Ag-Ni-oxide electrical contact material and preparation method thereof

A technology of contact materials and oxide electricity, which is applied in contact materials, circuits, electric switches, etc., can solve problems such as poor welding resistance, uneven distribution of additives, excessive particle size of additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

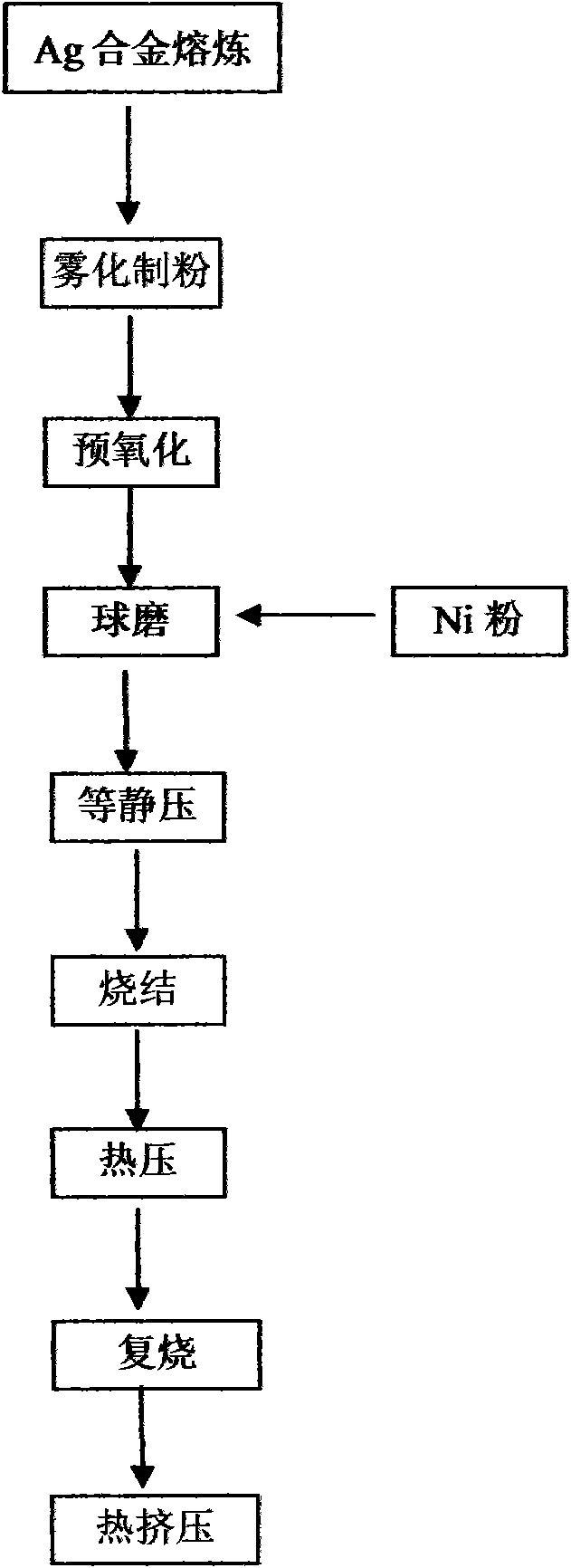

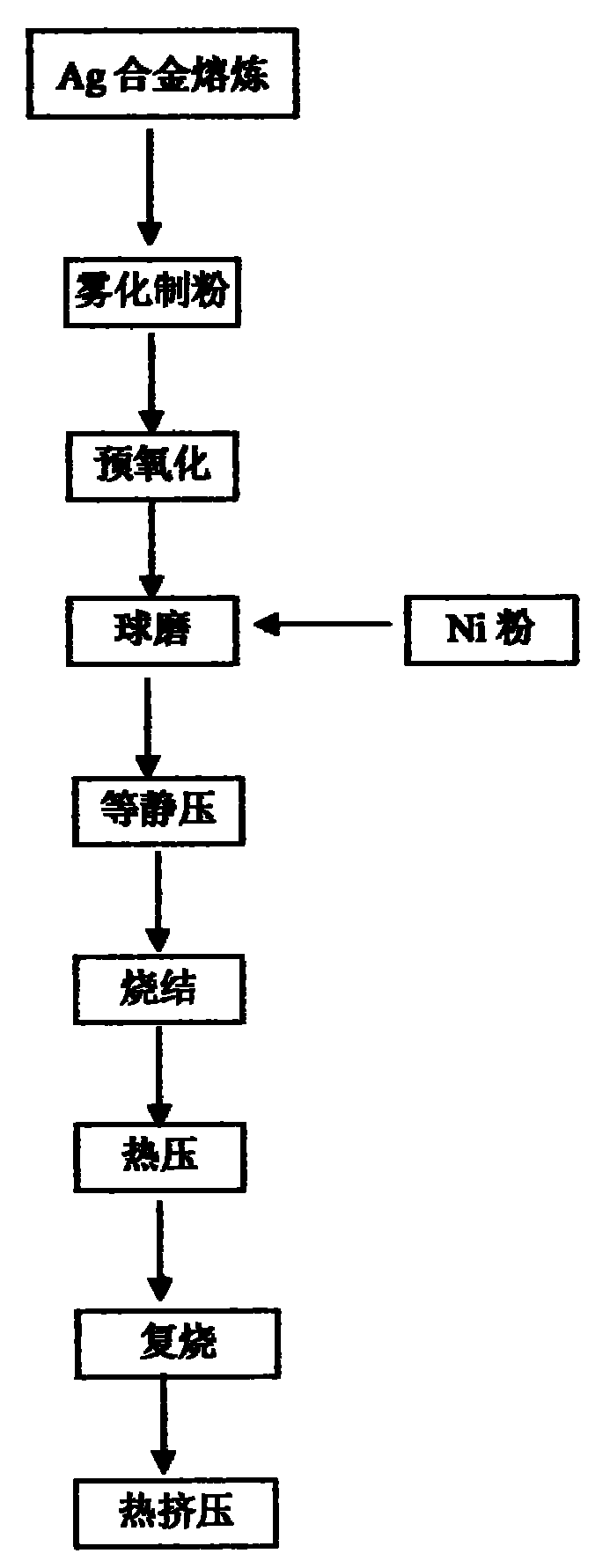

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the weight percent composition of the novel Ag-Ni-oxide contact material is: Ag-10Ni-0.5CdO-0.5SnO 2 , wherein the average particle size of the oxide is 0.1 μm.

[0046] 1) First, the corresponding proportion of Ag block, Cd and Sn metals are smelted together, and the smelting temperature is 1000°C;

[0047] 2) Afterwards, it is atomized into powder; the method of atomization into powder is to adopt the prior art, that is, to impact the above-mentioned molten liquid metal flow with high-pressure gas or water flow to atomize it into small metal droplets, and then solidify into powder;

[0048] 3) Then pre-oxidize the atomized powder in a high-temperature and high-pressure furnace, the pre-oxidation temperature is 900°C, the oxidation pressure is 3MPa, and the oxidation time is 0.5h;

[0049] 4) Mix the pre-oxidized powder with Ni powder for ball milling, the average particle size of Ni powder is 0.1 μm; the ball milling speed is 200 rpm, the ball mil...

Embodiment 2

[0057] In this embodiment, the weight percent composition of the novel Ag-Ni-oxide contact material is: Ag-10Ni-0.05ZnO-0.05Bi 2 o 3 , wherein the average particle size of the oxide is 1 μm.

[0058] 1) Melt the corresponding proportion of Ag block, Cu and Ni metals together, and the melting temperature is 1300°C;

