Patents

Literature

63results about How to "Reduce operating severity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

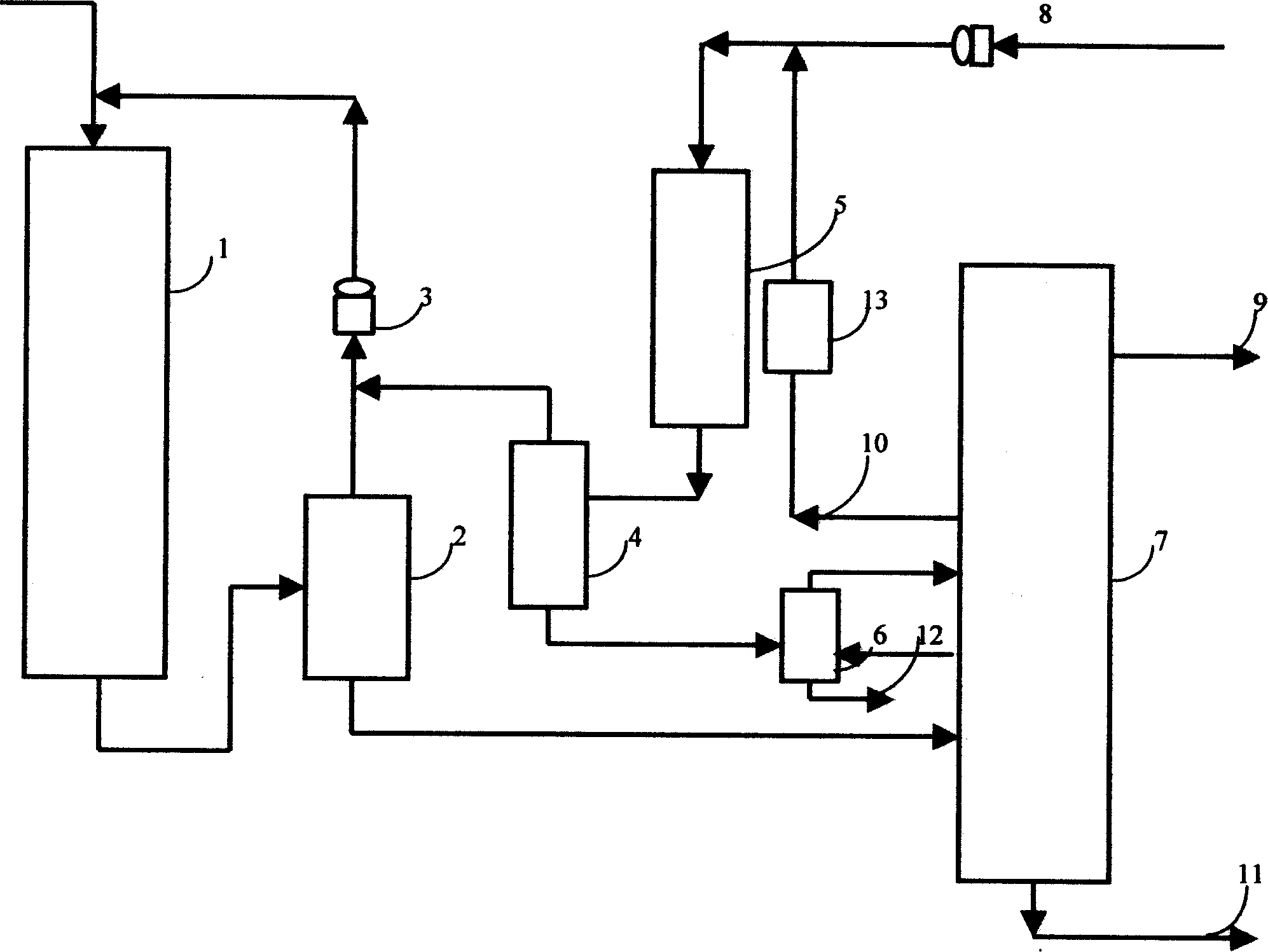

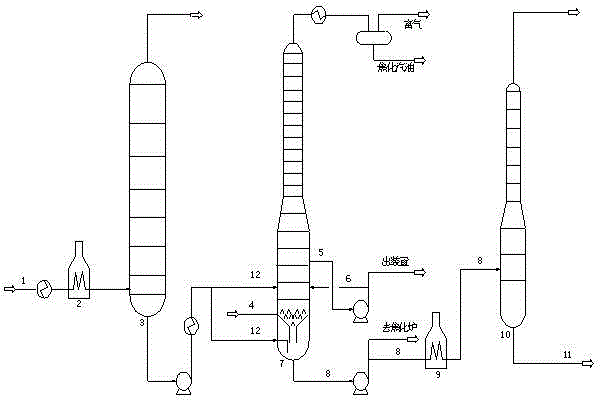

Process for coking full fraction oil hydrogenation refining

InactiveCN1458233AImprove product propertiesDiesel properties improvedHydrocarbon oils refiningProcess engineeringHeating energy

The present invention is one process of hydrofining coked full fraction oil. Based on available process of hydrofining coked full fraction oil, new hydrogen of the system is used in further refining of diesel oil, so that diesel oil is refined under ideal thermodynamic and dynamic conditions. This results in high product quality, flexible, economic and practical technological process, less investment increment, fully utilization of heat energy and low operation cost. The present invention is suitable for reforming and constructing coked full fraction oil hydrofining apapratus.

Owner:CHINA PETROLEUM & CHEM CORP +1

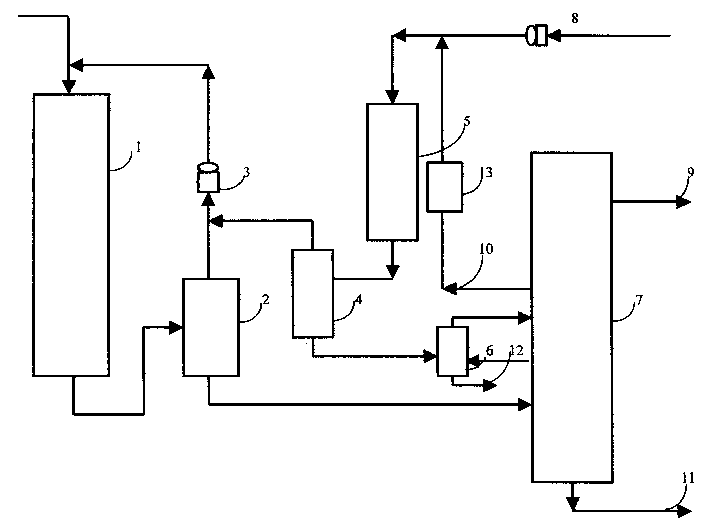

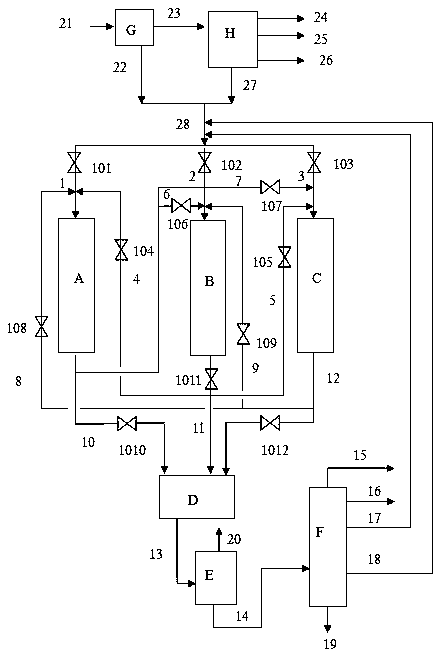

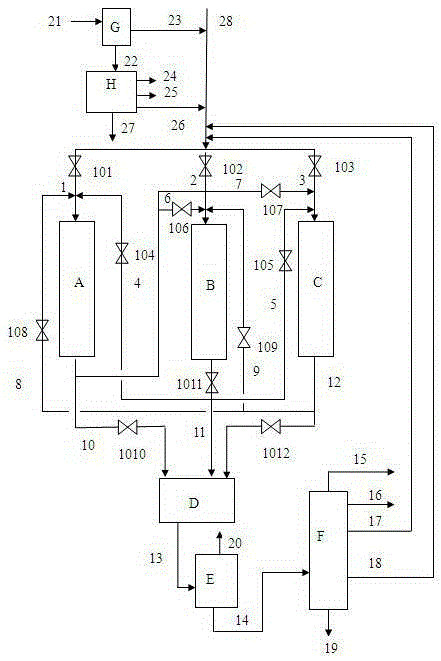

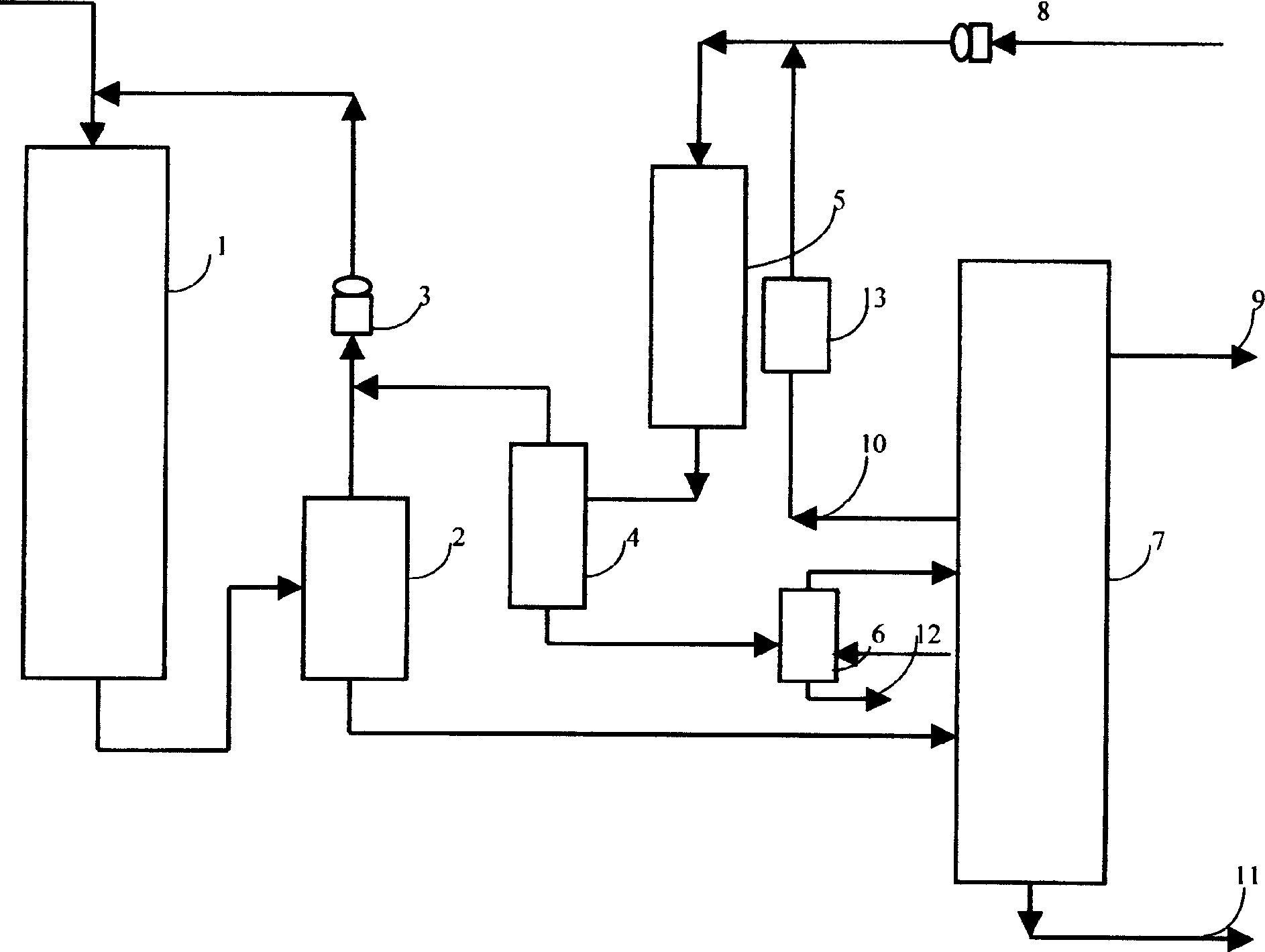

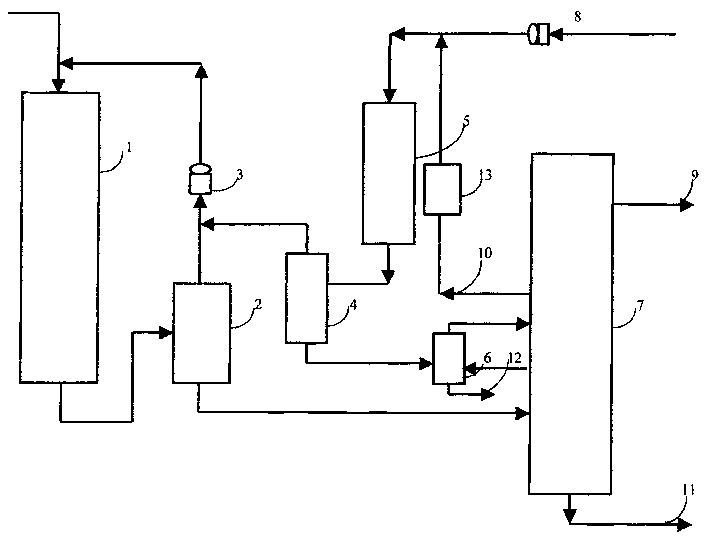

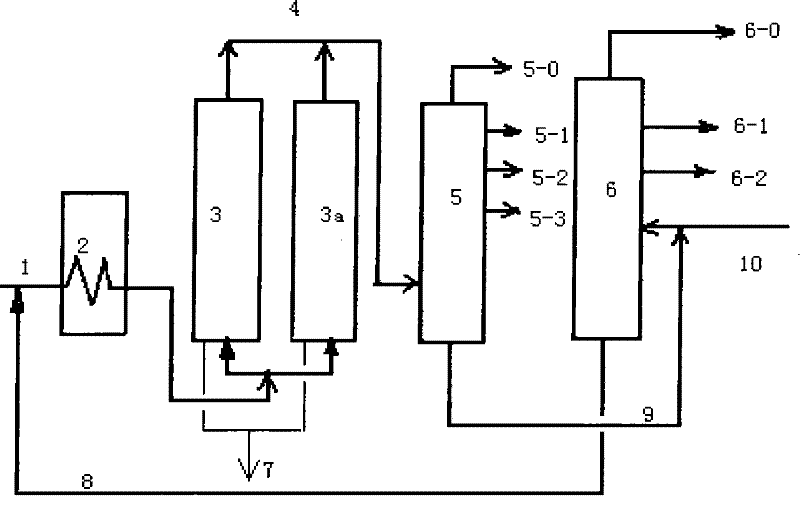

Method and apparatus for high-efficient crude oil desalination / dehydration

InactiveCN102226100AReduce difficultyReduce the water content of crude oilRefining by water treatmentTreatment with plural serial refining stagesChemistryElectric field

The invention belongs to the technical field of petrochemical industry, and particularly relates to a method and an apparatus for high-efficient crude oil desalination / dehydration by a combined filtration-electric field coalescence method. The apparatus for high-efficient crude oil desalination / dehydration of the invention comprises a raw material conveying system, a mixing device, a dehydration filtration device, and an electrical desalting device which are connected in order. The method for high-efficient crude oil desalination / dehydration of the invention is realized by using the apparatus for high-efficient crude oil desalination / dehydration of the invention and through the steps of raw material preheating, mixing, preliminary demulsification, and electrical desalination / dehydration. The invention adopts a combined filtration-electric field coalescence method for crude oil desalination / dehydration, which can overcome respective disadvantages of performing desalination / dehydration process by a filtration method or an electric field coalescence method, decrease running severity of both the two methods, not only improves the adaptability of the crude oil desalination process, the desalination / dehydration rate, and the stable running rate, but also reaches the purposes of energy saving and consumption reduction.

