A method for producing white oil and fuel oil by hydrogenation of coal tar

A coal tar and fuel oil technology, which is applied in the field of coal tar hydrogenation to produce white oil and fuel oil, can solve the problems of affecting the operation cycle of the hydrogenation unit, high metal and mechanical impurities, and reduce the occurrence of secondary cracking conversion reactions , reduce the severity of operation, and reduce the effect of reaction temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

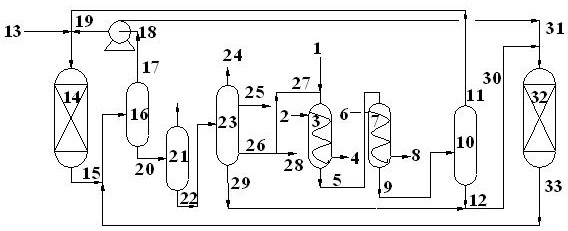

Method used

Image

Examples

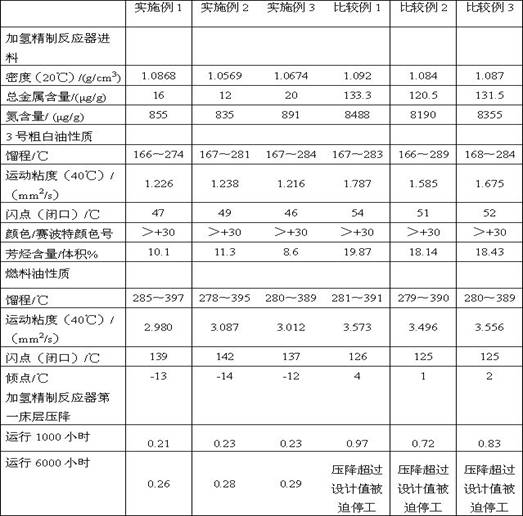

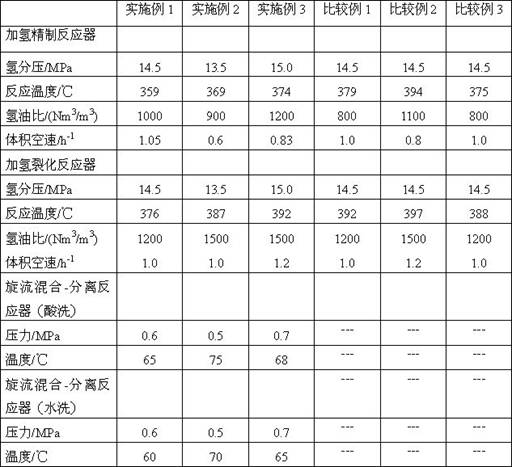

Embodiment 1

[0038] Coal tar raw material and fuel oil are mixed in a ratio of 6:4 to obtain a mixed flow, and then mixed with a sulfuric acid solution with a concentration of 6% in a ratio of 1:5 in a pickling cyclone mixing separator for pickling treatment, and the process is completed at the same time The oil and water are separated to obtain an aqueous phase and an oil phase. The oil phase and distilled water enter the water-washing cyclone mixer-separator at a ratio of 1:5. While washing with water, the oil-water separation is completed to obtain the water phase and the reaction raw materials with low metal content. The reaction raw materials with low metal content enter the separation tower to obtain light component raw materials and heavy component raw materials. The light component raw material enters the hydrofinishing reactor with new hydrogen and recycled hydrogen, contacts with the hydrofinishing catalyst, and undergoes reactions such as hydrodesulfurization, hydrodenitrogenati...

Embodiment 2

[0040] Coal tar raw material and fuel oil are mixed in a ratio of 4:3 to obtain a mixture flow, and then mixed with a sulfuric acid solution with a concentration of 6% in a ratio of 1:5 in a pickling cyclone mixing-separator for pickling treatment. At the same time, oil-water separation is completed to obtain an aqueous phase and an oil phase. The oil phase and water enter the water-washing cyclone mixer-separator at a ratio of 1:5. While washing with water, the oil-water separation is completed to obtain the water phase and the reaction raw materials with low metal content. The reaction raw materials with low metal content enter the separation tower to obtain light component raw materials and heavy component raw materials. The light component raw material enters the hydrofinishing reactor with new hydrogen and recycled hydrogen, contacts with the hydrofinishing catalyst, and undergoes reactions such as hydrodesulfurization, hydrodenitrogenation, and saturation of aromatic hyd...

Embodiment 3

[0042] Coal tar raw material and fuel oil are mixed in a ratio of 5:4 to obtain a mixture flow, and then mixed with a sulfuric acid solution with a concentration of 8% in a ratio of 1:4 in a pickling cyclone mixing-separator for pickling treatment. At the same time, oil-water separation is completed to obtain an aqueous phase and an oil phase. The oil phase and water enter the water-washing cyclone mixer-separator at a ratio of 1:5. While washing with water, the oil-water separation is completed to obtain the water phase and the reaction raw materials with low metal content. The reaction raw materials with low metal content enter the separation tower to obtain light component raw materials and heavy component raw materials. The light component raw material enters the hydrofinishing reactor with new hydrogen and recycled hydrogen, contacts with the hydrofinishing catalyst, and undergoes reactions such as hydrodesulfurization, hydrodenitrogenation, and saturation of aromatic hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com