Electrochemical active material with core-shell structure, preparation method and battery

A technology of core-shell structure and active materials, applied in the direction of electrochemical generators, structural parts, battery electrodes, etc., can solve the problems of poor safety, poor cycle life, and difficulty in obtaining wide applications, so as to avoid the loss of active materials and improve performance, improvement of first discharge efficiency and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

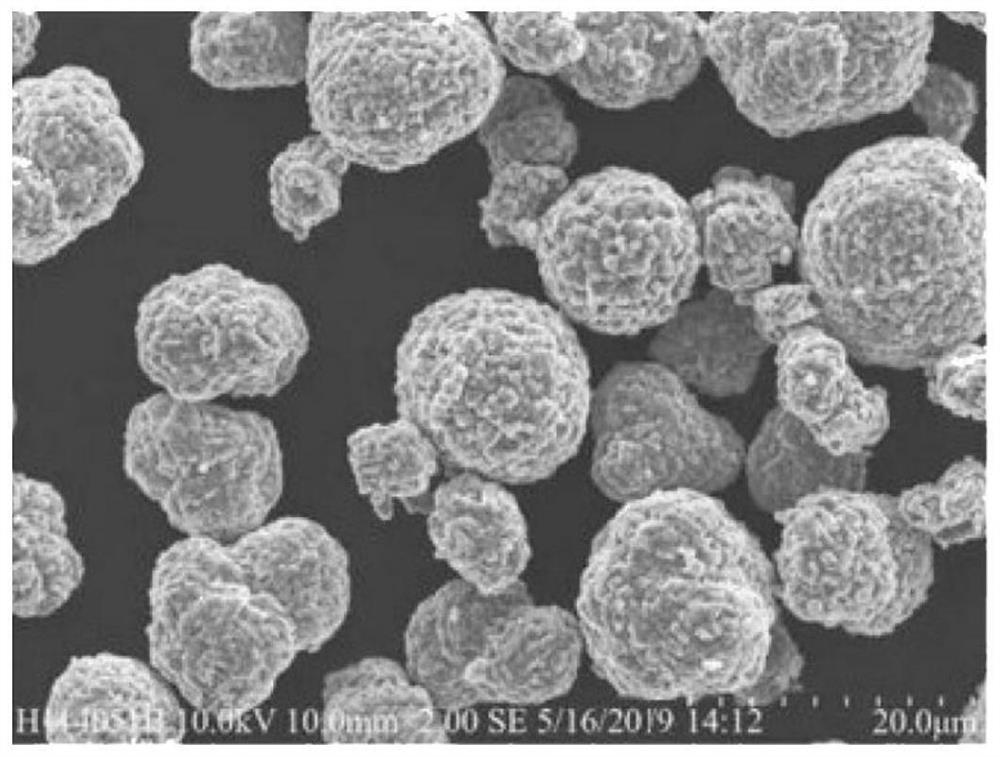

[0033] The embodiment of the present invention relates to a method for preparing the above-mentioned electrochemically active material with a core-shell structure, including:

[0034] Co-precipitation step: under the protection of an inert atmosphere, Li 5 FeO 4 The precursor LFO-P and the shell salt solution are homogenized in the reaction kettle, the temperature is controlled within the range of 40-70°C, and the pH value of the solution in the kettle is adjusted with a complexing agent under continuous stirring conditions until the pH value is in the range of 11-12; Conduct constant temperature reaction in the range of 40-70°C, stir and age to obtain LFO-P / Ni x co y mn z (OH) 2(x+y+z) ·Al 1-x-y-z (OH) 3(1-x-y-z) Suspension, finally solid-liquid separation to obtain a solid solution, washing and drying the solid solution to obtain LFO-P / Ni x co y mn z (OH) 2(x+y+z) ·Al 1-x-y-z (OH) 3(1-x-y-z) Powder;

[0035] Synthesis steps of core-shell structure: LFO-P / Ni x c...