Owner:GUANGZHOU BOXENERGY TECH

Coking light distillate hydrogenation modification method

ActiveCN101434864AAdaptableSimple processTreatment with hydrotreatment processesLiquid productHydrogen

The invention relates to a method used for hydrogenation modification of coking light distillate oil; under hydrogenation refining condition, the raw material of the coking light distillate oil and hydrogen are contacted with W-Mo-Ni series of hydrogenation catalysts firstly; subsequently, naphtha distillate, coal oil distillate and diesel distillate are gained by stripping and distillation; wherein, the coal oil distillate and new hydrogen enter a low-pressure hydrogenation reactor and are contacted with Ni-series of hydrogenation catalysts; the product is separated by a gas-liquid separator; and the liquid product is used as high-quality jet fuel components and the hydrogen-rich gas is returned to the coking light distillate oil raw material and used for hydrogenation refining. The method can process the coking light distillate oil with bad quality into high-quality jet fuel, high-quality naphtha and clean diesel components by simple process, has the advantages of wide application of the raw material, flexible operation, stable running, and the like, and effectively improves the economical benefits of the enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

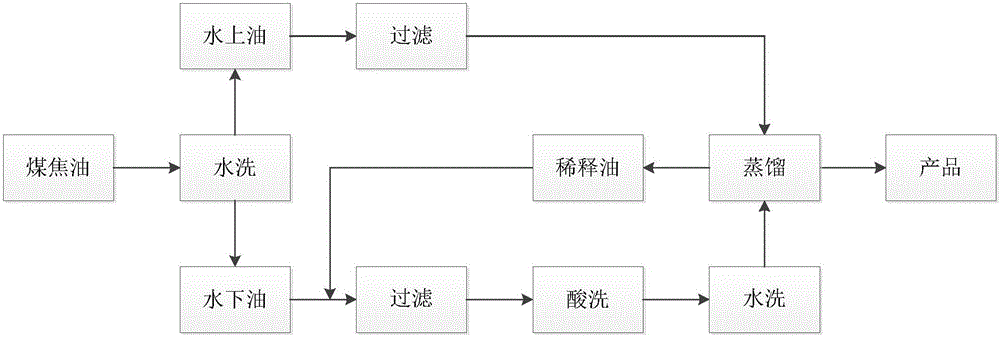

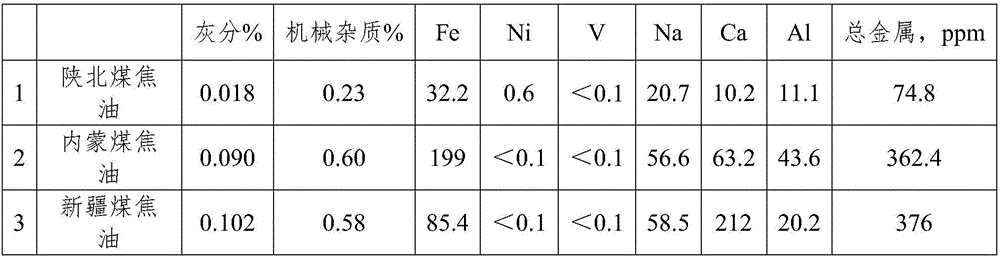

Coal tar pretreatment method

InactiveCN106398735AQuality assuranceHigh selectivityTar working-up by distillationTar working-up by chemical refiningPretreatment methodBoiling point

The invention discloses a coal tar pretreatment method. The method comprises the following steps: 1, fully mixing a coal tar raw material with water, salt and a de-emulsifier A, and using an oil-water separation device to separate the coal tar raw material at 50-200 DEG C under 0.1-5.0 Mpa into oil above water, water and oil under water, wherein the addition amount of water is 5-50% of the weight of the coal tar raw material, the addition amount of the de-emulsifier A is 0.003-0.05% of the weight of the coal tar raw material, and the addition amount of the salt makes the density of the salt in water reach 1.001-1.015 g / cm<3>; 2, treating the oil above water obtained in step 1 to obtain refined coal tar I; 3, treating the oil under water obtained in the step 1 to obtain standing coal tar II; and 4, mixing the refined coal tar I obtained in step 2 with the standing coal tar II obtained in step 3 to obtain refined coal tar, adding the refined coal tar to a distillation system, separating to obtain a fraction with the boiling point being smaller than 150 DEG C and a fraction with the boiling point being greater than 150 DEG C, and mixing a part of the fraction with the boiling point being smaller than 150 DEG C with the fraction with the boiling point being greater than 150 DEG C to obtain pretreated coal tar.

Owner:特思锐能源科技(北京)有限责任公司

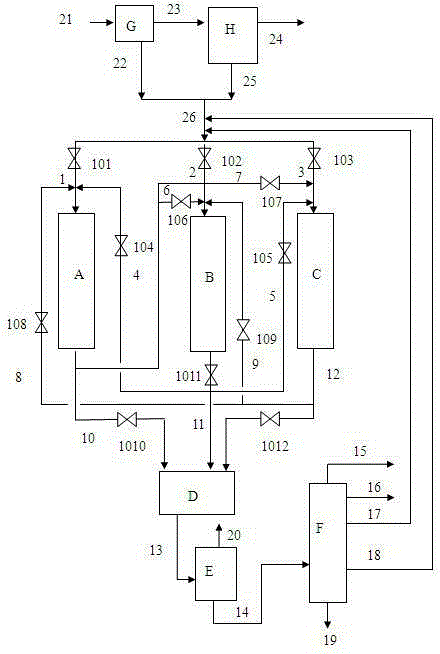

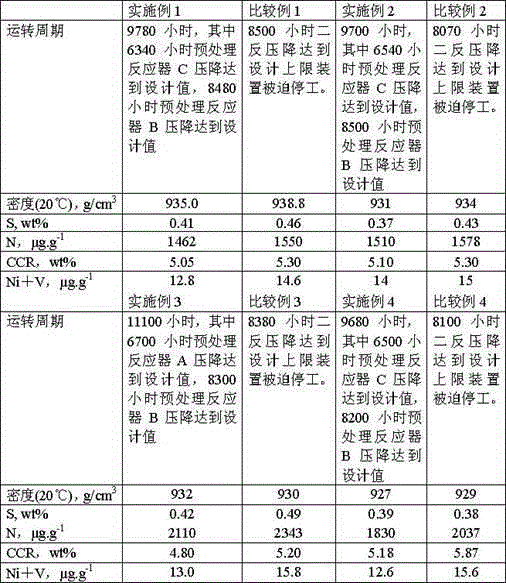

Process method for treating residual oil

ActiveCN106701192AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a process method for treating residual oil. A hydrogenation pretreatment unit, a coking device, a hydrogenation treatment unit and a catalytic cracking device are provided; the hydrogenation pretreatment unit comprises a hydrogenation pretreatment reaction area and a hydrogenation treatment reaction area; the process method comprises the following steps: performing a reaction on a residual oil raw material by using the hydrogenation pretreatment unit, and performing oil fractionation so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. Due to adoption of the process method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

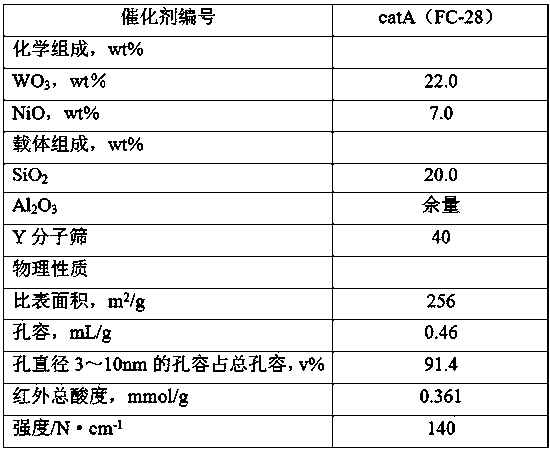

Method for producing lubricant base oil by hydrogenation isomerization dewaxing

ActiveCN103773467AViscosity index requirements are not highHigh yieldTreatment with hydrotreatment processesLubricant compositionAlkaneMolecular sieve

The invention relates to a method for producing lubricant base oil by hydrogenation isomerization dewaxing. The method is as follows: raw oil is mixed with hydrogen, then enters into a hydrocracking reaction zone to contact with a Y-type molecular sieve-containing noble metal hydrocracking catalyst for reaction, the polycyclic napthene ring-opening reaction is performed, and a reaction effluent, without separation, directly enters into a hydrogenation isomerization dewaxing reaction zone to contact with a hydrogenation isomerization dewaxing catalyst for n-alkane isomerization reaction to obtain high viscosity index lubricant base oil with the pour point meeting the requirements. According to the method, the ring-opening reaction of polycyclic napthenes with more than two rings in the raw material is performed, the content of low viscosity index component polycyclic napthenes is reduced, the viscosity index loss in the isomerization dewaxing process is reduced, and the high viscosity index lubricant base oil with the pour point meeting the requirements is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing lubricant base oil by isomerization dewaxing

ActiveCN103773468AViscosity index requirements are not highHigh yieldTreatment with hydrotreatment processesLubricant compositionAlkaneIsomerization

The invention relates to a method for producing lubricant base oil by isomerization dewaxing. The method is as follows: raw oil is mixed with hydrogen, then enters into a hydrocracking reaction zone to contact with an amorphous silica alumina-containing noble metal hydrocracking catalyst for reaction, the polycyclic napthene ring-opening reaction is performed, and a reaction effluent, without separation, directly enters into a hydrogenation isomerization dewaxing reaction zone to contact with a hydrogenation isomerization dewaxing catalyst for n-alkane isomerization reaction to obtain high viscosity index lubricant base oil with the pour point meeting the requirements. According to the method, the ring-opening reaction of polycyclic napthenes with two or more than two rings in the raw material is performed, the content of low viscosity index component polycyclic napthenes is reduced, the viscosity index loss in the isomerization dewaxing process is reduced, and the high viscosity index lubricant base oil with the pour point meeting the requirements is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

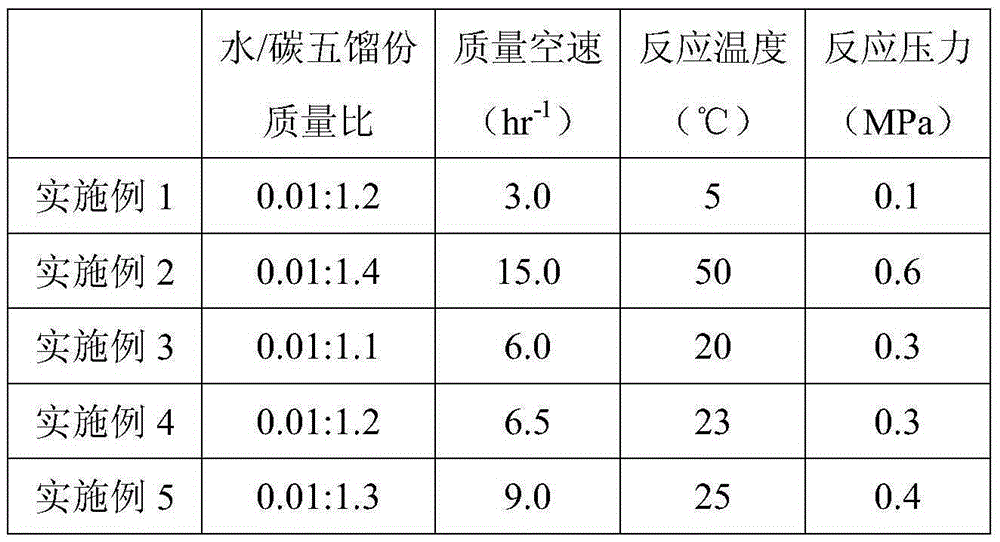

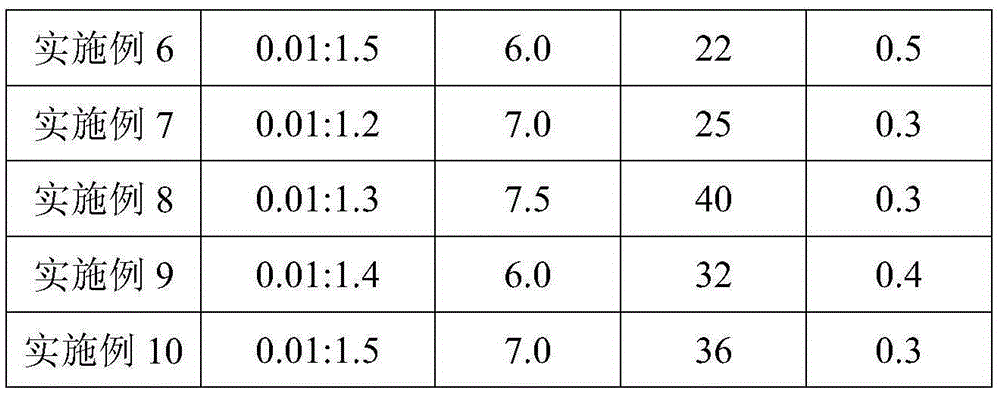

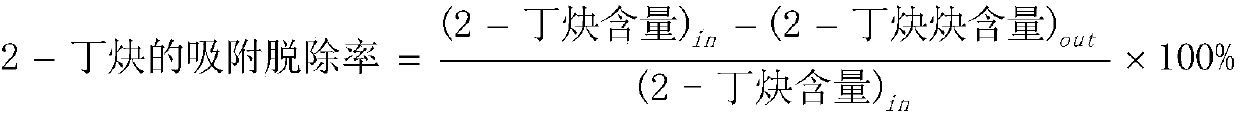

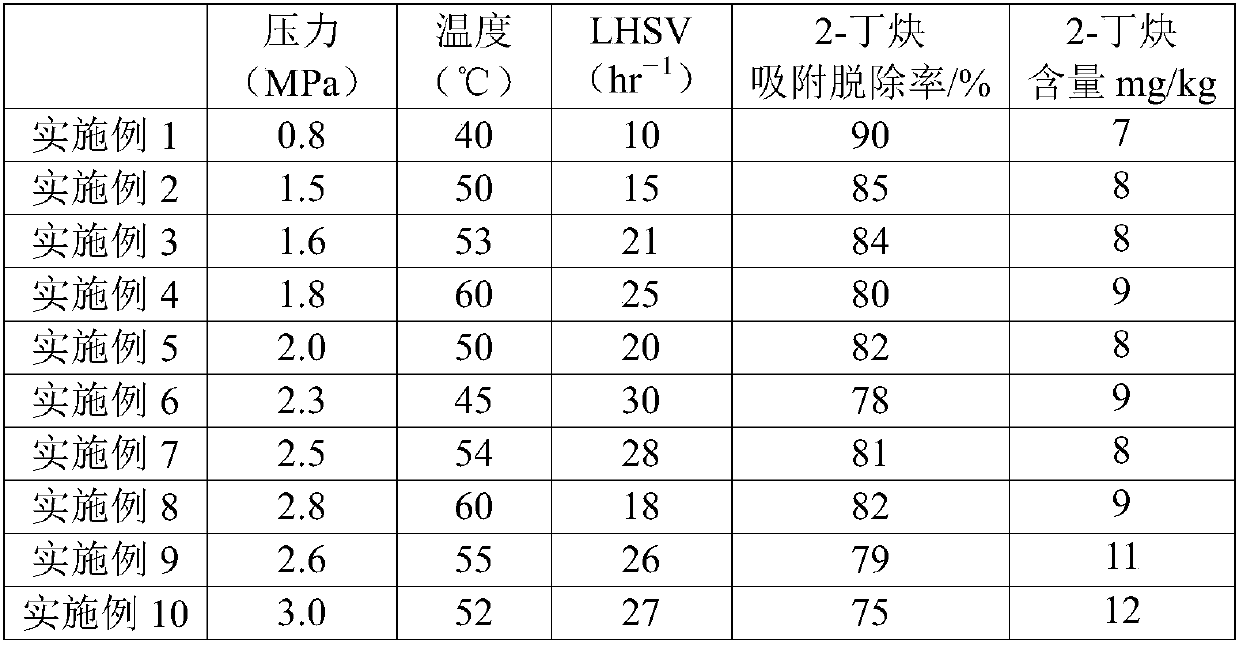

Method for removing 2-butyne by conducting selective hydrogenation on C5 fractions

InactiveCN106588553ANo emissionsNo lossHydrocarbonsAdsorption purification/separationWastewaterFixed bed

The invention belongs to the technical field of organic chemical industry, and particularly relates to a method for removing 2-butyne by conducting selective hydrogenation on C5 fractions. The method particularly comprises the following steps of 1 denitrification, wherein denitrification treatment is conducted on the C5 fractions through a fixed bed containing sulfonic group cation exchange resin and water; 2 selective hydrogenation, wherein selective hydrogenation is conducted on the C5 fractions obtained after denitrification through a bubbling bed reactor containing a Pd-Ni-Ag-M / Al2O3 catalyst, and then 2-butyne is converted into butane. The method has the advantages that the processes are simple, no wastewater is drained, the denitrification precision is high, no material is lost, and polymerization side reactions can be effectively inhibited.

