Low-temperature-resistant flame-retarding ABS material and preparation method thereof

A technology of ABS material and low temperature resistance, which is applied in the field of flame retardant ABS material, low temperature resistant flame retardant ABS material and its preparation, can solve the problems of heat resistance, low smoke, and low temperature impact resistance, and achieve technological progress Significant, easy processing, excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1--4

[0018] A kind of preparation method of low temperature resistant flame retardant ABS material of the present invention, comprises the following steps:

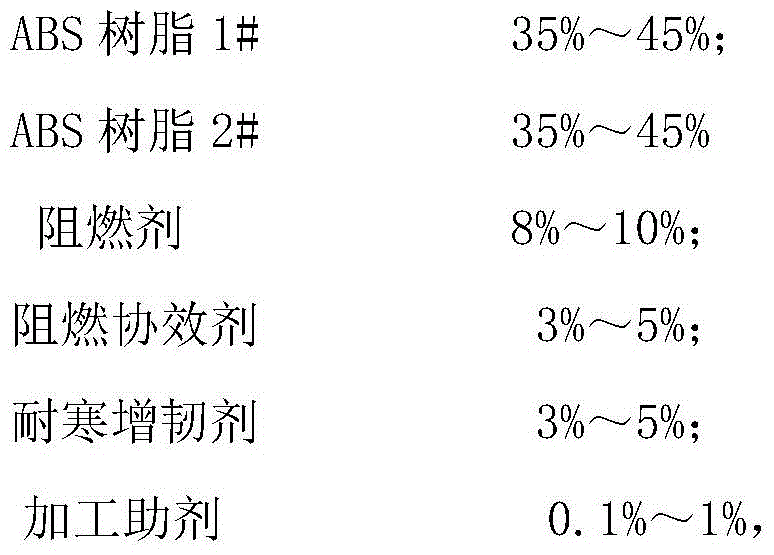

[0019] 1) Take ABS resin 1#, ABS resin 2#, flame retardant, flame retardant synergist, cold-resistant toughening agent, processing aid according to mass percentage ratio;

[0020] 2) After mixing the raw materials evenly, put them into the twin-screw extruder to extrude and granulate. ℃±10℃, 200℃±10℃, 200℃±10℃, 190℃±10℃, 190℃±10℃, 180℃±10℃, 180℃±10℃, die head: 190℃±10℃;

[0021] 3) Then through water cooling, pelletizing and drying, a low temperature resistant flame retardant ABS material is obtained.

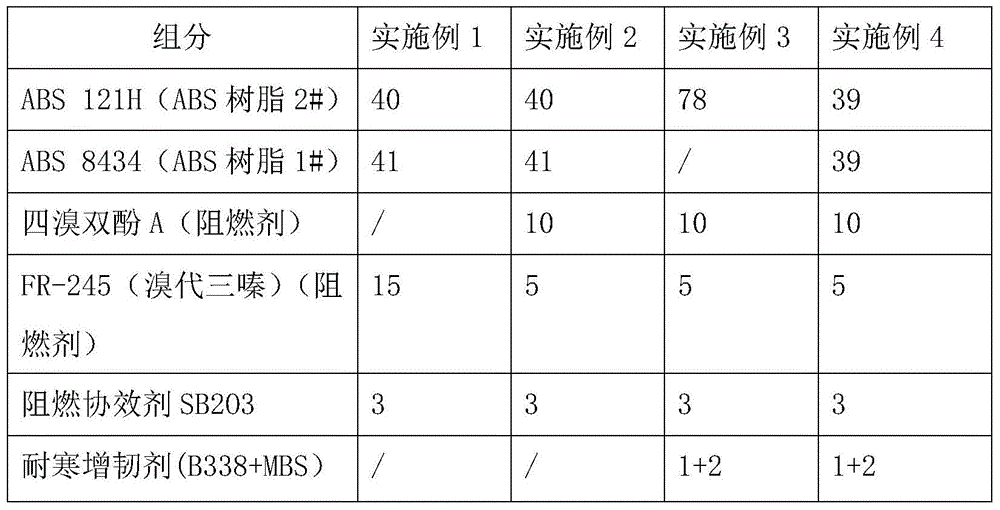

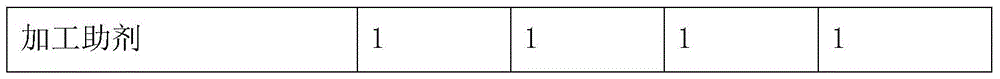

[0022] Table 1 Raw material composition distribution ratio

[0023]

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com