Preparation method for high-capacity Sn-Ni alloy compound as lithium ion battery negative electrode material

A technology for lithium ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of complex preparation process, low yield and high cost, and achieve simple process, high yield and high specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

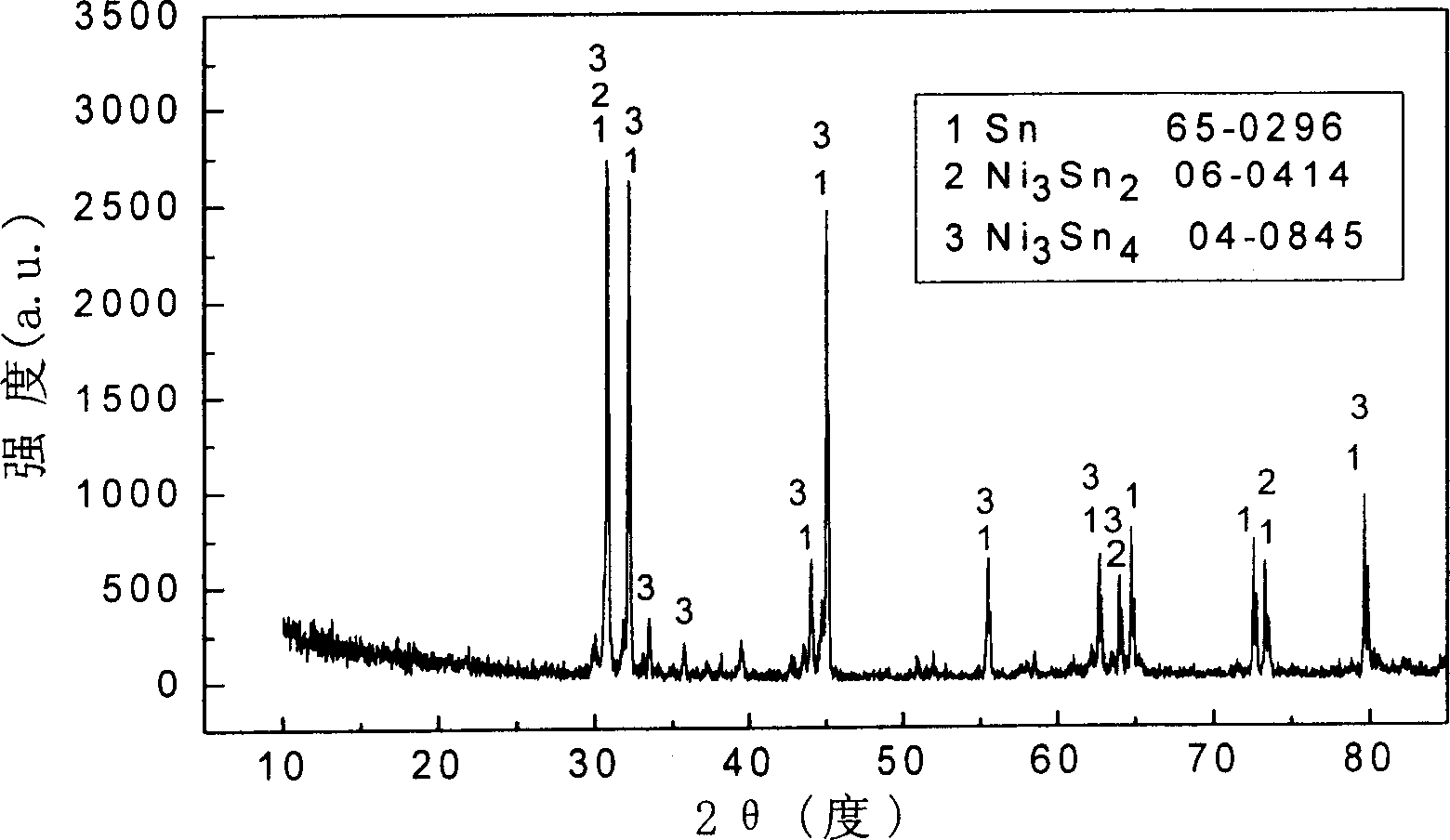

[0015] with SnO 2 (purity > 99.9%), NiO (purity > 99.9%), and activated carbon (purity > 99%) are the initial raw materials, and the molar ratio is 3: 1: 7.5 (equivalent to Sn: Ni atomic ratio is 3: 1 ), after the mixture was ground evenly, it was placed in a flowing argon atmosphere and raised to 900°C at a rate of 5°C / min, and kept for 2 hours, then turned off and cooled to room temperature naturally. The XRD phase analysis results of the obtained sample show that the synthetic product is Sn / Ni 3 sn 2 / Ni 3 sn 4 Alloy composite without any oxide impurity phase.