Owner:CHINA PETROLEUM & CHEM CORP +1

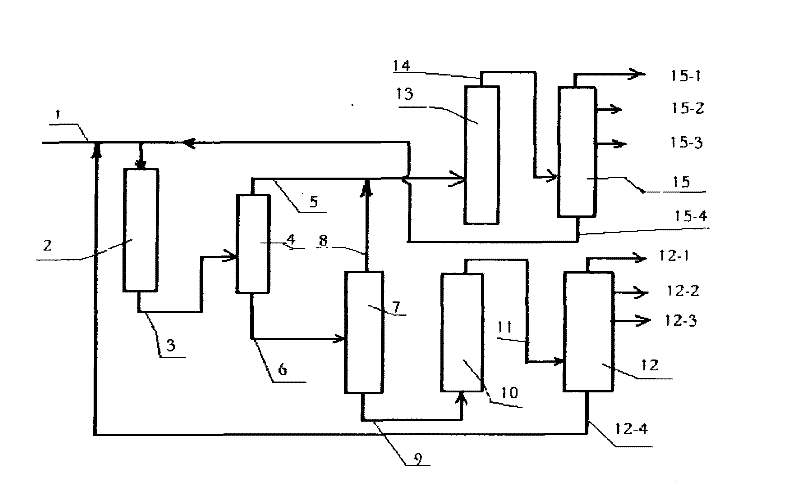

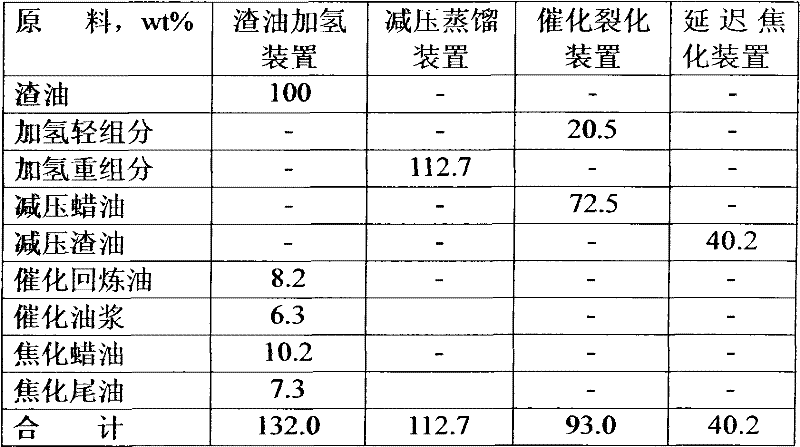

Method for lightening residual oil

ActiveCN102453545AIncrease throughputIncrease productionTreatment with hydrotreatment processesWaxDistillation

The invention discloses a method for lightening residual oil. According to the method, residual oil raw materials goes through a hydrotreatment device, and the obtained hydrogenated oil undergoes flash evaporation to obtain light components and heavy components; the heavy components enters a reduced pressure distillation device to separate out reduced pressure wax oil, and the reduced pressure wax oil which is mixed with the hydrogenated light components enters a catalytic cracking device and undergoes fractionation to obtain a gas, gasoline and diesel oil which are discharged form the catalytic cracking device and recycle oil and oil slurry which are returned to the hydrotreatment device; and reduced pressure residual oil obtained by the reduced pressure distillation device enters a delayed coking device and undergoes the fractionation to obtain a gas, gasoline and a diesel oil fraction which are discharged from the delayed coking device and coked wax oil and tail oil which are returned to the hydrotreatment device. The method which combines the residual oil hydrotreatment, the catalytic cracking, the reduced pressure distillation and above delayed coking technology allows charged material compositions of the residual hydrogenation, the catalytic cracking and the delayed coking to be optimized, and target product yields of the catalytic cracking and the delayed coking to be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

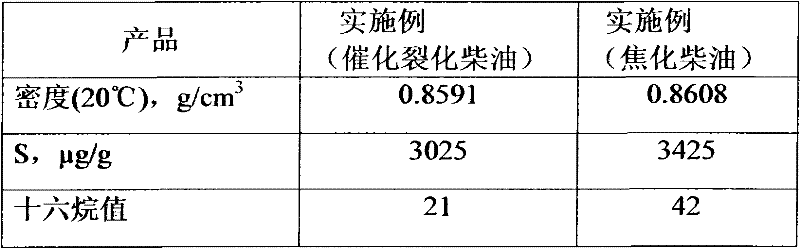

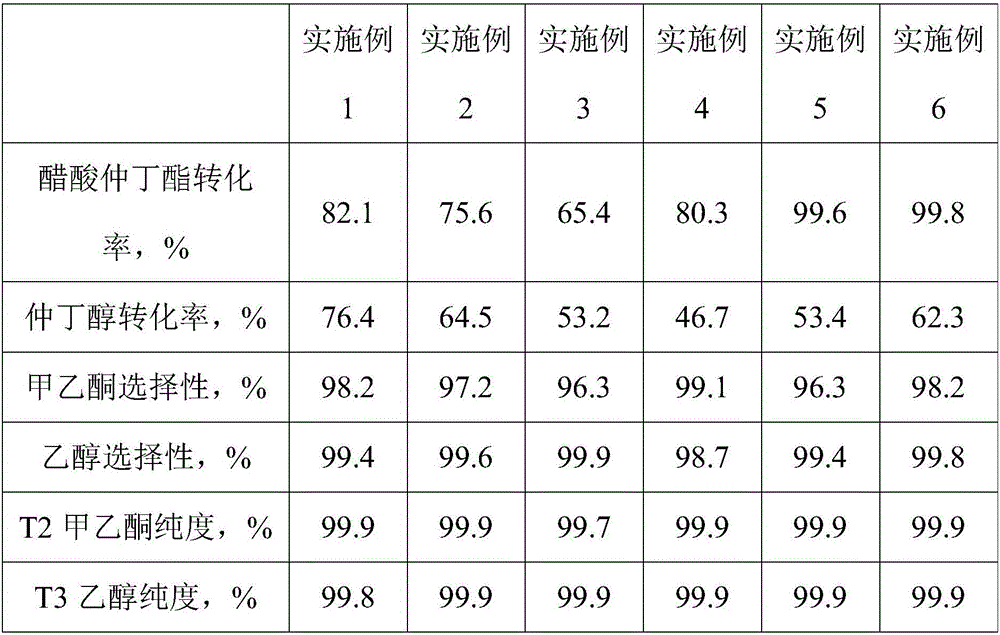

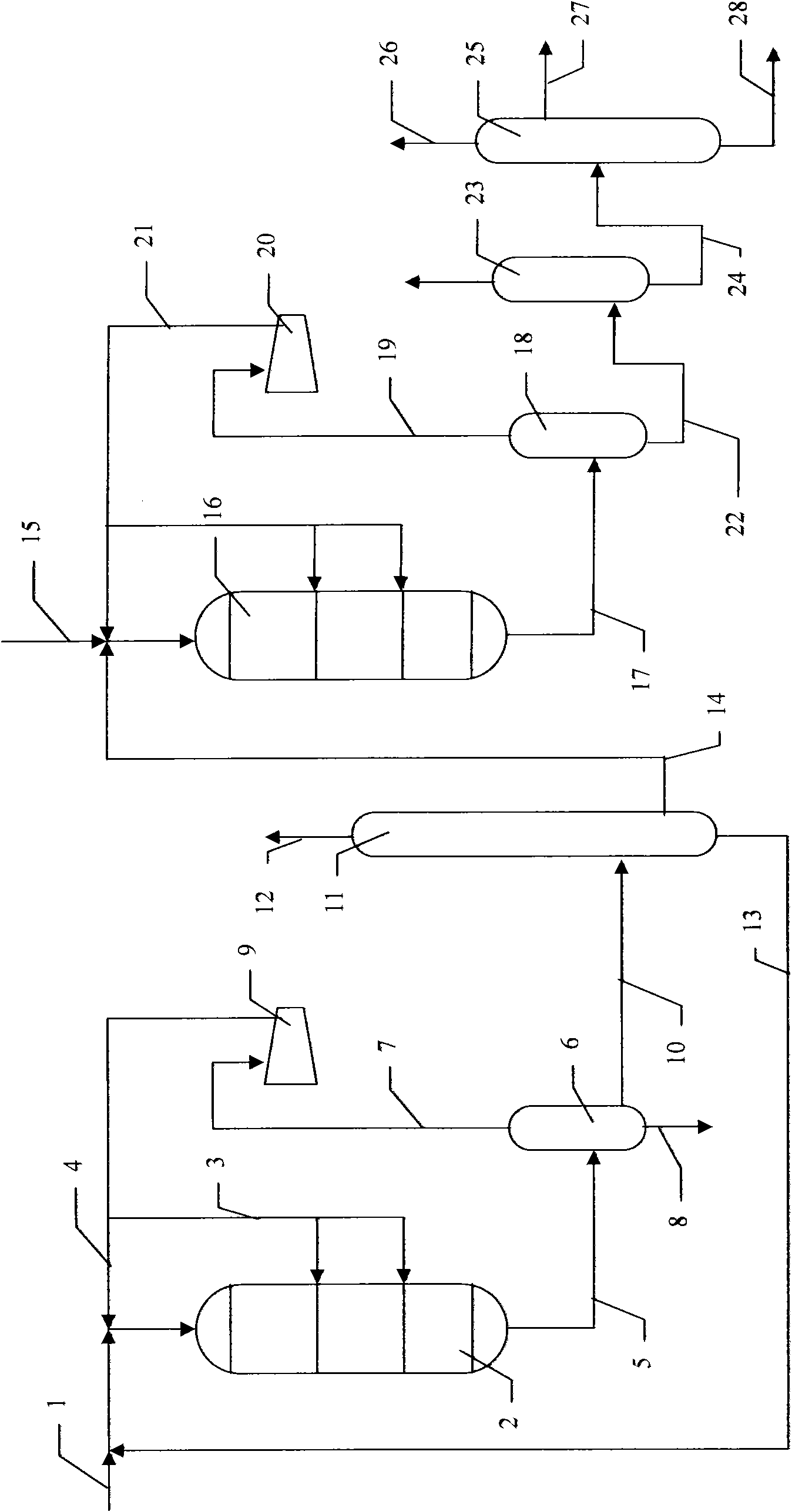

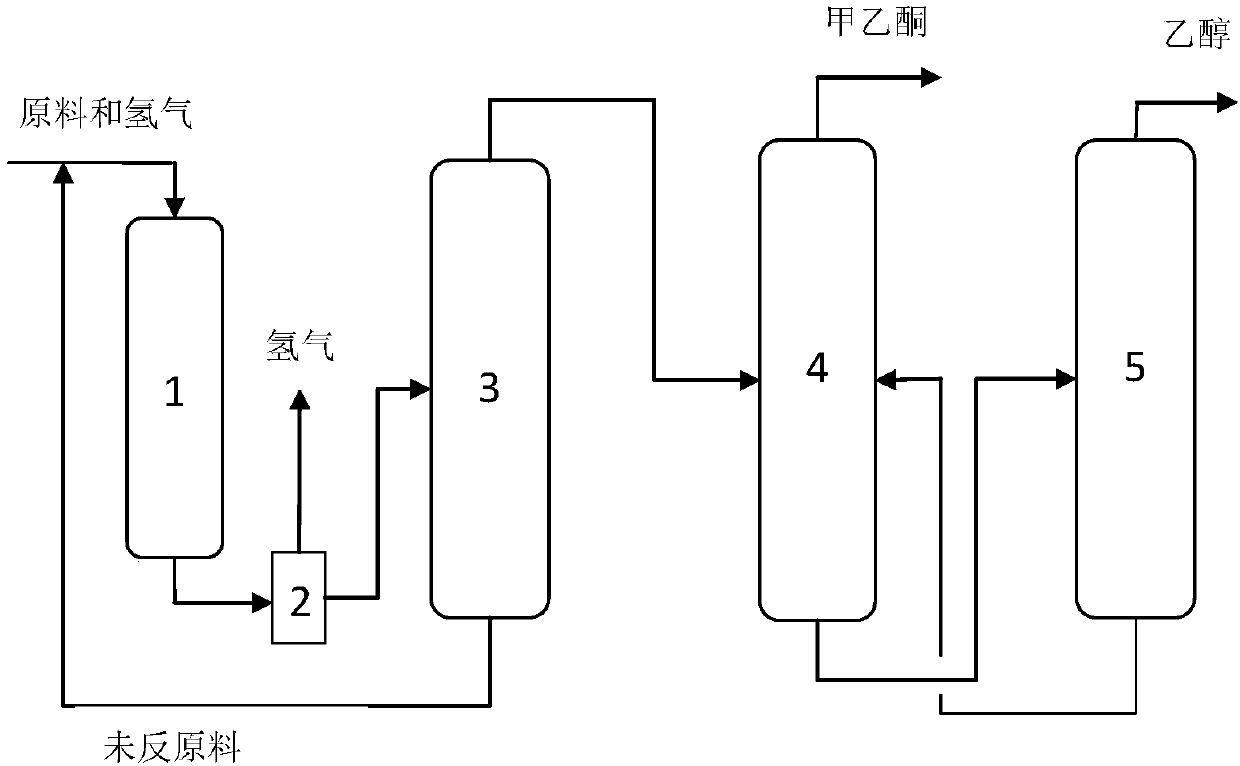

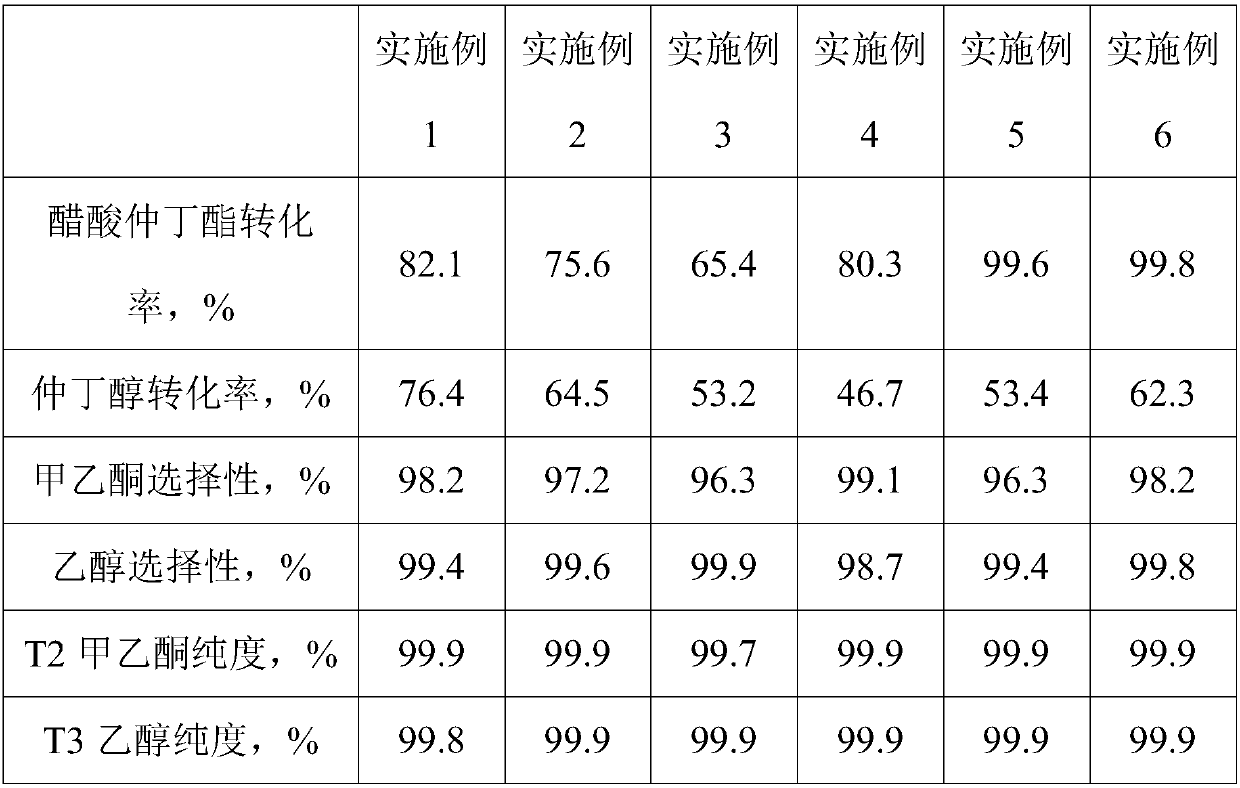

Technological method for transferring hydrogenation for sec-butyl acetate by secondary butyl alcohol and simultaneously producing methyl ethyl ketone

ActiveCN106117025AImprove conversion rateReduce operating severityOrganic compound preparationPreparation by dehydrogenationLiquid productHydrogen

The invention relates to a technological method for transferring hydrogenation for sec-butyl acetate by sec-butyl alcohol and simultaneously producing methyl ethyl ketone. According to the method, the composition of sec-butyl alcohol and sec-butyl acetate is taken as a raw material, the transferring hydrogenation for sec-butyl acetate by sec-butyl alcohol is realized under the effect of a hydrogenation catalyst, and the sec-butyl alcohol is dehydrogenized, so that the methyl ethyl ketone is obtained, the sec-butyl acetate is subjected to transferring hydrogenation, so as to produce the sec-butyl alcohol and ethyl alcohol; the produced sec-butyl alcohol is dehydrogenized, so that the methyl ethyl ketone is obtained. A product is subjected to gas-liquid separation, high-purity hydrogen is obtained, and a liquid product is subjected to distillation separation firstly, so that the composition of ethyl alcohol and methyl ethyl ketone is obtained, and the sec-butyl alcohol or the composition of the sec-butyl alcohol and the sec-butyl acetate in a column reactor returns a transferring hydrogenation reactor, so as to be reacted continuously; the composition of ethyl alcohol and the methyl ethyl ketone is subjected to extractive distillation firstly, so that a high-purity methyl ethyl ketone product is obtained, an extraction agent containing ethyl alcohol in the column reactor is rectified again, a high-purity ethyl alcohol product is obtained, and the extraction agent in the column reactor returns an extractive distillation column to be recycled. The method solves the problems that the sec-butyl acetate and the sec-butyl alcohol are azeotropic and high-purity sec-butyl alcohol and methyl ethyl ketone cannot be obtained.

