Process integration for carbonization-carbonization full cut fraction hydrotreatment

A technology of coking whole distillate oil and hydrotreating, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve problems such as unachievable effect, simplify operation complexity, reduce operation difficulty and operation cost, The effect of reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

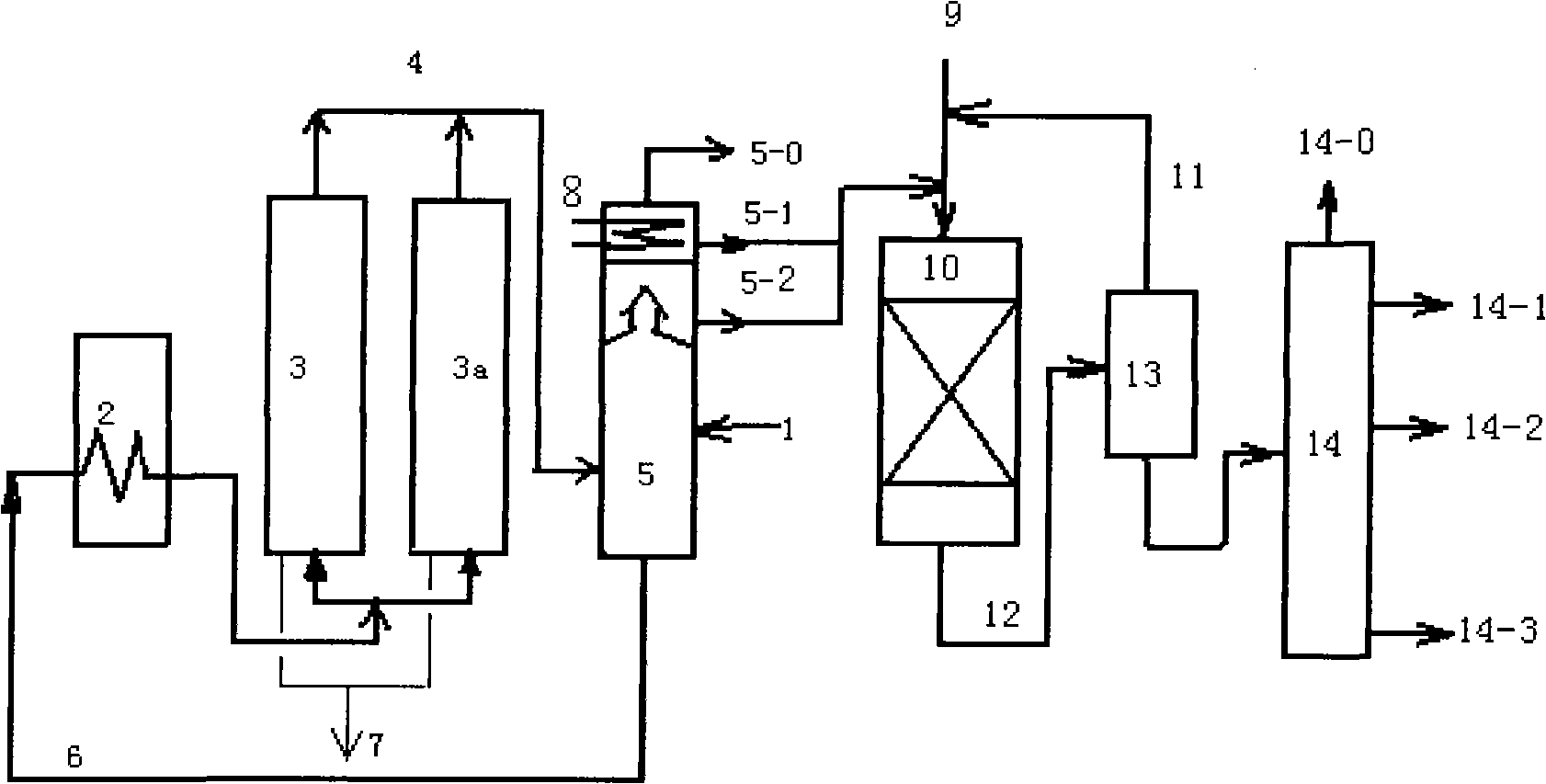

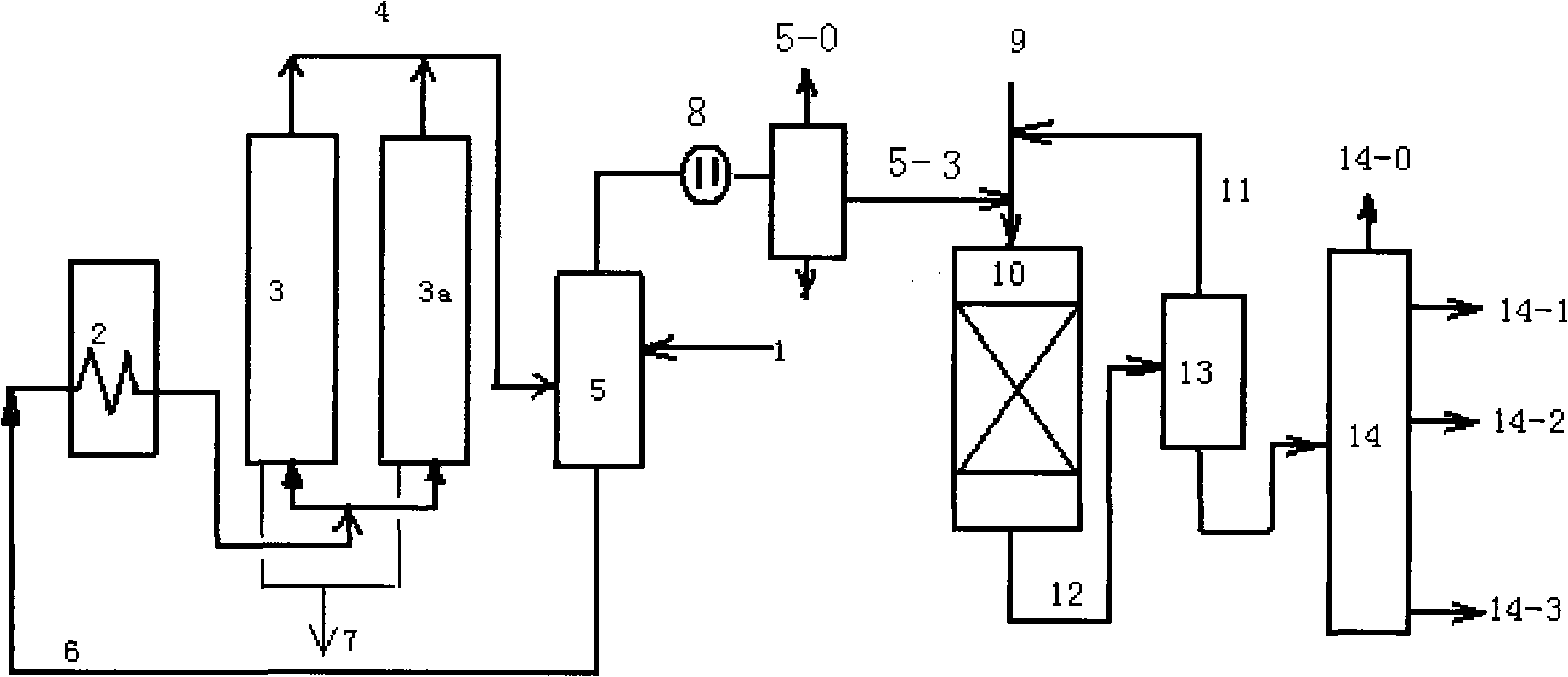

