Nanotube/porous Ti/W/Ni oxide thin film catalytic electrode in-site loaded with platinum/palladium nanoparticles and preparation method therefor

A technology of palladium nanoparticles and catalytic electrodes, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the utilization rate of nanotube walls, unstable activity, and less lumen distribution, so as to improve the active surface area and use efficiency , Excellent structural stability, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

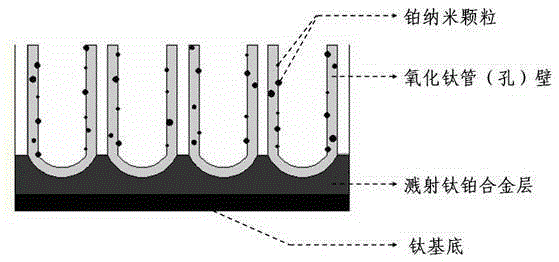

[0029] A nanotube (hole)-shaped Ti / W / Ni oxide in-situ supported platinum (palladium) nano-particle film catalytic electrode and a preparation method thereof. In the formed film electrode, the platinum nano-particles are embedded in the generated titanium oxide tube in situ (Hole)-like nanostructured tube (hole) wall, its structure diagram is as attached figure 1 As shown; its preparation method is as follows:

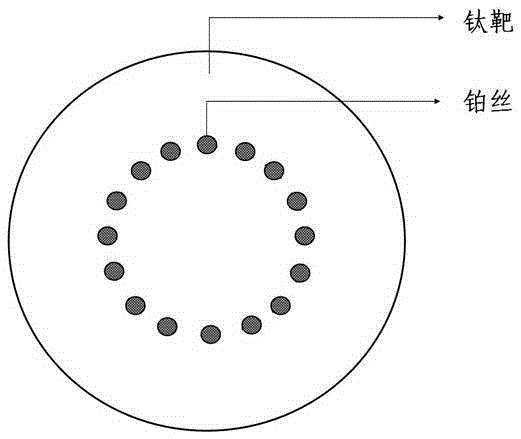

[0030] Step 1. First, design the multi-element sputtering target. Here, a disc-shaped titanium target with a purity of 99.5% is used as the base target. Platinum wires are embedded in the densely distributed areas of the magnetic field during magnetron sputtering. The titanium target is used. The diameter of the material is 100mm, the thickness is 5mm, the diameter of the inlaid platinum wire is 1mm, and the length is 5mm; the schematic diagram of the designed and processed titanium platinum composite target is attached figure 2 As shown; keep the inlaid platinum (palladi...

Embodiment 2

[0037] A nanotube (hole)-shaped tungsten oxide in-situ supported platinum nano-particle film catalytic electrode and a preparation method thereof. The platinum nano-particles in the formed film electrode are in-situ embedded in the generated tungsten oxide tube (hole)-shaped nano-structured tube (Hole) wall, its preparation method is as follows:

[0038] Step 1. First, design the multi-element sputtering target. Here, a disc-shaped tungsten target is used as the base target, with a purity of 99.9%. The platinum wire is embedded along the dense area of the magnetic field line during magnetron sputtering. The tungsten target is used. The diameter of the material is 100mm, the thickness is 3mm, the diameter of the inlaid platinum wire is 1mm, and the length is 3mm; then the processed composite target material is placed on the target position of the magnetron sputtering furnace.

[0039] Step 2. The selected sputtering substrate material is a titanium wafer with a purity of 99.9%, wi...

Embodiment 3

[0044] A nanotube (hole)-shaped tungsten oxide in-situ loaded palladium nano-particle film catalytic electrode and a preparation method thereof. The palladium nano-particles in the formed film electrode are embedded in the generated tungsten oxide tube (hole)-shaped nano-structured tube in situ (Hole) wall, its preparation method is as follows:

[0045] Step 1. First, design the multi-element sputtering target. Here, a disc-shaped tungsten target is used as the base target, with a purity of 99.9%. Palladium wire is embedded on the area where the magnetic field lines are densely distributed during magnetron sputtering. The tungsten target is used. The diameter of the material is 100mm, the thickness is 3mm, the diameter of the inlaid palladium wire is 1mm, and the length is 3mm; then the processed composite target material is placed on the target position of the magnetron sputtering furnace.

[0046] Step 2. The selected sputtering substrate material is a 99.9% purity titanium wafer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com