Owner:九江齐鑫化工有限公司 +2

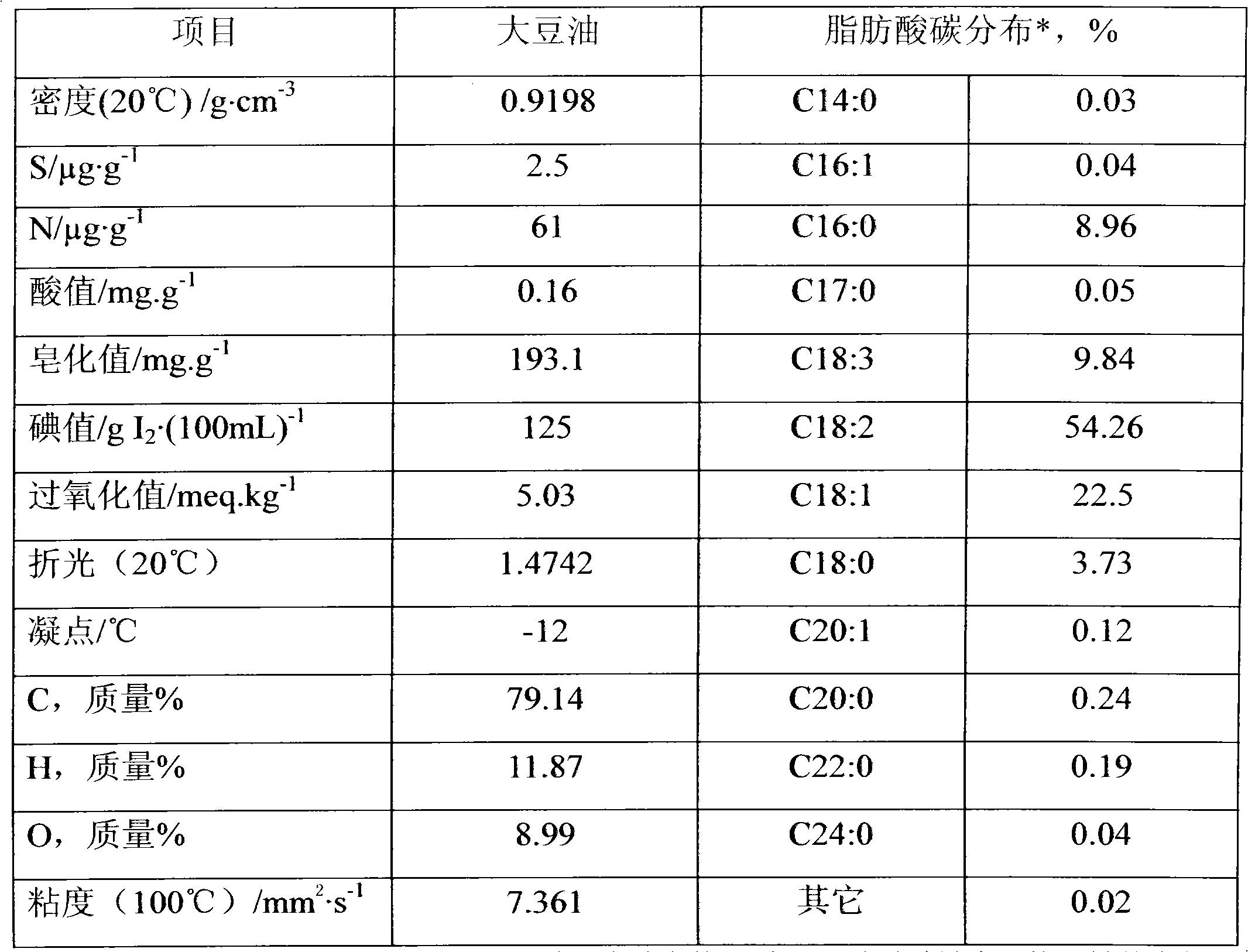

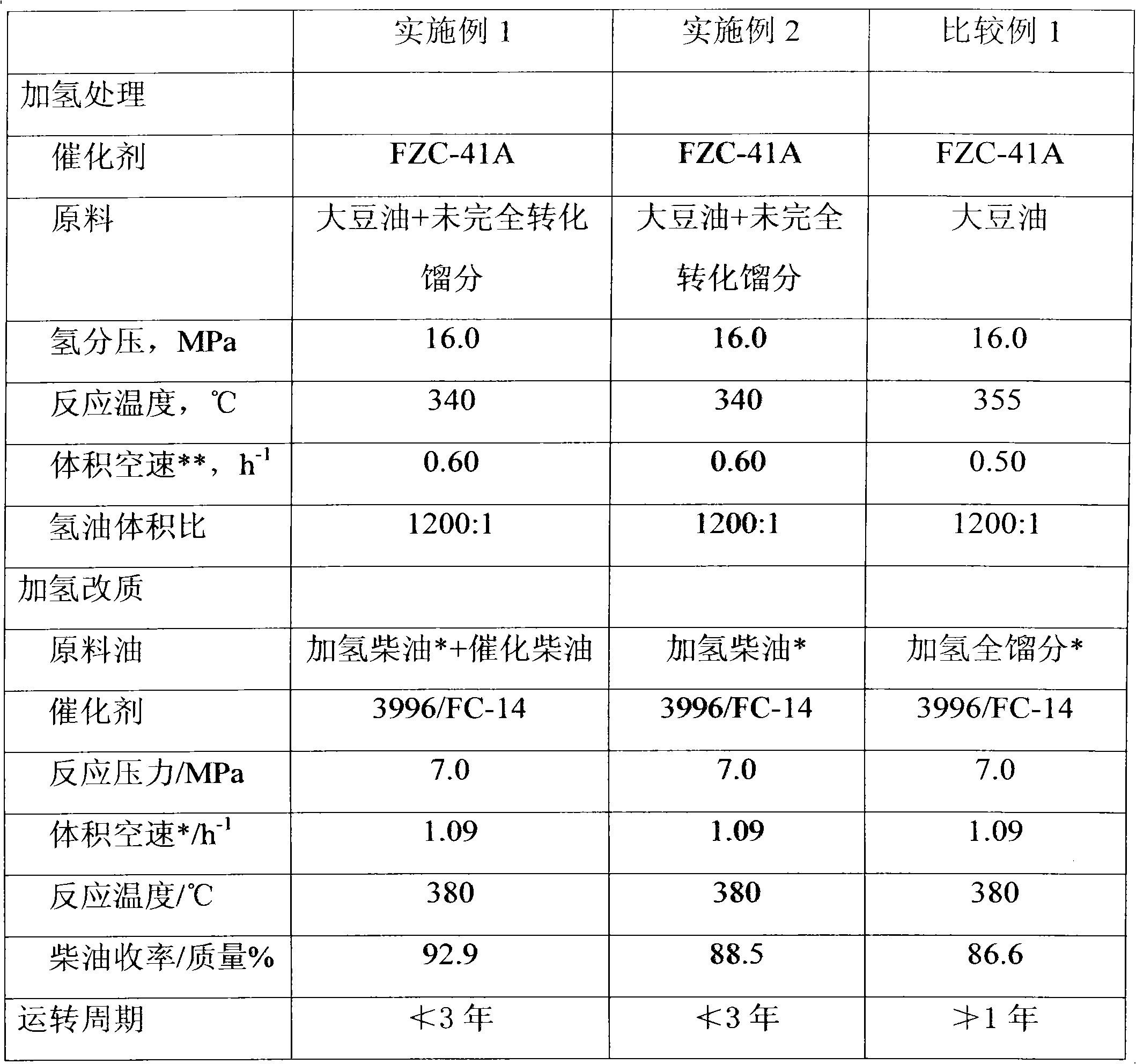

Method by catalyzing and hydrogenating animal and vegetable oil to produce high-quality diesel

ActiveCN102464998BNo reduction in activityStrong resistance to waterBiofuelsLiquid hydrocarbon mixture productionOil and greaseVegetable oil

The invention discloses a method by catalyzing and hydrogenating animal and vegetable oil to produce high-quality diesel. Animal and vegetable oil is subjected to hydrodeoxygenation and olefin saturation reaction with the existence of hydrogen and catalyst, gas and generated water are separated from effluents of hydrogenation reaction, gas, diesel fraction and incompletely-converted fraction are obtained by distilling the liquid, the incompletely-converted fraction is circulated back to a hydrogenation treatment reactor, the diesel fraction enters a hydrogenation modified reactor after being mixed with an optional modified raw material to be subjected to the modified reaction with the existence of hydrogen and modified catalyst, and gas products, naphtha and diesel fraction are obtained through the separation and distilling. Compared with the prior art, the hydrogenation reaction, hydrogenation modified reaction and / or pour point depression reaction of the animal and vegetable oil can be carried out under a relatively tempered technique condition, and the method has the advantages such as wide range of raw materials, high quality of products, high yield of diesel and fewer byproducts.

