Catalyst grading process for reducing polycyclic aromatic hydrocarbon in diesel oil

A polycyclic aromatic hydrocarbon and catalyst technology, applied in the field of catalyst grading process, can solve the problems of affecting catalyst activity, incomplete sulfuration of molybdenum and tungsten, and high hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

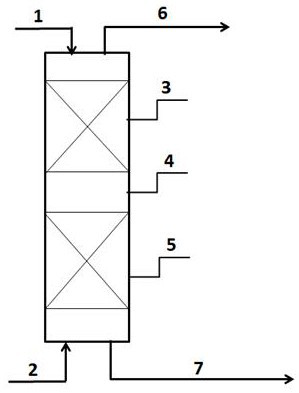

Method used

Image

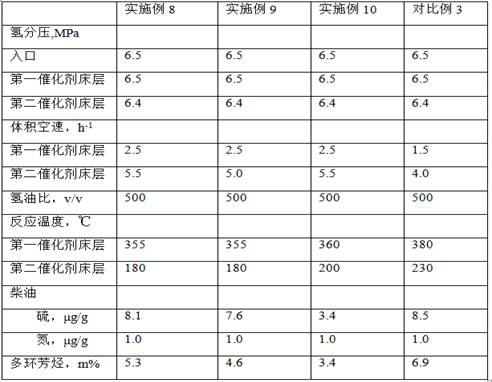

Examples

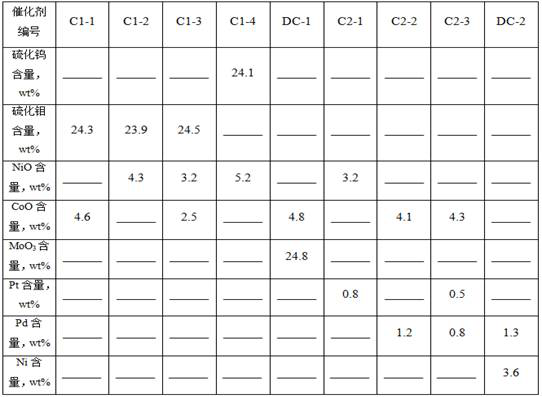

Embodiment 1

[0034] Adjust the ammonium heptamolybdate with ammonia water until it is completely dissolved, prepare an impregnating solution with a concentration of 0.12g / mL, then impregnate an equal volume on the alumina carrier, and dry at 120°C for 3h. Then use 1.5% H 2 The hydrogen of S is vulcanized, the vulcanization temperature is 360°C, the vulcanization pressure is 4.5MPa, the vulcanization time is 6h, and then in N 2 atmosphere down to room temperature, MoS 2 / Al 2 o 3 .

[0035] Dissolve cobalt nitrate in deionized water to prepare an impregnation solution with a concentration of 0.13g / mL, and impregnate MoS with equal volume 2 / Al 2 o 3 , then in N 2 Under the atmosphere, dry at 90°C for 4h, and bake at 320°C for 3h to obtain MoS 2 -CoO / Al 2 o 3 Catalyst C1-1.

Embodiment 2

[0037] Adjust the ammonium heptamolybdate with ammonia water until it is completely dissolved, prepare an impregnating solution with a concentration of 0.12g / mL, then impregnate an equal volume on the alumina carrier, and dry at 120°C for 3h. Then use dimethyl disulfide for vulcanization treatment, the vulcanization temperature is 330 ° C, the vulcanization pressure is 4.5 MPa, the vulcanization time is 6 hours, and then in N 2 atmosphere down to room temperature, MoS 2 / Al 2 o 3 .

[0038] Dissolve nickel nitrate in deionized water, prepare an impregnation solution with a concentration of 0.12g / mL, and impregnate MoS with equal volume 2 / Al 2 o 3 , then in N 2 Under the atmosphere, dry at 80°C for 4h, and bake at 300°C for 3h to obtain MoS 2 -NiO / Al 2 o 3 Catalyst C1-2.

Embodiment 3

[0040] Adjust the ammonium heptamolybdate with ammonia water until it is completely dissolved, prepare an impregnating solution with a concentration of 0.12g / mL, then impregnate an equal volume on the alumina carrier, and dry at 120°C for 3h. Then use 1.5% H 2 The hydrogen of S is vulcanized, the vulcanization temperature is 350°C, the vulcanization pressure is 4.5MPa, the vulcanization time is 6h, and then in N 2 atmosphere down to room temperature, MoS 2 / Al 2 o 3 .

[0041] Dissolve nickel nitrate and cobalt nitrate in deionized water, prepare an impregnation solution with a concentration of 0.12g / mL, and impregnate MoS with equal volume 2 / Al 2 o 3 , then in N 2 Under the atmosphere, dry at 60°C for 4h, and bake at 320°C for 3h to obtain MoS 2 -NiO-CoO / Al 2 o 3 Catalysts C1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com