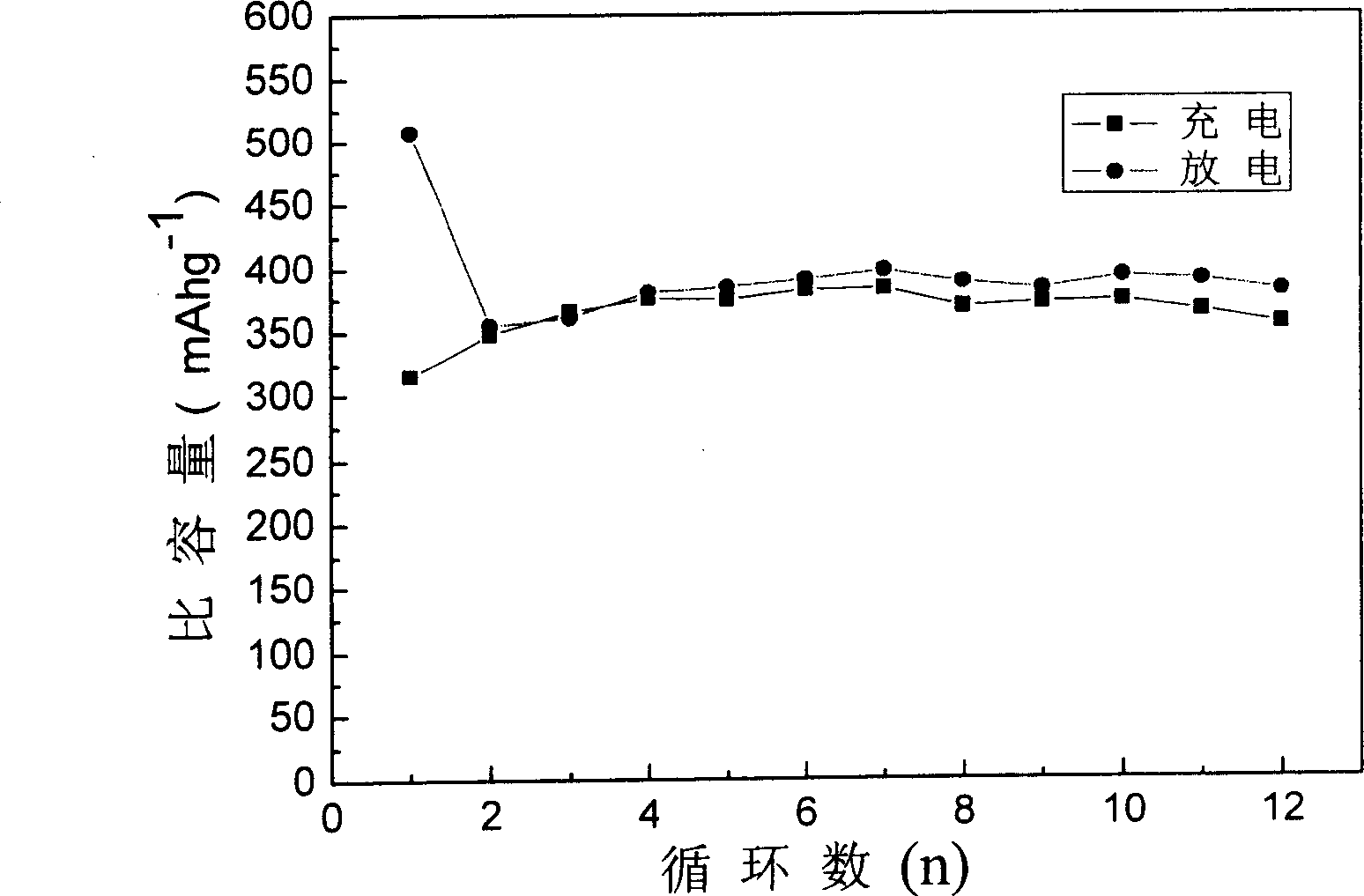

[0016] Add 10wt% conductive agent acetylene black and 10wt% binder PVDF to the synthesized material to make a slurry, evenly spread it on the copper foil, after drying, card it into a circular pole piece, and form a test battery with metal lithium. Carry out constant current charge and discharge experiments, the charge and discharge current is 100mA / g, and the charge and discharge voltage range is controlled be...

Embodiment 2

[0018] with SnO 2 (purity > 99.9%), NiO (purity > 99.9%), and activated carbon (purity > 99%) are the initial raw materials, and the molar ratio is 2: 1: 5.3 for batching (the atomic ratio of Sn: Ni is 2: 1) After grinding the mixture evenly, place it in a flowing argon atmosphere, raise the temperature to 1000°C at a rate of 10°C / min, keep it warm for 1 hour, then turn off the power, and cool it down to room temperature naturally. The XRD phase analysis of the obtained sample shows that the synthetic product is Ni / Ni 3 sn 2 / Ni 3 sn 4 Alloy composite without any oxide impurity phase.

[0019] Add 13wt% conductive agent acetylene black and 12wt% binder PVDF to the synthesized material to make a slurry, evenly coat it on copper and platinum, after drying, clamp it into a circular pole piece, and form a test battery with metal lithium. Carry out constant current charge and discharge experiments, the charge and discharge current is 100mA / g, and the charge and discharge volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com