Multistage countercurrent extraction device and method for catalyzing diesel polycyclic aromatic hydrocarbon by using ionic liquid

A technology of ionic liquid and polycyclic aromatic hydrocarbons, which is applied in the direction of multi-stage series refining process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of increasing the load of catalytic cracking unit, affecting the processing capacity of the unit, and reducing light distillate oil To achieve the effect of increasing the cetane number, convenient operation and reducing the content of polycyclic aromatic hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

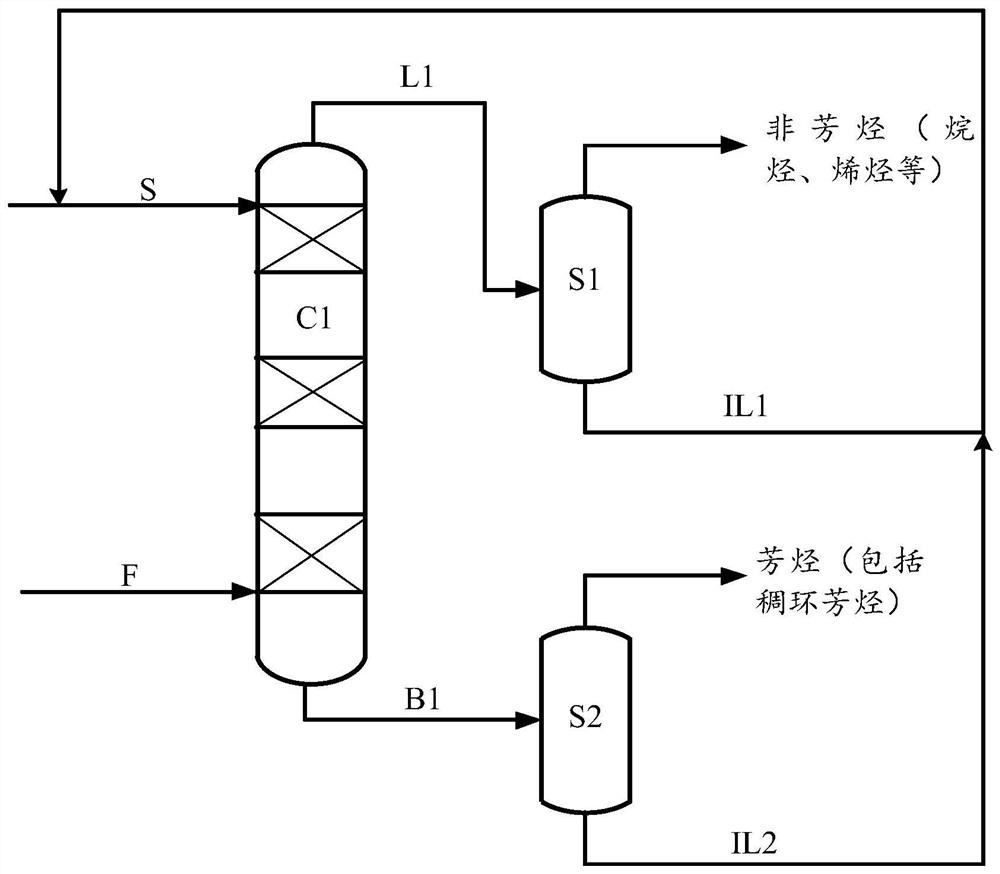

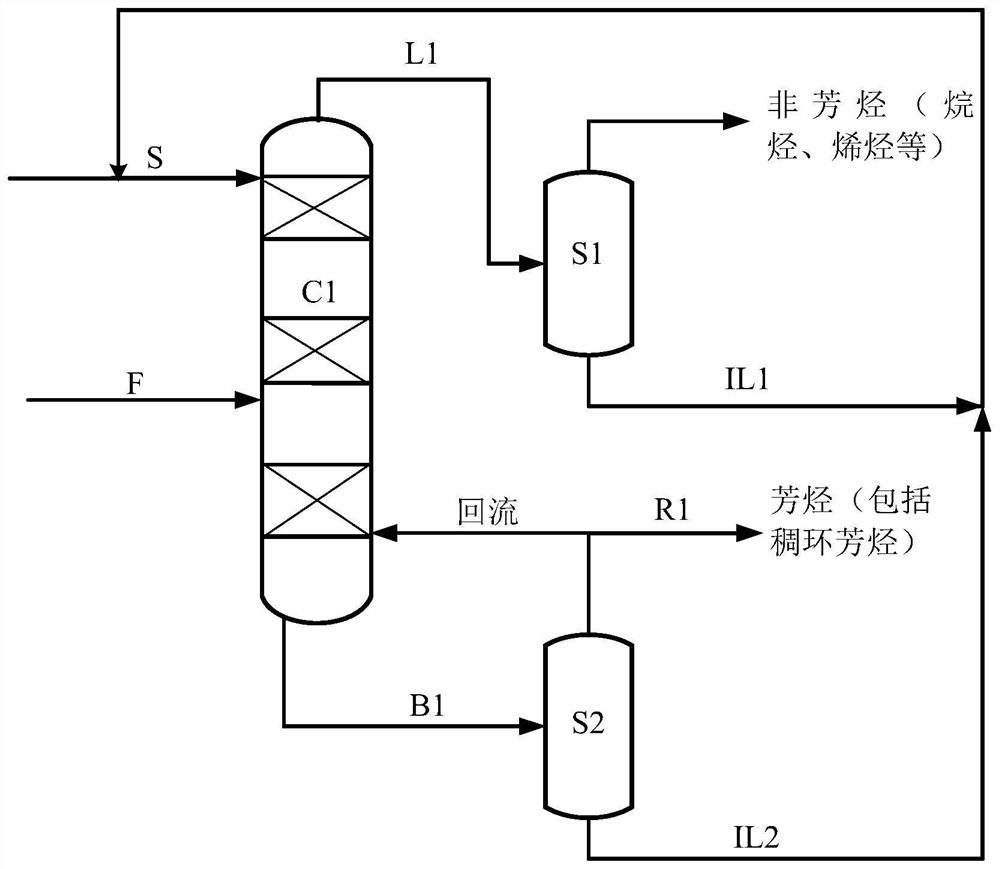

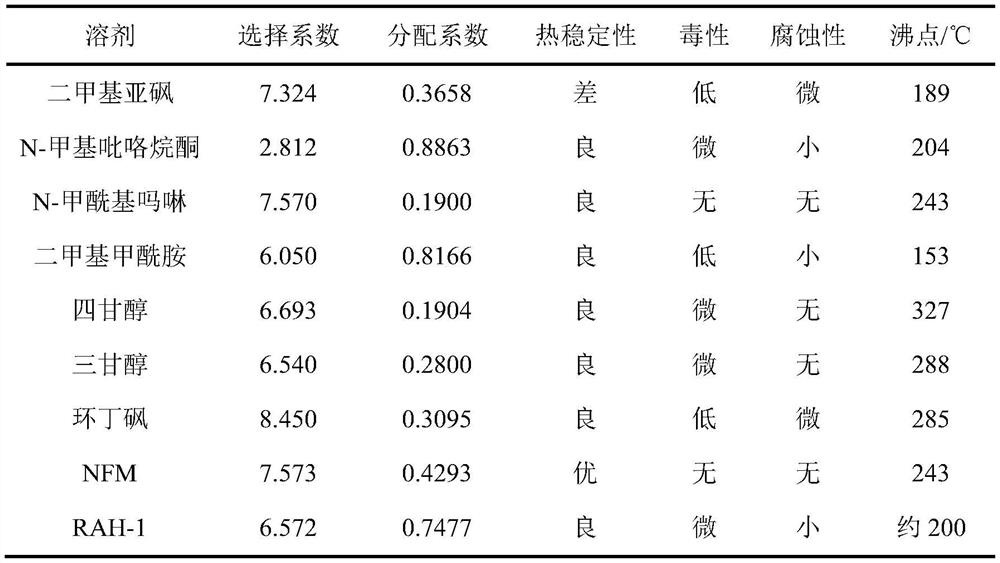

Method used

Image

Examples

Embodiment 1

[0036] A single ionic liquid (specifically [BMIM][BF4]) was used as the extractant.

[0037]The feed flow rate was 100 kg / h, and the feed contained 70% (mass fraction) of n-hexadecane and 30% (mass fraction) of 1-methylnaphthalene. The theoretical plate number of the countercurrent mixing extraction tower (C1) is 6, the feed position of the diesel aromatics mixture is the 6th block, and the single ionic liquid is fed from the first plate position of the countercurrent mixing extraction tower (C1), and the extraction process The volume ratio of the medium ionic liquid to the feed of the diesel aromatics to be separated is 1:1, and the recovery rate of n-hexadecane and 1-methylnaphthalene is 99.65% and 99.20% after high-efficiency separation. The purity of n-hexadecane in the extract was 99.9% (mass fraction), and the purity of 1-methylnaphthalene in the raffinate was 98.9% (mass fraction).

Embodiment 2

[0039] Mixed ionic liquids (specifically [BMIM][BF4] and [EMIM][BF4] with a volume ratio of 1:1) were used as extractants.