Owner:CHINA PETROLEUM & CHEM CORP +1

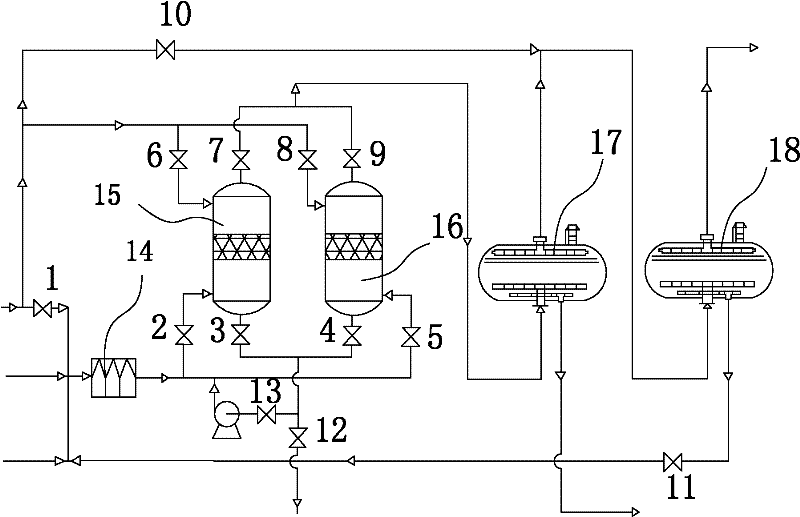

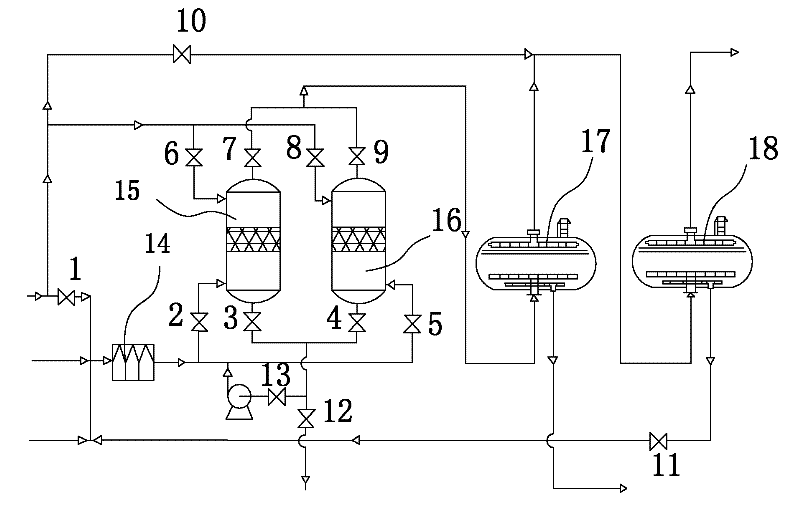

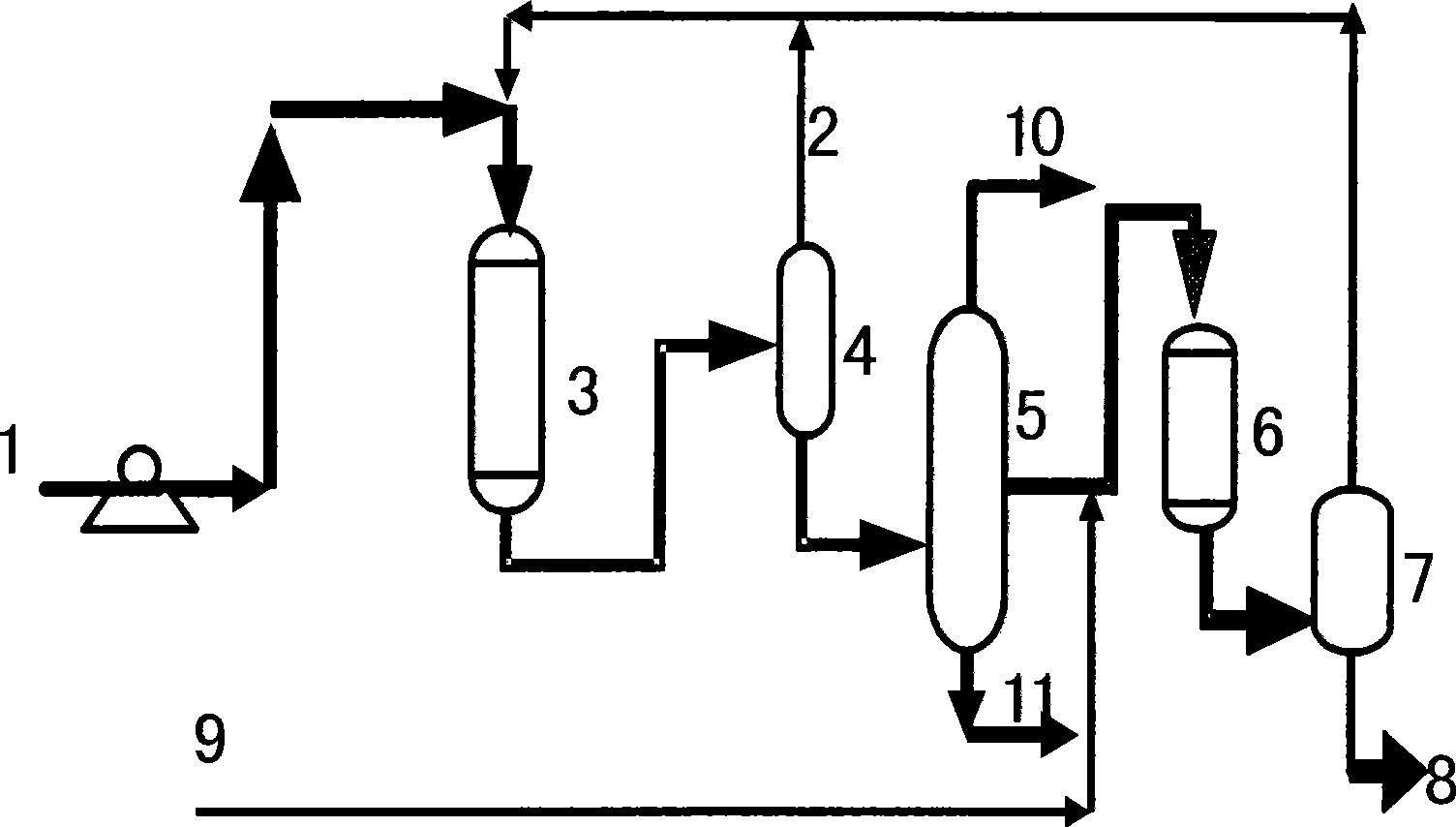

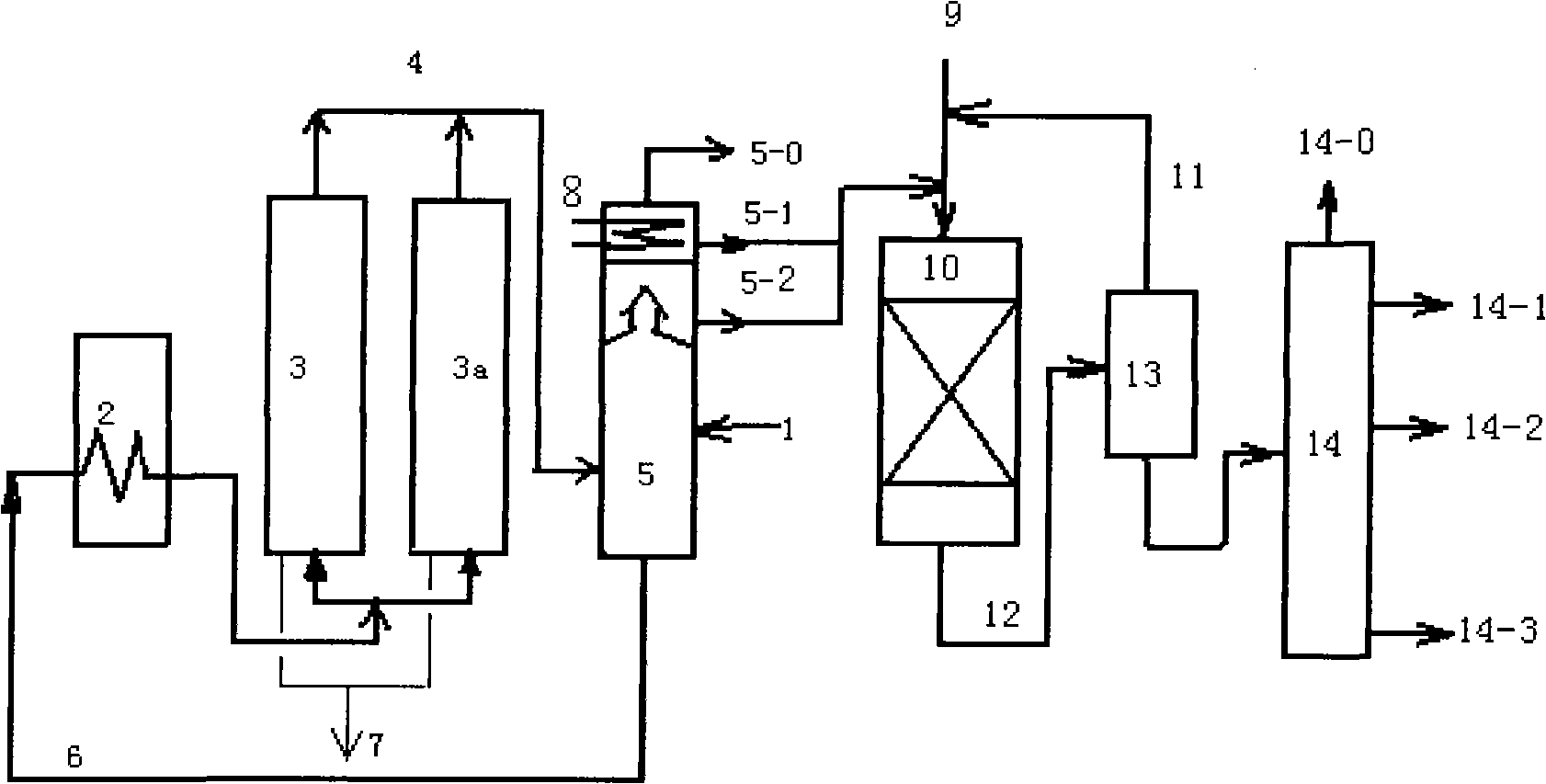

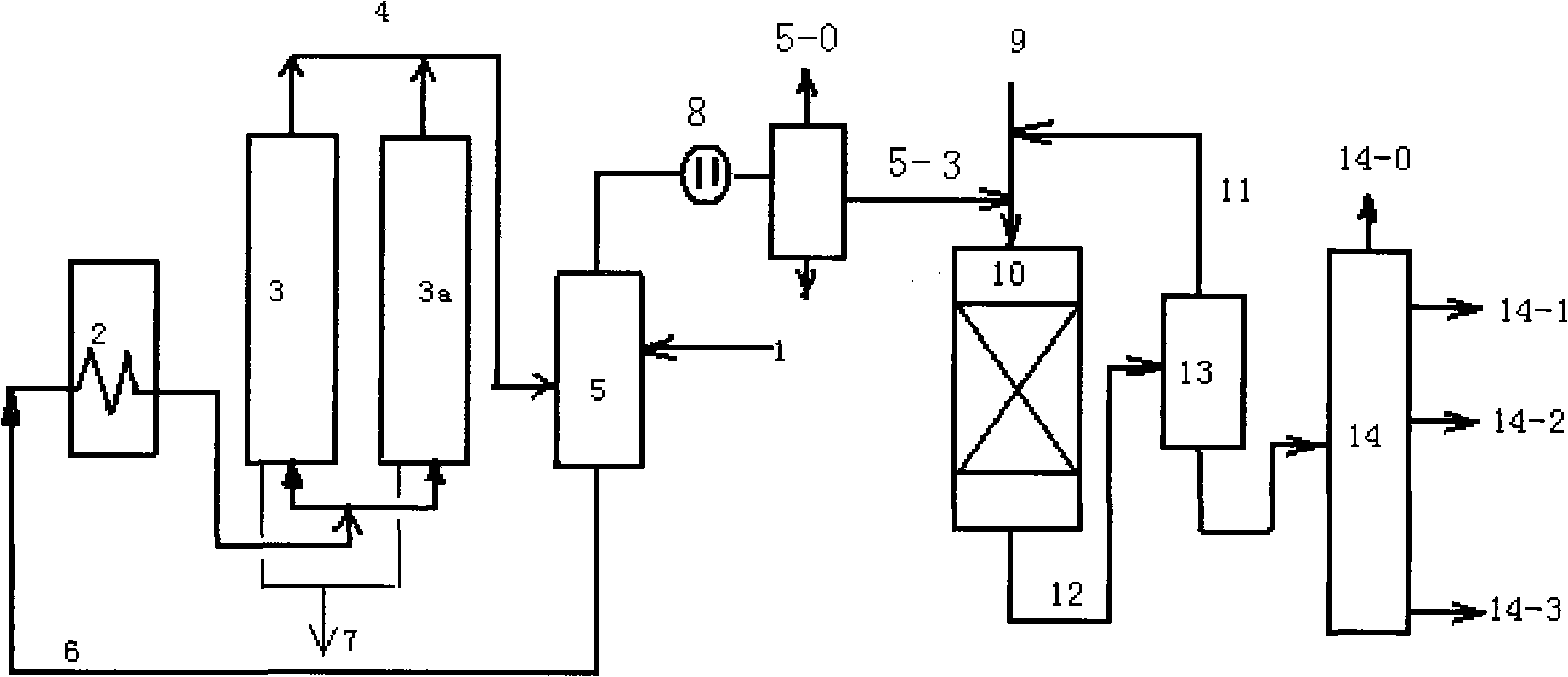

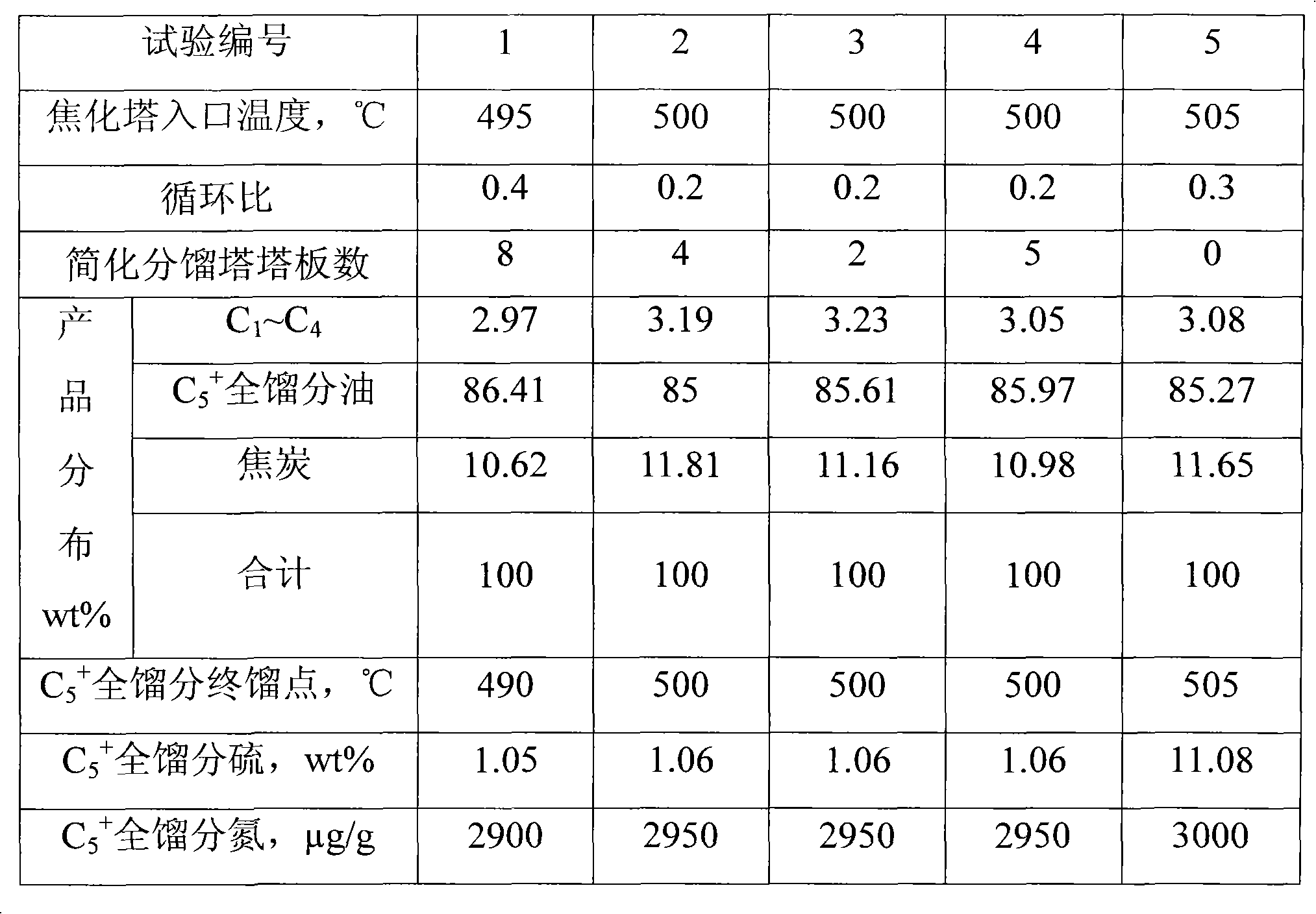

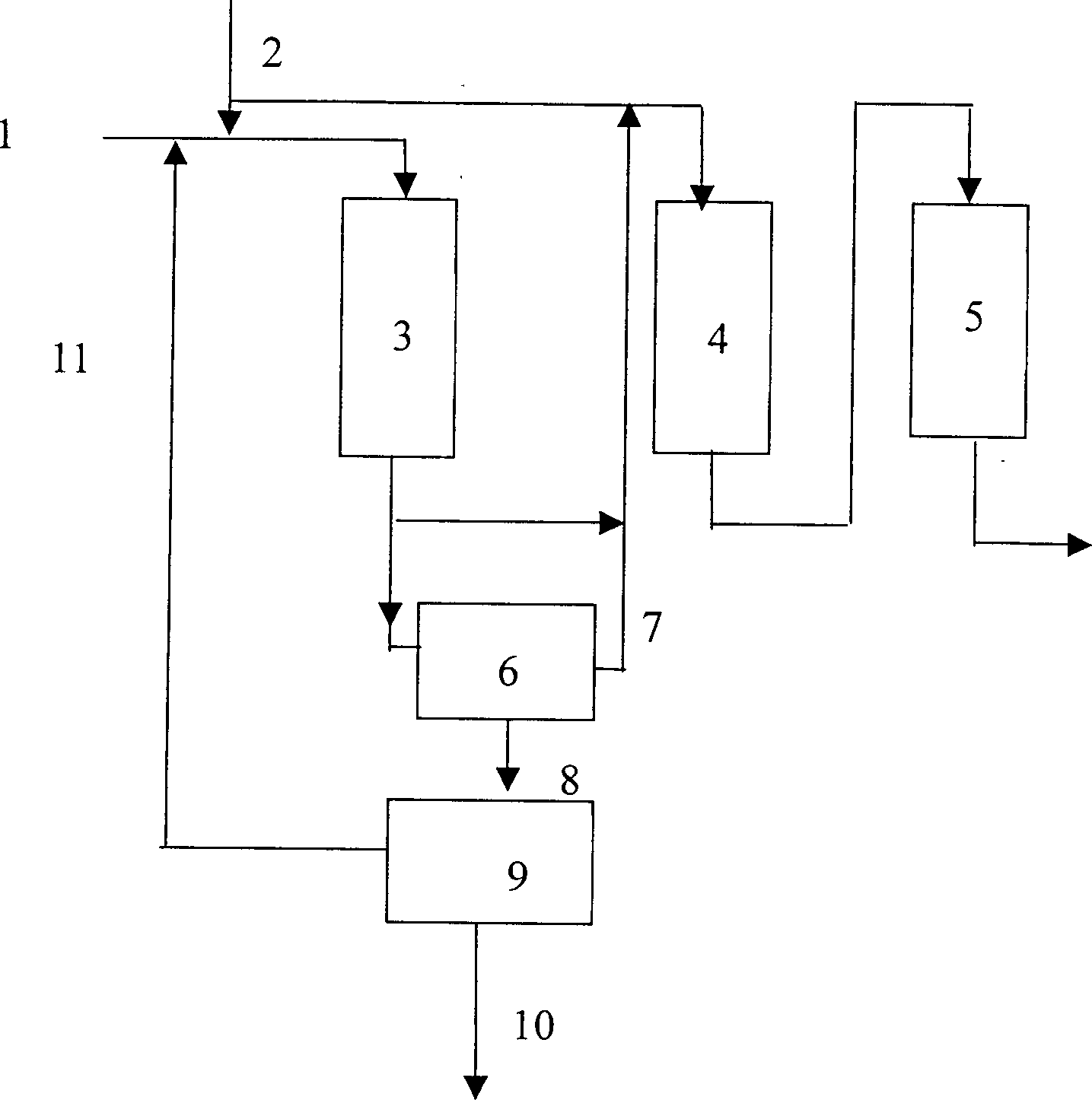

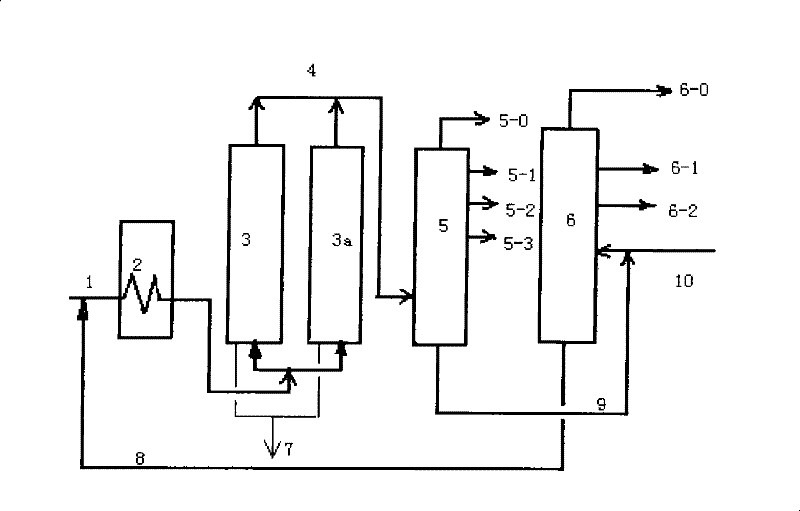

Process integration for carbonization-carbonization full cut fraction hydrotreatment

ActiveCN101343567ASimple structureReduce operating severityTreatment with hydrotreatment processesWaxProcess integration

The invention discloses a coking-coking full range hydroprocessing combined process method. A simplified fractionating tower is arranged at a coking part, and a heat-exchange evaporation section and a condensing fractionation section are respectively arranged at the lower part and the upper part of the simplified fractionating tower. Oil gas produced by the coking reaction enter the simplified fractionating tower from the lower part, and flows upwards into the condensing fractionation section at the upper part of the simplified fractionating tower after being leached and exchanging heat with coking material, most of the oil gas is liquefied in the condensing fractionation section and led out of the simplified fractionating tower, a condensate led out of the simplified fractionating tower undergoes the hydroprocessing after separating out water, and a hydroprocessing product is separated into hydrogenated gasoline, hydrogenated diesel oil and hydrogenated wax oil. The method organically combines the coking technique and the hydroprocessing technique to simplify the coking technical process and improve the economical efficiency and reliability of the hydroprocessing part in the meanwhile.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil

ActiveCN106701187AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a method for treating residual oil. A coking device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area are provided, the method comprises the following steps: performing fractionation on a residual oil raw material so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. By adopting the method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-purity piperylene preparation method

InactiveCN109721454ANo pollution in the processHigh adsorption selectivityHydrocarbonsAdsorption purification/separationPiperyleneRaw material

The invention discloses a high-purity piperylene preparation method, wherein isoprene and cyclopentadiene are removed from C5 distillate, the obtained C5 distillate is used as a raw material, and treatment is performed through adsorption and extraction rectification to obtain the high-purity piperylene. With the method of the present invention, a small of difficultly-removed cyclopentadiene and 2-butyne can be effectively removed from piperylene; the process is simple and effective; and with the method, the high-purity piperylene with the cyclopentadiene content of less than 50 ppm and the 2-butyne content of less than 20 ppm can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Matrix asphalt production method

ActiveCN104610995AOvercome deficienciesOvercome defectsWorking-up pitch/asphalt/bitumen by distillationHydrocarbon distillationWaxDistillation

The present invention discloses a matrix asphalt production method, which comprises that: normal pressure residual oil obtained from normal pressure distillation on raw oil enters a coking main fractionation tower and contacts coking reaction oil gas at the desuperheating section of the coking main fractionation tower, the obtained material falls into the bottom of the coking fractionation tower and is mixed with coking circulating oil, one part of the coking circulating oil is pumped into a pressure reducing distillation tower to carry out pressure reducing distillation, the relatively-light distillate is extracted from the pressure reducing distillation tower, and the pressure reducing tower bottom oil is extracted as the raw material for asphalt production. According to the method of the present invention, the process is short, the process is advanced and reasonable, the high-quality direct distillation asphalt can be significantly increased, the aromatic-rich and wax-poor distillate oil is reduced or is not used to blend the asphalt raw material, and the high-quality matrix asphalt yield increase purpose is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for coking full fraction oil hydrogenation refining

InactiveCN1205312CIncrease the hydrofining processImprove natureHydrocarbon oils refiningHydrogenation processEngineering

The invention discloses a method for hydrofining coking whole distillate oil, which overcomes the problems in the prior art that high-quality clean diesel oil cannot be obtained by hydrofining coking whole distillate oil, and the investment and operation cost of separate hydrofining of diesel oil are large. The problem. The present invention fully relies on the original coking whole distillate oil hydrofining process, and uses the new hydrogen of the system for further hydrofining of diesel oil, so that diesel oil can be refined under ideal thermodynamic conditions and dynamic conditions, not only the product quality is high, but also the The flexibility, economy and practicability of the process, at the same time, the investment in equipment is less, the heat energy is fully utilized, and the operating cost is low. The method of the invention is suitable for the transformation of coking whole distillate oil hydrogenation unit or the construction of a similar flow process.

