Method for reducing polycyclic aromatic hydrocarbon in diesel oil

A technology for polycyclic aromatic hydrocarbons and diesel oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., and can solve the problems of increasing energy consumption and operating costs of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

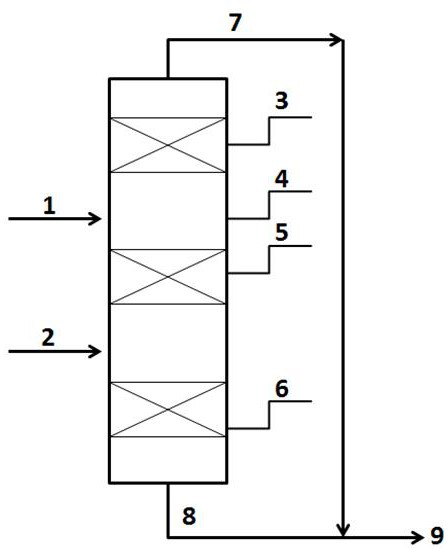

Image

Examples

preparation example Construction

[0030] The preparation method of noble metal hydrogenation catalyst of the present invention comprises the following contents:

[0031] (1) Impregnate a solution containing a palladium compound and / or a platinum compound into an alumina carrier, dry and calcinate to obtain a catalyst precursor.

[0032] (2) Immerse the solution containing the auxiliary agent into the catalyst precursor prepared in step (1), and obtain the catalyst through drying, roasting and reduction treatment.

[0033] In the preparation method of the noble metal hydrogenation catalyst of the present invention, the palladium-containing compound in step (1) is selected from palladium chloride, palladium nitrate, palladium acetate, sodium tetrachloropalladate, dichlorotetraammine palladium, palladium trifluoroacetate, di Palladium acetylacetonate or palladium hexafluoroacetylacetonate, the solution concentration is 0.001-0.5g / mL calculated as palladium element.

[0034] In the preparation method of the noble...

Embodiment 1

[0038] Prepared noble metal catalyst in embodiment 1:

[0039] Example 1

[0040] Dissolve chloroplatinic acid in deionized water, in which the concentration of platinum is 0.002g / mL, impregnate an equal volume of the chloroplatinic acid solution into an alumina carrier, dry at 120°C for 6h, and then bake at 450°C for 5h.

[0041] Dissolve nickel nitrate in deionized water, in which the concentration of nickel oxide is 0.02g / mL, impregnate the nickel nitrate solution into the catalyst precursor in equal volume, then dry at 90°C for 5h, calcinate at 250°C for 3h, and then in a hydrogen atmosphere , and reduced at 400°C and 3.0 MPa for 6 hours to obtain a noble metal catalyst C3-1, in which the metal platinum content is 0.25%, and the nickel content is 3.5%.

Embodiment 2

[0044] Dissolve ammonium metatungstate and aluminum chloride in deionized water to prepare mixed solution A, and WO in mixed solution A 3 The weight concentration is 80g / L, Al 2 o 3 The weight concentration is 50g / L. Slowly add sodium hydroxide with a concentration of 1.0mol / L into 1L of solution A under stirring, keep the gelling temperature at 75°C, control the pH value at 7~8 at the end, control the gelling time at 60 minutes, and form Slurry I containing tungsten and aluminum precipitates.

[0045] Mix 160 mL of 1.0 mol / L magnesium nitrate solution with slurry I evenly, then adjust the pH value to 7~8 with ammonia water, then wash with deionized water three times, filter and dry at 110°C for 5 hours to obtain a mixed powder. Then take 150g of mixed powder and mix them with 5g of nitric acid, 5g of starch and 60g of deionized water evenly, then knead and extrude into strips, dry at 100°C for 3h, and roast at 550°C for 3h, and then use 1.5%H 2 The hydrogen of S is vulcan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com