A kind of thermoplastic polymer foam beads and preparation method thereof

A technology of thermoplastic polymers and foaming beads, which is applied in other household appliances, household appliances, household components, etc., can solve the problems of low foaming ratio, low heat resistance level, complicated process, etc., and achieve high foaming ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

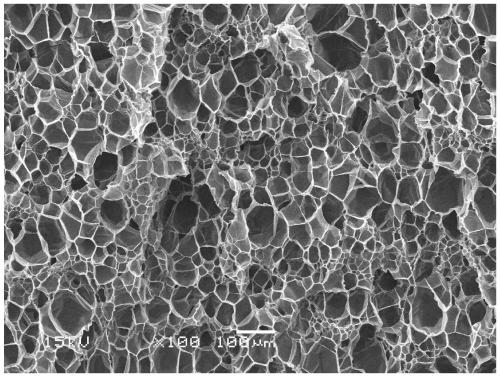

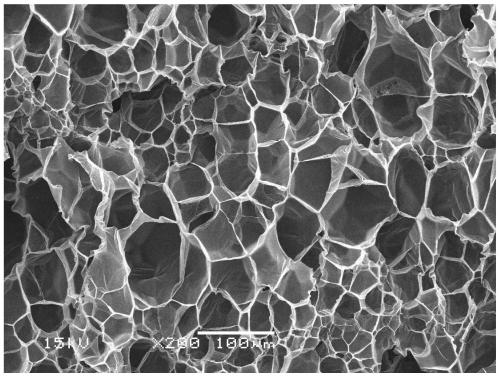

[0037] A thermoplastic polymer foamed bead of the present invention has a foaming ratio of 5-30 times, has a special core-shell structure, has a surface pore size of 100-500 μm, and an internal pore size of 10-100 μm; it is prepared by the following preparation method Obtained, this preparation method comprises the steps:

[0038] 1) extruding and granulating the foaming-grade thermoplastic polymer resin composition to make granules to be expanded with uniform shape and weight;

[0039] 2) Next, the polymer particles are placed in a high-pressure reactor at a constant temperature, filled with supercritical fluid for infiltration and swelling, to achieve diffusion equilibrium, and form a polymer-supercritical fluid homogeneous system;

[0040] 3) Then the pressure in the system is slowly released, and the swollen polymer particles are taken out and surface treated;

[0041] 4) Finally, through the microwave foaming drying tunnel, the frequency of the microwave drying tunnel is...

Embodiment 1

[0052] First, select 100 parts of general-purpose polypropylene, resin MI at 3g / 10min (2.16kg weight at 190°C), 0.8 parts of talcum powder as nucleating agent, 2 parts of cell stabilizer, and 3 parts of antistatic agent. The screw extruder is melt-extruded to produce particles with an average particle diameter of 1.5 mm and an average weight of 20 mg, and the resin particles are dried for later use.

[0053] Then, measure the particles and place them in a high-pressure reactor with a constant temperature above 32°C. After replacing the air in the kettle, fill it with carbon dioxide to a supercritical state, control the pressure in the kettle above 7.3MPa, and keep the pressure for 3 hours.

[0054] Next, slowly release the pressure of the supercritical fluid in the kettle to 0, control the pressure release rate below 20MPa / min, take out the resin particles, and immerse them in the pre-prepared one-thousandth to two-thousandth surfactant aqueous solution for surface treatment (...

Embodiment 2

[0057] First, select 100 parts of general-purpose polypropylene, resin MI at 3g / 10min (2.16kg weight at 190°C), 0.8 parts of talcum powder as nucleating agent, 2 parts of cell stabilizer, and 3 parts of antistatic agent. The screw extruder is melt-extruded to produce particles with an average particle diameter of 1.5 mm and an average weight of 20 mg, and the resin particles are dried for later use.

[0058] Then, measure the particles and place them in a high-pressure reactor with a constant temperature above 32°C. After replacing the air in the kettle, fill it with carbon dioxide to a supercritical state, control the pressure in the kettle above 7.3MPa, and keep the pressure for 3 hours.

[0059] Next, slowly release the pressure of the supercritical fluid in the kettle to 0, control the pressure release rate below 20MPa / min, take out the resin particles, and immerse them in the pre-prepared one-thousandth to two-thousandth surfactant aqueous solution for surface treatment ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com