[0040] The feed flow rate was 100 kg / h, and the feed contained 80% (mass fraction) of n-hexadecane and 20% (mass fraction) of 1-methylnaphthalene. The number of theoretical plates of the countercurrent mixing extraction tower (C1) is 5, the feed position of the diesel aromatics mixture is the 5th, and the mixed ionic liquid enters the countercurrent mixing extraction tower (C1) from the position of the second plate, and the mixture is mixed during the extraction process. The volume ratio of the ionic liquid to the feedstock of diesel aromatics to be separated is 0.5:1, the recovery rate of n-hexadecane and 1-methylnaphthalene are 99.46% and 98.8% after high-efficiency separation. The purity of n-hexadecane in the extract was 99.5% (mass fraction), and the purity of 1-methylnaphthalene in the raffinate was 98.9% (mass fraction).

Embodiment 3

[0042] A mixed solution of common ionic liquid (specifically [BMIM][BF4]) + organic solvent (specifically, sulfolane) (the volume ratio of ionic liquid to organic solvent is 3:7) was used as the extractant.

[0043] The feed flow rate was 100 kg / h, and the feed contained 75% (mass fraction) of n-hexadecane and 25% (mass fraction) of 1-methylnaphthalene. The number of theoretical plates of the countercurrent mixing extraction tower (C1) is 6, the feed position of the diesel aromatics mixture is the 5th block, and the mixture of ionic liquid and traditional organic solvent enters the countercurrent mixing extraction tower (C1) from the 2nd block, extracting During the process, the volume ratio of the mixed extractant to the feed of the diesel aromatics to be separated is 1.5:1, and the recovery rate of n-hexadecane and 1-methylnaphthalene is 99.72% and 99.27% after high-efficiency separation. The purity of n-hexadecane in the extract was 99.85% (mass fraction), and the purity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com