Metal phosphide-porous carbon framework composite material, and preparation method and application thereof

A metal phosphide and frame material technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of metal phosphide nanoparticles encountering bottlenecks, collapse, and specific surface area decline, and achieve The preparation method is simple and novel, the cost is low, and the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of preparation of metal phosphide-porous carbon framework composite material, comprises the steps:

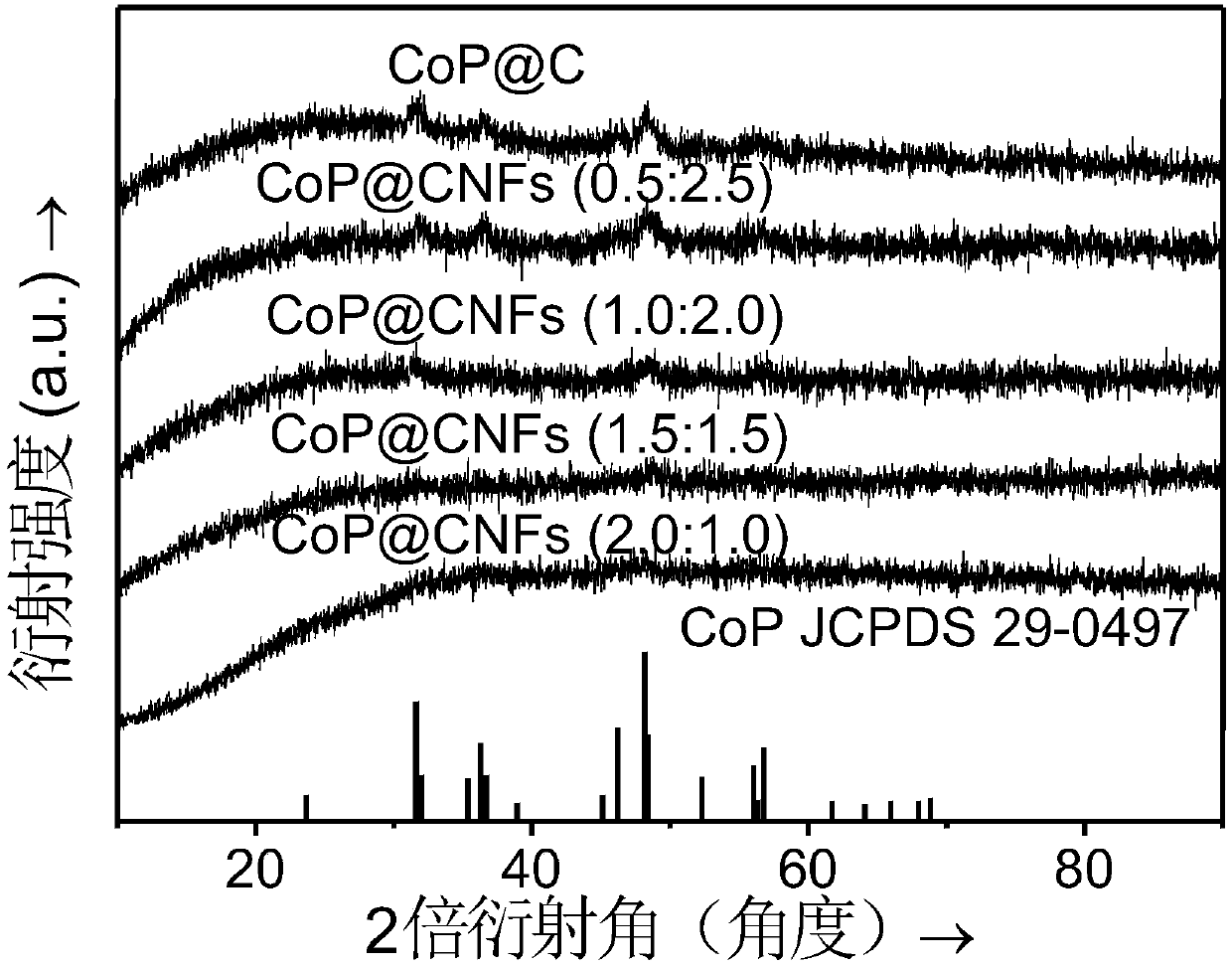

[0058] 1) Weigh 727.68 mg of cobalt nitrate hexahydrate and 148.75 mg of zinc nitrate hexahydrate dissolved in 30 ml of methanol solution as solution A, weigh 1.97 g of dimethylimidazole dissolved in 20 ml of methanol solution as solution B , quickly pour solution A into solution B, stir rapidly at room temperature for 24 hours, and use a centrifuge at 10,000 rpm -1 Centrifuge for 3 minutes, wash with ethanol three times, dry, then calcinate in a muffle furnace at 350°C for 2 hours, and cool down naturally to obtain Zn,Co-O@CNFs (namely zinc oxide and cobalt tetroxide-porous carbon framework composite material), in which The mol ratio of zinc salt and cobalt salt is 0.5:2.5;

[0059] 2) Take 65mg of Zn,Co-O@CNFs prepared in step 1) and put it in the downwind direction of the tube furnace, take 650mg of sodium hypophosphite phosphorus source and put it in the upwi...

Embodiment 2

[0061] A kind of preparation of metal phosphide-porous carbon framework composite material, comprises the steps:

[0062] 1) Weigh 582.14 mg of cobalt nitrate hexahydrate and 297.49 mg of zinc nitrate hexahydrate and dissolve it in 30 ml of methanol solution as solution A, weigh 1.97 g of dimethylimidazole and dissolve it in 20 ml of methanol solution as solution B , quickly pour solution A into solution B, stir rapidly at room temperature for 24 hours, and use a centrifuge at 10,000 rpm -1 Centrifuge for 3 minutes, wash with ethanol three times, dry, and then calcined in a muffle furnace at 350°C for 2 hours, and naturally cool down to obtain Zn,Co-O@CNFs (namely zinc oxide and cobalt tetroxide-porous carbon frame composite material), and feed The mol ratio of zinc salt and cobalt salt in is 1.0:2.0;

[0063] 2) Take 65mg of Zn,Co-O@CNFs prepared in step 1) and put it in the downwind direction of the tube furnace, take 650mg of sodium hypophosphite phosphorus source and put ...

Embodiment 3

[0065] A kind of preparation of metal phosphide-porous carbon framework composite material, comprises the steps:

[0066] 1) Weigh 436.61mg of cobalt nitrate hexahydrate and 446.24mg of zinc nitrate hexahydrate and dissolve it in 30 milliliters of methanol solution as solution A, weigh 1.97g of dimethylimidazole and dissolve it in 20 milliliters of methanol solution as solution B , quickly pour solution A into solution B, stir rapidly at room temperature for 24 hours, centrifuge with a centrifuge at 10,000 rpm for 3 minutes, wash with ethanol three times, dry, and then calcinate in a muffle furnace at 350°C for 2 hours, and naturally cool down to obtain Zn , Co-O@CNFs is zinc oxide and cobalt tetroxide-porous carbon framework composite material, in which the molar ratio of zinc salt and cobalt salt in the feed is 1.5:1.5; zinc oxide and cobalt tetroxide-porous carbon framework composite material under the scanning electron microscope Energy spectrum such as Figure 12 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com