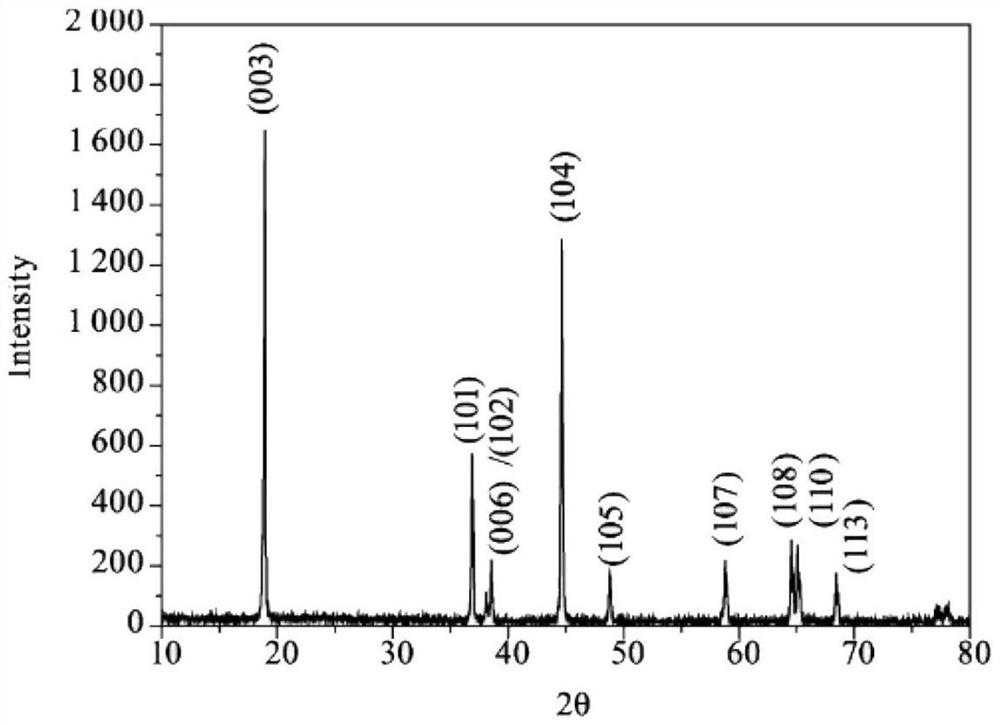

Embodiment 1

[0046] This embodiment relates to the core-shell structure electrochemically active material LFO-LiNi x co y mn z Al 1-x-y-z o 2 The preparation method comprises the following steps:

[0047] S1, preparation of Li 5 FeO 4 Precursor LFO-P: According to the stoichiometric ratio of Li:Fe=35:1, lithium acetate and iron citrate were sanded and mixed evenly, spray dried, tableted and granulated, then placed in a tube furnace at 2°C / The heating rate of min is raised to 450°C, and the temperature is kept for 4.5 hours to pre-decompose at low temperature to obtain Li 5 FeO 4 Precursor LFO-P, LiFeO 2 -17Li 2 CO 3 ;

[0048] S2, preparation of Ni 0.5 co 0.2 mn 0.25 (OH) 1.9 ·Al 0.05 (OH) 0.15 : According to the ratio of Ni, Co, Mn and Al stoichiometric ratio 0.5:0.2:0.25:0.05, weigh NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O and Al(NO 3 )3 9H 2 O, be prepared with the shell salt solution that total metal ion content is 3mol / L; Press the ratio of 80 parts by w...

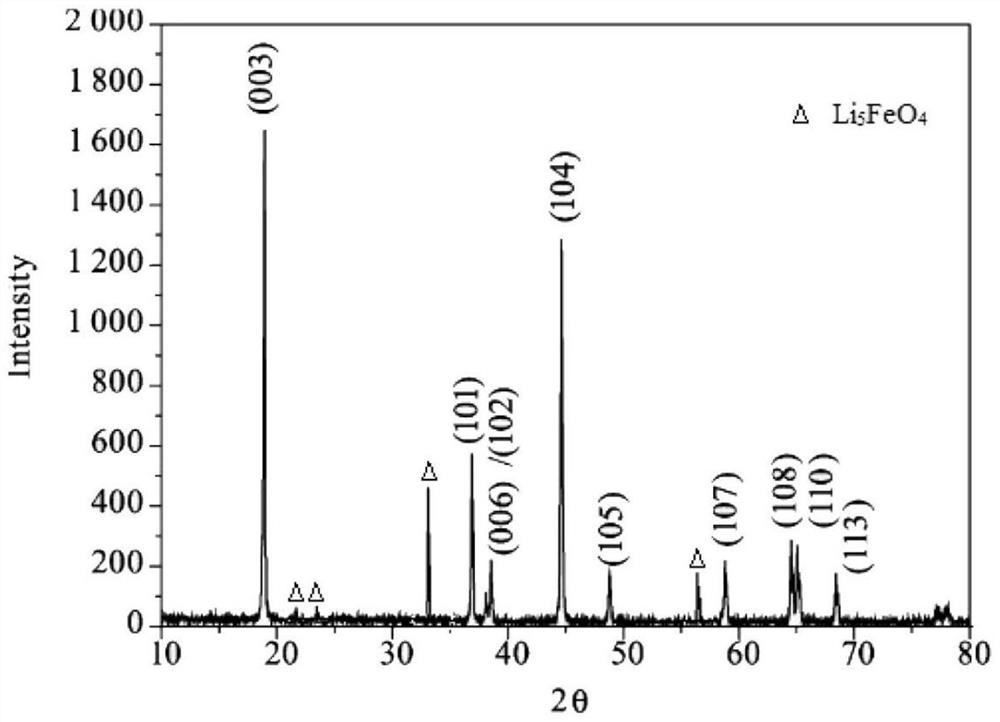

Embodiment 2

[0051] S1, preparation of Li 5 FeO 4 Precursor LFO-P: According to the stoichiometric ratio of Li:Fe=27:1, Lithium acetate and iron citrate were sanded and mixed evenly, spray-dried, tableted and granulated, then placed in a tube furnace at 2°C / The heating rate of min is raised to 450°C, and the temperature is kept for 4.5 hours to pre-decompose at low temperature to obtain Li 5 FeO 4 Precursor LFO-P, LiFeO 2 -13Li 2 CO 3 ;

[0052] S2, preparation of Co(OH) 2 : Weigh an appropriate amount of CoSO 4 ·7H 2 O formulated as Co 2+ Salt solution with an ion content of 3mol / L; 17.1 parts by weight of LFO-P, CoSO 4 ·7H 2 Add LFO-P in the ratio of 100 parts by weight to the above-mentioned salt solution, homogenize it, pump it into the reaction kettle protected by an inert atmosphere, control the temperature at 65° C., and continuously stir with 300r / min stirring speed. Adjust the pH value of the solution in the kettle to 11.6, react at a constant temperature, and carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com