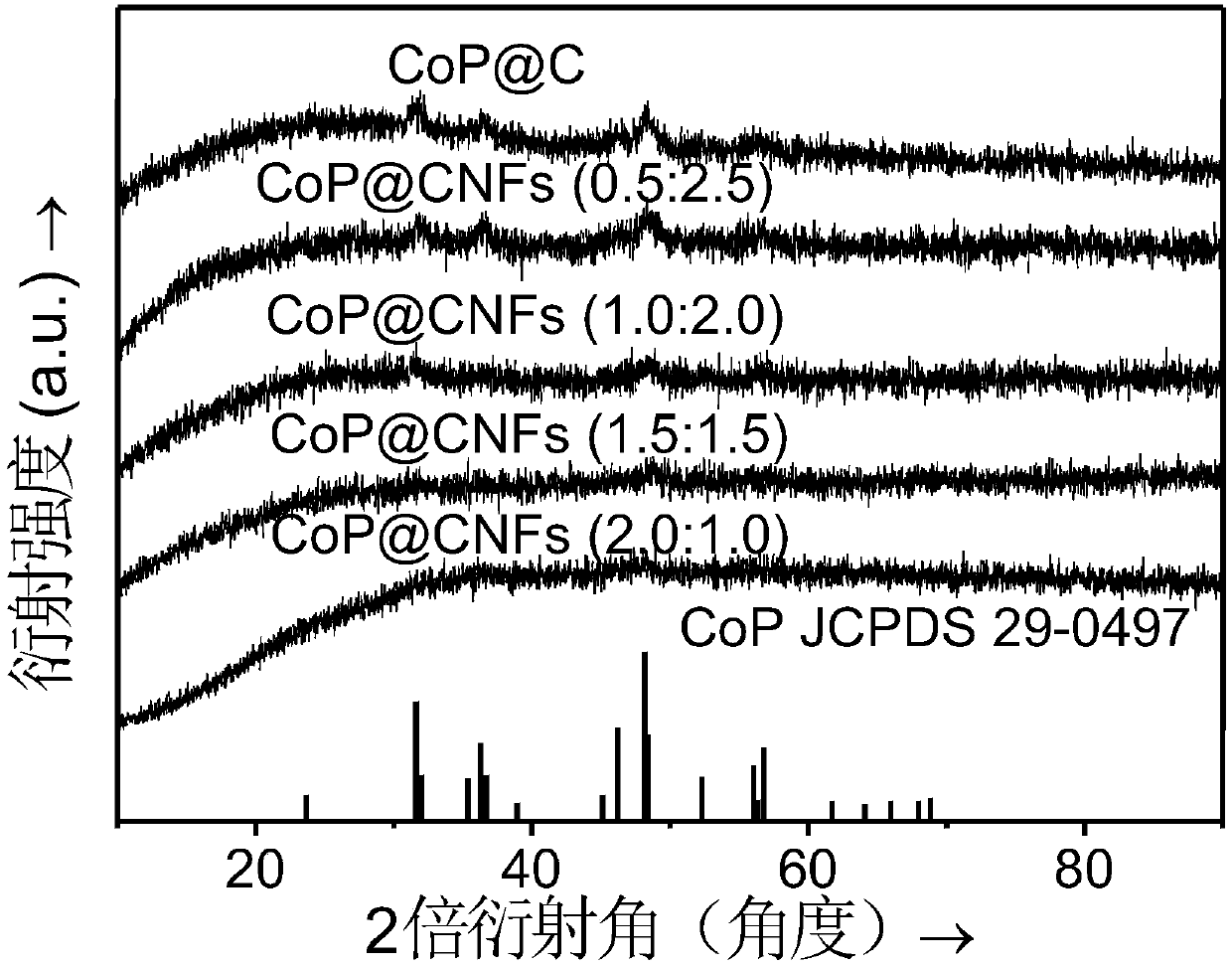

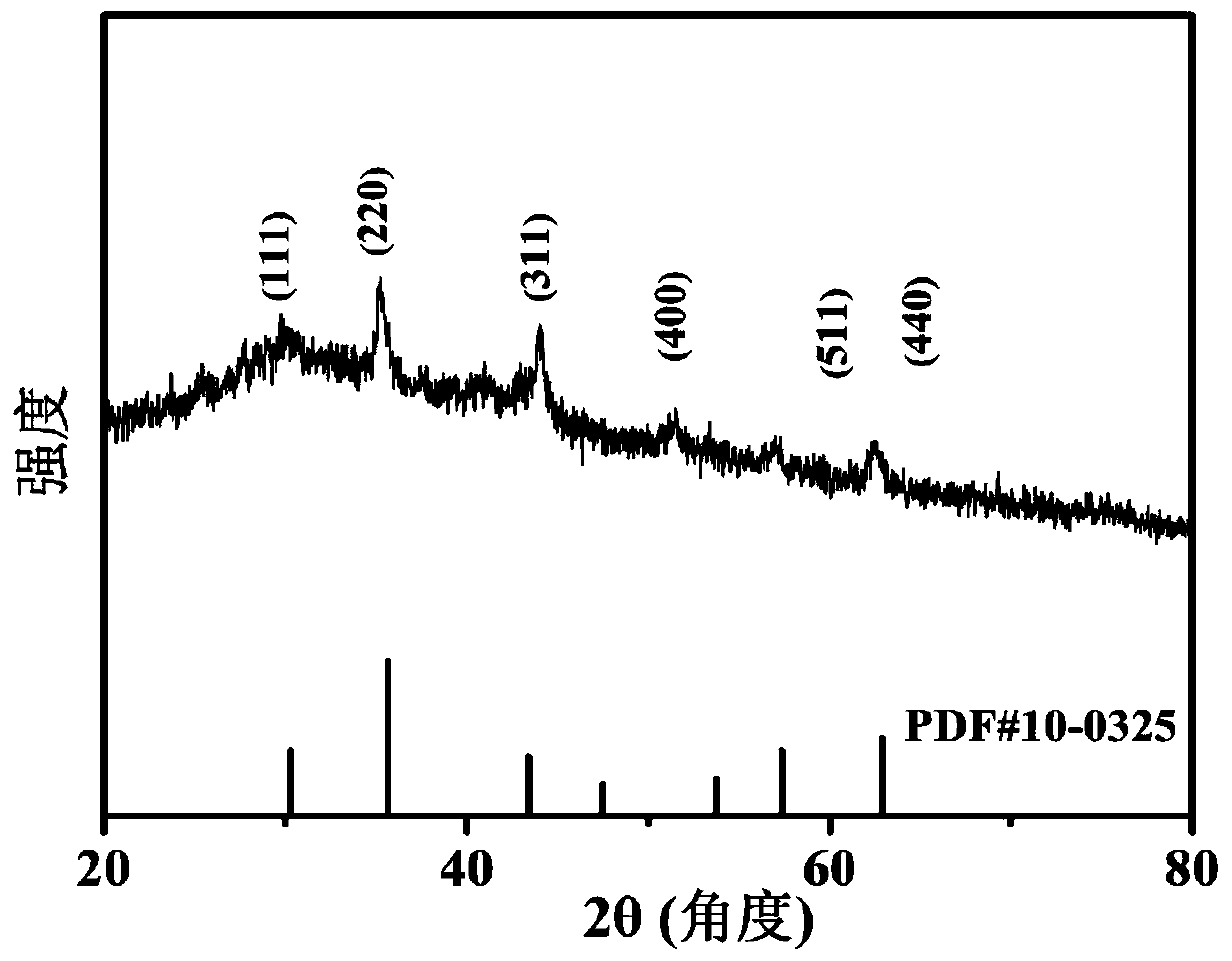

Metal phosphide-porous carbon framework composite material, and preparation method and application thereof

ActiveCN107744822ASmall particle sizeLarge specific surface areaCatalyst activation/preparationHydrogen productionPorous carbonMetal-organic framework

The invention discloses a preparation method of a metal phosphide-porous carbon framework composite material. The method comprises the following steps: calcining a bimetallic metal organic framework material to obtain a porous carbon framework material, respectively placing the porous carbon framework material and a phosphorus source in two ends of a tubular furnace, introducing an inert gas, heating the tubular furnace to a certain temperature, carrying out a phosphating reaction, and washing the obtained reaction product with an acid to obtain the metal phosphide-porous carbon framework composite material. The invention also discloses the metal phosphide-porous carbon framework composite material and an application thereof. The metal phosphide-porous carbon framework composite material prepared through the preparation method has the advantages of large specific surface area, small particle size of metal phosphide, and excellent catalytic hydrogen desorption performance. The porous metal phosphide with a large specific surface area is obtained by using a bimetallic metal organic framework as a self-template through a selective phosphating technology capable of phosphating Co3O4 ornickel oxide but incapable of phosphating zinc oxide under the same conditions; and the preparation method has the advantages of simplicity, novelty and low cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Lithium secondary battery anode and lithium secondary battery using the same

InactiveCN1571198AExtended service lifeReduce manufacturing costElectrode carriers/collectorsSecondary cellsSilica gelLithium electrode

The invention relates to a lithium secondary battery anode, including active anode material and water absorbent scattered in the active anode material. The active anode material includes Li-Mn oxide, Li-Ni oxide, Li-Co oxide, and other compound oxides of Li and transition metal; the water absorbent includes lithiated molecular sieve, activated carbon, active aluminum oxide, silica gel, calcium oxide, calcium sulfate, etc, and has strong water absorptivity with dew point lower than -56deg.C. The water absorbent can completely absorb residual water in lithium secondary battery manufacturing procedure and osmotic water due to air permeability of water molecules as use, preventing the poisoning of lithium ion battery, thus prolonging the service life of lithium secondary battery. The invention also relates to a lithium secondary battery using this anode.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

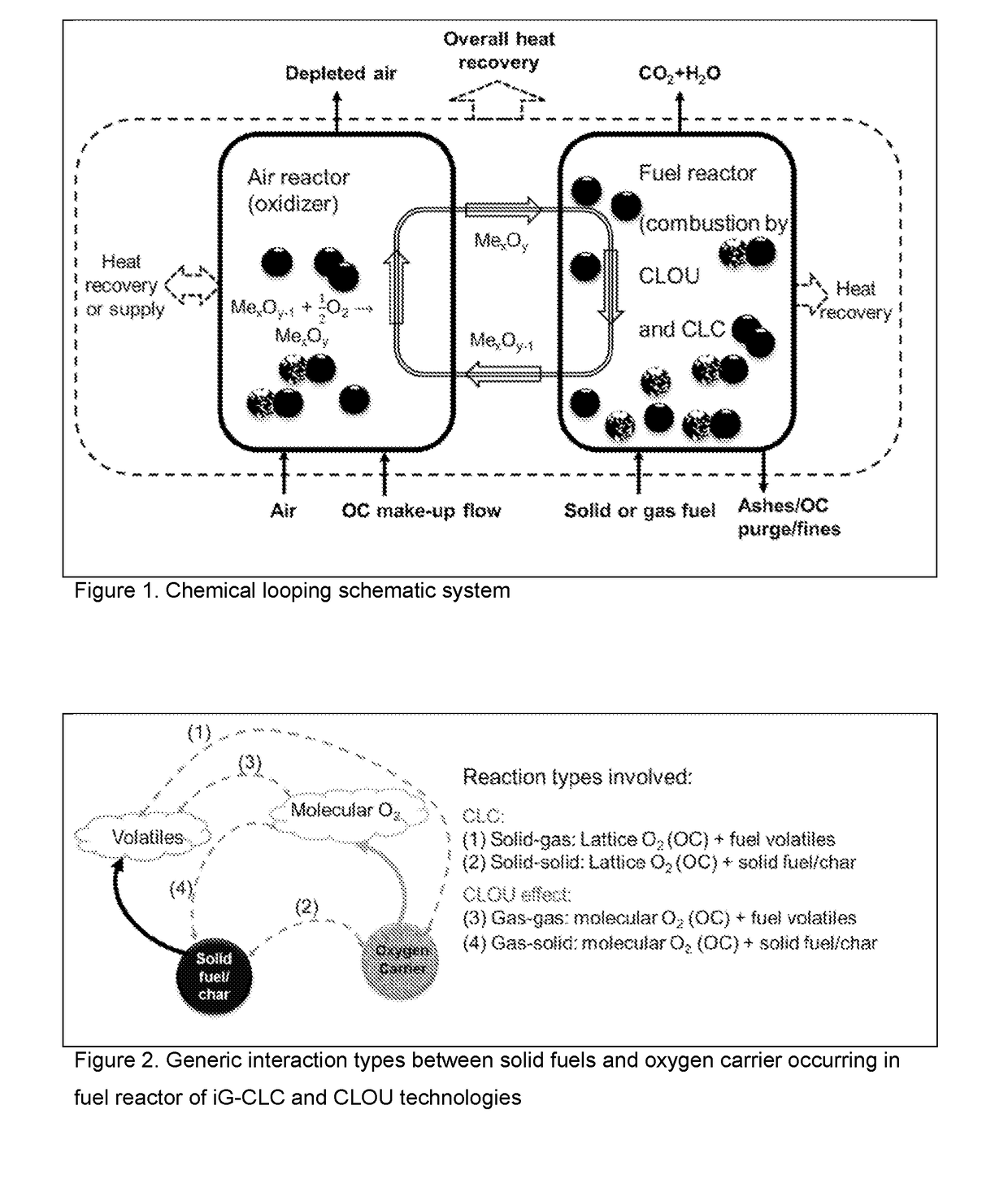

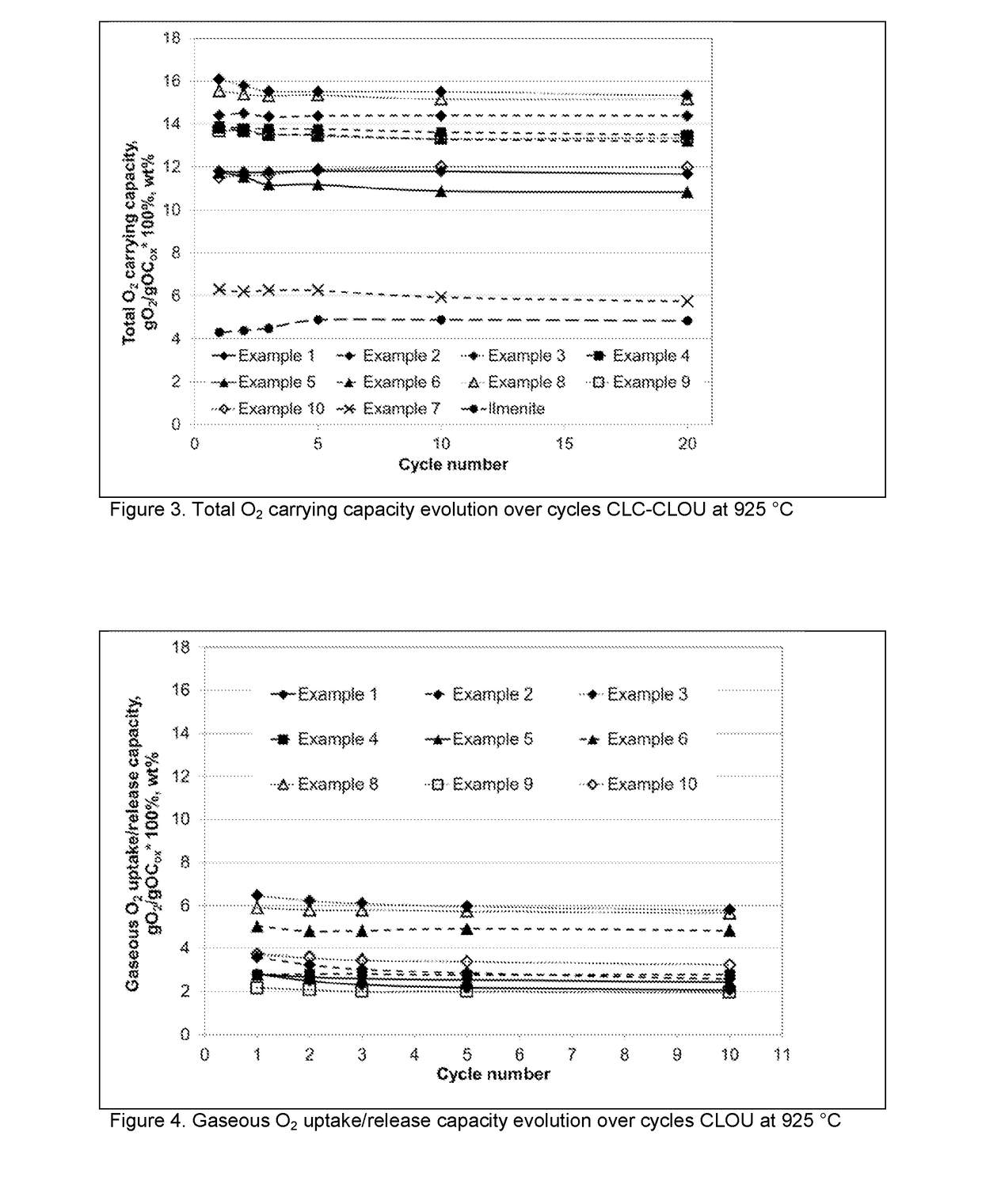

Sustainable Oxygen Carriers for Chemical Looping Combustion with Oxygen Uncoupling and Methods for Their Manufacture