Owner:CHINA PETROLEUM & CHEM CORP +1

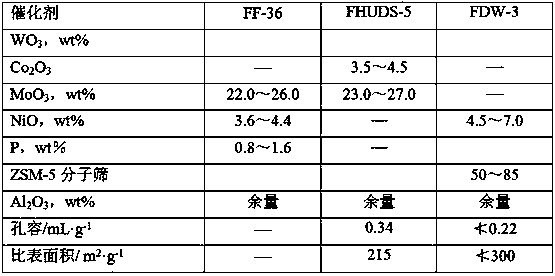

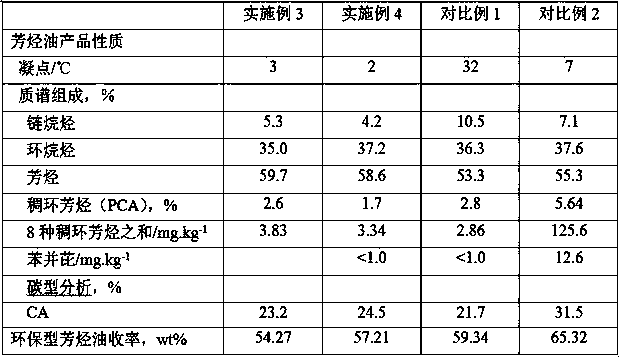

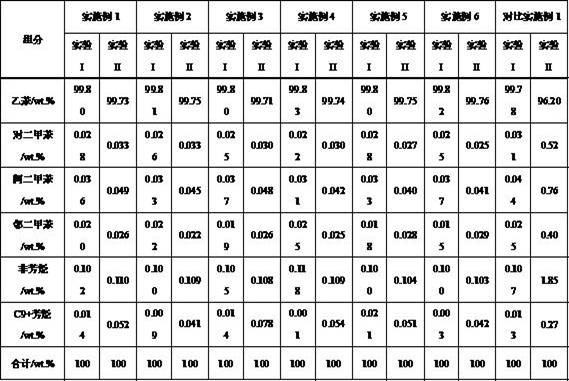

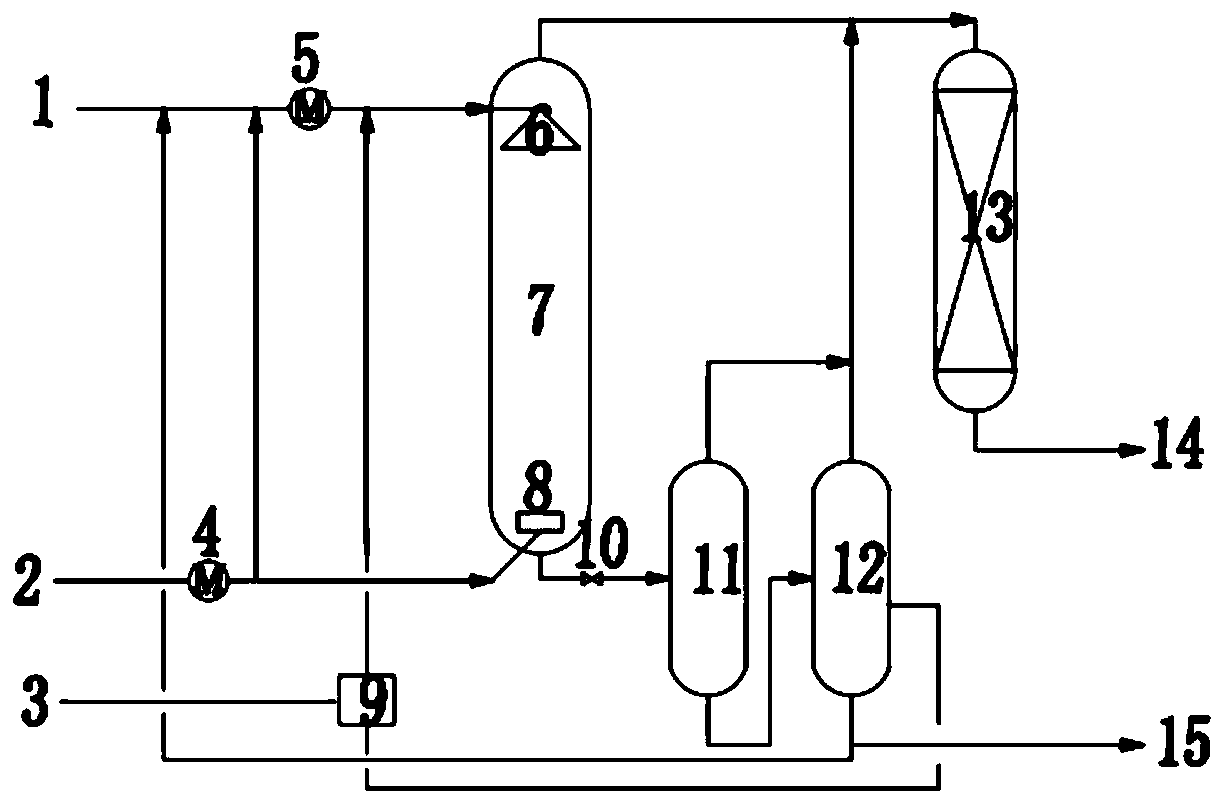

Production method of environment-friendly aromatic hydrocarbon oil for tires

ActiveCN111378498AAdaptableReduce lossesTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonProcess engineering

The invention discloses a production method of environment-friendly aromatic hydrocarbon oil for tires. The environment-friendly tire aromatic hydrocarbon oil meeting the European Union standard can be produced by taking positive-sequence furfural extract oil with a relatively high condensation point as a raw material and adopting a hydrotreatment-hydrodewaxing-solvent extraction combined process.The method comprises the following steps: performing hydrotreatment on raw materials under mild conditions to saturate polycyclic aromatic hydrocarbon, performing hydrodewaxing to reduce the condensation point to 0-10 DEG C, and finally performing shallow extraction to obtain the environment-friendly aromatic hydrocarbon oil for tires. The method expands sources of raw materials for producing theenvironment-friendly aromatic hydrocarbon oil, and has the characteristics of strong raw material adaptability and mild process conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

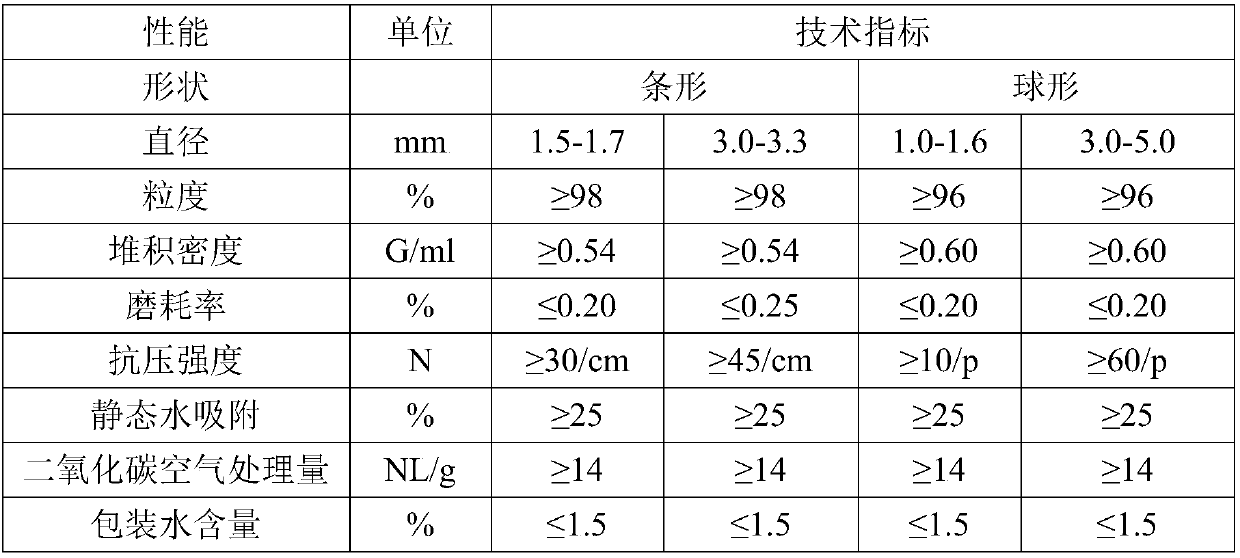

Adsorbent for separating ethylbenzene from C8 aromatic hydrocarbon and preparation method thereof

ActiveCN114160096AReduce operating severityHigh purityOther chemical processesChemical industryPhysical chemistryIon exchange

The invention discloses an adsorbent for separating ethylbenzene in C8 aromatic hydrocarbon and a preparation method thereof, the adsorbent mainly comprises X zeolite, the silica-alumina ratio (SiO2 / Al2O3) of the adsorbent is 2.0-2.3, the grain size of the adsorbent is 0.5-5 [mu] m, and the adsorbent is prepared by treating the X zeolite through a combined treatment process of alkali metal ion exchange and surface estersil modification. The adsorbent provided by the invention can separate ethylbenzene from mixed C8 aromatic hydrocarbons, and the ethylbenzene product has high purity and yield.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Reaction and separation integrated countercurrent hydrogenation reaction process

InactiveCN111575054AReduce contact timeReduced activityTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

Disclosed is a reaction and separation integrated countercurrent hydrogenation reaction process. A reaction raw material is mixed with part of hydrogen, heating is performed, a mixed feed is formed with catalyst slurry, the mixed feed is sprayed into a hydrocracking reactor from the upper part of the reactor, the reaction hydrogen is heated and boosted and then enters the hydrocracking reactor from the bottom of the reactor, and the reaction raw material and hydrogen are subjected to countercurrent heat and mass transfer and a hydrocracking reaction in the reactor; a gas-phase product directlyenters a fixed bed hydrogenation device from a top outlet of the reactor, so that clean fuel is obtained; a liquid (solid) phase product is depressurized and degassed and enters an atmospheric and vacuum distillation device from the bottom of the reactor; and side oil of the atmospheric and vacuum distillation device enters the fixed bed for hydrogenation, and bottom oil residues are partially directly discharged out of the device and partially circularly enter a raw material system.

