Hydrodenitrification catalyst as well as preparation method and application thereof

A technology for hydrodenitrogenation and catalyst, which can be used in catalyst activation/preparation, chemical instruments and methods, and hydrorefining of aromatic hydrocarbons, etc., and can solve problems such as limited utilization of active metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

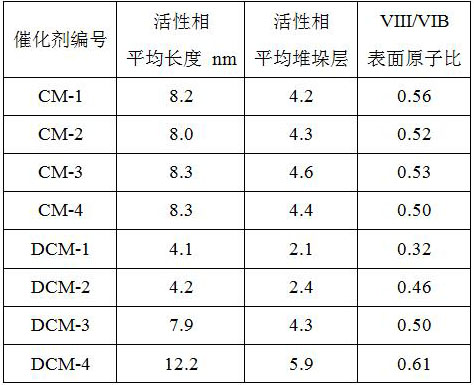

Embodiment 1

[0052] Add 40.0 g of nickel acetate and 10.0 g of amine triacetic acid to QL-2, stir thoroughly for 20 minutes, add 4.0 g of nonylphenol polyoxyethylene ether-8, and stir for 20 minutes, the obtained colloid is designated as QJ- 2.

[0053] S-0 was impregnated with QJ-2, air-dried for 12.0 h, and dried at 140 °C for 4 hours. The obtained catalyst was designated as CM-2.

[0054] Example 3

The preparation method of carrier S-0 is the same as that in Example 1.

[0055] Weigh 60.5 g of molybdenum trioxide, 7.5 g of 85% phosphoric acid by mass fraction, 200 g of deionized water, heat at 80 ºC for 2.0 h, and record the obtained solution as QP-3.

[0056] Add 26.4 g of ascorbic acid to QP-3, heat at 75°C for 2.0 h, and the obtained liquid is designated as QL-3.

Embodiment 2

[0058] S-0 was impregnated with QJ-3, air-dried for 12.0 h, and dried at 140 °C for 4 hours. The obtained catalyst was designated as CM-3.

[0059] Example 4

The preparation method of carrier S-0 is the same as that in Example 1.

[0060] Take 50.4 g of molybdenum trioxide, 6.0 g of ammonium dihydrogen phosphate, and 200 g of ionized water, heat at 80 ºC for 2.0 h, and the obtained solution is designated as QP-4.

[0061] Add 19.2 gMoS to QP-4 2 , heated at 85 °C for 3.0 h, and the liquid obtained after filtration was designated as QL-4.

[0062] Add 47.3g of nickel nitrate hexahydrate and 10.0g of dimethylethanolamine to QL-4, and after fully stirring for 20 minutes, add 4.0g of dodecylphenol polyoxyethylene ether-8, and after fully stirring for 20 minutes, the obtained The colloid is recorded as QJ-4.

Embodiment 3

[0064] Comparative example 1

[0065] Add 47.3 g of nickel nitrate hexahydrate to QP-1, and stir it thoroughly for 20 min, the resulting solution is designated as DQP-1.

[0066] S-0 was impregnated with DQP-1, air-dried for 12.0 h, and dried at 140 °C for 4 hours. The obtained catalyst was designated as DCM-1.

[0067] Comparative example 2

[0068] After adding 88.6 g nickel citrate and 7.0 g monoethanolamine to QP-1 and stirring for 20 minutes, the obtained solution was designated as DQP-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com