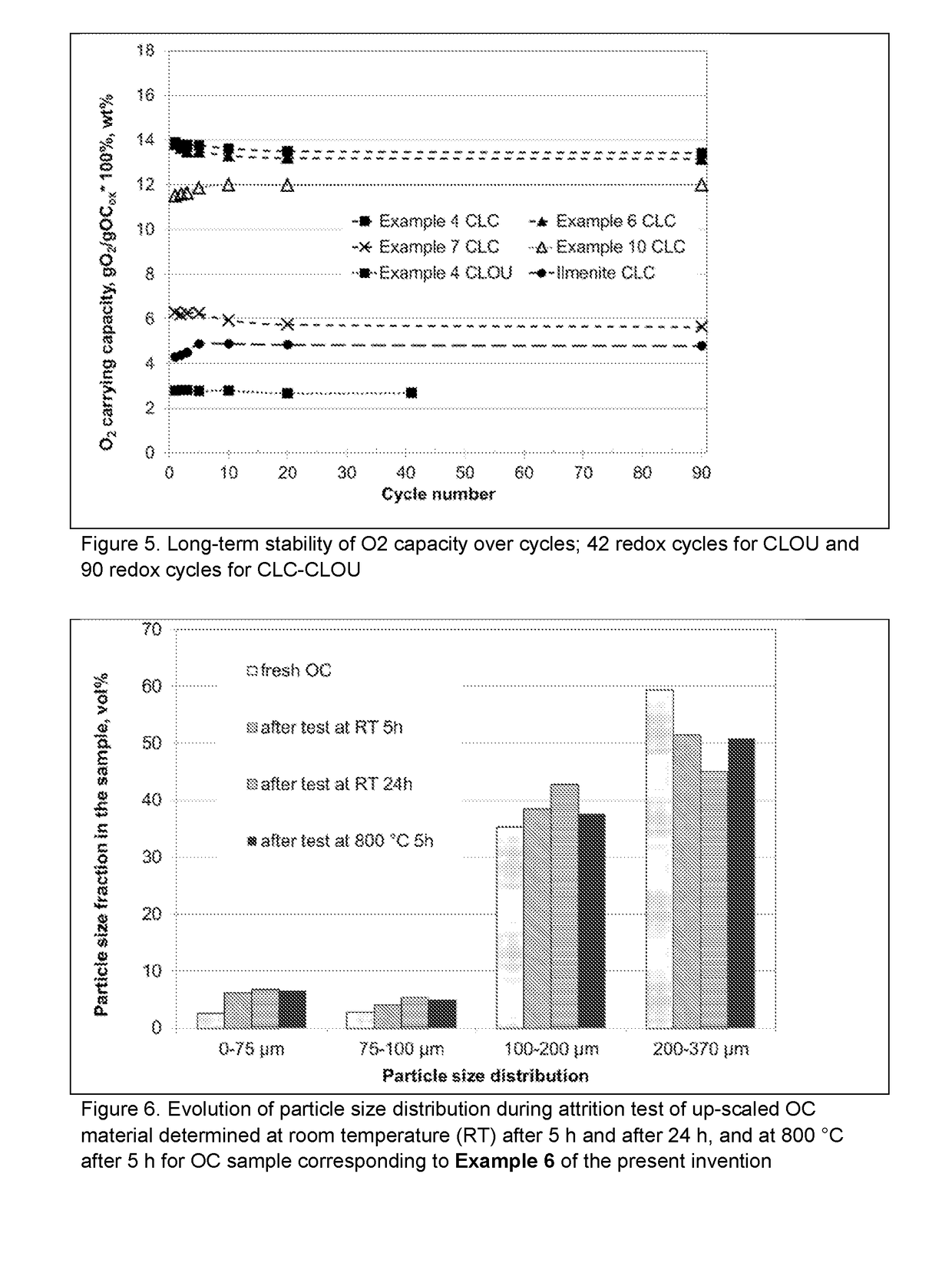

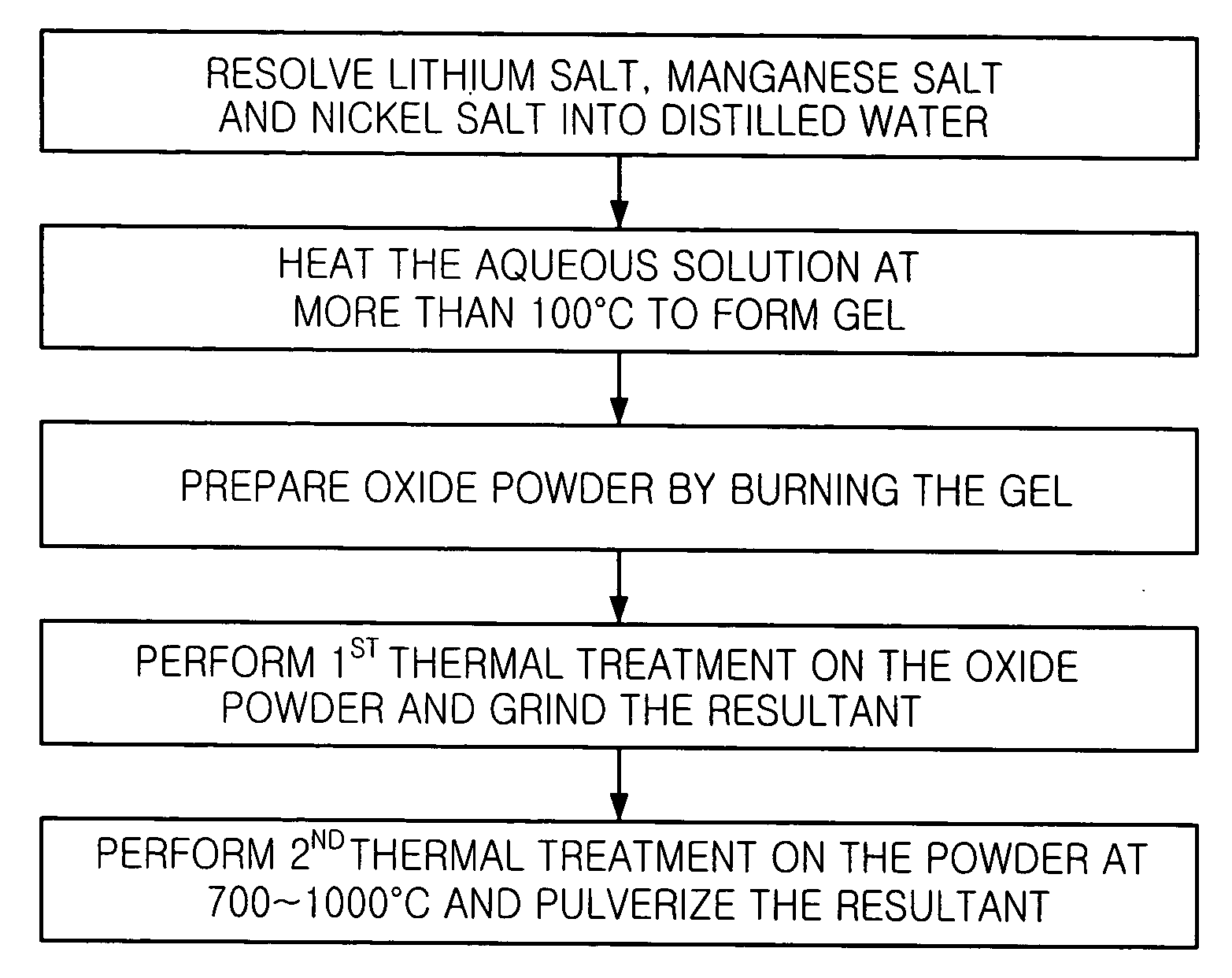

InactiveUS20190003704A1Simple and scalable and cost-effective methodImprove mechanical stabilityFluidized bed combustionCatalytic crackingCarrying capacityCompound (substance)

An oxygen carrier (OC) for use in Chemical Looping technology with Oxygen Uncoupling (CLOU) for the combustion of carbonaceous fuels, in which commercial grade metal oxides selected from the group consisting of Cu, Mn, and Co oxides and mixtures thereof constitute a primary oxygen carrier component. The oxygen carrier contains, at least, a secondary oxygen carrier component which is comprised by low-value industrial materials which already contain metal oxides selected from the group consisting of Cu, Mn, Co, Fe, Ni oxides or mixtures thereof. The secondary oxygen carrier component has a minimum oxygen carrying capacity of 1 g of O2 per 100 g material in chemical looping reactions. Methods for the manufacture of the OC are also disclosed.

Owner:INSTITUTT FOR ENERGITEKNIKK

Enamelware and Glaze

ActiveUS20080318029A1Improve adhesionSuperior in sulfuric acid resistance acidRecord information storageMetallic material coating processesImpurityCorrosion

The present invention provides enamelware and a glaze improving the bondability between the steel substrate and enamel layer and superior in resistance to dew point corrosion by sulfuric acid and hydrochloric acid, that is, a steel substrate of a composition containing, by mass %, Cu: 0.05 to 0.5%, Si: 0.1 to 2.0%, Mn: 0.05 to 2.0%, P: 0.005 to 0.10%, and S: 0.005 to 0.1%, restricting C to C: 0.20% or less, and comprising a balance of Fe and unavoidable impurities on the surface of which an enamel layer of a thickness of 50 to 700 μm is provided. At that time, the content of Co oxides in the enamel layer is made, converted to Co, 0.01 to 10% and / or the content of Ni oxides is made, converted to Ni, 0.05 to 20% or the total content of Ni in the steel substrate and enamel layer is made 0.005 to 4.5% with respect to the total mass of the enamelware and / or the total content of Co is made 0.008 to 4.0% with respect to the total mass of the enamelware.