Owner:SHAANXI YANCHANG PETROLEUM GRP

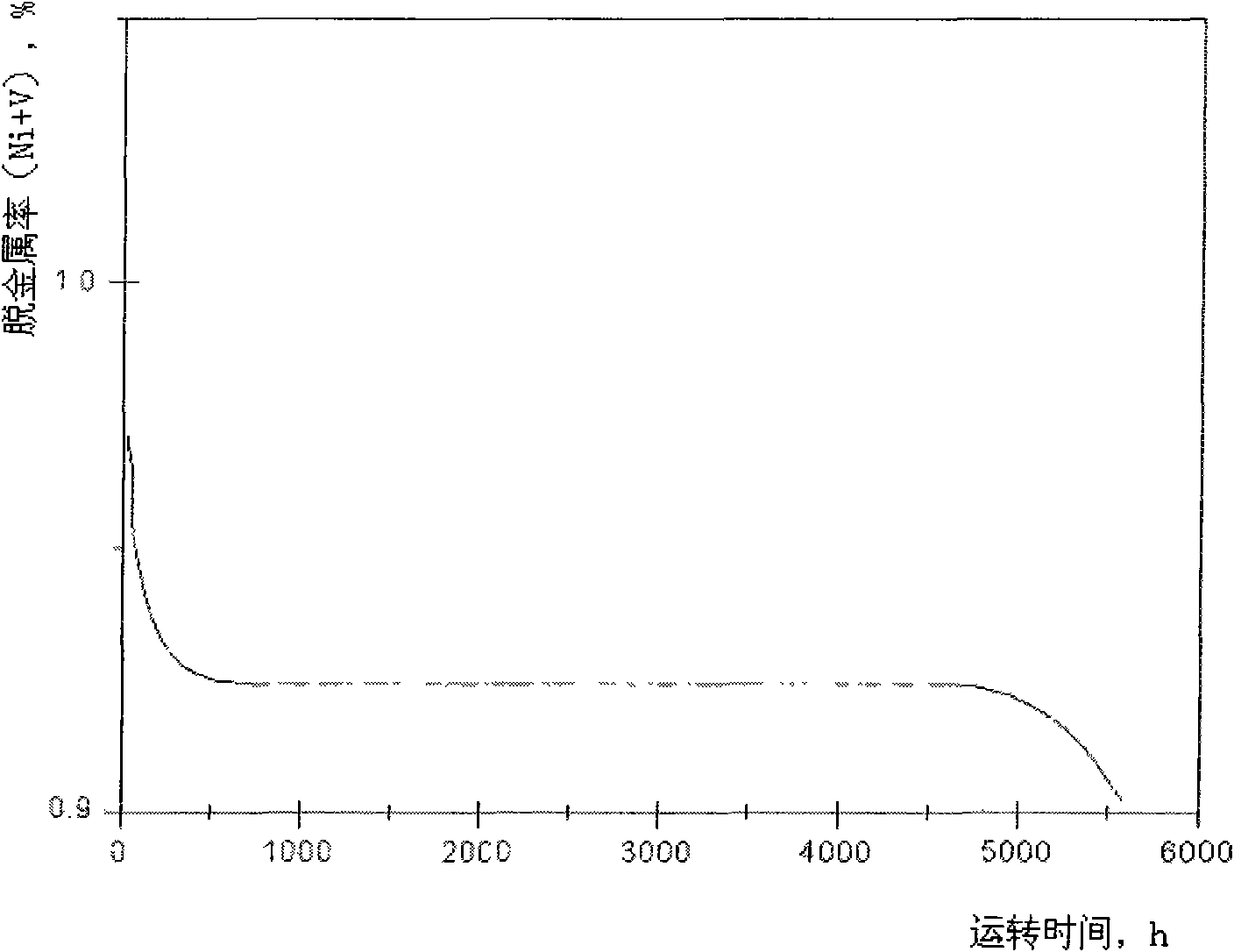

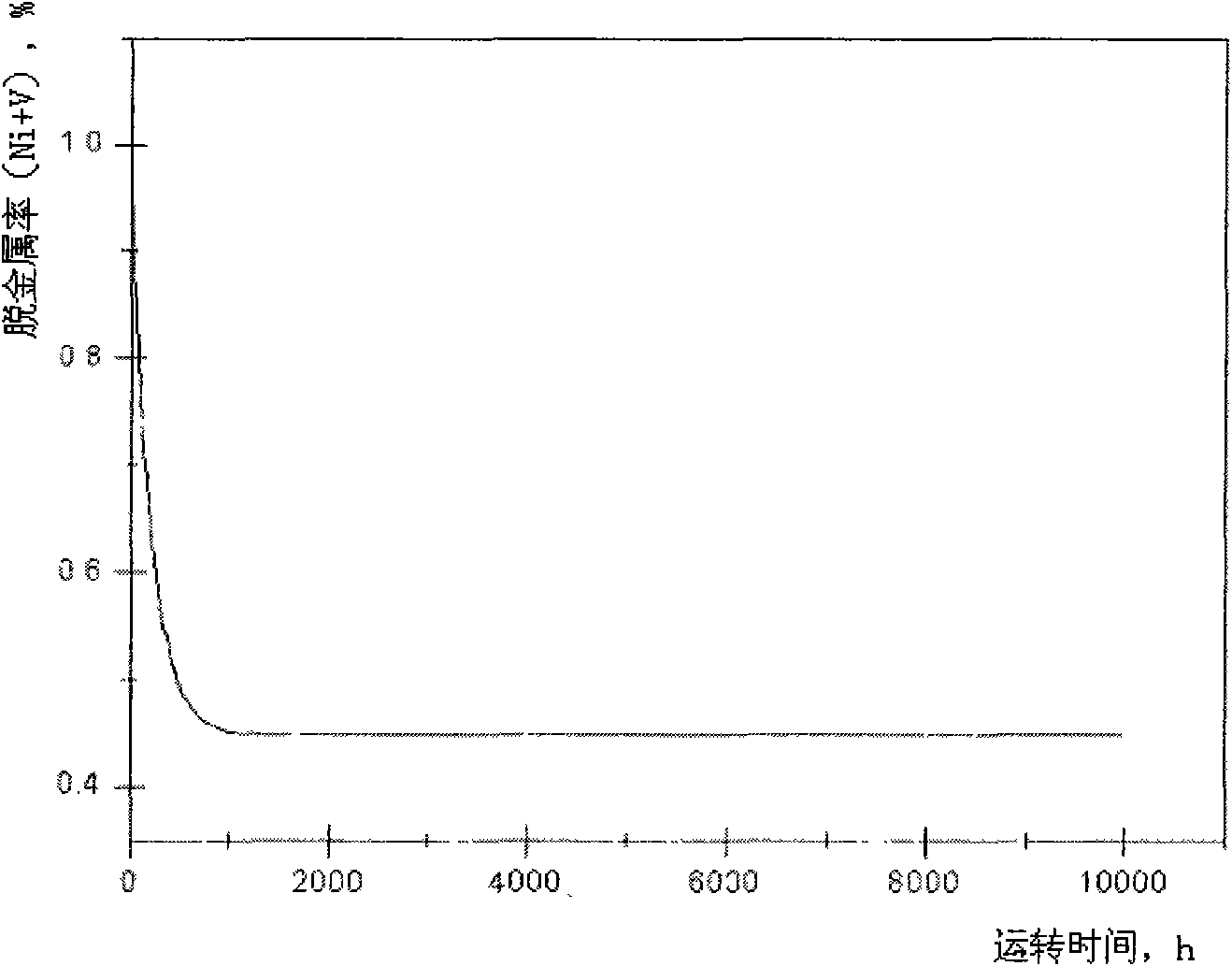

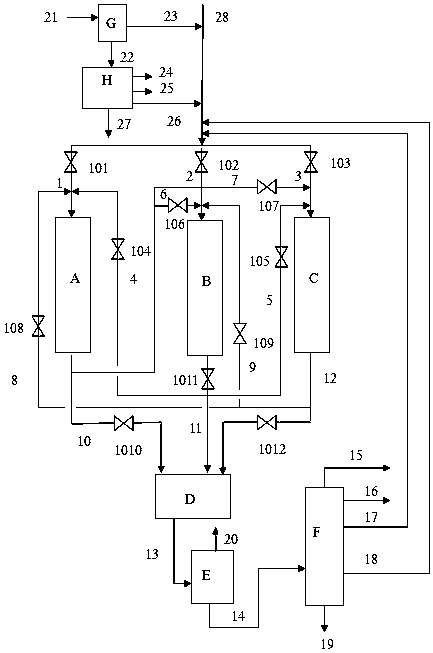

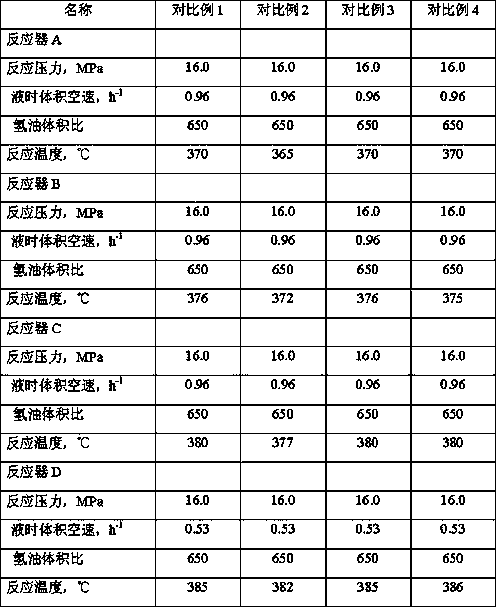

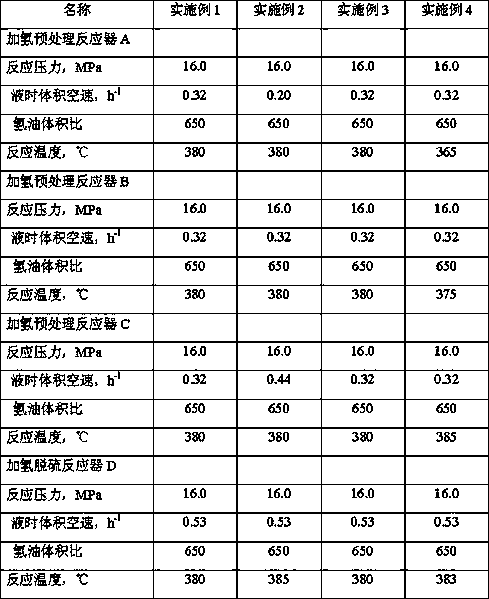

Method of prolonging service life of heavy oil and residual oil hydrogenating catalyst

InactiveCN1274419CIncrease flexibilityLow viscosityCatalyst carriersHydrocarbon oils refiningWaxSulfur

The method of prolonging service life of heavy oil and residual oil hydrogenating catalyst includes hydrogenating to eliminate metal, eliminating asphalt with solvent, hydrogenating to eliminate sulfur and hydrogenating to eliminate nitrogen. The liquid phase effluent after hydrogenating to eliminate metal is asphalt eliminated to obtain asphalt-eliminating oil and oil-eliminating asphalt; the asphalt-eliminating oil together with the rest liquid phase effluent after hydrogenating to eliminate metal is made to enter the area of hydrogenating to eliminate sulfur and hydrogenating to eliminate nitrogen; and the oil-eliminating asphalt is coked to obtain coked wax oil with at least part returned to the area of hydrogenating to eliminate metal. Compared with available technology, the present invention has raised flexibility and prolongs the service life of the hydrogenating catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

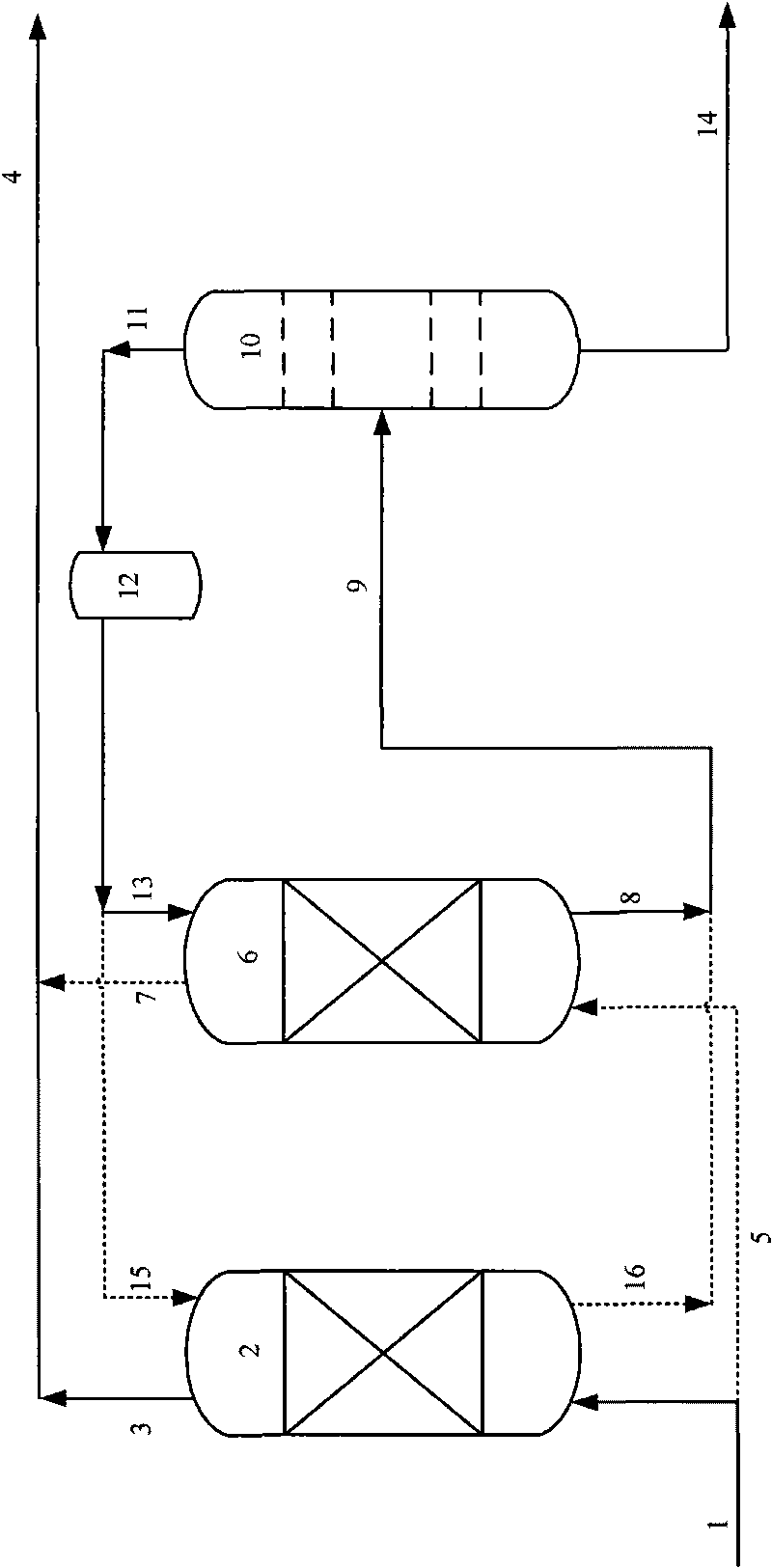

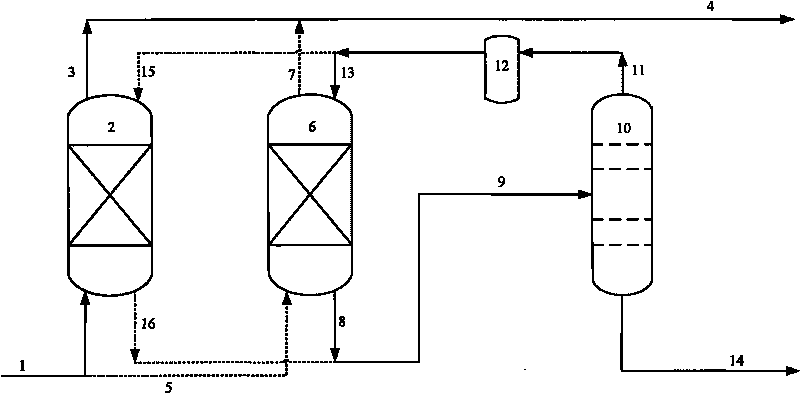

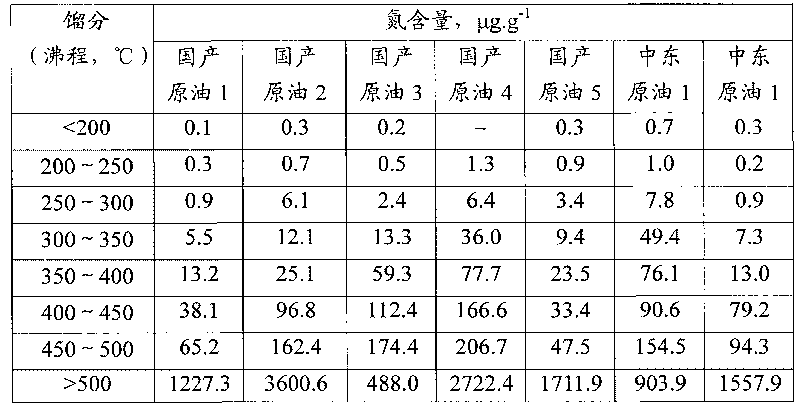

Production method of clean diesel

InactiveCN101735855ALess investmentReduce lossesTreatment with hydrotreatment processesDistillates petroleumDistillation

The invention provides a production method of clean diesel. According to the characteristics that the content of nitrogen is different along with the distribution of the distillation range in the petroleum distillate, the diesel raw material is divided into a heavy component and a light component, wherein the content of nitrogen in the heavy component accounts for 5-20% of the weight of the total content of nitrogen in the diesel raw materials; the heavy component is mixed with the light component and then enters the hydrogenation unit after the adsorption unit removes the nitrogen-containing compound, and clean diesel is obtained after hydrogenation treatment. In the invention, only part of the distillate is adsorbed, thus reducing the investment of the adsorption unit and the loss of oils; in addition, the content of nitrogen in the hydrogenation raw material is reduced, thus reducing the competitive adsorption with sulfide, lowering operating severity of the hydrogenation unit and prolonging the service life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

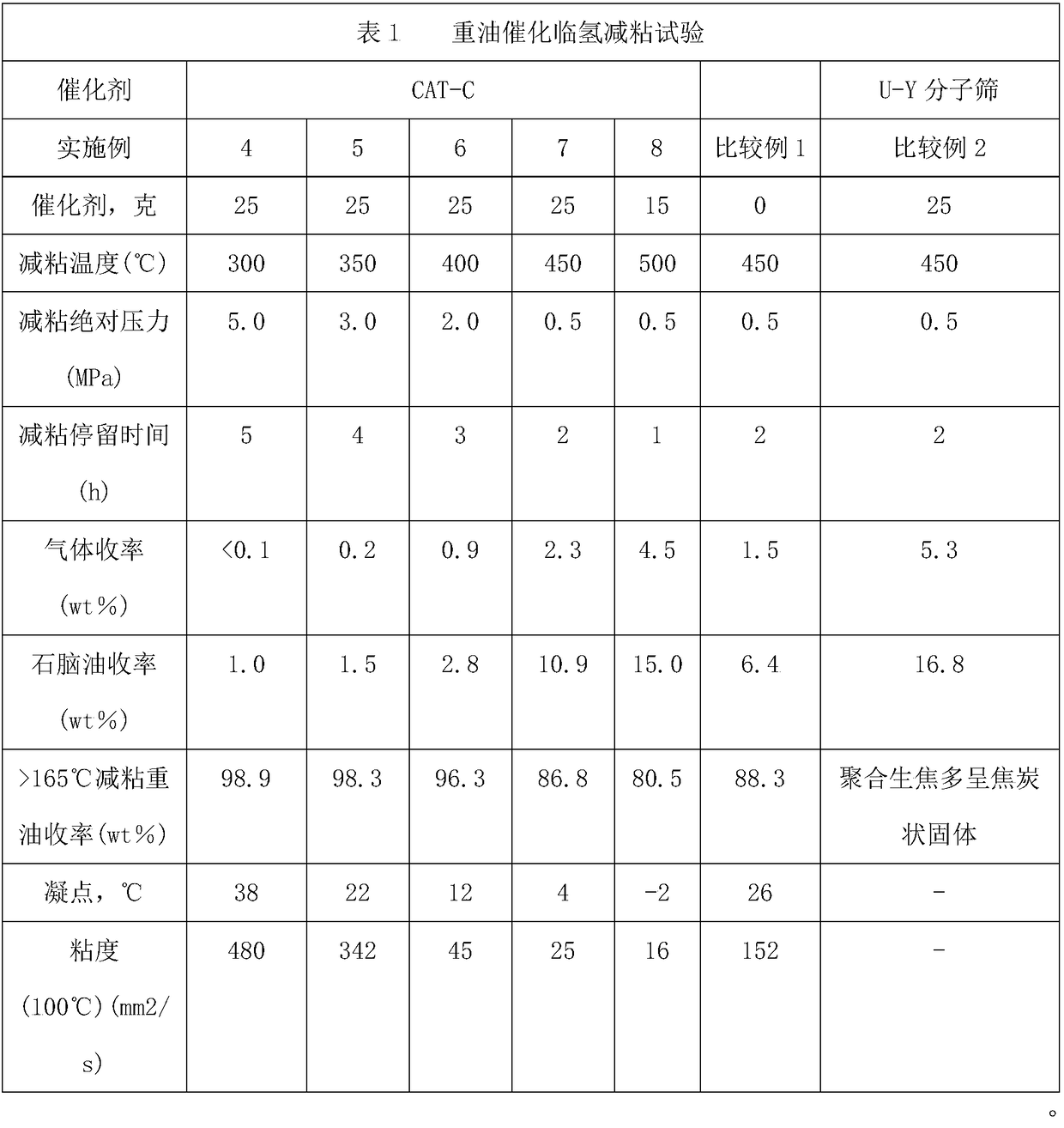

Method for reducing viscosity of heavy oil

InactiveCN108587675AReduce tendency to polymerize and cokePromote coke formationCatalytic crackingCatalyst activation/preparationOil processingIsomerization

The invention discloses a method for reducing the viscosity of heavy oil and belongs to the technical field of petroleum processing. The method comprises the steps: contacting a heavy oil component with a catalyst with an alkaline carrier without silicon and aluminum elements in a viscosity reducing reactor, and carrying out cracking, isomerization, de-coagulation and viscosity reduction under thecondition of an oxygen-free and / or reducing atmosphere, wherein the process conditions are that the reaction temperature is 300-550 DEG C, the reaction pressure if 0.01-6.0Mpa, and the reaction timeis 0.1-5.0h. The viscosity of the heavy oil can be remarkably reduced, and a heavy oil fuel or heavy oil can provide a raw material for further processing and producing oil and gas products after theviscosity is reduced. A heavy oil viscosity reducing and cracking catalyst with the alkaline carrier without silicon and aluminum is adopted due to the polymerization coke generation promoting effectof an acidic catalyst and a polymerization coke generation inhibiting effect of an alkaline catalyst, viscosity reduction is carried out under the condition of the oxygen-free and / or reducing atmosphere, and therefore, on one hand, the polymerization coke generation tendency of a reaction product can be reduced under the condition of deep viscosity reduction, and on the other hand, the operation severity can be reduced when the relatively deep viscosity reducing effect is achieved.

