Composite catalyst for coking wastewater treatment and preparation method thereof

A composite catalyst, coking wastewater technology, applied in oxidation water/sewage treatment, physical/chemical process catalysts, chemical instruments and methods, etc. problems such as reproduction, to achieve the effect of easy large-scale industrial production, improved COD removal rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention also provides a method for preparing a composite catalyst for coking wastewater treatment, comprising the following steps:

[0025] a. Mix the salt solution of the active components Fe, Cu and Ni and the salt solution of the auxiliary agent Cd to obtain the impregnation solution;

[0026] b. adding a carrier into a granulator, spraying the impregnation solution on the carrier, and granulating to obtain pellets;

[0027] c. Drying and calcining the pellets to prepare a spherical catalyst.

[0028] The preparation method of the composite catalyst for coking wastewater treatment in the embodiment of the present invention adopts the pelletizing method to prepare the catalyst, and the powder particles are agglomerated under the action of liquid bridge and capillary force to form micronuclei, and the friction force generated by the rotation of the container Under the impact of rolling and rolling, it will continue to rotate and grow in...

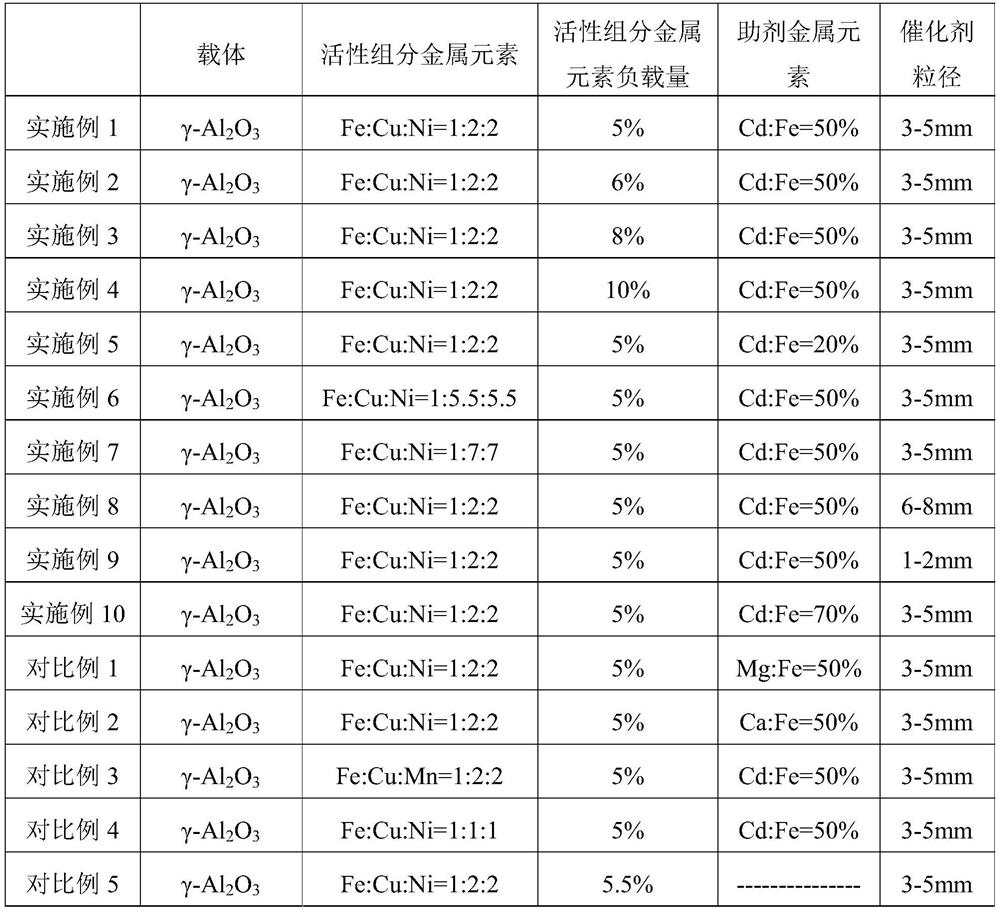

Embodiment 1

[0033] Mix ferric nitrate, copper nitrate, nickel nitrate, and cadmium nitrate with water to form an impregnation solution, and add the carrier γ-Al in small amounts and multiple times in the granulator 2 o 3 , while spraying the impregnating solution on the carrier, so that the carrier and the components of the impregnating solution are fully mixed, slowly grow into balls, sieve out 3-5mm small balls, after 24 hours of development, dry and roast at 500°C for 4 hours to obtain a spherical catalyst.