[0059] 2) atomize it into powder afterwards;

[0060] 3) Then pre-oxidize the atomized powder in a high-temperature and high-pressure furnace, the pre-oxidation temperature is 300°C, the oxidation pressure is 3MPa, and the oxidation time is 10h;

[0061] 4) Mix and ball-mill the pre-oxidized powder with the corresponding Ni powder, the average particle size of the Ni powder is 10 μm; the ball milling speed is 20 rpm, the ball milling time is 20 h, and the ball-to-material ratio is 1:1;

[0062] 5) Then the ball-milled powder is pressed into a green body under an isostatic pressure of 500 MPa;

[0063] 6) Sintering the green compact at 750° C. for 10 h under an ...

Embodiment 3

[0069] In this embodiment, the weight percent composition of the new Ag-Ni-oxide contact material is: Ag-5Ni-1CuO-4NiO, wherein the average particle size of the oxide is 2 μm.

[0070] 1) First, the corresponding proportion of Ag block, Cu and Ni metals are smelted together, and the smelting temperature is 1050°C;

[0071] 2) atomize it into powder afterwards;

[0072] 3) Then preoxidize the atomized powder in a high temperature and high pressure furnace, the preoxidation temperature is 600°C, the oxygen pressure is 3MPa, and the oxidation time is 5h;

[0073] 4) Mix the pre-oxidized powder with corresponding Ni powder and ball mill, the average particle size of Ni powder is 2 μm; the ball milling speed is 100 rpm, the ball milling time is 10 h, and the ball-to-material ratio is 5:1;

[0074] 5) Then the ball-milled powder is pressed into a green body under an isostatic pressure of 400 MPa;

[0075] 6) Sintering the green compact at 900° C. for 8 hours under an Ar gas atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com