Coal tar pretreatment method

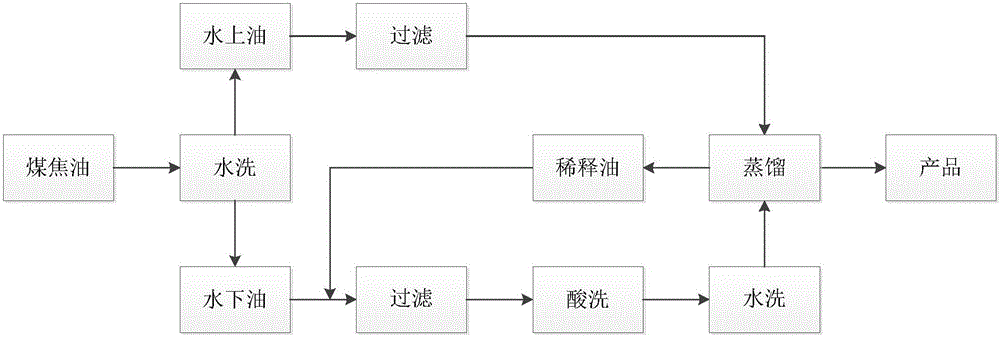

A coal tar and pretreatment technology, which is applied in tar processing, tar processing by distillation, tar extraction by chemical method, etc. It can solve the problems of affecting process economy, high loss rate of coal tar, and low utilization efficiency of equipment, etc. problem, to achieve the effect of improving process selectivity and removal efficiency, improving removal efficiency and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

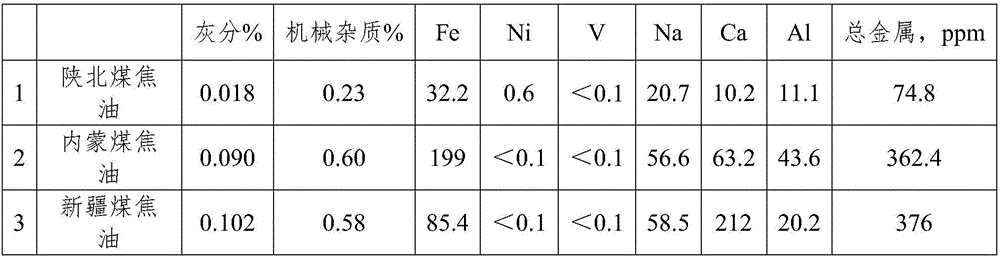

Embodiment 1-3

[0069] For the above three raw materials, add 20% water and 0.01% demulsifier at 90°C, and after sedimentation and separation, submerged oil 1-3 and supernatant oil 1-3 are obtained, and the yields of supernatant oil are 32%, 18% respectively. % and 21%, after being filtered by a 0.5 micron filter element, its properties are shown in Table 2. The ash content and mechanical impurity content are all lower than the detection limit of the national standard method, and the metal content is 4.5μg / g, 6.9μg / g and 6.4μg / g / g

Embodiment 4

[0071] After underwater oil 1 is mixed with diluted oil (mass ratio 2:1), after filtering through a 0.3 micron filter element, add dilute nitric acid (concentration: 5%) with 20% underwater oil at 75°C, and add 0.03% Metal chelating agent, after being fully stirred for 2 hours, the mixture of underwater oil and diluent oil will be lost under the acid solution after standing still, and the loss rate of underwater oil is 0.8%. After the product on the acid solution was washed with water twice, the diluent oil therein was evaporated, and the content of ash, metal and mechanical impurities in the product was measured, and the results are shown in Table 3.

Embodiment 5

[0073] After underwater oil 2 is mixed with diluent oil (mass ratio 1:1), after filtering through a 0.3 micron filter element, add 20% oxalic acid solution (concentration: 10%) of underwater oil at 65°C, and add 0.05% of Metal chelating agent, after being fully stirred for 2 hours, the mixture of underwater oil and diluent oil will be lost under the acid solution after standing still, and the loss rate of underwater oil is 1.8%. After the product on the acid solution was washed with water three times, the diluent oil therein was distilled off, and the content of ash, metal and mechanical impurities was determined, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com