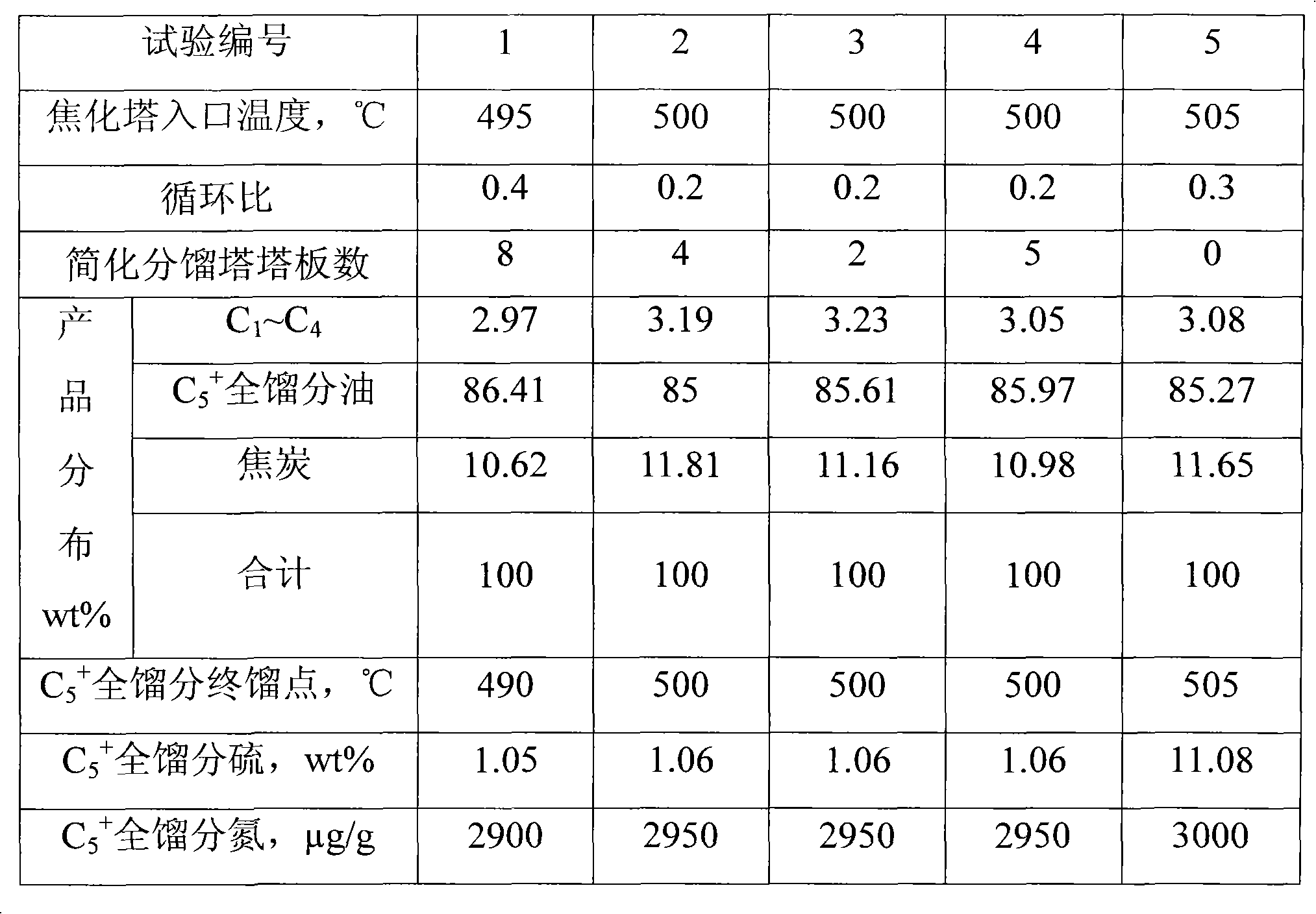

[0034] The properties of the raw oil used in the experiment are shown in Table 1, the coking test conditions and test results are shown in Table 2, the coking whole distillate oil hydrofining conditions are shown in Table 3, and the main properties of the hydrogenated product after fractionation are shown in Table 4. Embodiment 1~4 according to figure 1 Process operation, embodiment 5 according to figure 2 Process operation.

[0035] Table 1 Properties of raw oil

[0036] project

Raw oil

Density, (20℃), Kg / m 3

984.2

Carbon residue, wt%

15.7

Sulfur content, wt%

1.34

H / C atomic ratio

1.53

Initial boiling point, ℃

385

50%,℃

460

95%,℃

556

[0037] Table 2 Coking process operating conditions and results

[0038]

[0039] Table 3 coker full distillate oil (C 5 + Whole distillates) hydrotreating conditions

[0040]

[0041] Table 4 Main properties of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com