[0034] In the spherical catalyst prepared in this example, the total loading of active components Fe, Cu and Ni oxides was 5%, and the mass ratio of Fe, Cu, Ni and Cd oxides was 1:2:2:0.5.

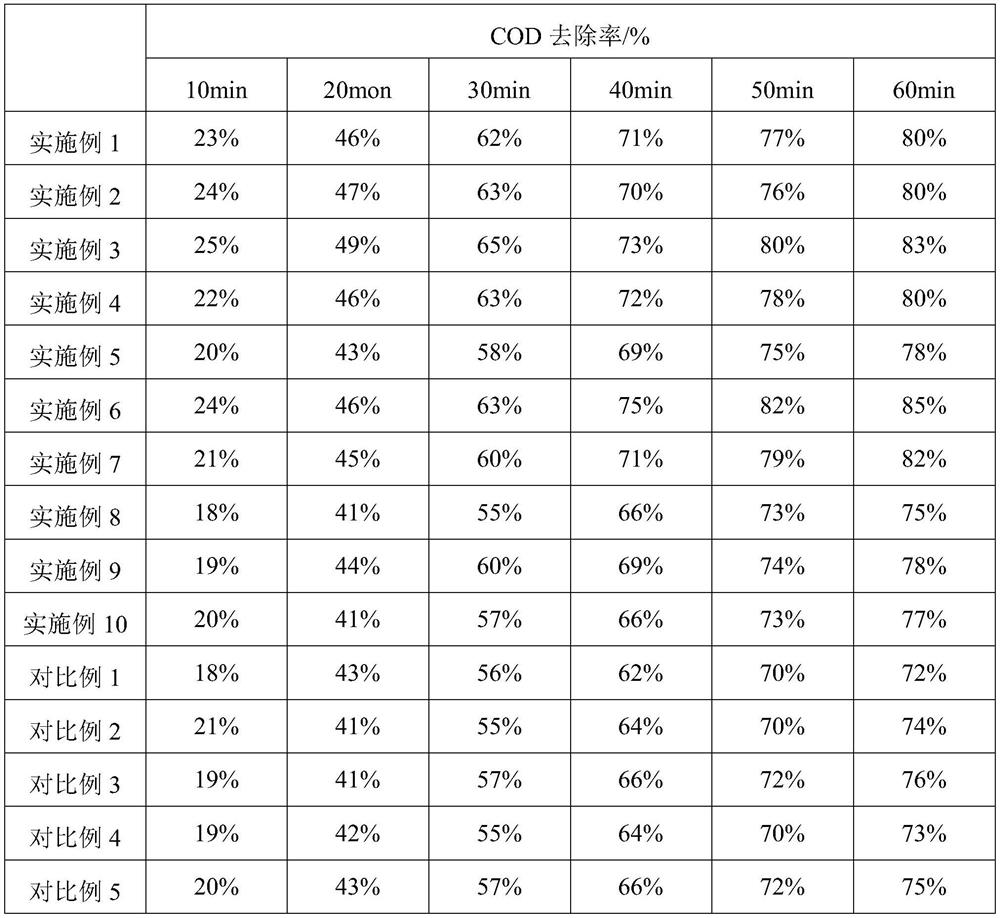

[0035] Catalyst stability test: Soak the catalyst in a simulated water sample composed of quinoline, nitrobenzene, hydroquinone, isopentyl glycol, n-heptane, etc., with a COD value of about 240mg / L, and set After shaking on a shaking table, the concentration of metal ions in the water was mea...

Embodiment 2

[0041] The method is the same as that of Example 1, except that in the prepared spherical catalyst, the total loading of active components Fe, Cu and Ni oxides is 6%.

[0042] The catalytic performance test of the catalyst prepared in this embodiment is shown in Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com