Modified carbon-coated alumina supporter with nucleocapsid structure and preparation method thereof

A carbon-alumina, hydrated alumina technology, applied in catalyst carriers, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of difficult to use micropores, difficult to apply, poor mechanical strength, etc. Anti-coking performance, large pore volume, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 , Preparation of carbon-coated alumina carrier

[0034] 1.1, preparation of colloid: 1.5118gNi(NO 3 ) 2 ·6H 2 O was dissolved in 40mL of isopropanol, adding 0.4064g of aluminum isopropoxide, with 4MHNO 3Adjust the pH to 5, stir well until the aluminum isopropoxide is completely dissolved, put the three-neck flask in a water bath at 80°C, continue stirring and add 10 mL of water for hydrolysis for 0.5 hours, then cool to room temperature to obtain hydrated alumina colloid.

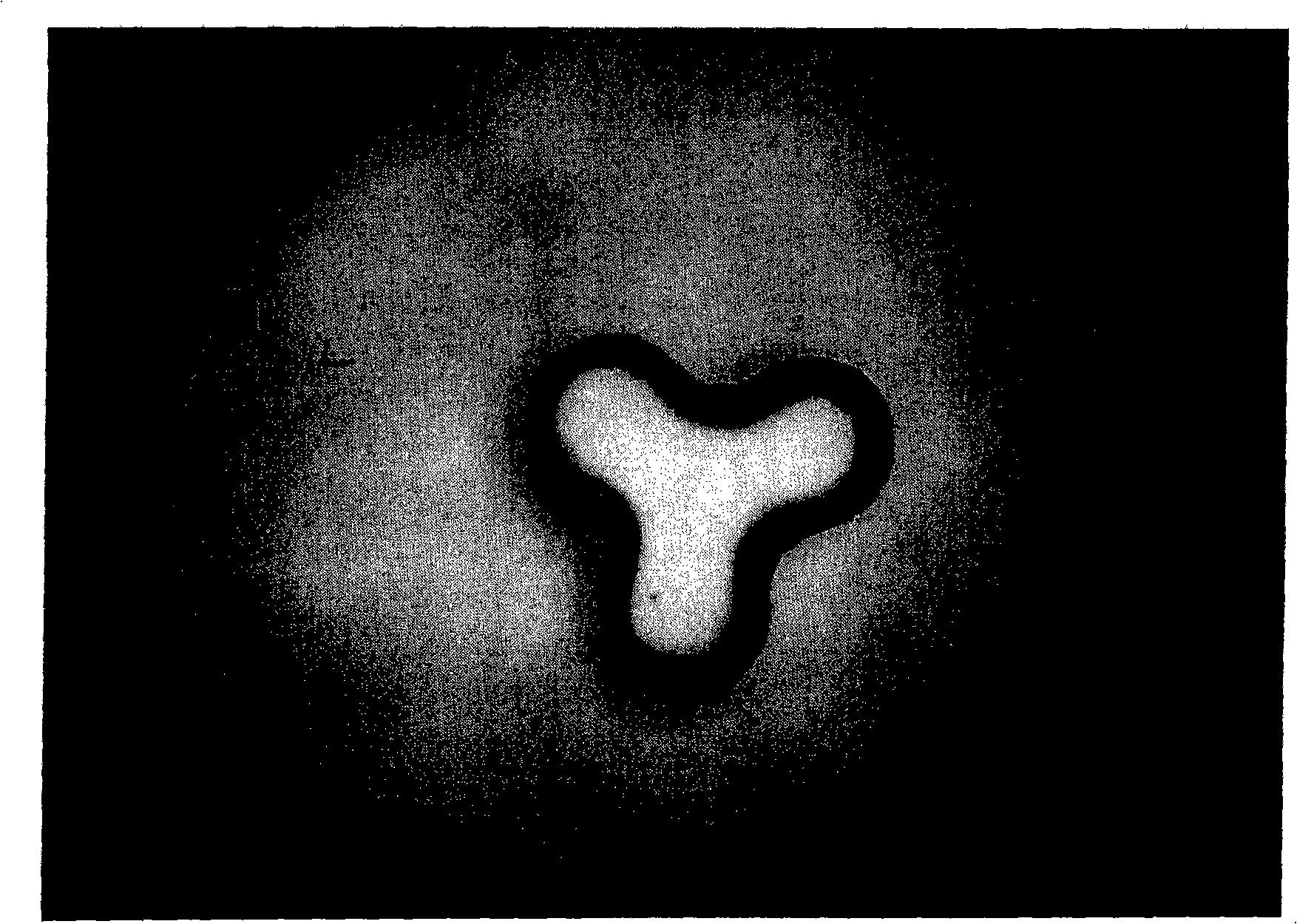

[0035] 1.2. Loading of colloid: immerse 2g clover-shaped alumina strips in the above colloid for 2 minutes, filter dry, place in ventilation for 30 minutes, and then send it to an oven for drying at 100-120°C for 10 hours. The dried samples were fired in a muffle furnace at 400°C for 4 hours.

[0036] 1.3. Carbon coating on the surface of industrial alumina: the roasted sample is placed in the reaction furnace, and the mixed gas of argon and hydrogen is introduced, and the flow rate i...

Embodiment 2

[0038] Example 2 , Preparation of carbon-coated alumina carrier

[0039] 2.1. Preparation of colloid: add 0.5906g of aluminum sec-butoxide to 30ml of ethanol, and add 4M HNO at the same time 3 2mL, stir well at room temperature, add 1.0581g Ni(NO 3 ) 2 ·6H 2 O and water 10mL, the pH value is 1, start to heat up to 60 ° C, continue to stir for 2 hours, stop stirring and cool to room temperature after a clear sol is formed, and obtain hydrated alumina colloid.

[0040] 2.2. Loading of colloid: Weigh 16.05g of spherical industrial alumina carrier with a diameter of 4mm and place it in a dry beaker, slowly add the prepared sol to the alumina carrier drop by drop, stir while adding, and place the beaker at the same time Heat in a water bath at 60-80°C until the sol is completely absorbed by the industrial alumina carrier. Then put the alumina carrier into an oven for drying at 100-120°C for 6 hours. The dried samples were calcined in a muffle furnace at 550°C for 3 hours.

...

Embodiment 3

[0042] Example 3 , Preparation of carbon-coated alumina carrier

[0043] 3.1. Preparation of colloid: Add 0.6g aluminum isopropoxide and 1g Ni(NO 3 ) 2 ·6H 2 O, after adding 10mL of water, with 4M HNO 3 Adjust the pH to 2, raise the temperature to 40°C and stir for 4 hours to obtain a clear colloid.

[0044] 3.2. Loading of colloid: After putting the colloid solution into the sprayer, spray 20g of columnar industrial alumina with a diameter of 2mm, and then dry it in an oven for 4 hours, and bake the dried sample in a muffle furnace at 600°C for 2 hours .

[0045] 3.3. Carbon coating on the surface of industrial alumina: the roasted sample is placed in the reaction furnace, and the mixed gas of argon and hydrogen is introduced, and the flow rate is Ar / H respectively. 2 =80 / 20 (mL / min), the reaction furnace is heated up to 650°C at a temperature of 3°C / min and kept for 0.5 hours, then stop feeding the mixed gas of argon and hydrogen, and switch to the mixed gas of carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com