Hydrotreatment catalyst, and preparation method and application thereof

A technology for hydrotreating and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Reduce utilization rate, uniform dispersion of unfavorable additives, etc., to achieve the effect of reasonable distribution of acidity and acidity and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] According to the preparation method of the modified alumina-based carrier provided by the present invention, it can specifically adopt the following steps:

[0035] 1. Prepare the soluble additives into solution A, in which the concentration of additives is 0.1g / 100mL~32g / 100mL in terms of oxides;

[0036] 2. Prepare water-soluble silicone oil into solution B, wherein the concentration of water-soluble silicone oil is 0.1g / 100mL~20g / 100mL in terms of silicon oxide;

[0037] 3. Mix soluble additives and water-soluble silicone oil to prepare solution C, wherein the concentration of additives is 0.1g / 100mL~16g / 100mL in terms of oxides, and the concentration of water-soluble silicone oil is 0.1g / 100mL~10g / 100mL;

[0038] 4. Use at least one of the following methods to introduce water-soluble silicone oil and additives onto the alumina-based carrier:

[0039] I. Immerse the alumina-based carrier with solution C, and after curing, obtain a modified alumina-based carrier th...

Embodiment 1

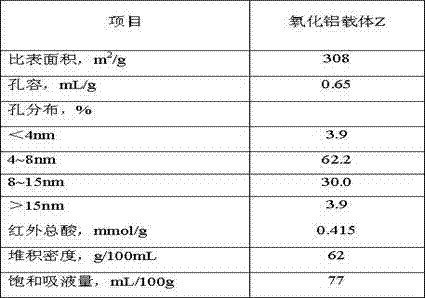

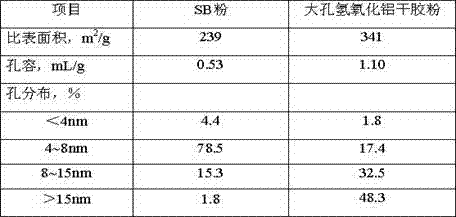

[0048] Take 3800g of macroporous aluminum hydroxide dry rubber powder, 200g of SB powder, add 160g of citric acid and 160g of safflower powder, and mix well. Then uniformly add 2900 g of dilute nitric acid aqueous solution, wherein the concentration of nitric acid is 3.0 wt%. The material was kneaded for 15 minutes, then rolled for 20 minutes, and extruded with a clover orifice plate with a diameter of 1.7 mm. Dry at 120°C for 4h and then bake at 500°C for 4h. The calcined carrier is marked as Z.

[0049] The physical and chemical properties of alumina carrier Z are shown in Table 2:

[0050] Table 2 Physicochemical properties of alumina carrier Z

[0051]

Embodiment 2

[0053] Weigh 33.2 g of aluminum nitrate, add an appropriate amount of deionized water to dissolve, and make the volume 105 mL, and obtain solution A1. Weigh 19.1 g of water-soluble silicone oil A, add an appropriate amount of deionized water to dissolve, and make the volume 105 mL to prepare solution B1. While stirring, slowly pour 35mL of B1 solution into 35mL of A1 solution, and add an appropriate amount of deionized water to make the final volume 77mL to prepare C1 solution.

[0054] Take 100g of alumina carrier Z, spray the solution C1 evenly on the alumina carrier, after curing for 10 hours, heat-treat at 100°C for 2h, then heat-treat at 220°C for 2h to obtain the modified carrier S1.

[0055] Take 100g of alumina carrier Z, dilute 35mL of solution B1 to 77mL with deionized water, spray evenly on the carrier Z, keep in good condition for 10 hours, heat-treat at 100°C for 2 hours, then dilute 35mL of solution A1 to 75mL with deionized water, Evenly sprayed on the carrier,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com