Petroleum hydrocarbon treating process

A processing method and technology of petroleum hydrocarbons, applied in the field of new technology, can solve the problems of not giving full play to the advantages of different devices, failing to meet environmental protection requirements, and poor quality of gasoline products, so as to increase the total liquid yield, realize rational utilization, and achieve zero "The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

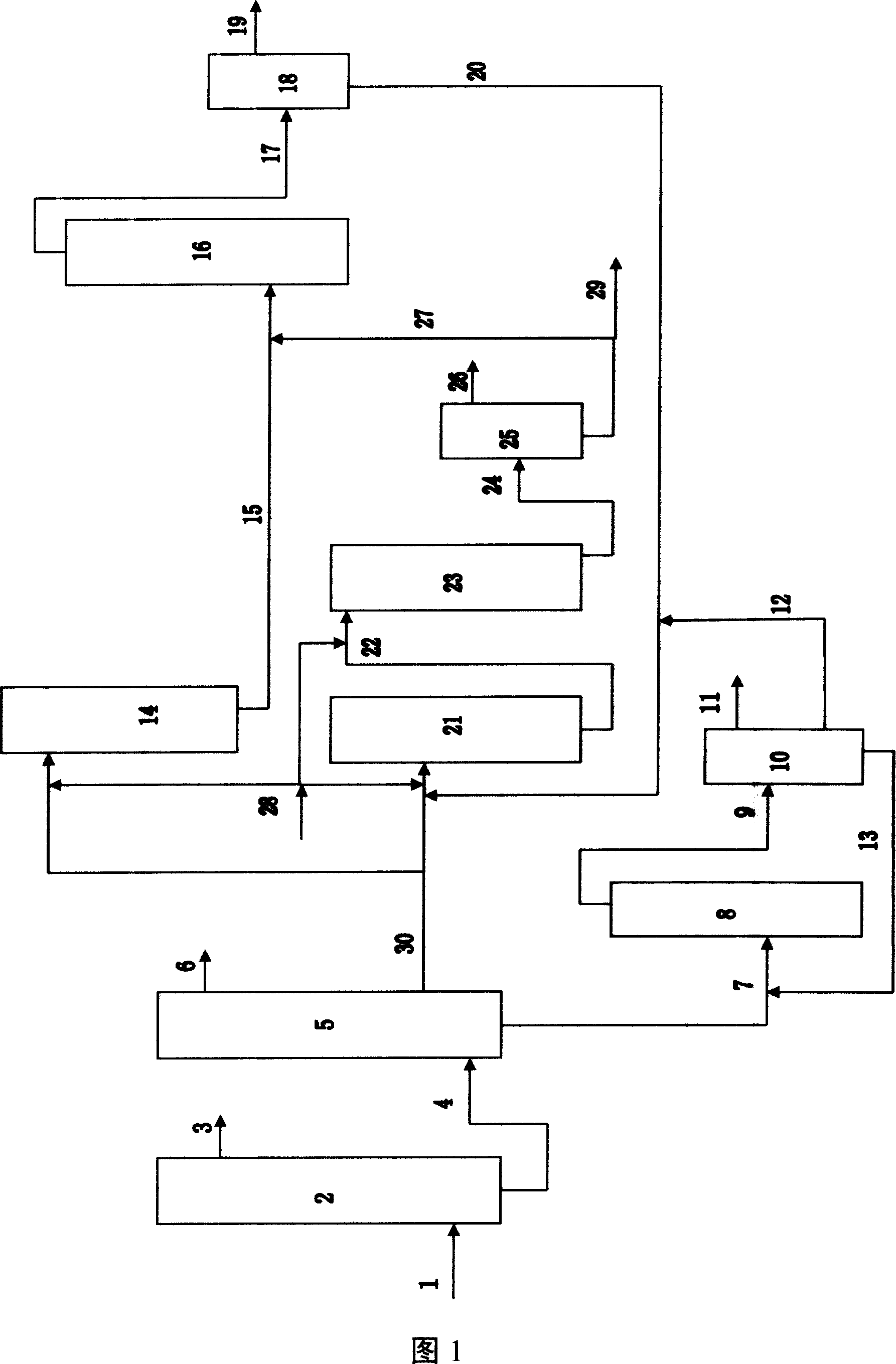

Image

Examples

Embodiment 1

[0018] The crude oils processed in Example 1 and Example 2 are different. After these two different crude oils are treated by the purification device, they enter the atmospheric and vacuum device to obtain light distillate oil, the vacuum wax oil fraction at 350-470°C and the vacuum wax oil fraction at 470°C+ Vacuum heavy oil fraction.

[0019] where 470°C + The vacuum heavy oil fraction is heated to 520°C and enters the coke tower, and after coking reaction, the products and their properties listed in the following table are obtained.

[0020] Example 1

[0021] Embodiment 1 is the vacuum wax oil+350 ℃ of 30wt% crude oil + Catalytic cracking tail oil + coker wax oil enters the hydrocracking unit and is controlled at 350°C + Distillation is converted into 350 DEG C fraction conversion rate is 60wt%; Embodiment 2 is the vacuum gas oil+350 DEG C of 20wt% crude oil + Catalytic cracking tail oil + coker wax oil enters the hydrocracking unit and is controlled at 350°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com