A kind of catalytic preparation method of veratraldehyde

A technology for the catalytic preparation of veratraldehyde, which is applied in the field of chemistry and chemical engineering, can solve the problems of limited industrial application, scarcity of precious metals and high price, and achieve the effect of high selective repeated use, good performance and high catalyst efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

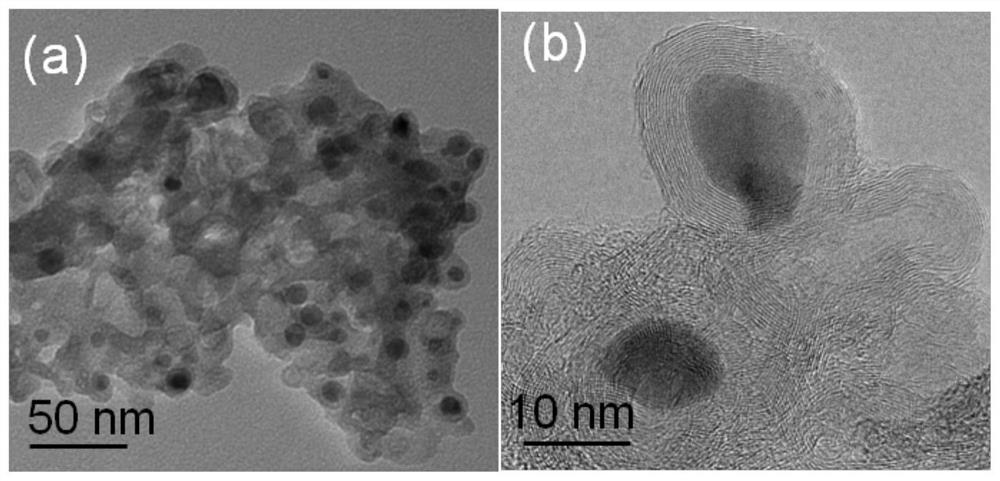

Image

Examples

Embodiment 13

[0023] Typical synthesis method A using catalyst Co / AC in Example 13: Dissolve metal cobalt hydrochloride in 2 g of water, add a certain amount of activated carbon carrier, and stir while adding until the solid just completely absorbs the metal salt solution. Continue to stir for 2 hours, dry it overnight and place it in an oven at 80°C for 12 hours, then heat it at a rate of 10°C / min in an inert atmosphere (nitrogen or argon), and keep it at 700°C for 2 hours to obtain a catalyst . Co catalysts supported by other supports such as silica, titania or alumina were prepared in the same way, labeled as Co / SiO 2 ,Co / TiO 2 ,Co / Al 2 o 3 .

Embodiment 2

[0024] Typical synthesis method B using the catalyst Co-BIm-600 in Example 2: Dissolve metal cobalt acetate in a certain amount of methanol solution, add a certain proportion of benzimidazole ligand, and stir at a certain temperature for 8 h to obtain a polymer. The solvent was removed by centrifugation, dried in an oven and placed in an inert atmosphere N 2 , heated at a heating rate of 10°C / min, kept at 600°C for 2h, and used directly as a catalyst. The rest of the acid-treated catalysts are then soaked in a certain concentration of acetic acid, hydrochloric acid or sulfuric acid to obtain catalysts. The synthesis conditions of the above catalyst are mild, the steps are simple, and the operation is easy.