Owner:NIPPON STEEL CORP

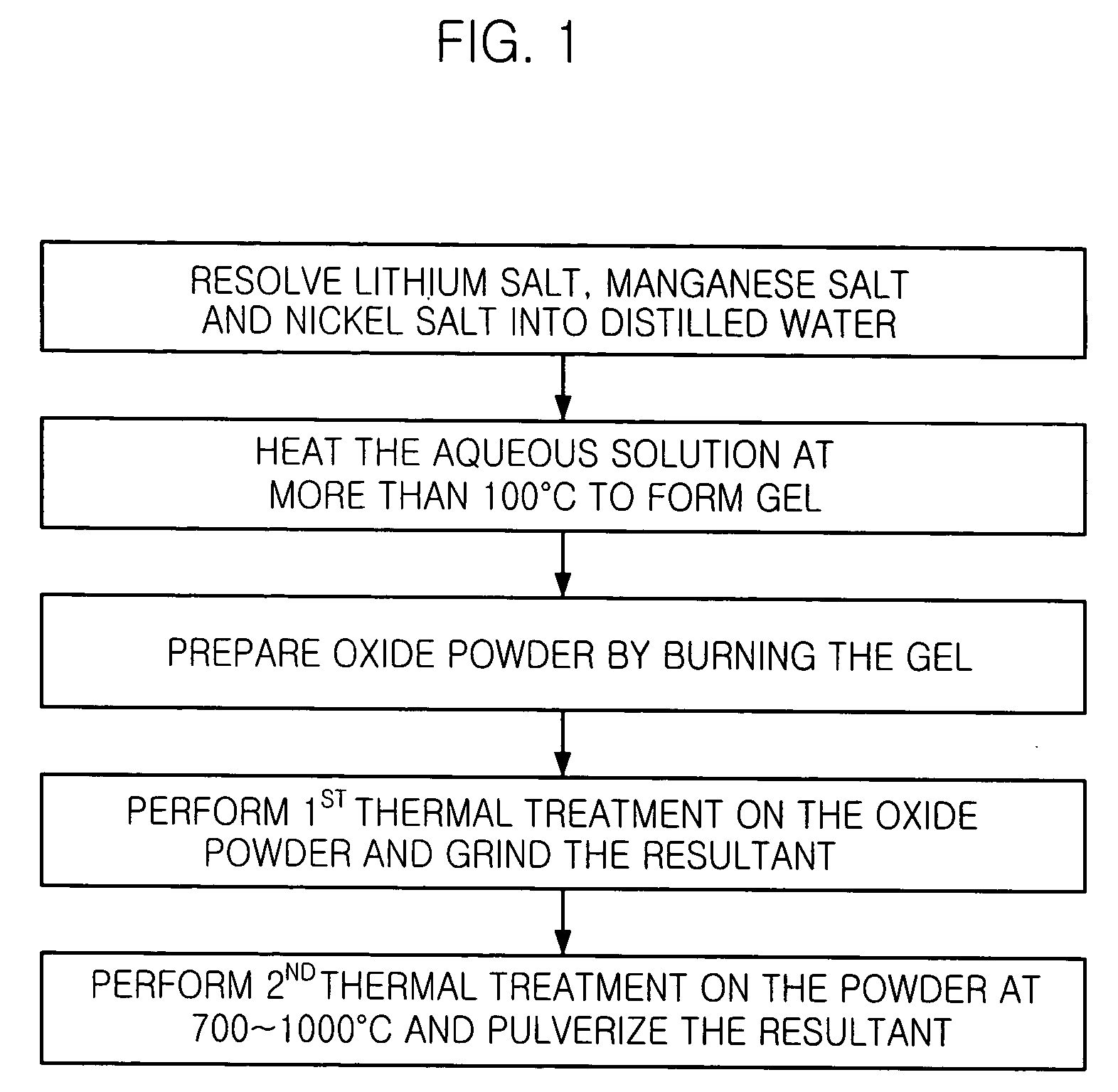

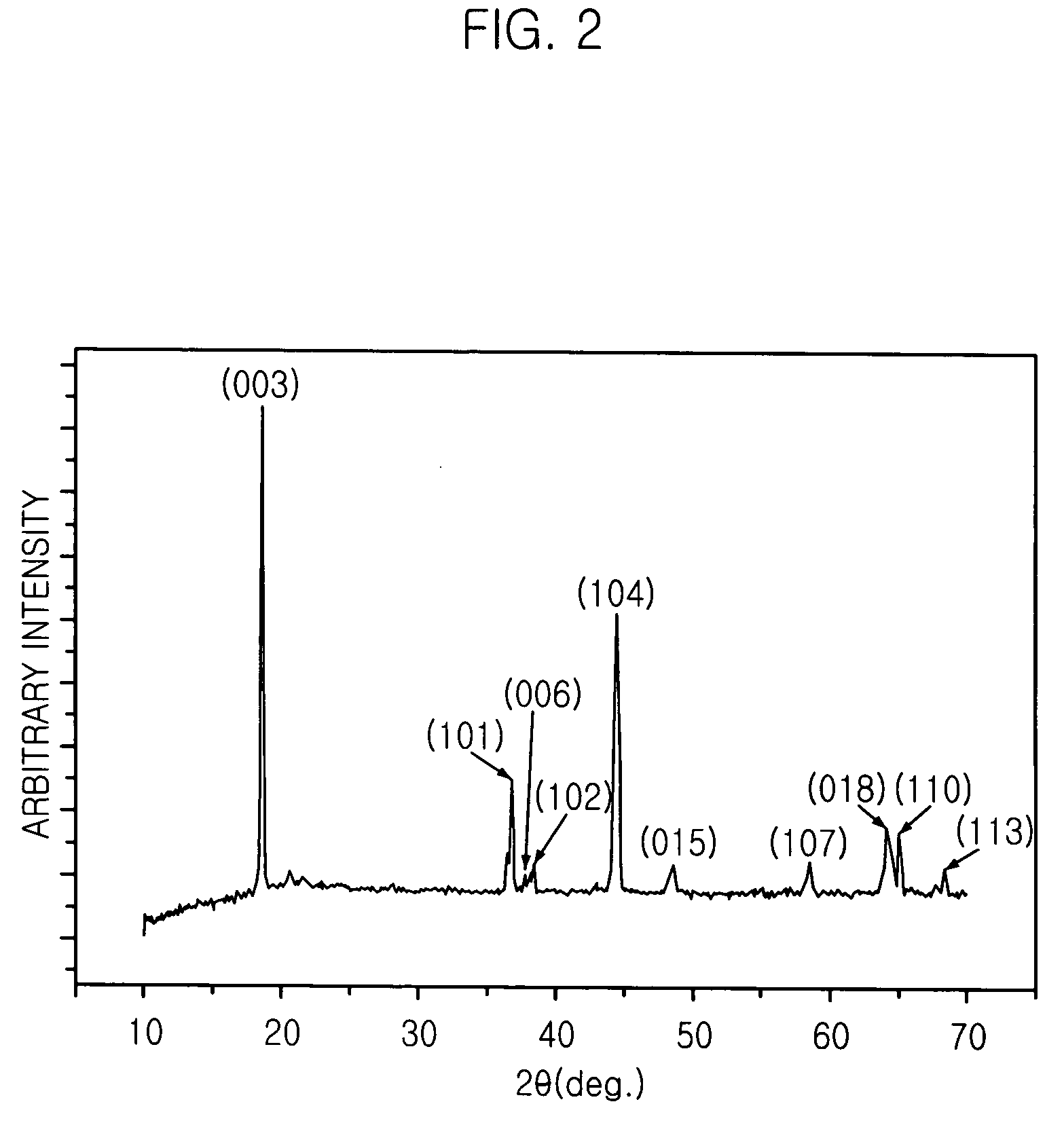

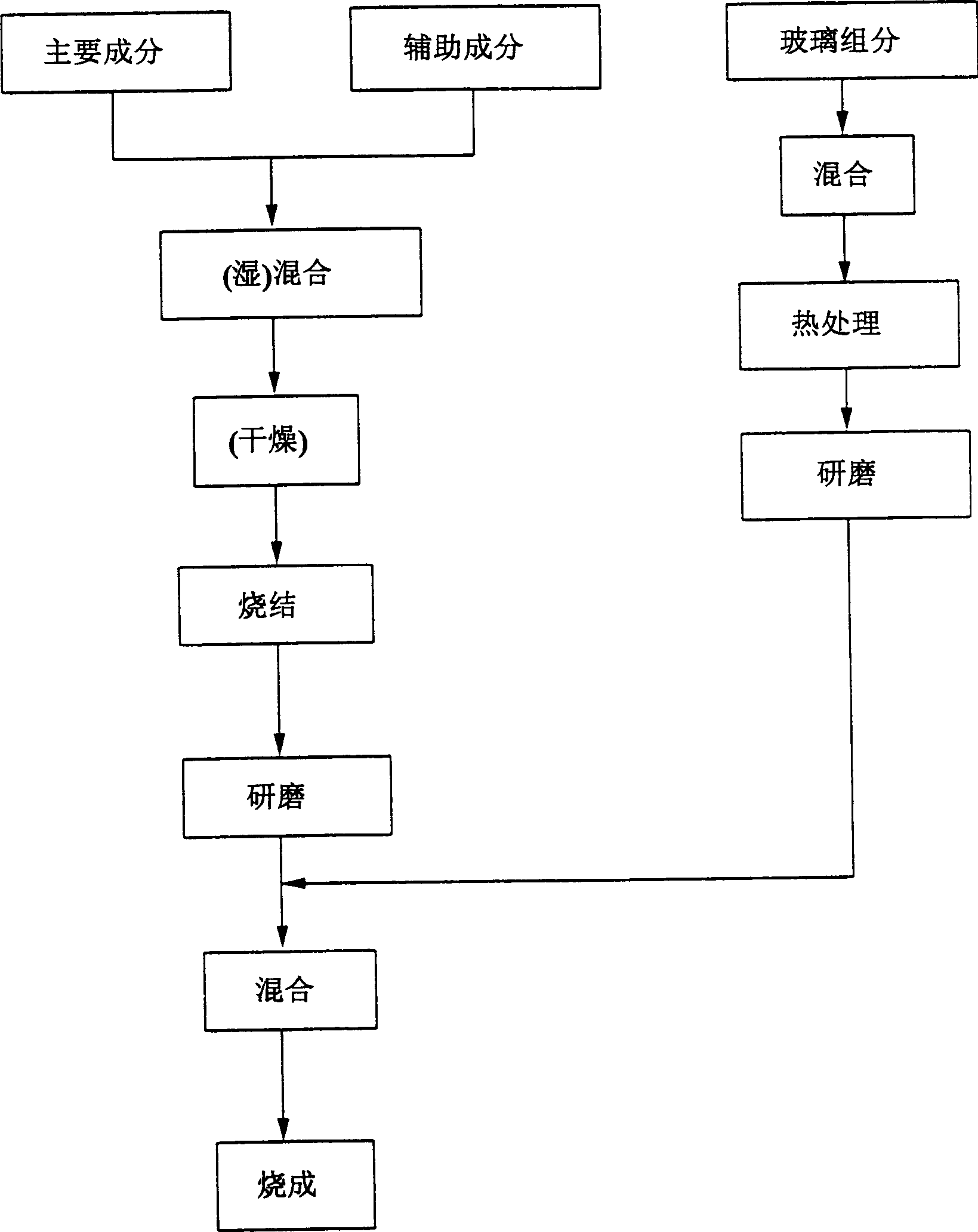

Method for preparing Li-Mn-Ni oxide for lithium secondary battery

InactiveUS20040115534A1Non-aqueous electrolyte accumulatorsAlkali metal oxidesNickel saltDistilled water

Provided is a method for preparing a Li-Mn-Ni oxide for a lithium secondary battery having a composition of Li[NixLi(1 / 3-2x / 3)Mn(2 / 3-X / 3)O2 (0.05<X<0.6), including the steps of: a] preparing an aqueous solution by resolving lithium salt, manganese salt and nickel salt into distilled water; b) forming gel by heating the aqueous solution; c) preparing oxide powder by burning the gel; d) performing a first thermal treatment on the oxide powder, and grinding the resultant; and e) performing a second thermal treatment on the resultant powder, and grinding the resultant. The technology of the present invention can prepare a Li-Mn-Ni oxide having a composition of Li[NixLi(1 / 3-2x / 3)Mn(2 / 3-x / 3)O2 (0.05<X<0.6) to be used as a cathode material of a lithium secondary battery having a stable and excellent electrochemical characteristics.

Owner:ELECTRONICS & TELECOMM RES INST

Natural gas partial oxidation catalyst prepared by making hydrotalcite as predecessor

InactiveCN1736591AHigh reactivityHigh selectivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsPartial oxidationHydrotalcite

The invention provides an oxidative catalyst prepared with hydrotalcite as the forerunner material, which comprises (wt %): 5- 40% NiO, 5- 15% Fe2O3, and the rest being MgO, Al2O3, and the oxides of other transient metal element, the mole ratio of divalent metallic ion to trivalent metal ion in whole oxides being among 1: 1- 10: 1. The catalyst has a perfect reaction activity and a high selectivity.

Owner:SHANDONG UNIV

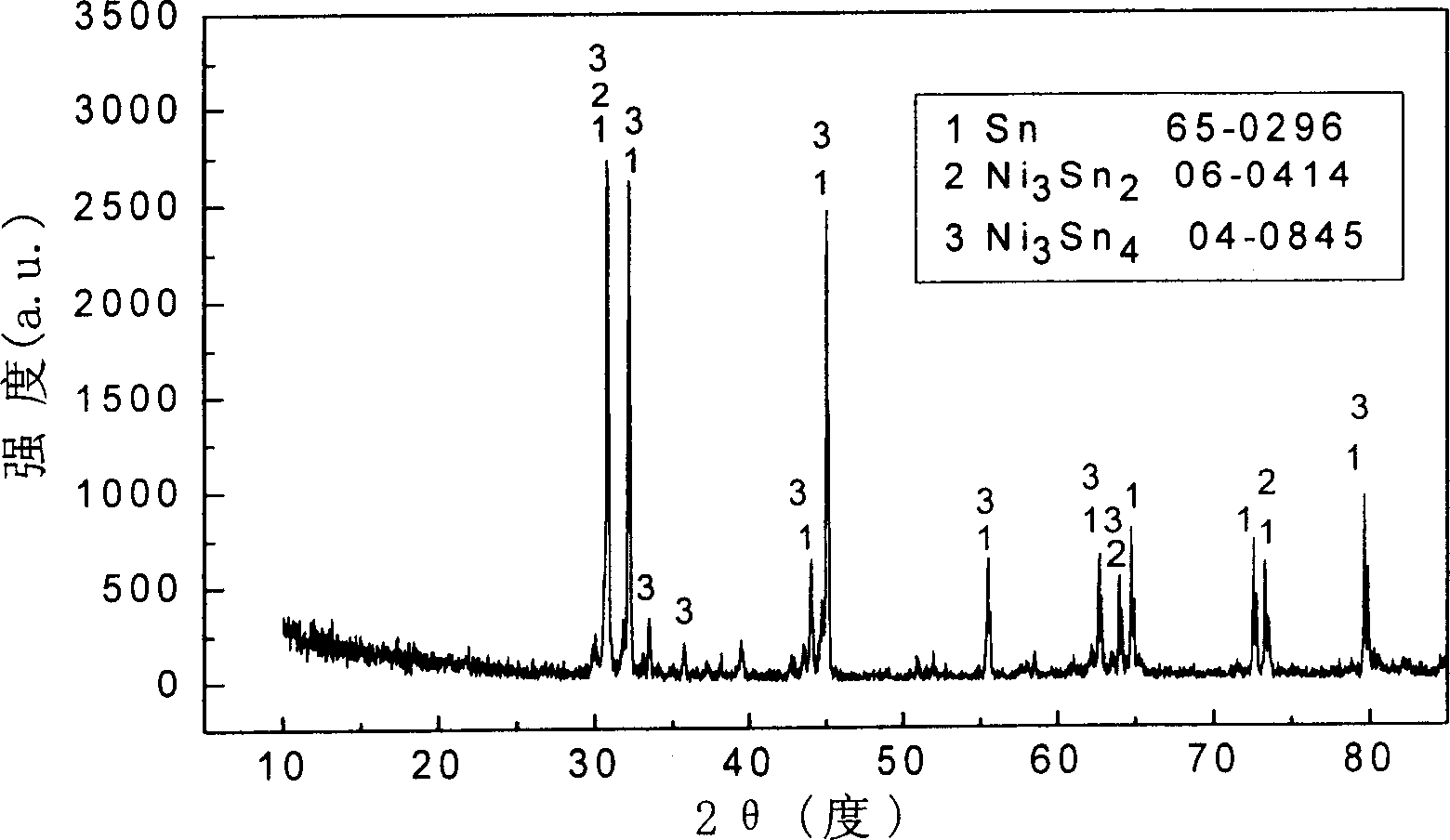

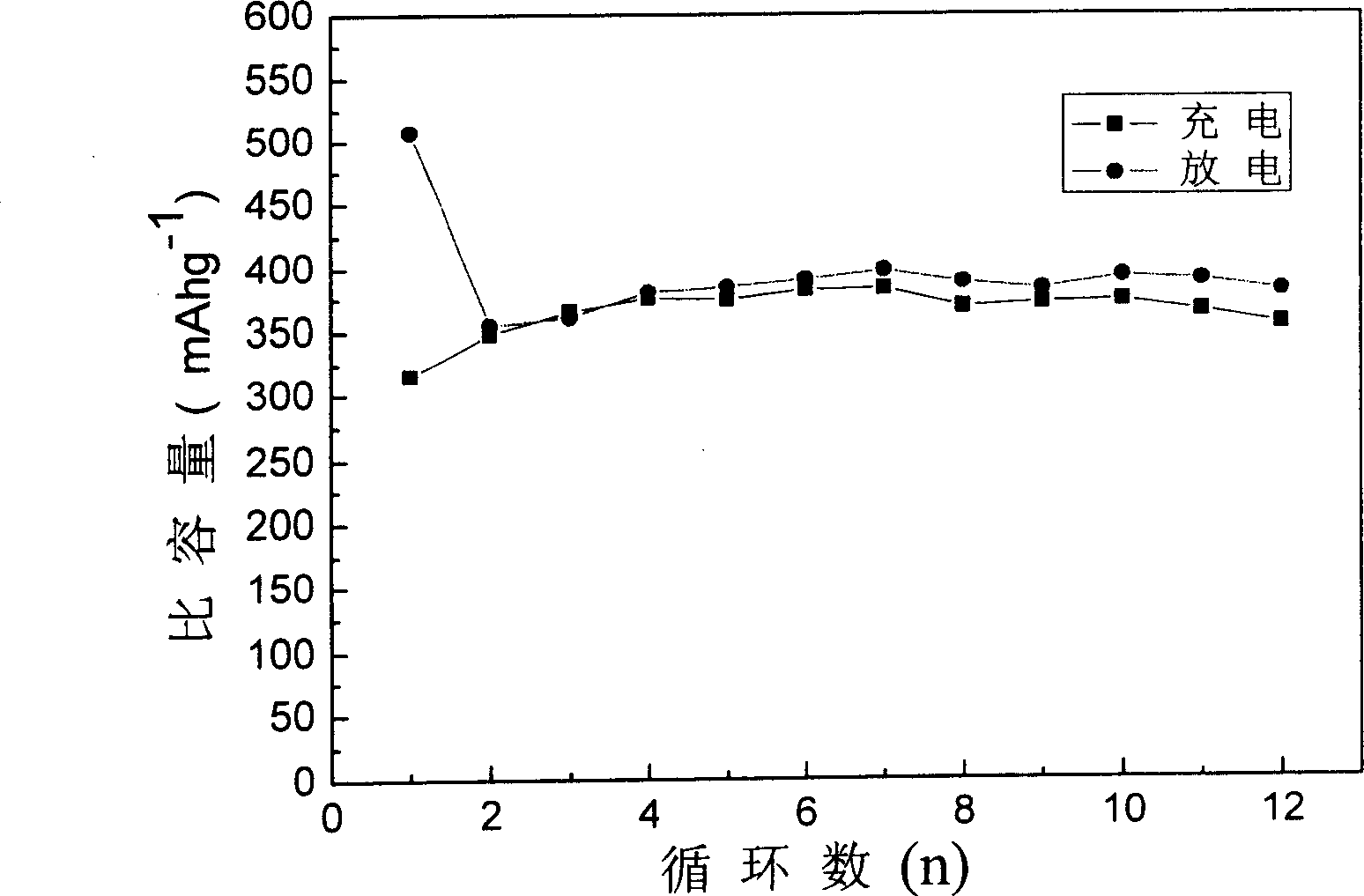

Preparation method for high-capacity Sn-Ni alloy compound as lithium ion battery negative electrode material

InactiveCN1866587AHigh crystallinityHigh specific capacityElectrode manufacturing processesAlloy compositeHigh capacitance

The invention discloses a preparing method of high-capacitance Sn-Ni alloy composite Li ion battery negative electrode material in the Li ion battery domain, which comprises the following steps: matching Sn and Ni oxide in the alloy composition according to proportion; adding fitful proportional carbon powder as reducer; grinding composition evenly; placing the composition in the flowing inert argon environment at 5-30 deg.c per min to 800-1200 deg.c for 1-6 h; interrupting; cooling the furnace to indoor temperature. The invention simplifies the preparing technology and reduces the cost, which produces high-specific content and stable circulation property Sn-Co Li ion battery negative material.

Owner:UNIV OF SCI & TECH BEIJING

Hydrogenation catalysts composite protective agent and manufacturing method thereof

InactiveCN101134166AImprove filtering effectIncrease pressure dropCatalyst protectionMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionPetroleum

The composite protectant for hydrogenation catalyst includes one protectant substrate of ceramic, and one layer of Mo or Ni oxide supported on the surface of the protectant substrate and combined closely through high temperature sintering. The porous composite protectant can support the main catalyst during the hydrogenation reaction process, filter off organic impurity from the material oil to avoid catalyst poisoning and prevent raise in pressure drop in the reactor, and raise catalysis efficiency with the supported Mo or Ni oxide to participate the hydrogenating polymerization reaction. The composite protectant may be applied widely as catalyst protectant in the petroleum hydrogenating process.

Owner:湖南省醴陵市鑫荷化工填料有限公司

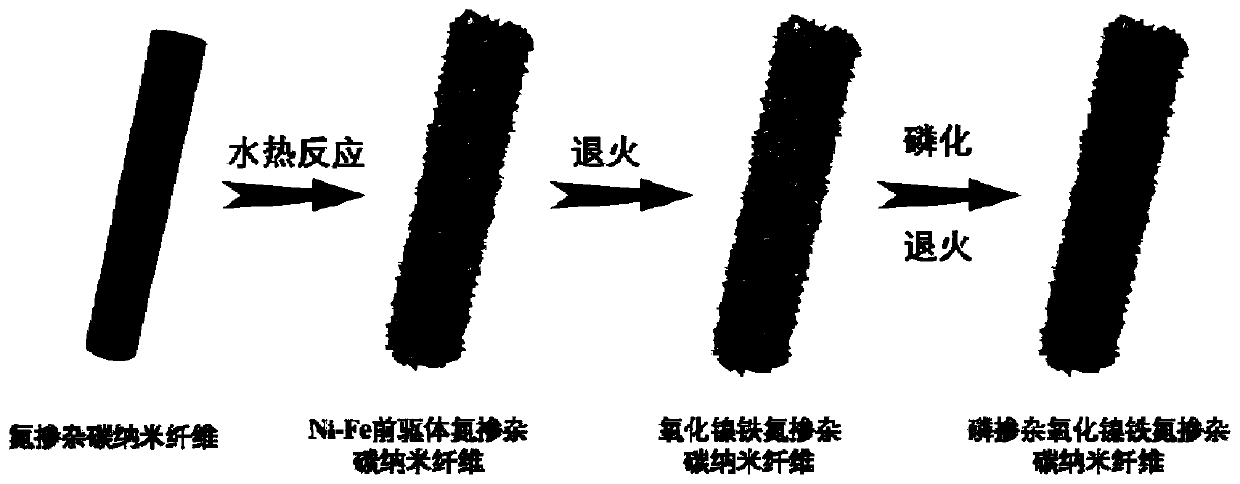

Phosphorus-doped ferronickel oxide nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

ActiveCN110975914ALarge specific surface areaImprove conductivityCatalyst activation/preparationElectrodesNanofiberCarbon nanofiber

The invention discloses a phosphorus-doped ferronickel oxide nitrogen-doped carbon nanofiber composite material which is characterized in that the phosphorus-doped ferronickel oxide nitrogen-doped carbon nanofiber composite material is prepared by taking nitrogen-doped carbon nanofibers as a carrier and growing NiFe-LDH nanosheets on the surface of the nitrogen-doped carbon nanofibers in situ. Thepreparation method comprises an annealing process and a high-temperature phosphorus doping process. The phosphorus-doped ferronickel oxide nitrogen-doped carbon nanofiber composite material has the advantages of large specific surface area, good conductivity, stable physical and chemical properties, excellent electrochemical performance and the like.

