Dielectric composition with improved uniformity and insulation resistance, its preparing method and multi-layer ceramic capacitor using same

A technology of dielectric composition and insulation resistance, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., and can solve problems such as enlarged grain size, large grain size of dielectric composition, and electrode fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

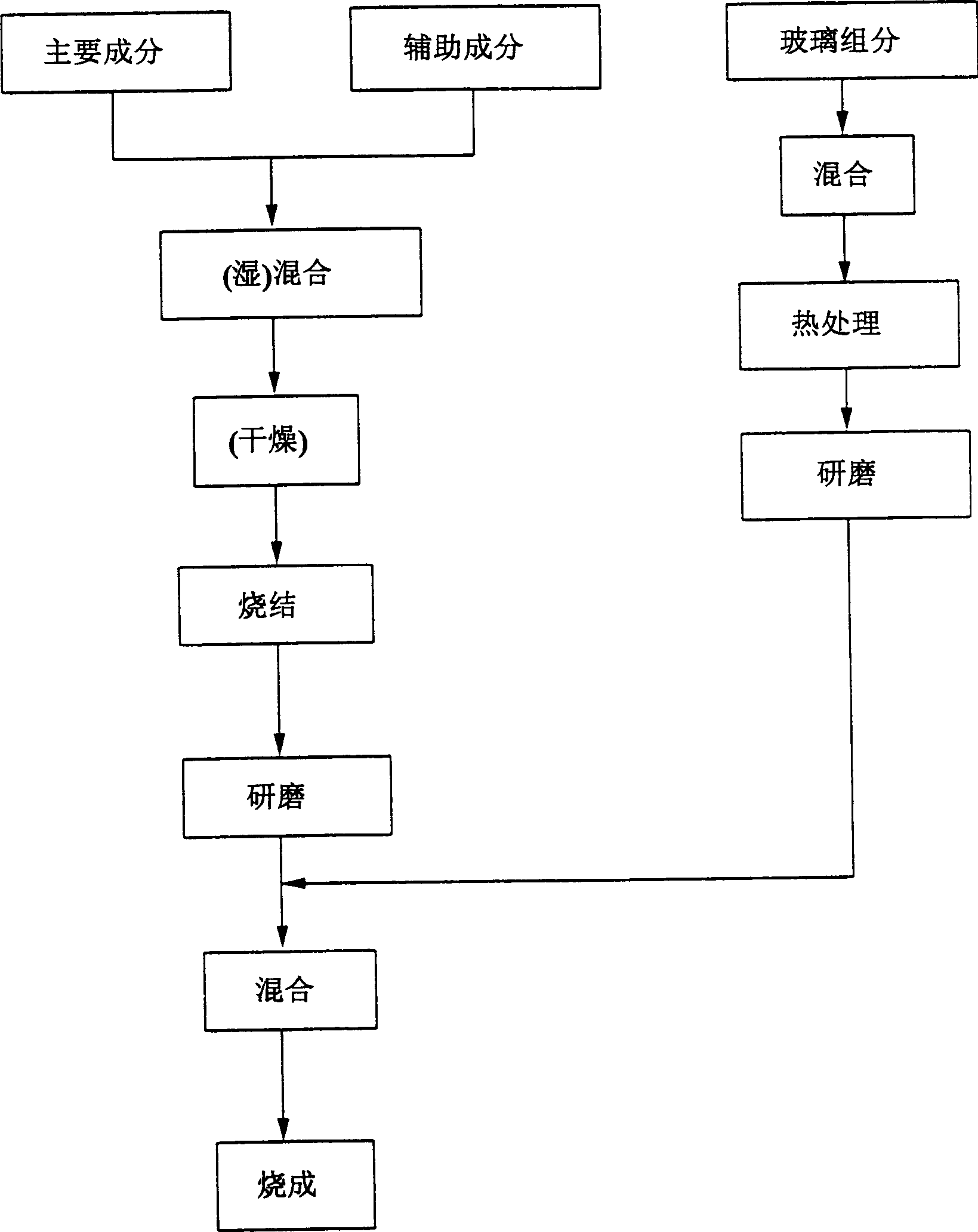

Method used

Image

Examples

Embodiment 1

[0085] Mix barium carbonate, calcium carbonate, zirconium, titanium oxide, yttrium, vanadium, manganese dioxide powder, after drying, heat treatment in an electric furnace at 1050°C for 4 hours, and sinter the main components and auxiliary components at the same time to obtain a dielectric Composition (Ba 1-x-y Ca x Y y ) m (Ti 1-a-b-c Zr a mn b V c )O 3+m (hereinafter referred to as "BCYTZMV").