Owner:HIGH TECH RES INST NANJING UNIV LIANYUNGANG

Heavy oil product treatment processing method

ActiveCN106701188AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsGas phaseSlurry

The invention discloses a heavy oil product treatment processing method. The method comprises a hydrogenation pretreatment device, a solvent deasphalting device, a hydrogenation treatment device and a catalytic cracking device, wherein the hydrogenation treatment device comprises a hydrogenation pretreatment reaction area and a hydrogenation treatment reaction area; the processing method comprises the following steps: residual oil raw material generated oil is subjected to fractional distillation after being reacted through a hydrogenation pretreatment unit to obtain light fraction and heavy fraction, wherein the heavy fraction is treated after entering the solvent deasphalting device so as to obtain deasphalted oil and deoiled asphalt, and the light fraction orderly passes through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are in series connection after mixing with the deasphalted oil and hydrogen; gas-liquid separation is performed on reaction effluent of the hydrogenation treatment reaction area, and a gas phase is recycled back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area; a liquid phase directly enters a catalytic cracking reaction area to perform catalytic cracking reaction, and effluent of the catalytic cracking reaction is separated to obtain dry gas, liquefied gas, catalytic-cracked gasoline fraction, catalytic-cracked diesel fraction, catalytic-cracked heavy cycle oil and catalytic-cracked oil slurry. The stable operation period of the device can be prolonged by use of the method disclosed by the invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process method for simultaneous production of methyl ethyl ketone by transfer hydrogenation of sec-butyl alcohol to sec-butyl acetate

ActiveCN106117025BImprove conversion rateReduce operating severityOrganic compound preparationPreparation by dehydrogenationLiquid productSec-Butanol

The invention relates to a technological method for transferring hydrogenation for sec-butyl acetate by sec-butyl alcohol and simultaneously producing methyl ethyl ketone. According to the method, the composition of sec-butyl alcohol and sec-butyl acetate is taken as a raw material, the transferring hydrogenation for sec-butyl acetate by sec-butyl alcohol is realized under the effect of a hydrogenation catalyst, and the sec-butyl alcohol is dehydrogenized, so that the methyl ethyl ketone is obtained, the sec-butyl acetate is subjected to transferring hydrogenation, so as to produce the sec-butyl alcohol and ethyl alcohol; the produced sec-butyl alcohol is dehydrogenized, so that the methyl ethyl ketone is obtained. A product is subjected to gas-liquid separation, high-purity hydrogen is obtained, and a liquid product is subjected to distillation separation firstly, so that the composition of ethyl alcohol and methyl ethyl ketone is obtained, and the sec-butyl alcohol or the composition of the sec-butyl alcohol and the sec-butyl acetate in a column reactor returns a transferring hydrogenation reactor, so as to be reacted continuously; the composition of ethyl alcohol and the methyl ethyl ketone is subjected to extractive distillation firstly, so that a high-purity methyl ethyl ketone product is obtained, an extraction agent containing ethyl alcohol in the column reactor is rectified again, a high-purity ethyl alcohol product is obtained, and the extraction agent in the column reactor returns an extractive distillation column to be recycled. The method solves the problems that the sec-butyl acetate and the sec-butyl alcohol are azeotropic and high-purity sec-butyl alcohol and methyl ethyl ketone cannot be obtained.

Owner:九江齐鑫化工有限公司 +2

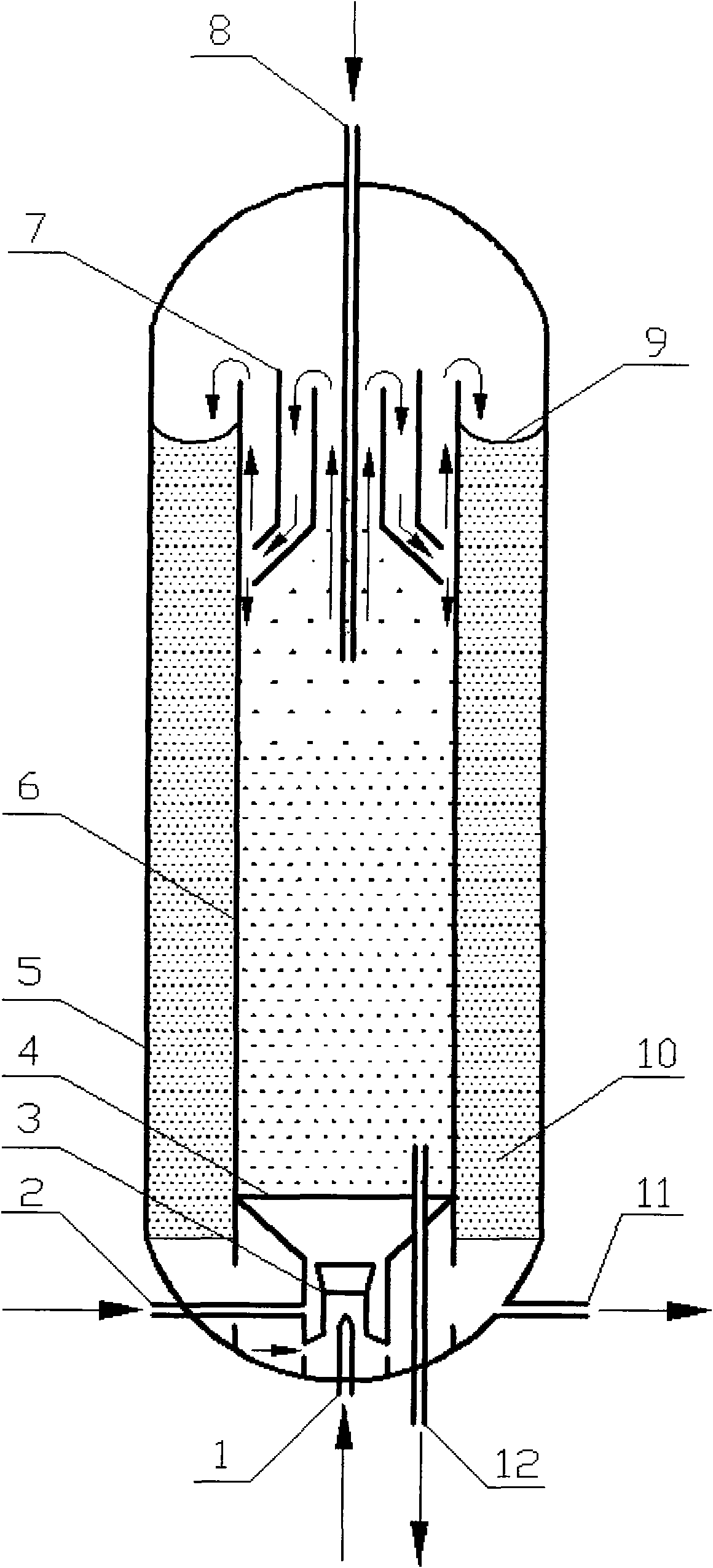

Heavy oil hydroprocessing method and reactor

ActiveCN101942325BImprove adaptabilityRealize continuous operationChemical/physical processesHydrocarbon oils treatmentFluidized bedHydrogenation process

The invention discloses a heavy oil hydroprocessing method and an internal loop reactor used by the method. In the heavy oil hydroprocessing method of the invention, the internal loop reactor is internally divided into two reaction segments, namely a fluidized bed reaction segment in a sleeve and a fixed bed reaction segment of a loop gap, and the mixture of heavy oil and hydrogen gas enters the reactor from the bottom and passes through the fluidized bed reaction segment first to undergo hydrogenation in the presence of a fluidized bed catalyst; and the catalyst is separated from the mixtureafter the reaction by a separator arranged on the upper part of the sleeve, and gas and liquid continuously go downwards to enter the fixed bed reaction segment of the loop gap to further undergo thehydrogenation in the presence of a fixed bed catalyst. The method has the combined characteristics of the fluidized bed and fixed bed hydrogenation processes, is well adapted to inferior raw materialoil with high metal and high asphaltene content and can realize the long-period stable operation of the device under the condition of achieving a high conversion rate and a high impurity removal rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for treating residual oil

ActiveCN106701187BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a method for treating residual oil. A coking device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area are provided, the method comprises the following steps: performing fractionation on a residual oil raw material so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. By adopting the method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Delayed coking and reduced pressure distillation combined processing method

ActiveCN101619238BReduce operating severityIncrease productionTreatment with plural serial stages onlyVacuum distillationWaxEconomic benefits

The invention discloses a delayed coking and reduced pressure distillation combined processing method. The method comprises the following steps that: high-temperature gases produced by the delayed coking device are delivered into a coking fractional distillation column for distillation and a dry point of the wax oil is controlled to ensure the quality of the wax oil; and coking tail oil and normal-pressure residual oil are delivered into a reduced pressure distillation device together to further and deep extract residual coking wax, the residual coking wax and straight run wax oil are discharged out from the device at the same time, and reduced pressure residual oil containing a small amount of coke powder is used as delayed coking feed. The method improves the yield of coking wax oil andensures the quality of the coking wax oil. With the increase of the extraction amount of the coking waxy oil, the amount of coking circulation oil is greatly reduced and the processing capacity of the coking device is improved, so the economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and apparatus for high-efficient crude oil desalination / dehydration

InactiveCN102226100BPrevent collapseImprove adaptabilityRefining by water treatmentTreatment with plural serial refining stagesFiltrationProcess engineering

The invention belongs to the technical field of petrochemical industry, and particularly relates to a method and an apparatus for high-efficient crude oil desalination / dehydration by a combined filtration-electric field coalescence method. The apparatus for high-efficient crude oil desalination / dehydration of the invention comprises a raw material conveying system, a mixing device, a dehydration filtration device, and an electrical desalting device which are connected in order. The method for high-efficient crude oil desalination / dehydration of the invention is realized by using the apparatus for high-efficient crude oil desalination / dehydration of the invention and through the steps of raw material preheating, mixing, preliminary demulsification, and electrical desalination / dehydration. The invention adopts a combined filtration-electric field coalescence method for crude oil desalination / dehydration, which can overcome respective disadvantages of performing desalination / dehydration process by a filtration method or an electric field coalescence method, decrease running severity of both the two methods, not only improves the adaptability of the crude oil desalination process, the desalination / dehydration rate, and the stable running rate, but also reaches the purposes of energy saving and consumption reduction.

Owner:GUANGZHOU BOXENERGY TECH

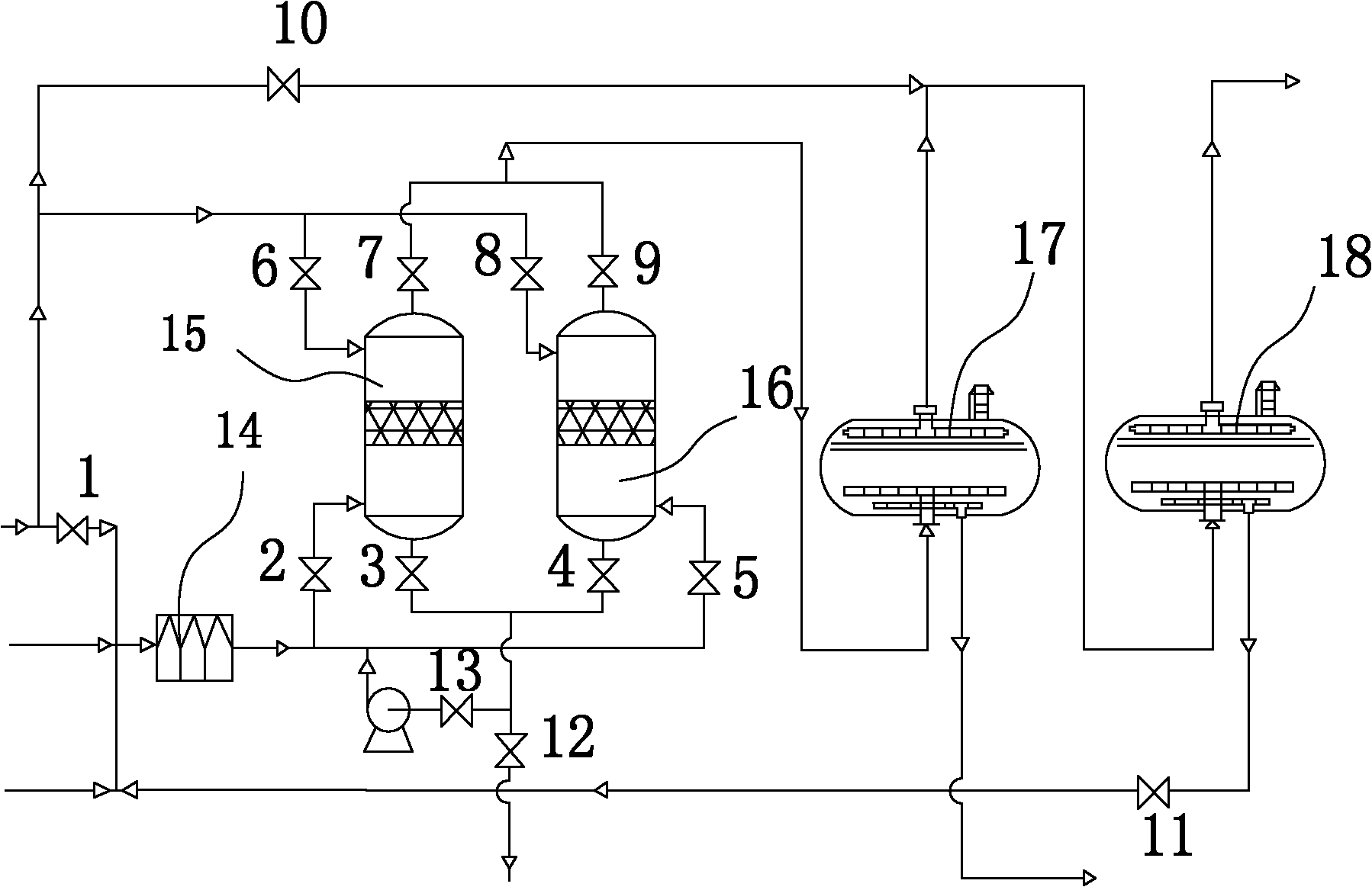

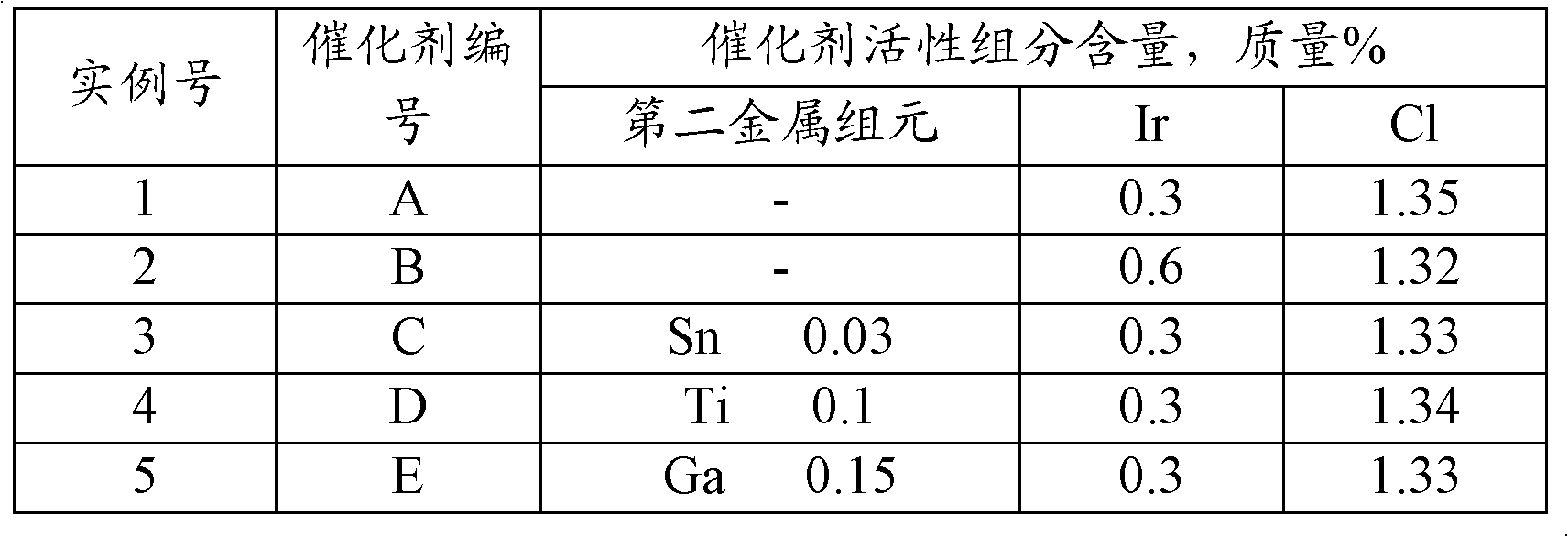

Regeneration method for coked iridium-containing catalyst

ActiveCN103203246BAvoid gatheringRestore reactivityPhysical/chemical process catalystsChemical recyclingIridiumOxygen

Owner:CHINA PETROLEUM & CHEM CORP +1

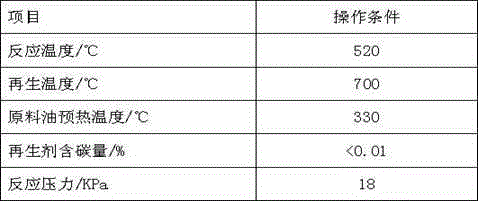

Petroleum hydrocarbon treating process

ActiveCN101089145AImprove feeding qualityReduce yieldTreatment with hydrotreatment processesWaxHydrodesulfurization

The process of producing clean fuel with petroleum hydrocarbons has well combined hydrocracking process, hydrodesulfurizing process, catalytically cracking process and coking process. It has most of decompressed wax oil from crude oil desulfurized and catalytically cracked, the coked wax oil obtained through coking catalytically cracked tail oil and vacuum residual oil hydrocracked, and the hydrocracked tail oil catalytically cracked for the second time. The combined process can obtain petroleum coke product, high quality hydrocracked light oil product and catalytically cracked light oil product simultaneously. Facilitate the operation of hydrocracking apparatus, increase the service life of the catalyst and obtain clean fuel in high economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com