Owner:DONGHUA UNIV

Composite catalyst used for reforming hydrogen prodn. using methane and water vapor as raw material, preparing process and use thereof

ActiveCN100398203CFacilitated releasePromote absorptionMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionSteam reformingCalcium hydroxide

A composite catalyst for preparing hydrogen by reforming the CO2 adsorbed and intensified methane vapor is proportionally prepared from CaO, NiO and Al2O3 as carrier. It features that the heat generated by reaction between calcium oxide and CO2 is used to promote said reforming reaction. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

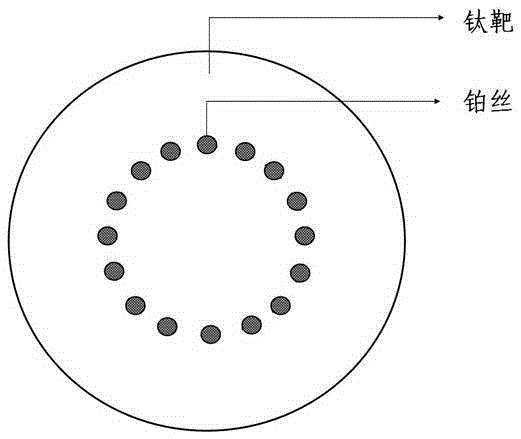

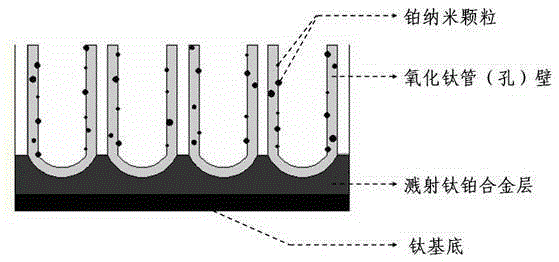

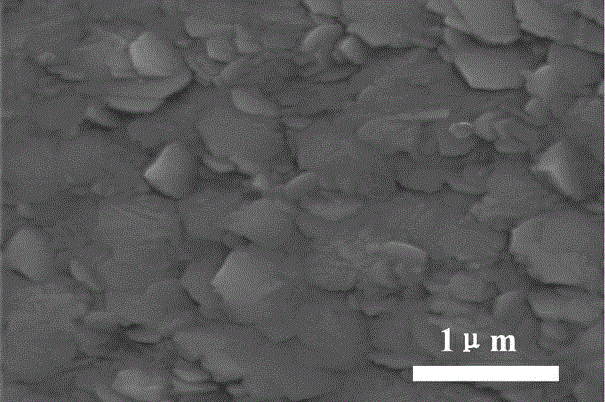

Nanotube/porous Ti/W/Ni oxide thin film catalytic electrode in-site loaded with platinum/palladium nanoparticles and preparation method therefor

The invention relates to a tubular (porous) Ti / W / Ni oxide thin film catalytic electrode in-site loaded with platinum (palladium) nanoparticles and a preparation method therefor, and belongs to the technical field of energy materials and electro-catalysis, for solving technical problems by providing the nano-tubular (porous) Ti / W / Ni oxide thin film catalytic electrode in-site loaded with the platinum (palladium) nanoparticles, having a simple preparation process, high possibility of large-scale industrial production without using noble metal salts and strong reducing agents in the production process, and low environmental harm, and the preparation method therefor; for fulfilling the purpose, the invention adopts the technical scheme as follows: depositing a Ti / W / Ni-Pt / Pd alloy thin film into a titanium sheet, a tungsten sheet, a nickel titanium alloy sheet or the surface of a conductive glass, then taking the metal sheet or the conductive glass deposited with the Ti / W / Ni-Pt / Pd alloy thin film as the positive electrode, and taking a graphite rod / sheet or a platinum filament / sheet as the negative electrode for performing an anodic oxidation treatment to obtain the nanotube / porous Ti / W / Ni oxide thin film catalytic electrode in-site loaded with the platinum / palladium nanoparticles, wherein the metal Pt / Pd in the electrode is in-site embedded in the nanotube / porous wall of the nanotube / porous Ti / W / Ni oxide and exists in the form of the metal-state nanoparticles.

Owner:TAIYUAN UNIV OF TECH

Dielectric composition with improved uniformity and insulation resistance, its preparing method and multi-layer ceramic capacitor using same

InactiveCN1459810AImprove uniformityHigh dielectric constantLayered product treatmentFixed capacitor dielectricNiobiumCeramic capacitor

Disclosed is a dielectric composition, which is advantageous in light of increased homogeneity and insulation resistance, a method of preparing the same and a multi-layer ceramic capacitor using the same. The dielectric composition consists of a dielectric component represented by (Ba1-x-yCaxAy)m(Ti1-a-b-cZraB'bB''c)O3+m, (wherein, 0.01<=x<=0.10, 0.003<=y<=0.015, 0.16<=a<=0.20, 0.003<=b<=0.015, 0<=c<=0.015, 1.000<=m<=1.010; the component A is selected from among Y oxides, La oxides, Ho oxides, Dy oxides, Er oxides, Hf oxides and combinations thereof; the component B' is selected from among Mn oxides, Co oxides, Ni oxides and combinations thereof; and the component B'' is selected from among V oxides, Nb oxides, Ta oxides and combinations thereof), and a sintering aid represented by zLi2O-2(1-z)SiO2(0<=Z<=0.9).

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

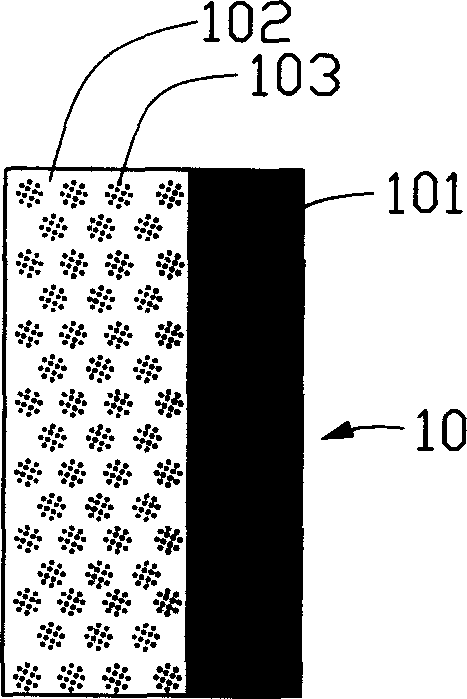

Hydrogenation catalysts composite protective agent and manufacturing method thereof

InactiveCN101134166BImprove filtering effectIncrease pressure dropCatalyst protectionMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionPetroleum

The composite protectant for hydrogenation catalyst includes one protectant substrate of ceramic, and one layer of Mo or Ni oxide supported on the surface of the protectant substrate and combined closely through high temperature sintering. The porous composite protectant can support the main catalyst during the hydrogenation reaction process, filter off organic impurity from the material oil to avoid catalyst poisoning and prevent raise in pressure drop in the reactor, and raise catalysis efficiency with the supported Mo or Ni oxide to participate the hydrogenating polymerization reaction. The composite protectant may be applied widely as catalyst protectant in the petroleum hydrogenating process.

Owner:湖南省醴陵市鑫荷化工填料有限公司

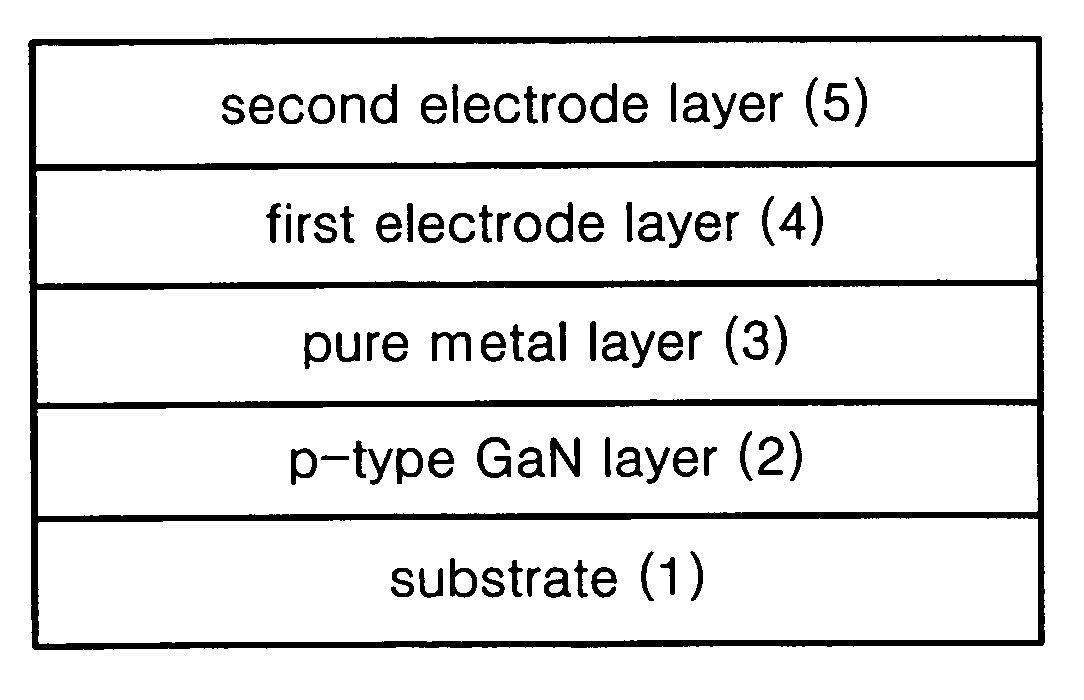

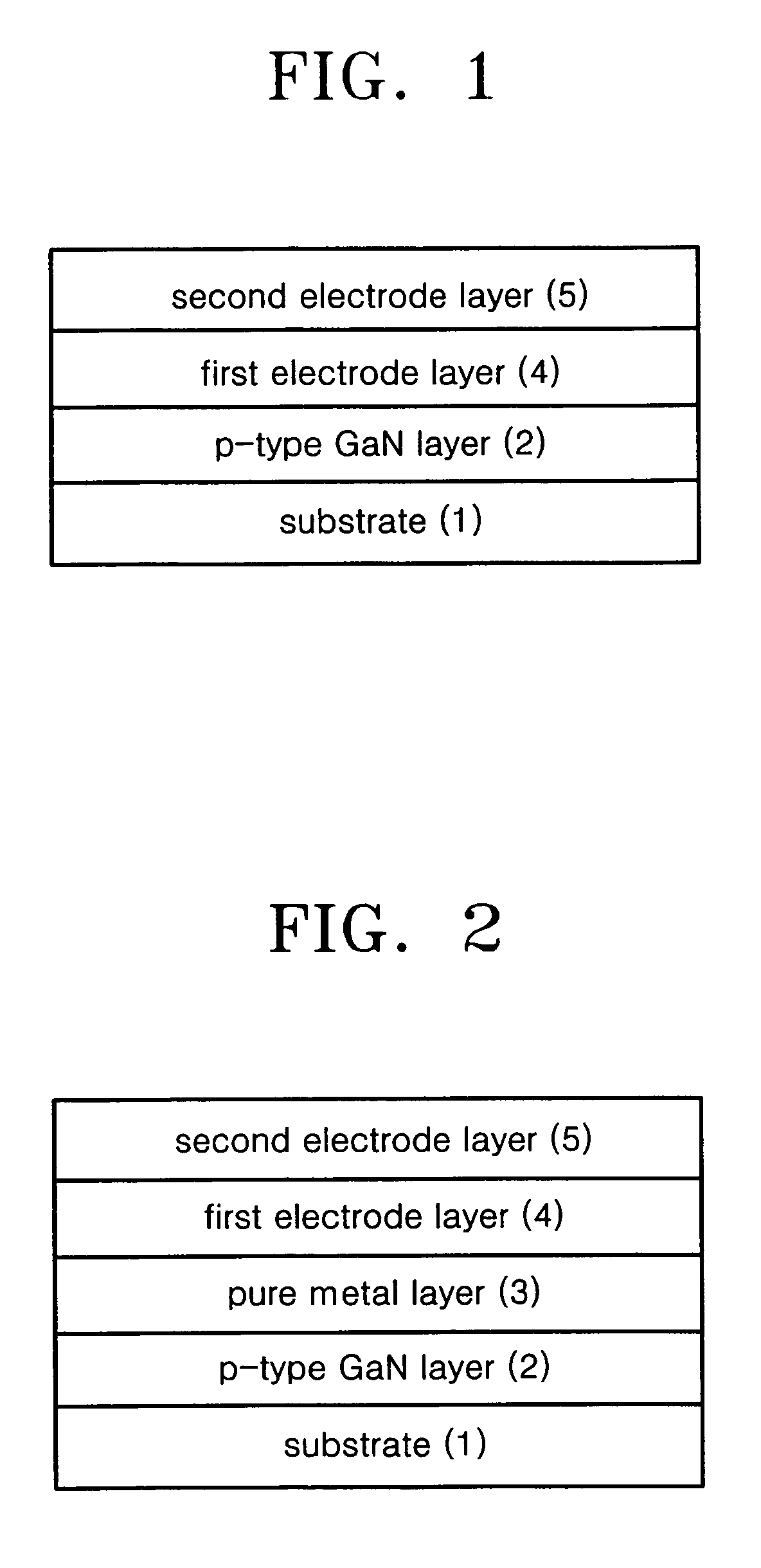

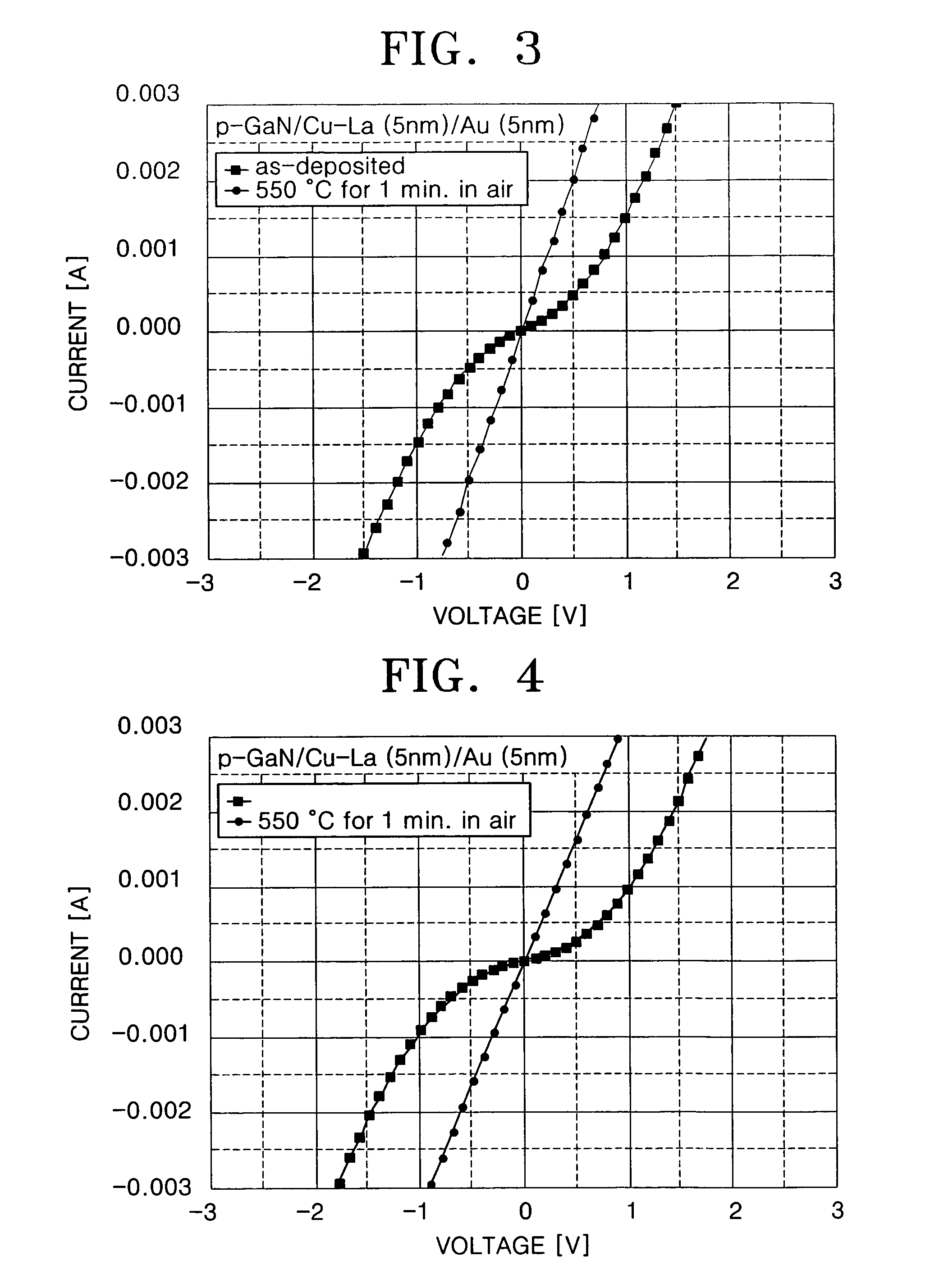

Thin film electrode for high-quality GaN optical devices

ActiveUS7687908B2Large work function valueImprove transmittanceSemiconductor/solid-state device detailsSolid-state devicesThin film electrodeOhmic contact

