Composite catalyst used for reforming hydrogen prodn. using methane and water vapor as raw material, preparing process and use thereof

A composite catalyst, methane steam technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Effects of design stability and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 Composite catalyst preparation

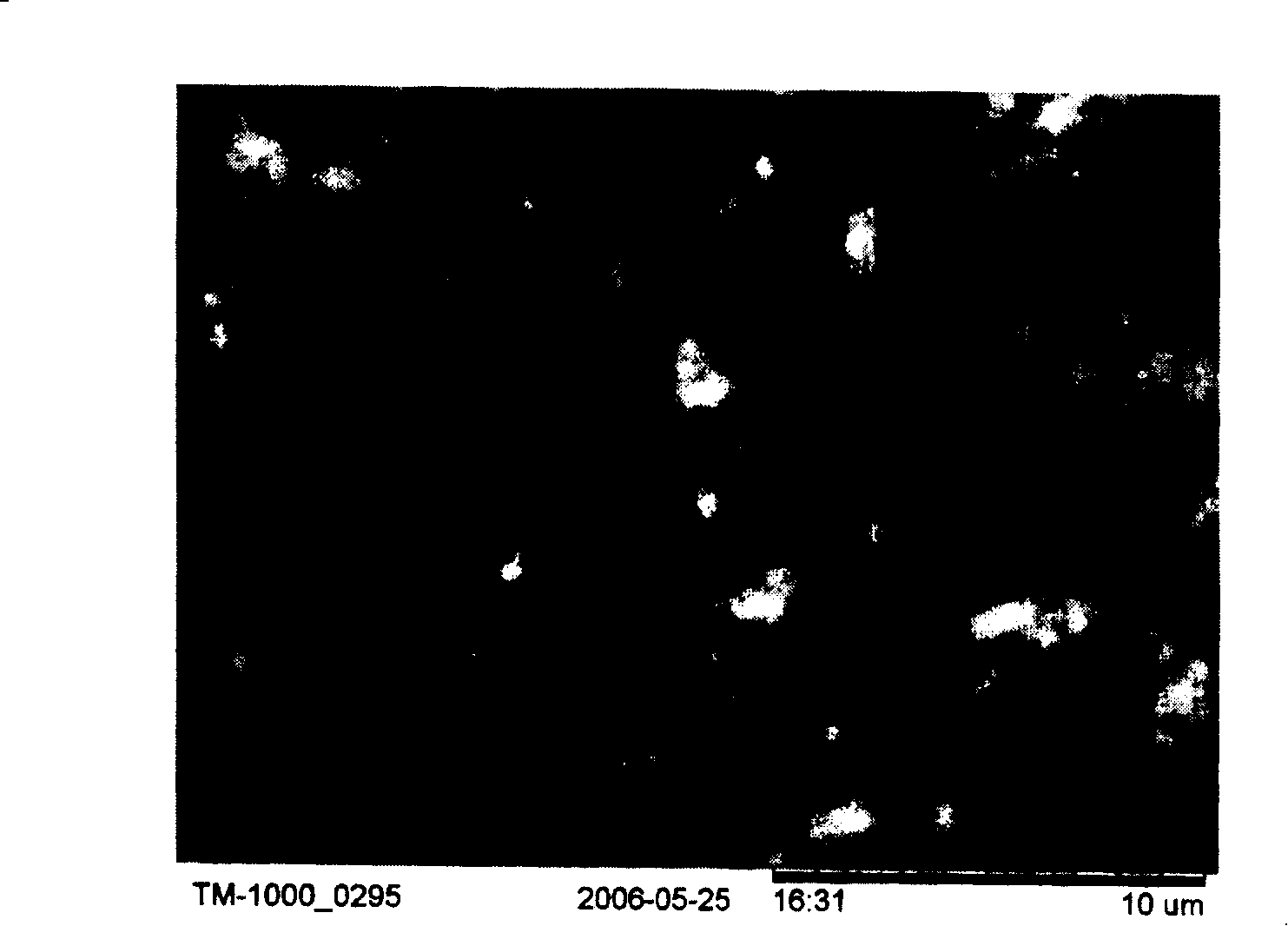

[0063] First add 15g of nano-calcium carbonate powder into the beaker, then add 70ml of 10% solid content alumina-hydrosol, add a small amount of water and mix well, then add 15g of nickel carbonate powder, mix well, infrared dry, extrude, and dry , Composite catalyst CA-1 prepared by calcining. see figure 1 , figure 2 , the catalyst was characterized by transmission electron microscope TEM analysis, and the results showed that the composite catalyst after thermal decomposition pretreatment had obvious deep micropores, and the calcium carbonate generated by CaO adsorbed carbon dioxide after thermal decomposition pretreatment had a spherical structure.