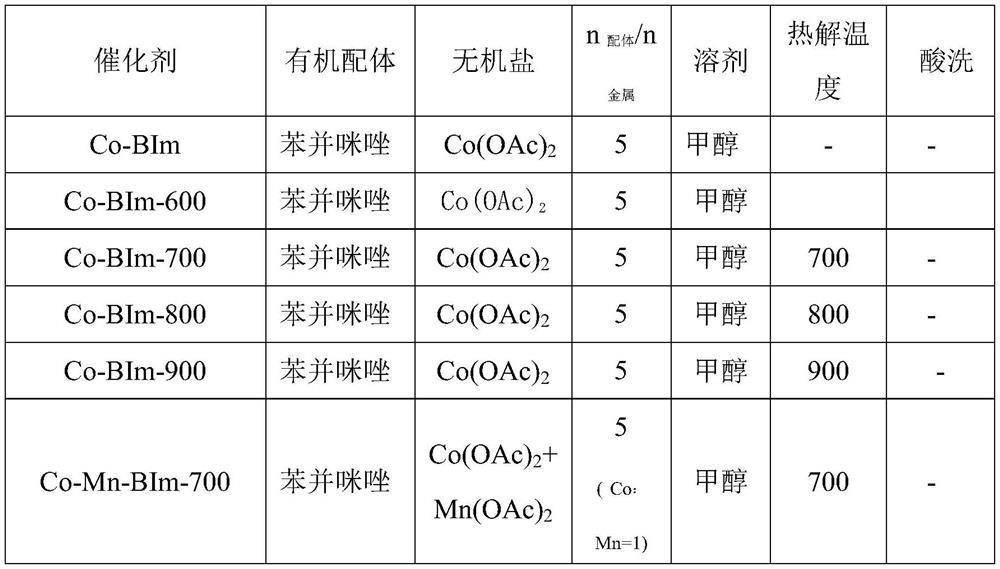

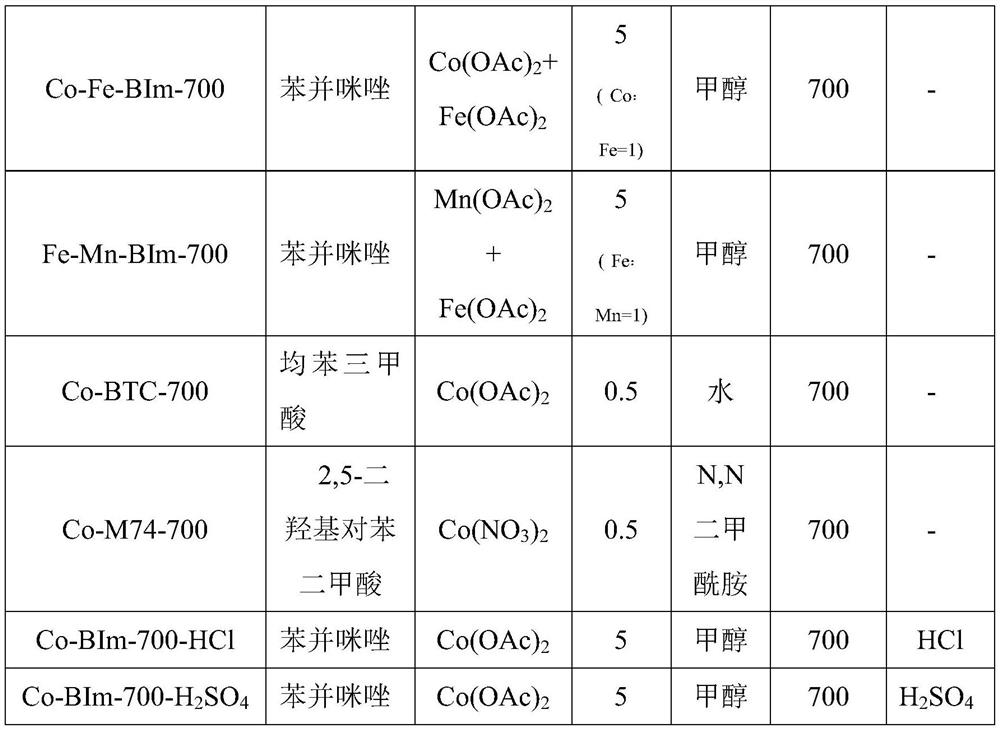

[0025] The catalysts used in Examples 1-12, 15-16 are synthesized according to the steps of Example 2, and the specific changed substances and addition amounts are shown in Table 1.

[0026] Synthesis of different catalysts in Table 1 Method B

[0027]

[0028]

Embodiment 1

[0030] Co-BIm catalyst, 2mmol veratrol, 0.4mmol K 2 CO 3 and 4 ml of toluene were added to a stainless steel autoclave with a polytetrafluoroethylene liner inside, wherein Co: veratrol = 0.05: 1 (mol: mol). The temperature was raised to a reaction temperature of 100° C. using an automatic temperature controller, and 1.0 MPa of oxygen was introduced to react for 12 hours. During the reaction, the pressure was kept constant. The reaction products were analyzed by GC, and the reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com