Owner:SAMSUNG ELECTRONICS CO LTD +1

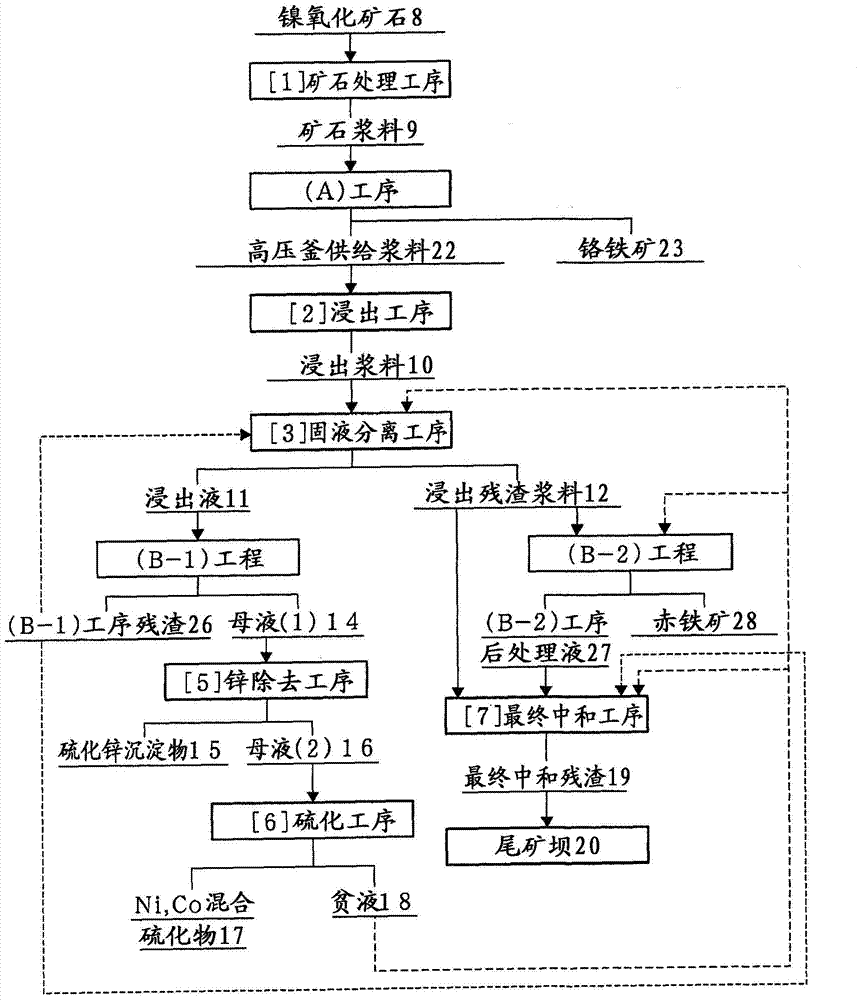

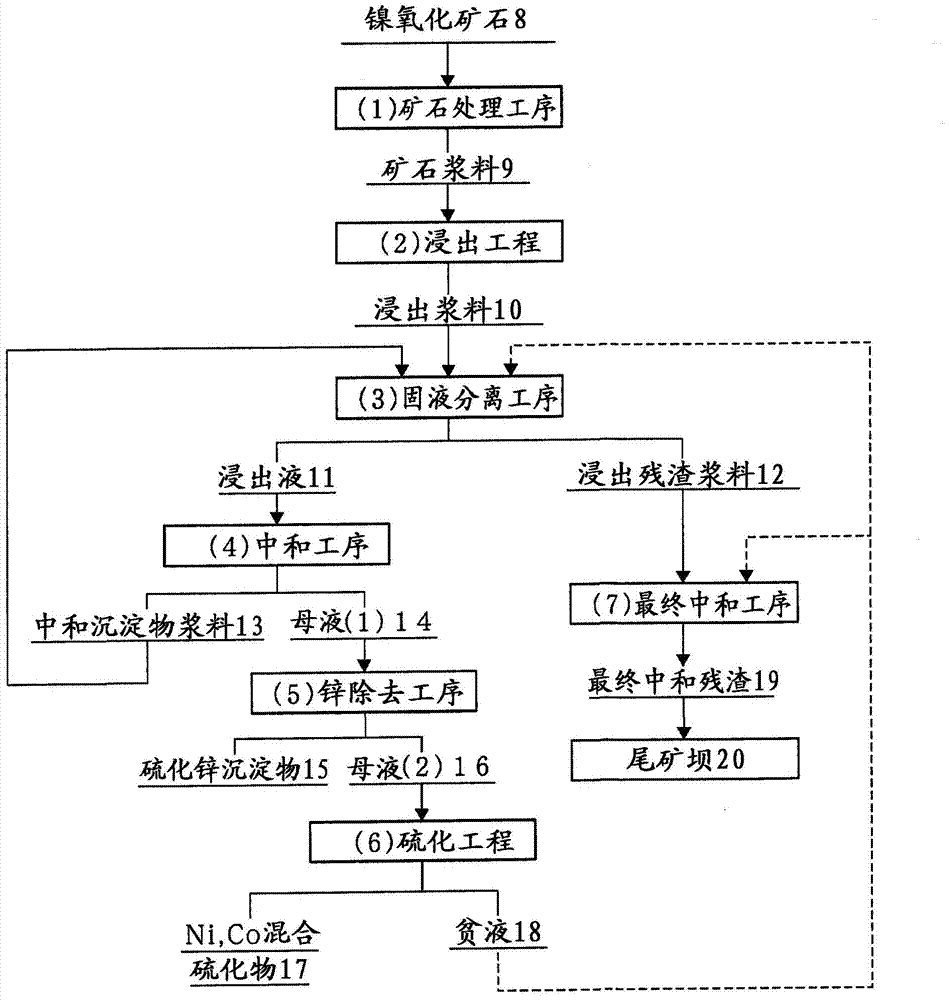

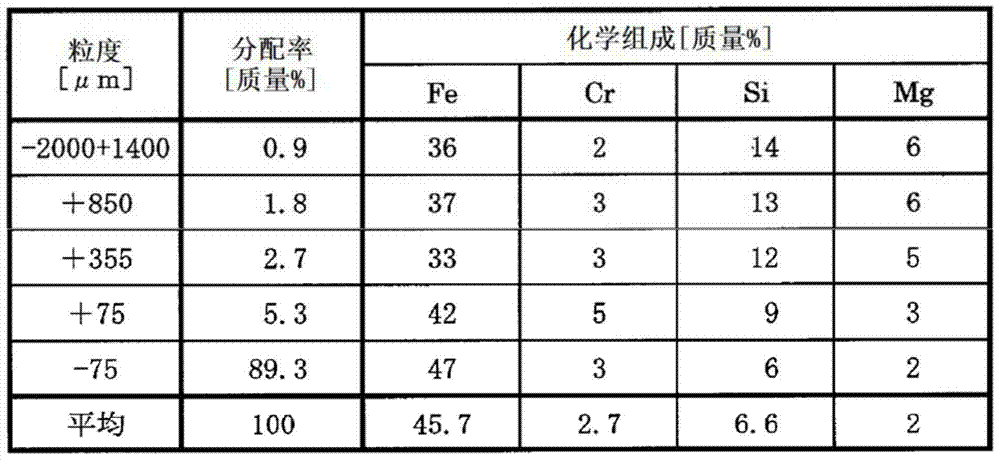

Wet-mode nickel oxide ore smelting method

ActiveCN104718301AHigh industrial valueInhibit wearProcess efficiency improvementSlurryHigh pressure

Provided is a wet-mode smelting method for collecting nickel (Ni) from a Ni oxide ore employing a high-pressure acid leaching process, in which the abrasion of a facility by an ore slurry can be prevented, the amount of a final neutralization residue can be reduced, and impurity components can be separated and recovered for recycling purposes. A wet-mode smelting method for collecting nickel from a nickel oxide ore, said method involving at least one step selected from steps (A), (B-1) and (B-2) as mentioned below in a high-pressure acid leaching process: step (A): separating and collecting chromite particles from an ore slurry produced in an ore treatment step by a collection process involving a gravity separation method; step (B-1): subjecting the ore slurry, which has been undergone step (A) to reduce the Cr grade thereof, to a leaching step and a solid / liquid separation step, and then neutralizing a leached solution obtained after the solid / liquid separation step with an Mg-containing alkali such as Mg(OH)2; and step (B-2): subjecting the ore slurry, which has been undergone step (A) to reduce the Cr grade thereof, to a leaching step and a solid / liquid separation step, then neutralizing a leaching residue slurry obtained after the solid / liquid separation step with an Mg-containing alkali such as Mg(OH)2, and then collecting hematite particles.

Owner:SUMITOMO METAL MINING CO LTD

Catalyst for producing ethyl alcohol through C2 acid ester hydrogenation, and preparation and application of catalyst

InactiveCN110385131AOrganic compound preparationHydroxy compound preparationAlcoholHydrogen pressure

The invention relates to a bimetallic (non-precious metal) catalyst for producing ethyl alcohol through C2 acid ester hydrogenation, and a preparation method and application of the bimetallic (non-precious metal) catalyst. The catalyst is prepared from M1-M2 / SiO2, wherein M1 and M2 are one of non-precious metal Cu, Co and Ni oxides, the molar ratio of M1 to M2 is (40:1) to (1:40), and the M1-M2 / SiO2 is prepared through a co-ammonia still method. The catalyst can highly selectively convert C2 acid ester into the ethyl alcohol under the reaction conditions that the temperature is 150-250 DEG C,the hydrogen pressure is 1-5 MPa, the liquid air speed is 0.1-0.8 h<-1>, and the molar ratio of hydrogen to the C2 acid ester is 100-300.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Enamelware and glaze

ActiveUS8758893B2Lower operating temperatureEasy to operateRecord information storageMetallic material coating processesImpurityCorrosion

The present invention provides enamelware and a glaze improving the bondability between the steel substrate and enamel layer and superior in resistance to dew point corrosion by sulfuric acid and hydrochloric acid, that is, a steel substrate of a composition containing, by mass %, Cu: 0.05 to 0.5%, Si: 0.1 to 2.0%, Mn: 0.05 to 2.0%, P: 0.005 to 0.10%, and S: 0.005 to 0.1%, restricting C to C: 0.20% or less, and comprising a balance of Fe and unavoidable impurities on the surface of which an enamel layer of a thickness of 50 to 700 μm is provided. At that time, the content of Co oxides in the enamel layer is made, converted to Co, 0.01 to 10% and / or the content of Ni oxides is made, converted to Ni, 0.05 to 20% or the total content of Ni in the steel substrate and enamel layer is made 0.005 to 4.5% with respect to the total mass of the enamelware and / or the total content of Co is made 0.008 to 4.0% with respect to the total mass of the enamelware.

