Catalyst for hydro-denitrification of inferior heavy distillate oil and preparation method and application of catalyst

A heavy distillate oil, hydrodenitrogenation technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as organic acid sintering, and achieve the effect of improving dispersion and vulcanization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

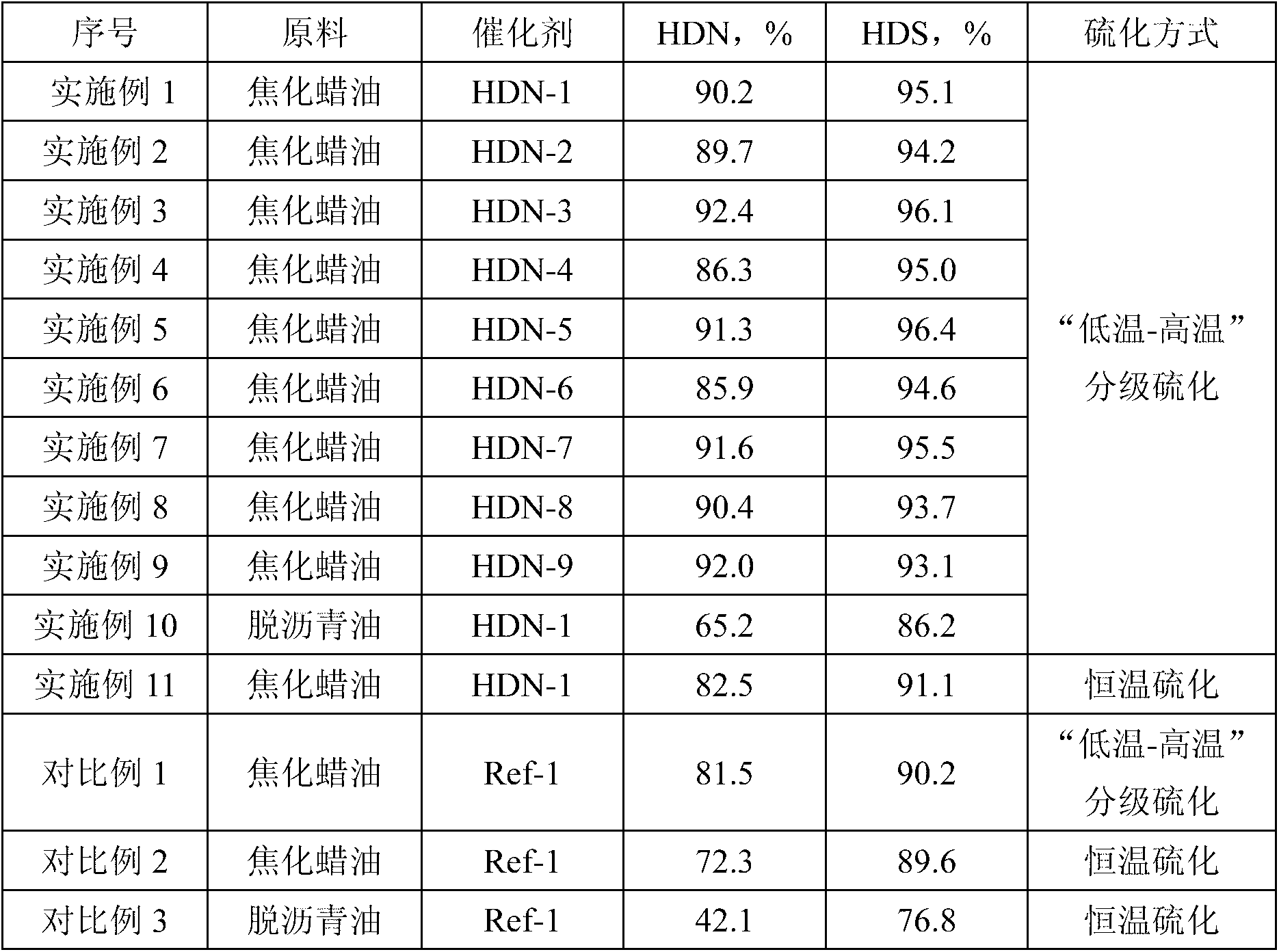

Examples

Embodiment 1

[0049] The first step: Acid treatment of alumina surface

[0050] Weigh 300g of pseudo-boehmite powder, prepare 6L of 0.04mol / L oxalic acid solution, and disperse the pseudo-boehmite powder in the oxalic acid solution in a constant temperature water bath at 40°C. The mass ratio of pseudo-boehmite to oxalic acid solution is 1:20, continuously stirred for 30 minutes, suction filtered and washed until the filtrate was neutral, dried at 120°C for 4 hours, and calcined at 550°C for 3 hours to obtain acid-treated alumina powder.

[0051] The second step: surface acid treatment of molecular sieve

[0052] Weigh 100g HY molecular sieve, prepare 1.5L of 0.05mol / L citric acid solution, put HY molecular sieve into the citric acid solution under the condition of constant temperature water bath at 45°C, stir mechanically for 30min, suction filter the suspension, and wash the filter cake with water Until the filtrate is neutral, dry at 120°C for 3h, and then roast at 500°C for 3h. The aci...

Embodiment 2

[0058] Adopt the aluminum oxide and molecular sieve surface acid treatment mode among the embodiment 1, get the aluminum oxide 85g after the acid treatment respectively, the HY molecular sieve 15g after the acid treatment, after fully mixing, add 4.61g nitric acid (65%), scallop powder 2.5g g, 5 g of citric acid, 80 g of water, kneaded and extruded to shape, dried at room temperature, dried at 120°C for 14 hours, roasted at 550°C for 7 hours, crushed into 20-40 mesh particles, weighed 21g for use. The step-by-step impregnation method is adopted to support metal W and Ni active components. Weigh 8.469g of ammonium metatungstate, dissolve it in 27.5g of deionized water, stir until the ammonium metatungstate particles are completely dissolved, let it stand at room temperature for 6 hours, dry at 120°C for 4 hours, and roast at 550°C for 3 hours. 3 / Al 2 o 3 Sample; then take by weighing 7.008g nickel nitrate, 10.133g citric acid, be dissolved in 27.5g water, will contain Ni and...

Embodiment 3

[0060] Adopt the aluminum oxide and molecular sieve surface acid treatment mode among the embodiment 1, get respectively the aluminum oxide 180g after the acid treatment, the HY molecular sieve after the acid treatment 20g, after fully mixing, add 9.2g nitric acid (65%), scallop powder 5g, citric acid 10g, water 150g, kneading and extrusion molding. After drying at room temperature, dry at 120°C for 14 hours, bake at 550°C for 7 hours, break into 20-40 mesh particles, weigh 70g for use (water absorption 1.25). A step-by-step impregnation method is adopted to support metal W, Mo and Ni active components. Weigh 26.64g of ammonium metatungstate and 7.57g of ammonium molybdate, dissolve them in 87.5g of deionized water, stir until the ammonium metatungstate particles are completely dissolved (can be properly heated), let stand at room temperature for 6 hours, and dry at 120°C for 4 hours. Calcined at 550°C for 3h, first made into Mo-WO 3 / Al 2 o 3 Sample; then weigh 7.57g nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com