N-doped porous carbon coated Mn-Co-Ni oxide core-shell structure electrode material and preparation method and application thereof

A mn-co-ni, core-shell structure technology, applied in battery electrodes, structural parts, circuits, etc., to achieve the effect of increasing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Dissolve manganese nitrate tetrahydrate, cobalt nitrate hexahydrate, and nickel nitrate hexahydrate in a molar ratio of 2:1:1 in 60 mL of deionized water to prepare a solution with a metal ion concentration of 0.5 mol / L.

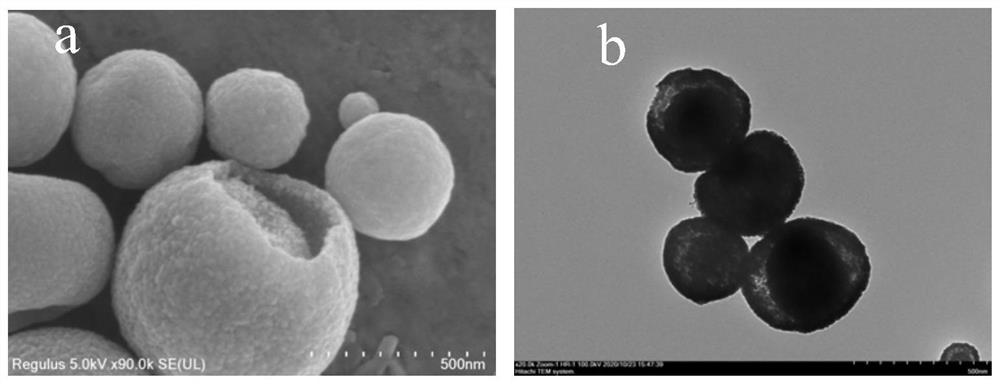

[0047] (2) Move the solution to an ultrasonic nebulizer for atomization. Under the action of a vacuum pump, the atomized droplets are introduced into a glass tube preheated to 500 °C, and the precursor powder is collected at the other end by a filter device.

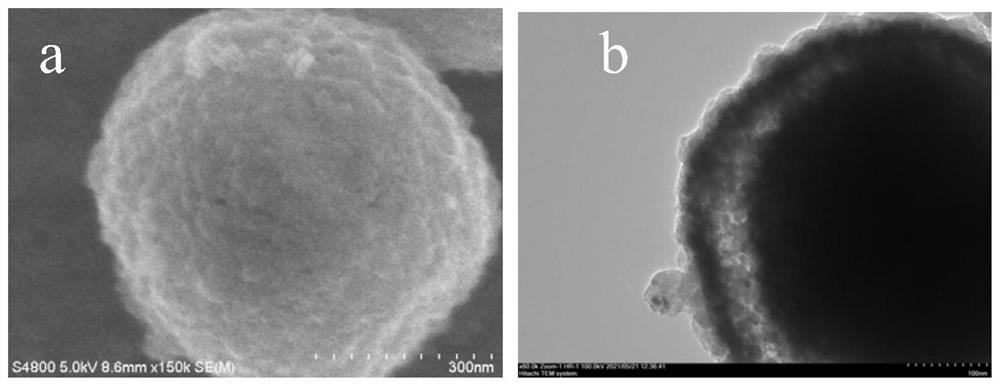

[0048] (3) Dissolve 0.08g of powder in 40mL of deionized water, add 4mg of sodium dodecylbenzenesulfonate, ultrasonically disperse for 10min, stir for 1h, add 15μL of pyrrole monomer, stir for 1h, add 12mL of ammonium persulfate to dissolve (concentration 0.1mol / L), stirred for 3 hours, washed with ethanol and deionized water respectively, and finally placed in a vacuum oven at 60°C for 36 hours to obtain the product.

[0049] (4) In an argon atmosphere, the product was heated from room tem...

Embodiment 2

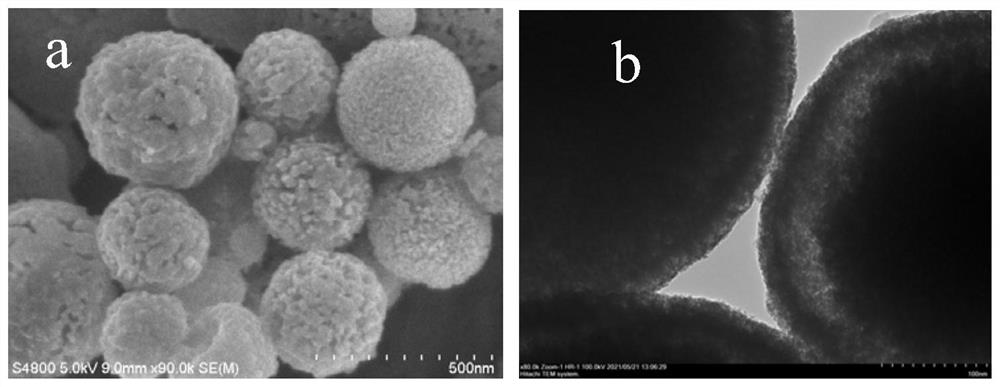

[0051] Carry out according to the method of Example 1, except that 5 μL of pyrrole monomer is added in step (3).

Embodiment 3

[0053] Carry out according to the method of Example 1, except that 25 μL of pyrrole monomer is added in step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com