Owner:NIPPON STEEL CORP

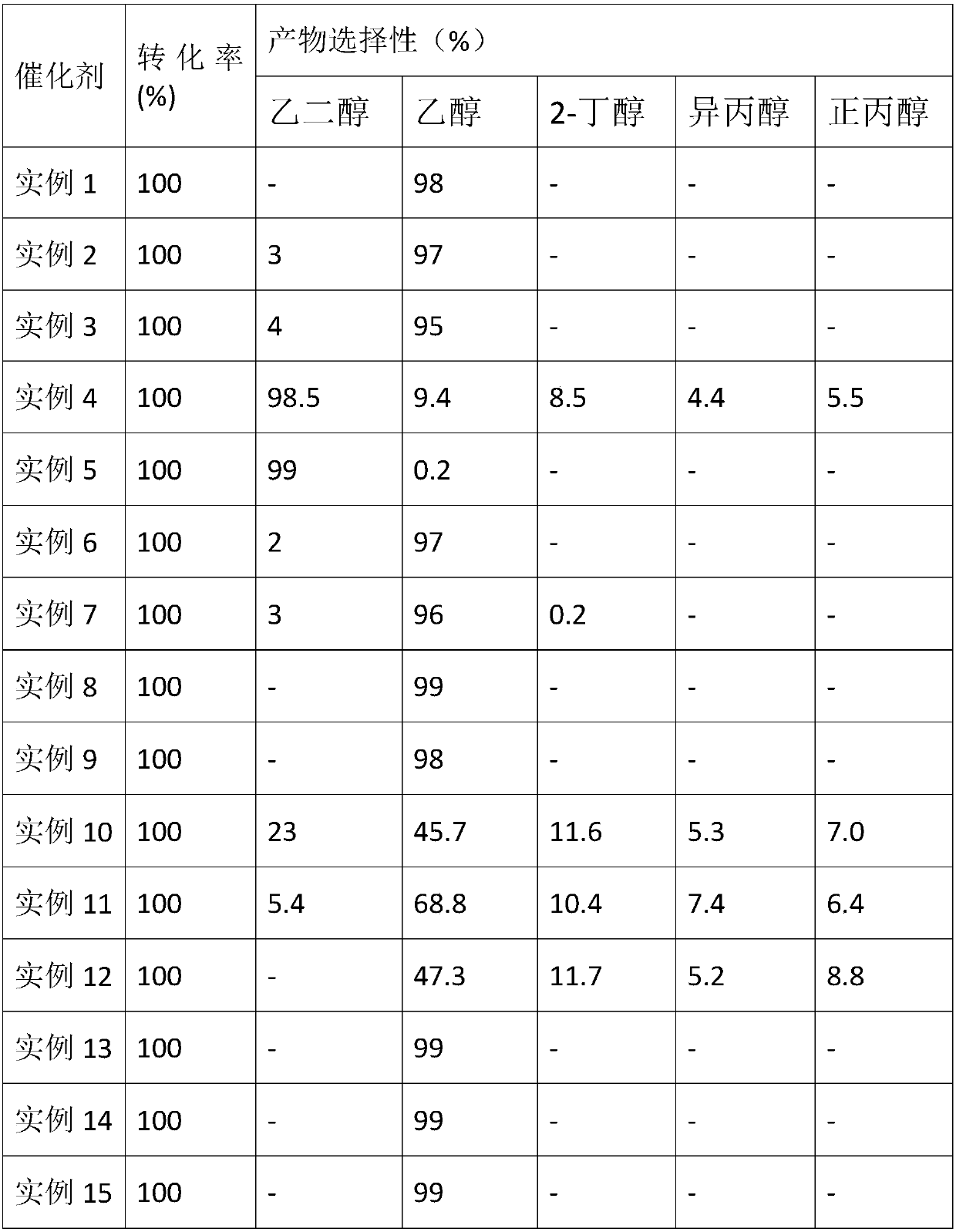

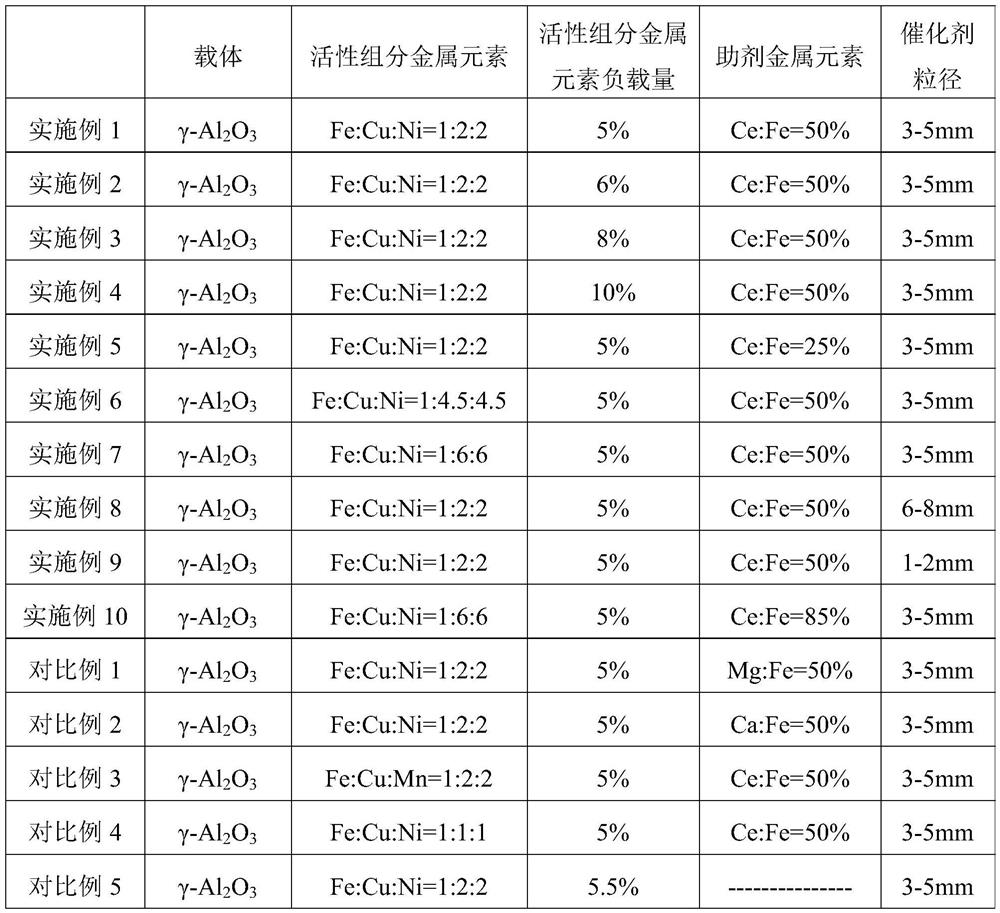

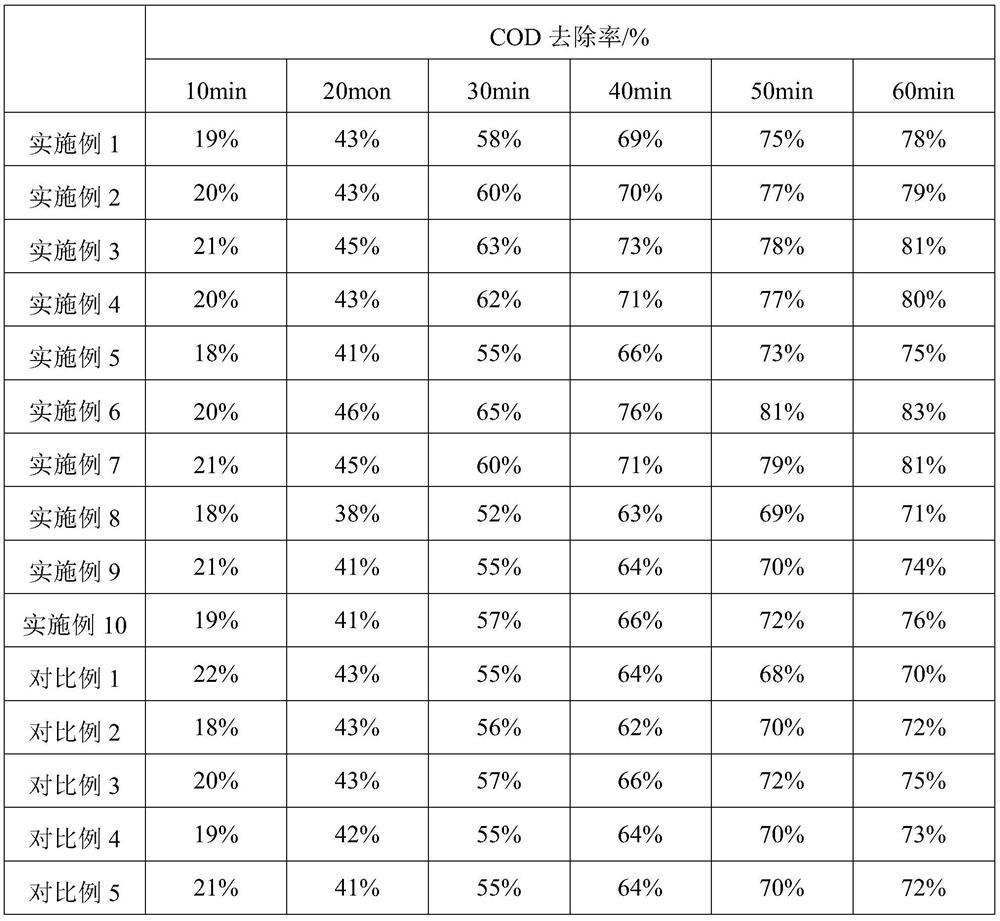

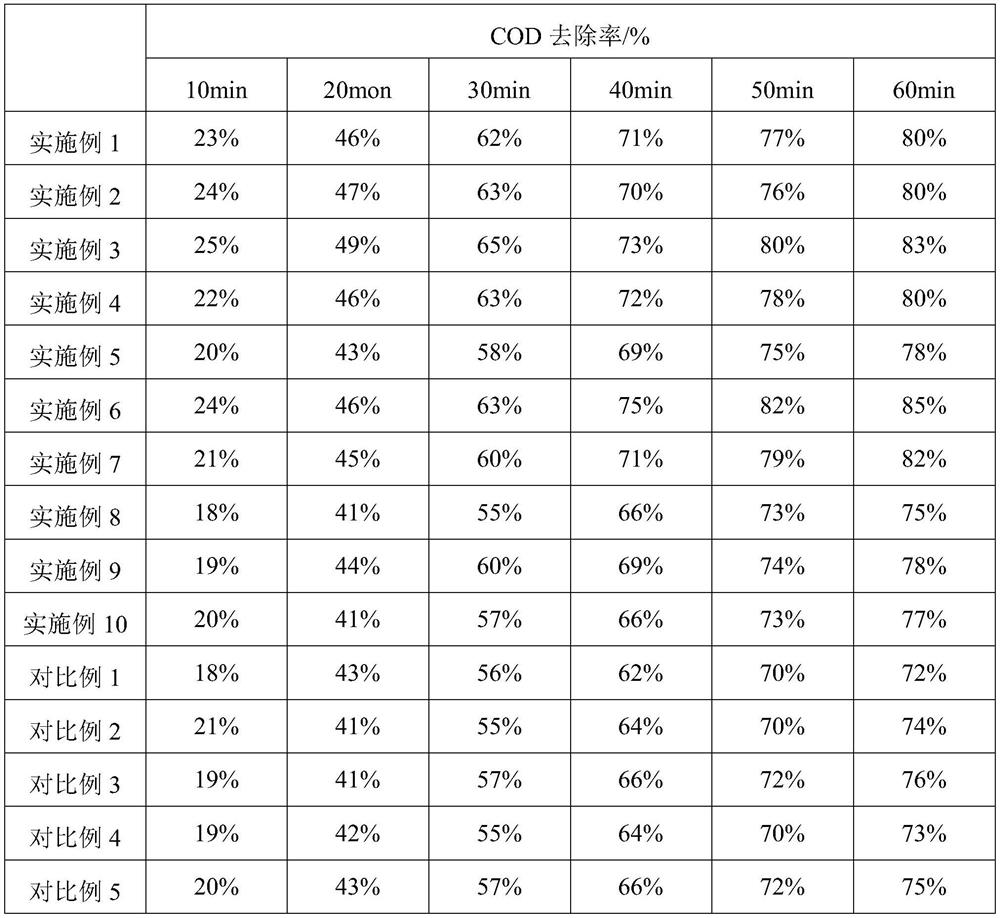

Ozone catalytic oxidation composite catalyst as well as preparation method and application thereof

PendingCN114289029AHigh removal rateEasy to prepareWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention discloses an ozone catalytic oxidation composite catalyst, which comprises a carrier, an active component and an auxiliary agent, the carrier comprises gamma-Al2O3, the active component is an oxide of Fe, Cu and Ni, and the auxiliary agent is a Ce oxide. In the active component, the mass ratio of Fe oxide to Cu oxide to Ni oxide is 1: (1.5-6): (1.5-6); the mass of the auxiliary agent Ce oxide is 25-85% of the mass of the active component Fe oxide; the loading capacity of the active component metal oxide is 5-10% based on the total mass of the catalyst. The ozone catalytic oxidation catalyst provided by the invention has the advantages of easily available raw materials, low cost and simple preparation method, and can effectively treat high-concentration coking wastewater, and the COD removal rate can reach 83%.

Owner:CCTEG CHINA COAL RES INST

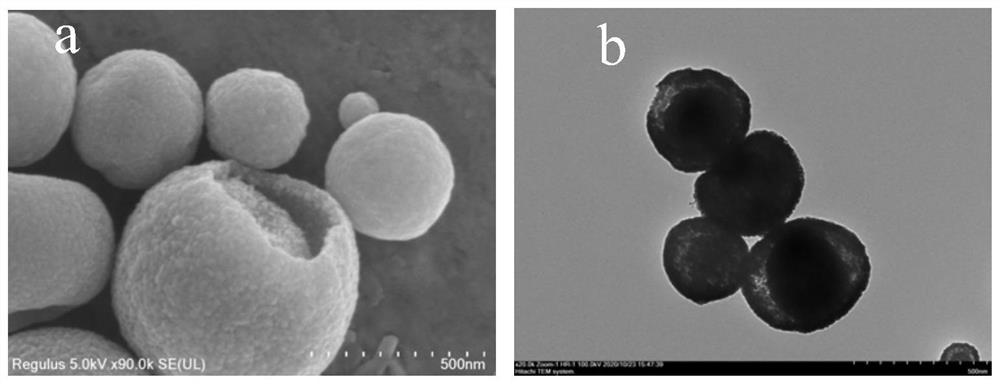

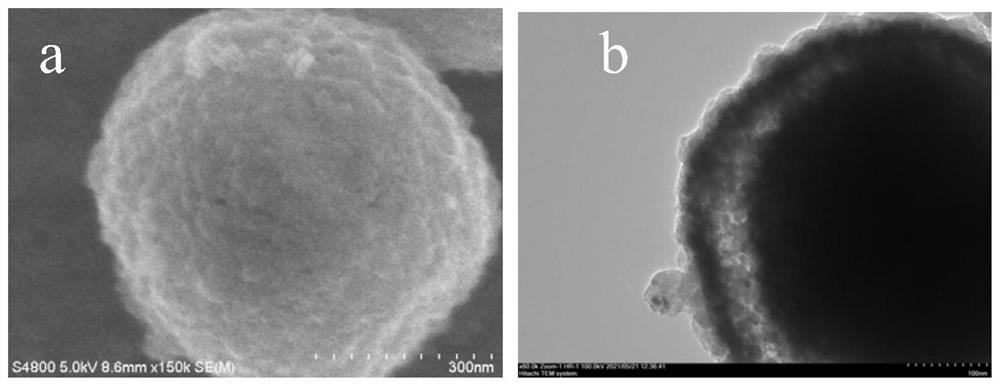

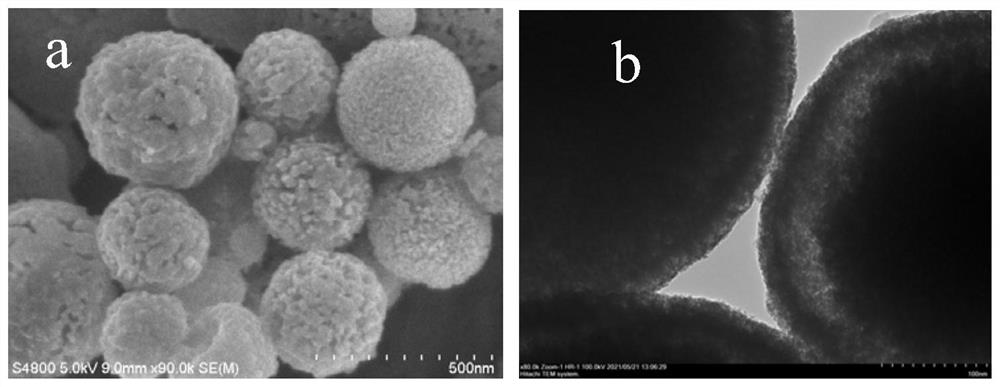

N-doped porous carbon coated Mn-Co-Ni oxide core-shell structure electrode material and preparation method and application thereof

PendingCN114497473ASpecial core-shell structureLarge specific surface areaCell electrodesElectrolytic agentPorous carbon

The invention discloses a method for preparing an N-doped porous carbon coated Mn-Co-Ni oxide core-shell structure electrode material, which comprises the following steps: (1) dissolving a manganese source, a cobalt source and a nickel source in a solvent I to obtain a mixed solution; (2) performing spray pyrolysis on the mixed solution, and collecting to obtain precursor powder; (3) uniformly mixing the precursor powder, a doping agent, a carbon and nitrogen source and an oxidizing agent in a solvent II, and then performing vacuum drying to obtain a product; and (4) carrying out high-temperature calcination on the product under protective gas to obtain the N-doped porous carbon coated Mn-Co-Ni oxide core-shell structure electrode material. The material has a special core-shell structure and a relatively large specific surface area, is high in specific capacity and good in stability, is beneficial to relieving volume expansion and permeation and diffusion of electrolyte, and is convenient for transmission of lithium ions.

Owner:ANHUI NORMAL UNIV

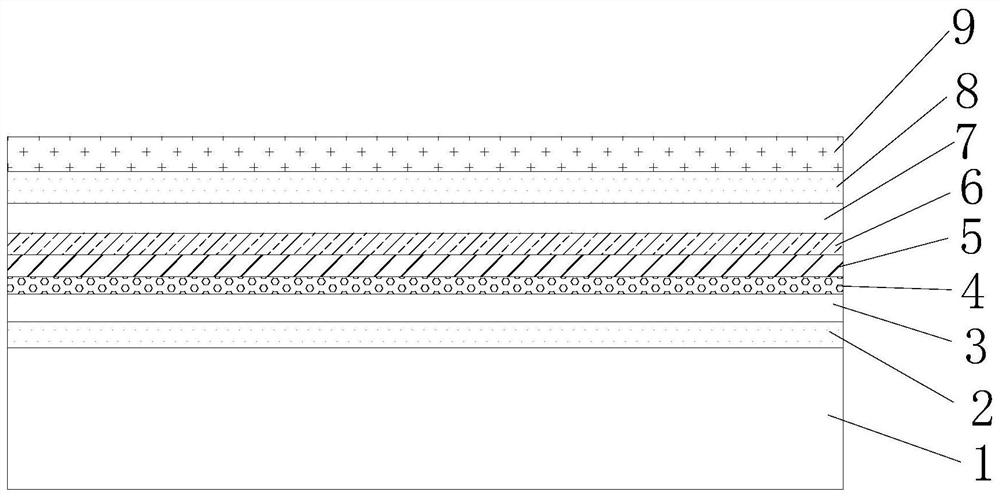

Passive low-energy-consumption offline temperable LOW-E coated glass and preparation process thereof

The invention discloses passive low-energy-consumption offline temperable LOW-E coated glass, which comprises a glass substrate, and a first dielectric layer, a second dielectric layer, a metal silver layer, a first shielding layer, a second shielding layer, a third dielectric layer, a fourth dielectric layer and a fifth dielectric layer are sequentially sputtered on the glass substrate from bottom to top, wherein the first dielectric layer and the fourth dielectric layer are silicon nitride layers, the second dielectric layer and the third dielectric layer are zinc oxide layers, the fifth dielectric layer is a zirconium oxide layer, the first shielding layer and the second shielding layer are a nichrome layer and a nichrome layer respectively, and the preparation process adopts high-vacuum magnetron sputtering coating equipment for layer-by-layer coating. The five dielectric layers are adopted, the visible light transmittance of the film layer is effectively increased, it is guaranteed that the film layer has a good anti-damage effect, the shielding layer effectively protects the silver layer, and the oxidation resistance of the silver layer is improved; the visible light transmittance of the low-emissivity glass is not lower than 89%, the emissivity is not larger than 0.095, and the use standard of passive low-energy-consumption buildings is met.