[0086] In the dielectric composition BCYTZMV, x is the mole fraction of calcium, y is the mole fraction of yttrium, a is the mole fraction of zirconium, b is the mole fraction of manganese, and c is the mole fraction of vanadium, as shown in Table 1.

[0087] In Table 1, No. 5 dielectric component is obtained by first sintering the oxides of barium carbonate, calcium carbonate, zirconium and titanium as the main components, and then mixing them with auxiliary components.

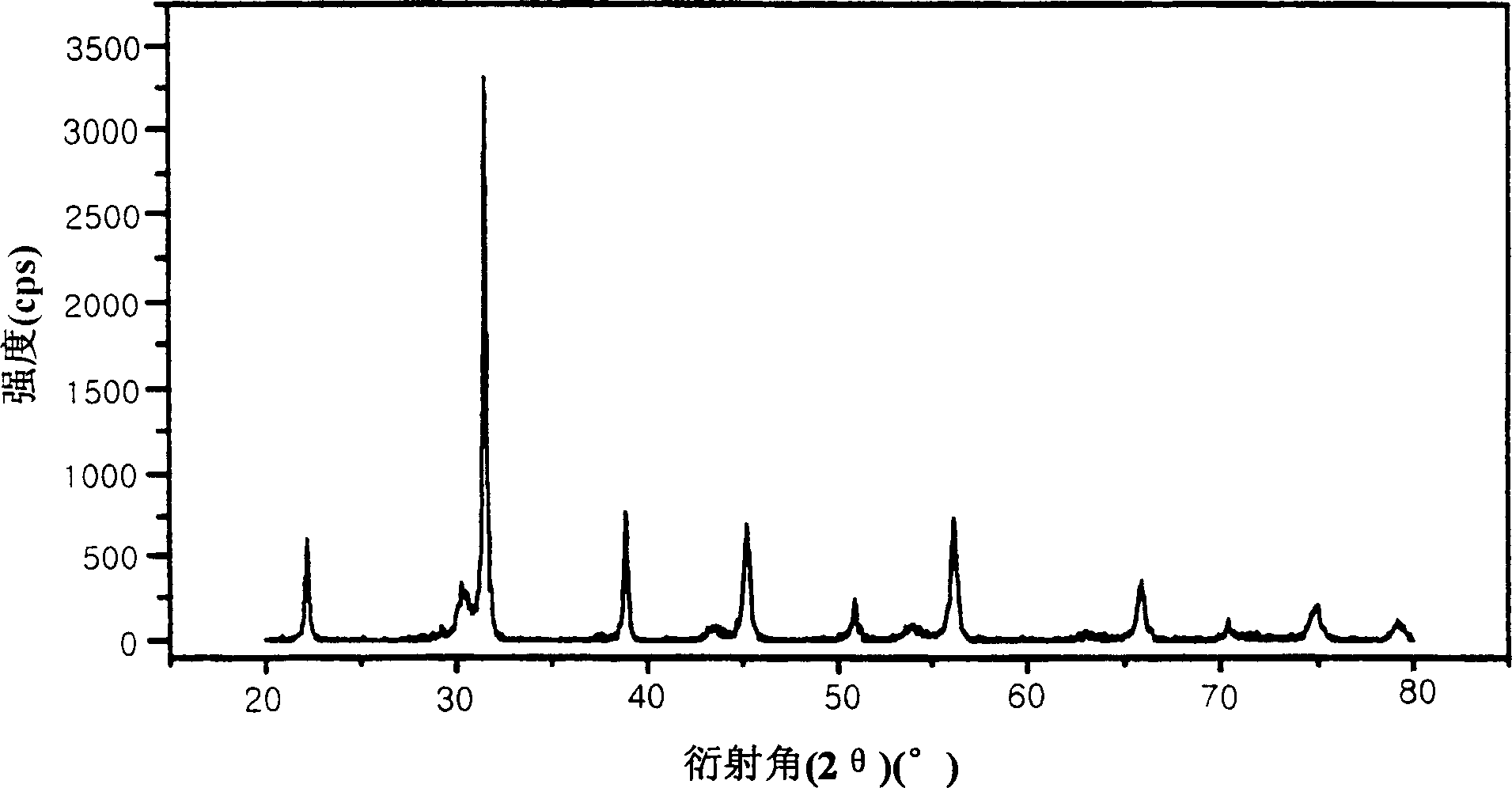

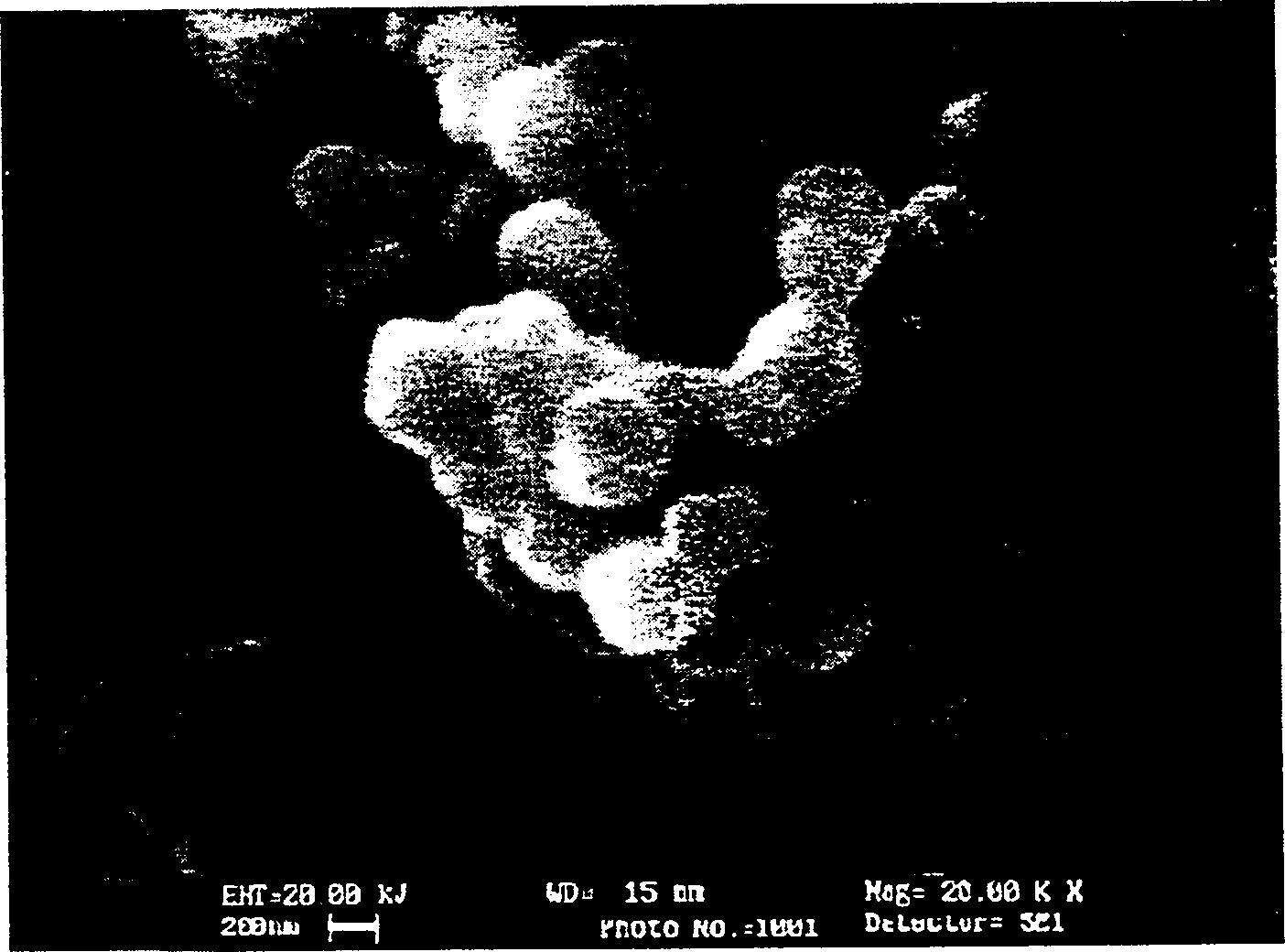

[0088] The average particle size of the BCYTZMV powder sintered in this way is 0.6 micron (detected by ...

Embodiment 2

[0100] The preparation method of each dielectric composition shown in Table 2 is the same as that in Example 1, and their electrical properties are tested at room temperature, and the results are shown in Table 2.

[0101] sample

No

(Ba 1-x-y Ca x A y ) m

(Ti 1-z-b-c Zr a B' b B″ c )O m+3

Burning aid

(LS)

constant

DF

(%)

Resistivity

(×10 13 Ω)

A

B′

B″

x

y

a

B

c

z

state

6

0.05

0.0064

0.175

0.0054

0.003

0.5

synthetic phase

13846

0.498

22.26

Dy

mn

V

7

0.05

0.0066

0.175

0.0054

0.002

0.5

synthetic phase

13474

0.535

12.59

Er

mn

V

8

0.05

0.0060

0.175 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com