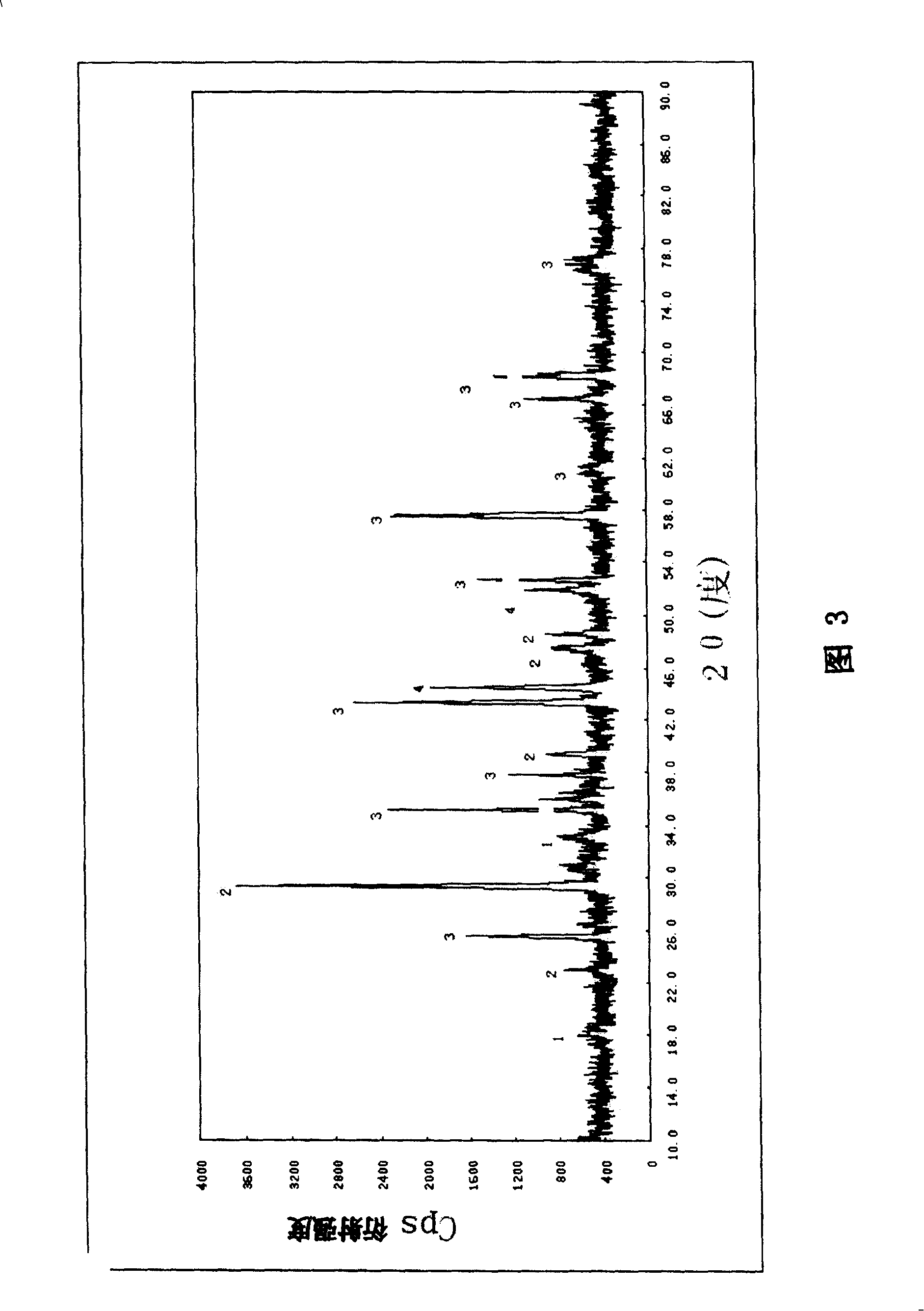

[0064] The catalyst was characterized by XRD, and the results showed that the catalytic components in the composite catalyst were nickel and nickel oxide, and the activity was good. Calcium as CaCO 3 and some Ca(OH) 2 Exist, part of calcium and aluminum form Ca 12 al ...

Embodiment 2

[0065] Embodiment 2 composite catalyst preparation

[0066] First add 10 g of micron calcium hydroxide powder into the beaker, then add 70 ml of alumina hydrosol with a solid content of 8%, stir and mix. Then add nickel carbonate powder of less than 100 meshes, mix well, infrared dry, extrude, dry and calcinate to obtain composite catalyst CA-2.

Embodiment 3

[0067] Embodiment 3 composite catalyst preparation

[0068] First add 5g of nano-calcium carbonate powder into the beaker, then add 35ml of 10% solid content alumina hydrosol, add a small amount of water, stir and mix well, add 10ml of saturated nickel nitrate salt solution, mix well, spray dry, granulate and calcinate , Obtain composite catalyst powder CA-3 with 20-100 microns.

[0069] The catalyst was characterized by XRD, and the results showed that the catalytic component in the composite catalyst was nickel, and the activity was better. Calcium as CaCO 3 and some Ca(OH) 2 Exist, part of calcium and aluminum form Ca 12 al 14 o 33 structure, thereby enhancing the strength of the catalyst and increasing the stability of the adsorption and desorption recycling process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com