Owner:ANHUI FENGYANG GLASS

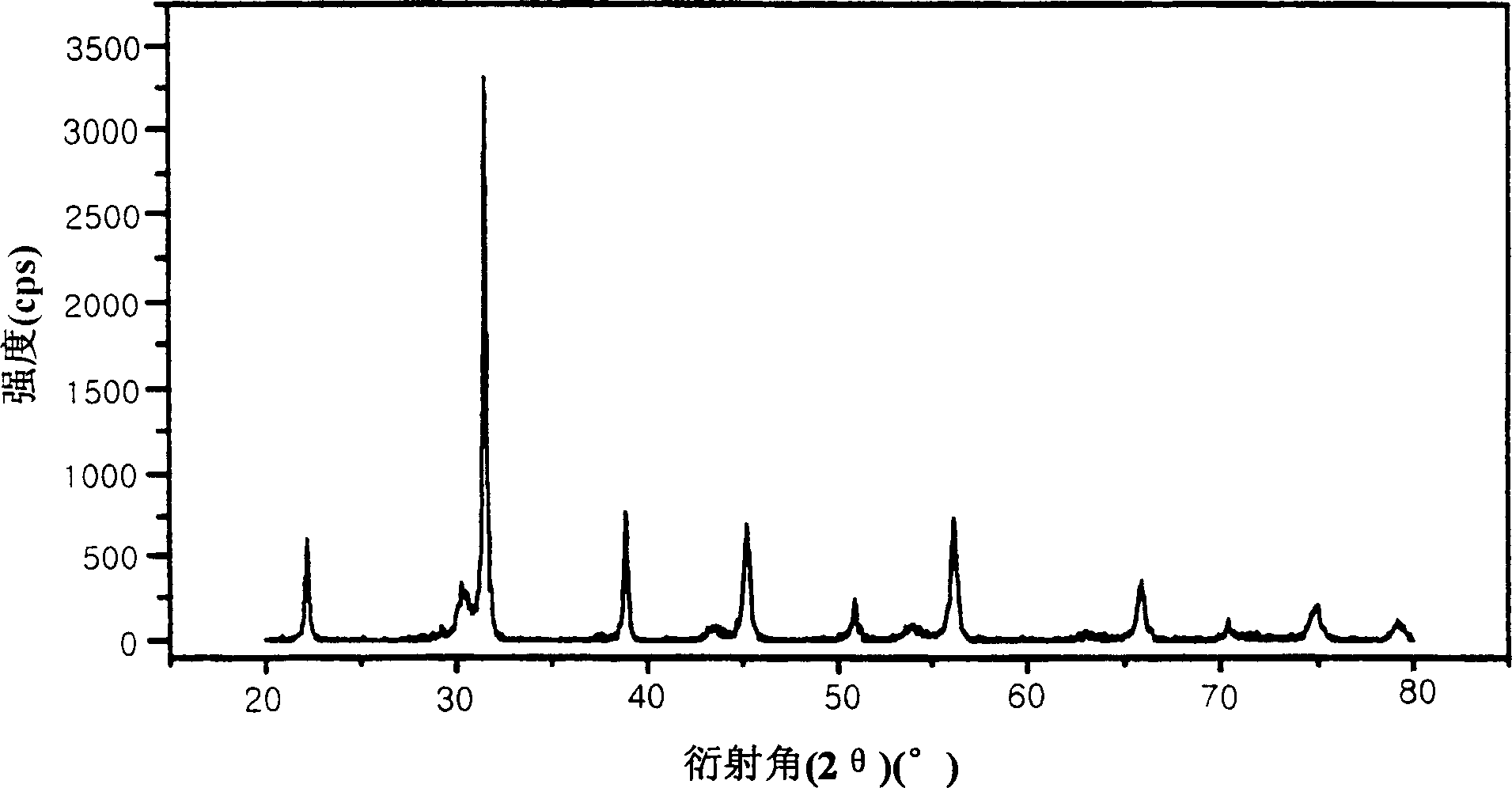

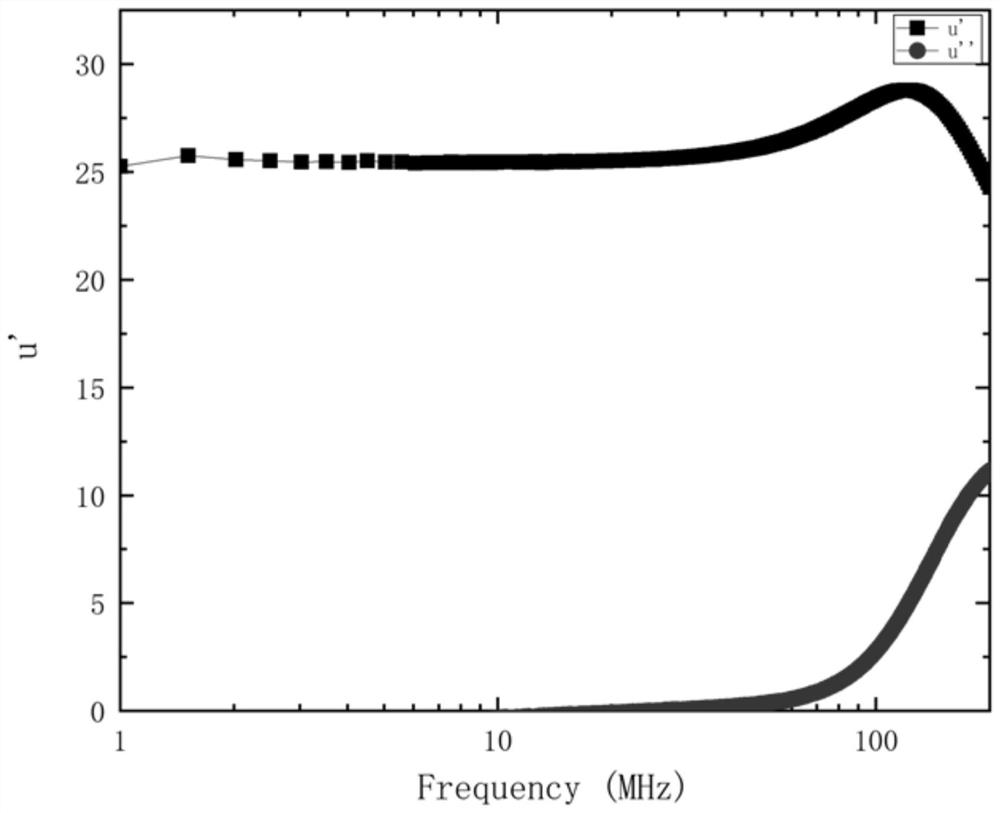

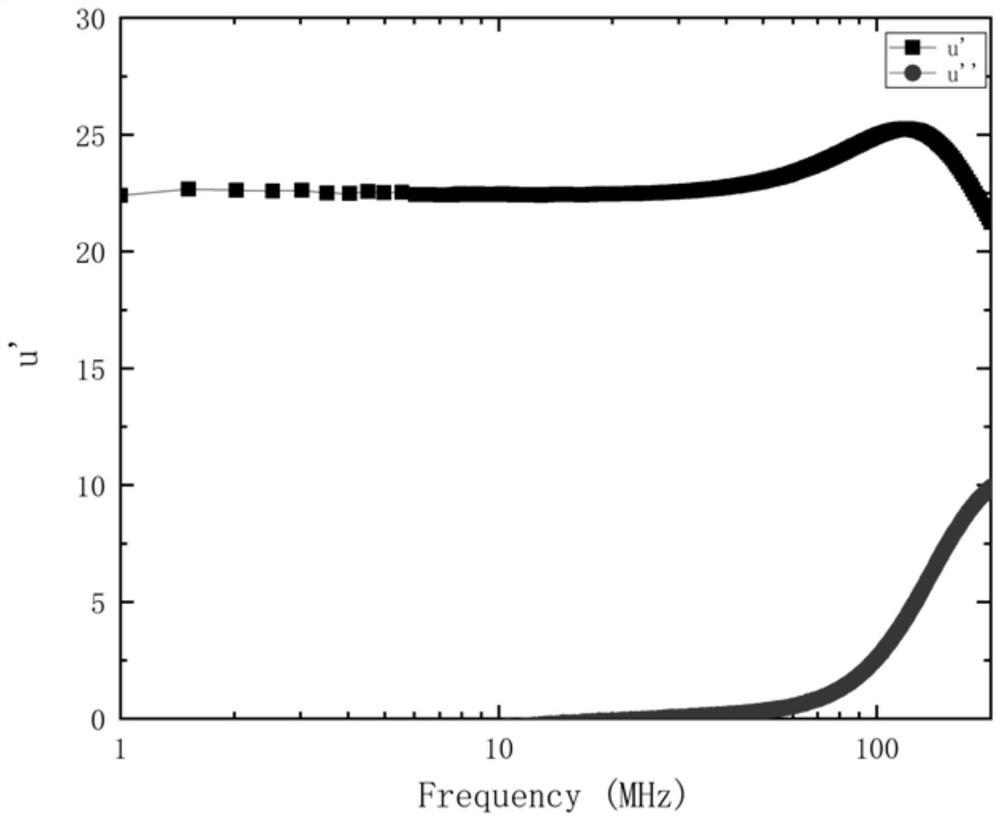

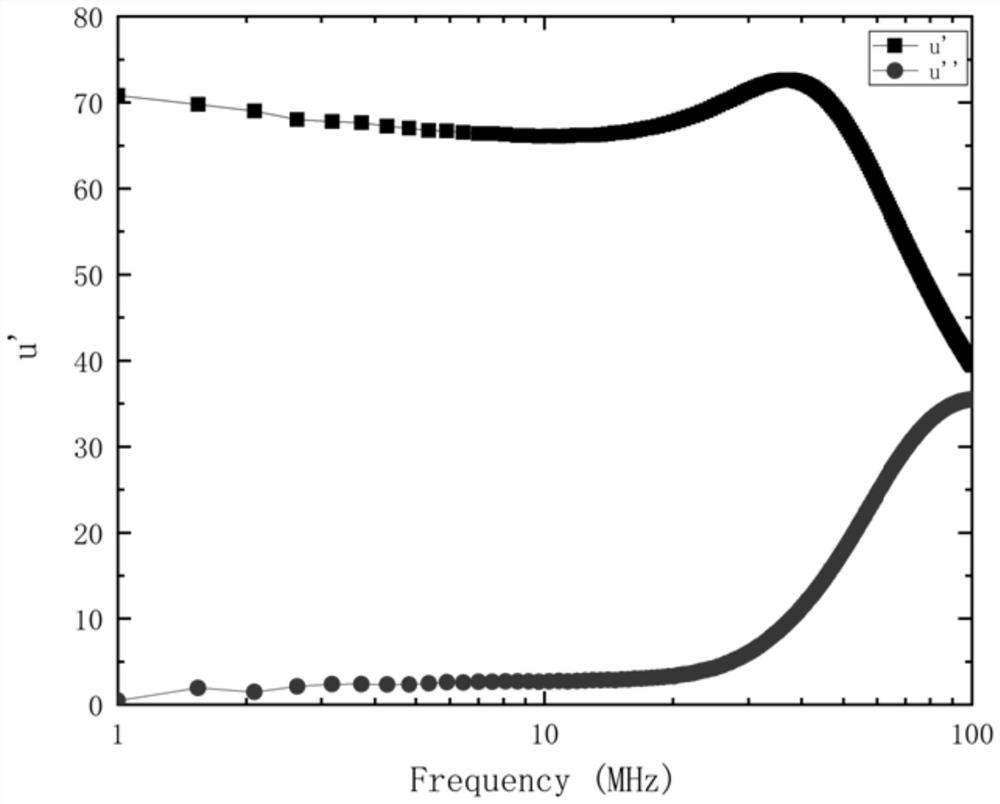

Nickel-zinc ferrite material and preparation method thereof

ActiveCN112194481AApplicable frequency range is wideHigh permeability peak frequencyInorganic material magnetismInductances/transformers/magnets manufactureNickel-zinc ferritePhysical chemistry

The invention discloses a nickel-zinc ferrite material and a preparation method thereof. The nickel-zinc ferrite material comprises main components and auxiliary components, wherein the main components consist of the following components in percentage by mole: 48%-51% of Fe oxide, 12%-18% of Ni oxide, 15%-23% of Zn oxide and 4%-7% of Co oxide, with the balance being Cu oxide; and the auxiliary components comprise a Mn compound and a Ca compound. The nickel-zinc ferrite provided by the invention has the characteristics of wide applicable frequency range, high magnetic conductivity peak frequency, small specific loss coefficient, high saturation magnetization, low coercive force and high Curie temperature, and presents wide application prospects.

Owner:LANZHOU UNIVERSITY

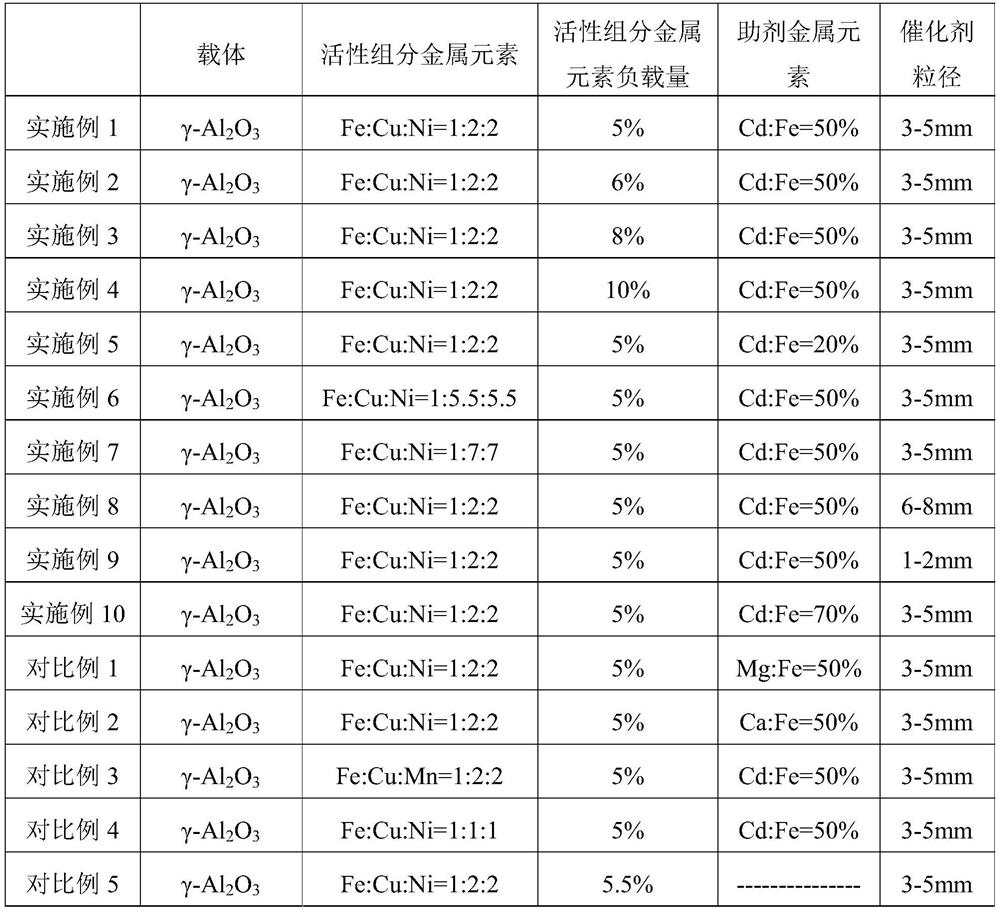

Composite catalyst for coking wastewater treatment and preparation method thereof

PendingCN114308045AHigh removal rateEasy to prepareWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationPtru catalyst

The invention discloses a composite catalyst for coking wastewater treatment, the composite catalyst comprises a carrier, an active component and an auxiliary agent, the carrier comprises gamma-Al2O3, the active component is an oxide of Fe, Cu and Ni, and the auxiliary agent is a Cd oxide. In the active component, the mass ratio of Fe oxide to Cu oxide to Ni oxide is 1: (1.5-7): (1.5-7); the mass of the auxiliary agent Cd oxide is 20-70% of the mass of the active component Fe oxide; the loading capacity of the active component metal oxide is 5-10% based on the total mass of the catalyst. According to the composite catalyst for coking wastewater treatment, the raw materials are easy to obtain, the cost is low, the preparation method is simple, high-concentration coking wastewater can be effectively treated, and the COD removal rate can reach 85%.

Owner:CCTEG CHINA COAL RES INST

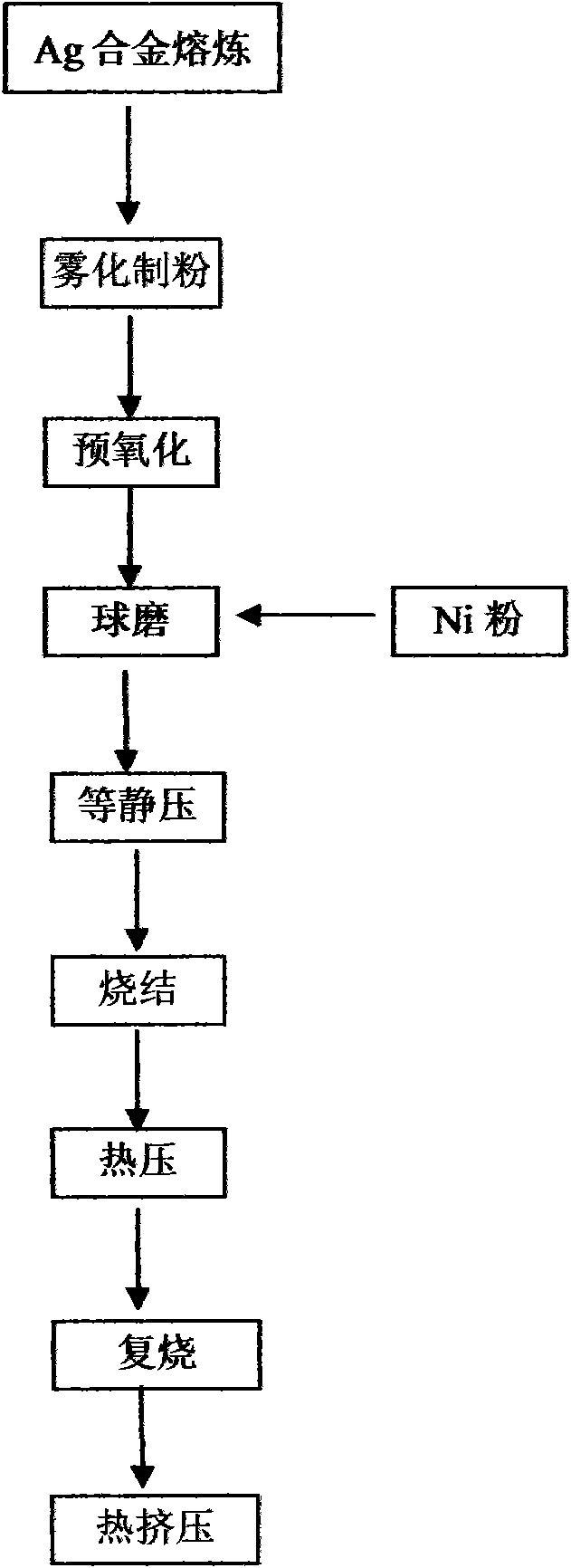

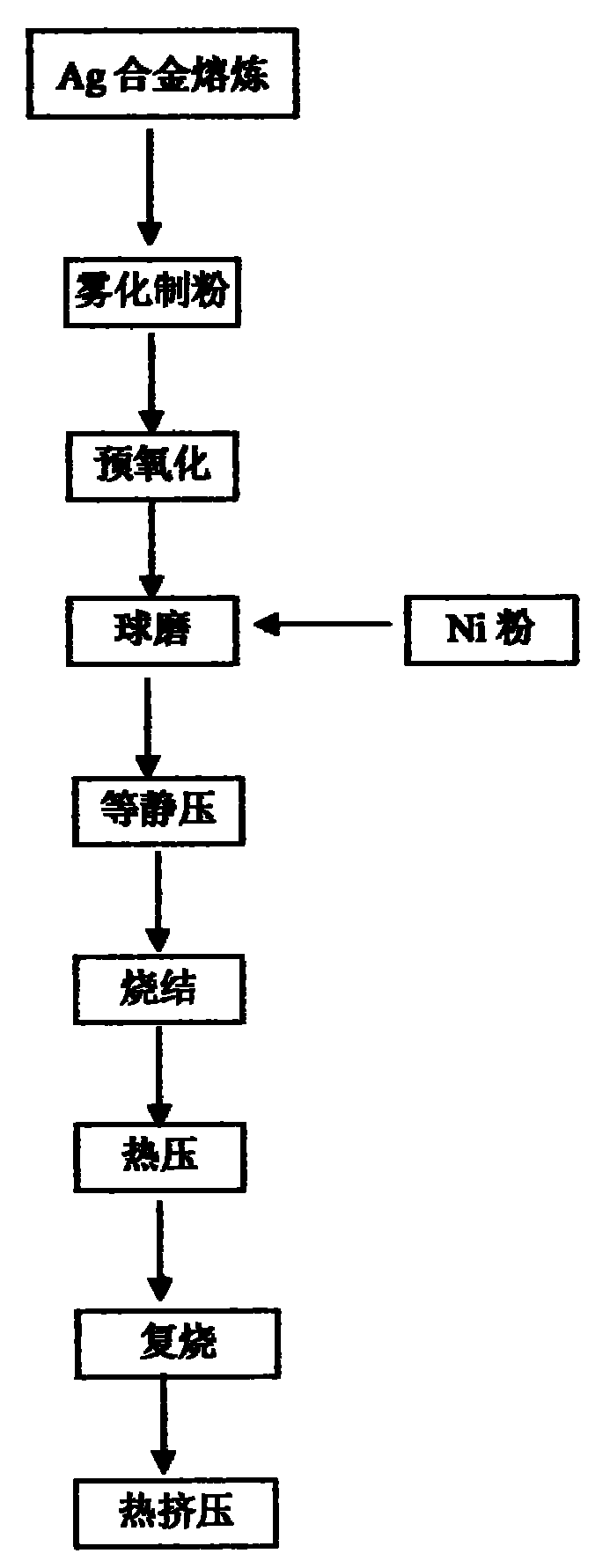

Ag-Ni-oxide electrical contact material and preparation method thereof

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

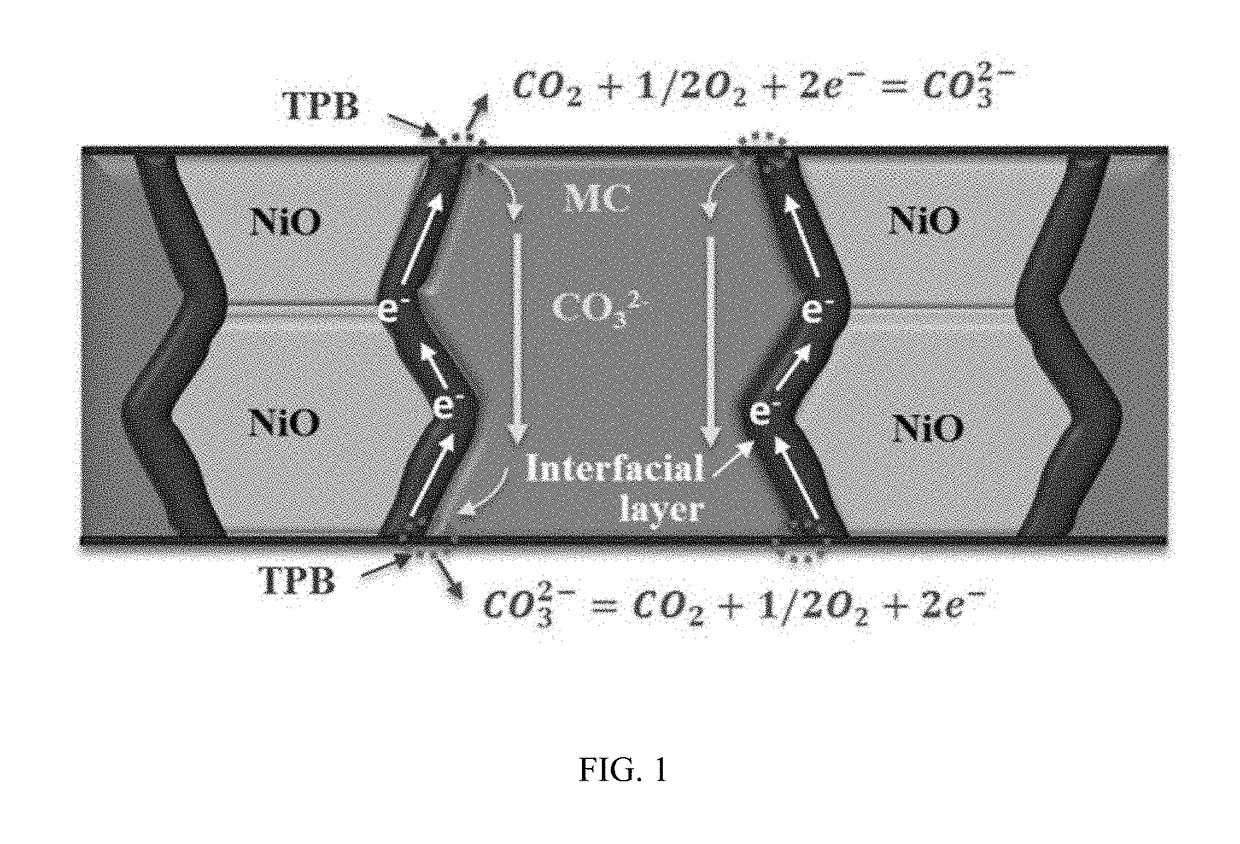

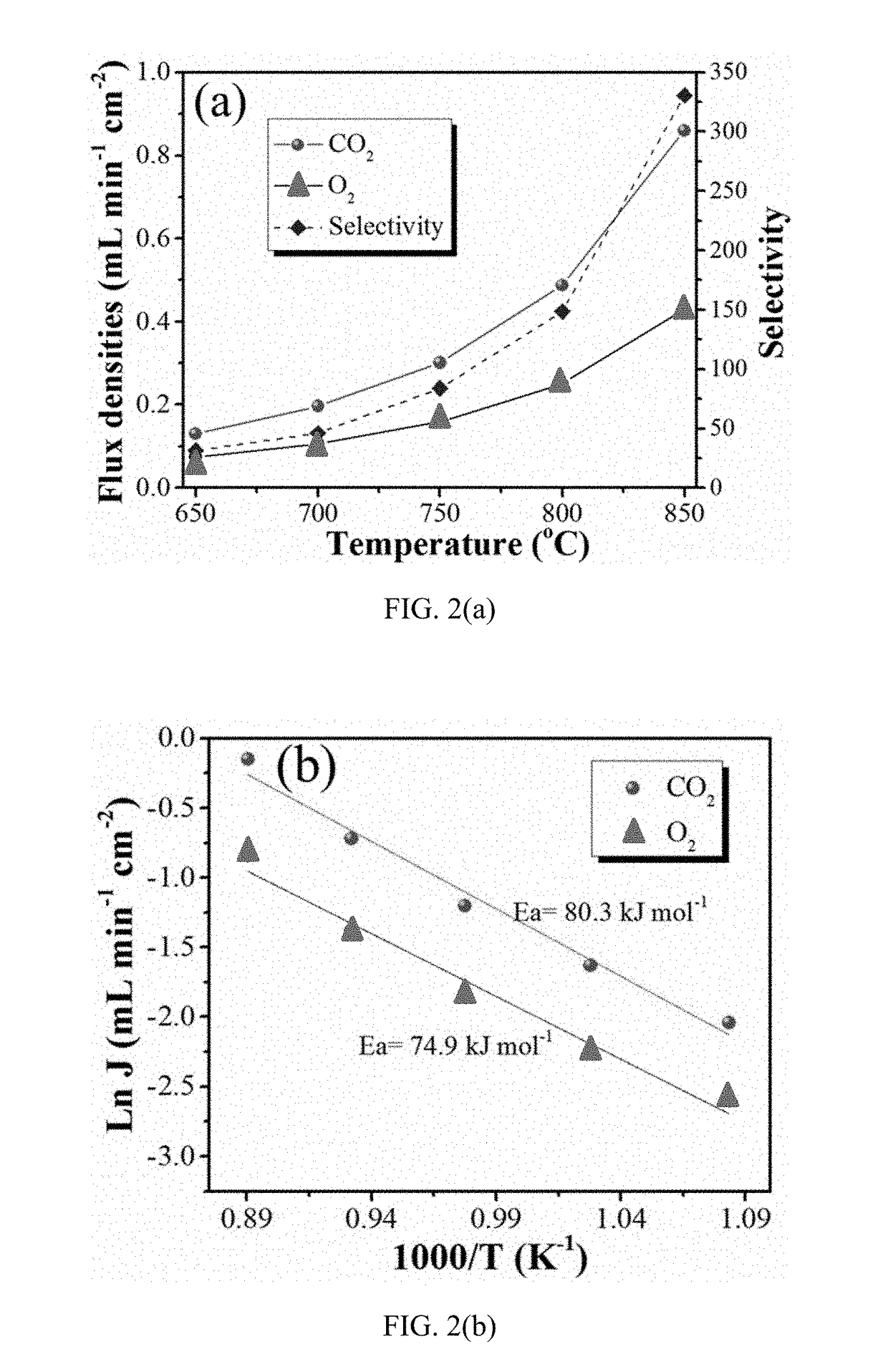

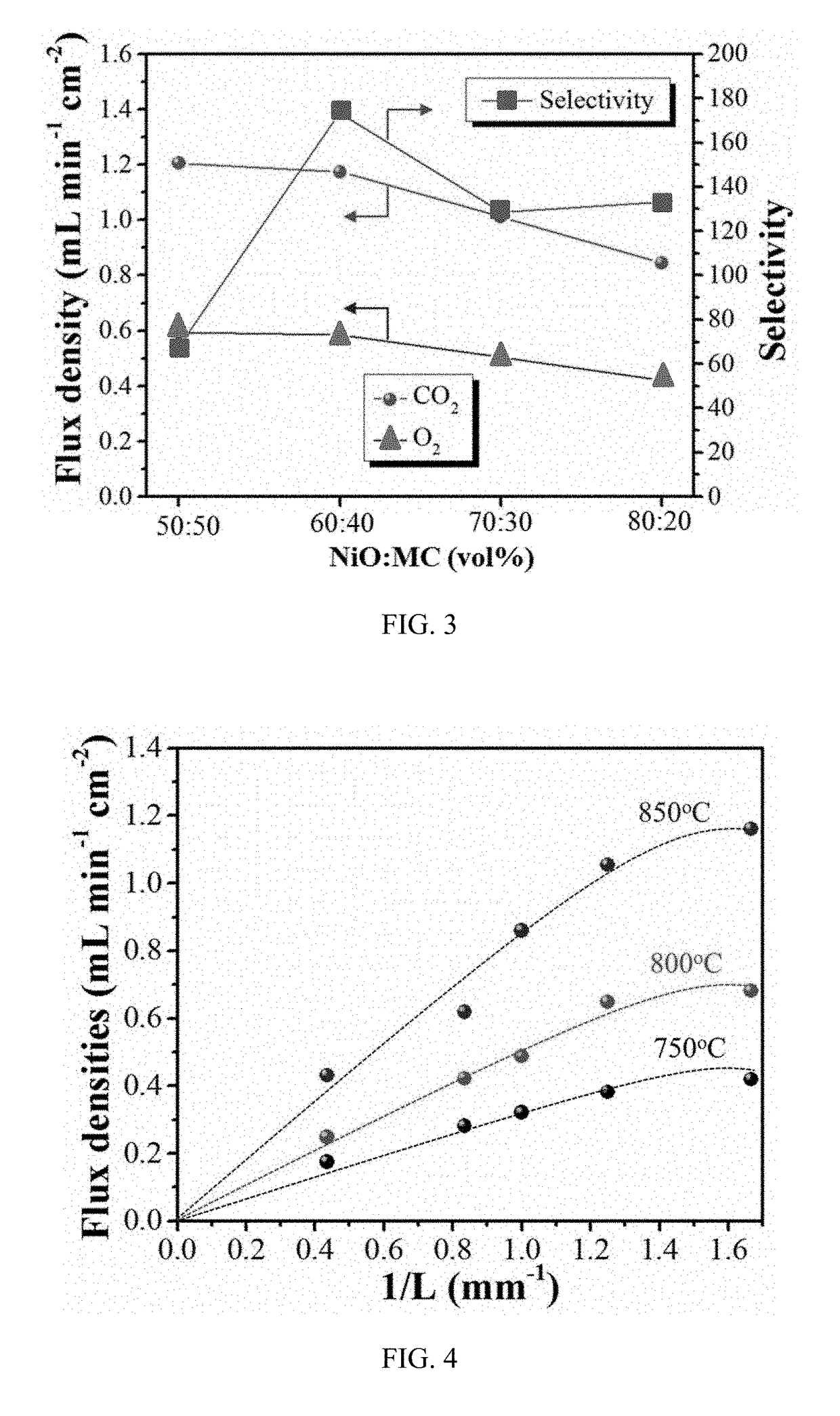

Self-forming membrane for high flux and selective electrochemistry-based co2 capture

A low-cost and easy-to-fabricate mixed e− and CO32− conducting membrane for advanced high-flux and selective electrochemical CO2 separation from flue gas is provided. The membrane includes a CO32−-conducting molten carbonate phase and an e−-conducting lithiated Ni-oxide interphase that can be formed in situ during operation. The membrane exhibits a CO2 flux density greater than 0.8 mL / (minute·cm2) at 850° C. with a selectivity ranging from about 100 to about 500 and excellent stability for up to about 450 hours. Further, the self-formed interphase Li0.4Ni1.6O2 is highly electron conducting and can provide electrons to the co-reduction of CO2 and O2 into CO32−. Such a membrane is an alternative to the conventional “size-sieving” inorganic and “dissolution-diffusion” organic counterparts for CO2 capture from flue gas.

Owner:UNIVERSITY OF SOUTH CAROLINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com