High-purity piperylene preparation method

A technology of crude piperylene and piperylene, which is applied in the field of preparation of high-purity piperylene, can solve the effect of affecting the application of piperylene, affect the subsequent application of piperylene, and cannot be removed at the same time Problems such as piperylene, to achieve the effect of reducing operating severity, reducing energy consumption, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

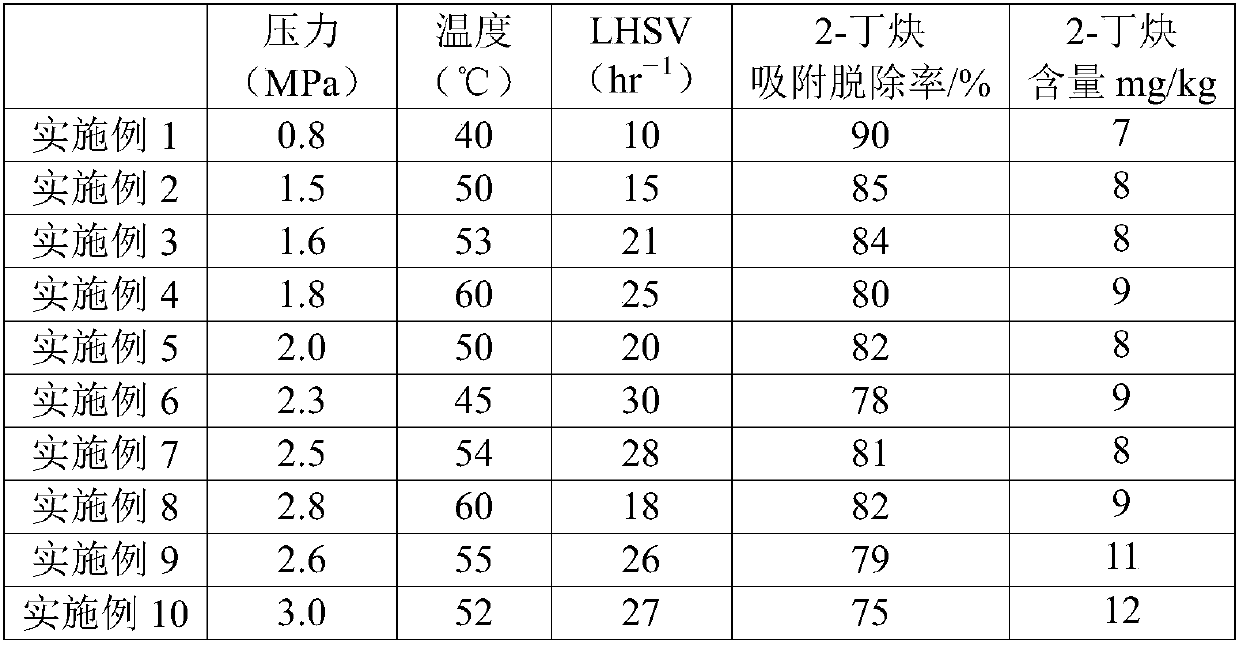

Embodiment 1~10

[0028] 1. Crude piperylene raw material

[0029] The crude piperylene used in Examples 1-10 is derived from the crude piperylene product obtained by separating cyclopentadiene and piperylene in a C5 separation device. Its components are shown in Table 1.

[0030] Table 1. Composition of crude piperylene

[0031] serial number

composition

Content / %(wt)

1

6.90

2

18.70

3

trans-1,3-pentadiene

44.30

4

cis-1,3-pentadiene

26.70

5

0.80

6

Carbon six and others

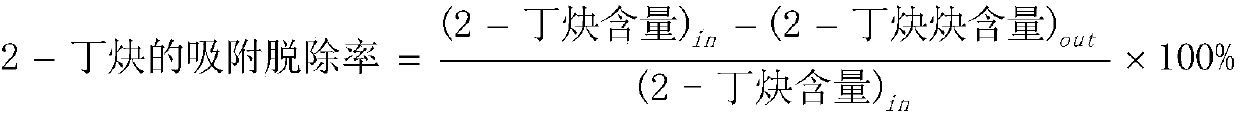

2.60

[0032] Two, piperylene de-alkyne

[0033]

[0034] Wherein (2-butyne content) in is the content of 2-butyne at the inlet; (2-butyne content) out is the content of 2-butyne at the outlet.

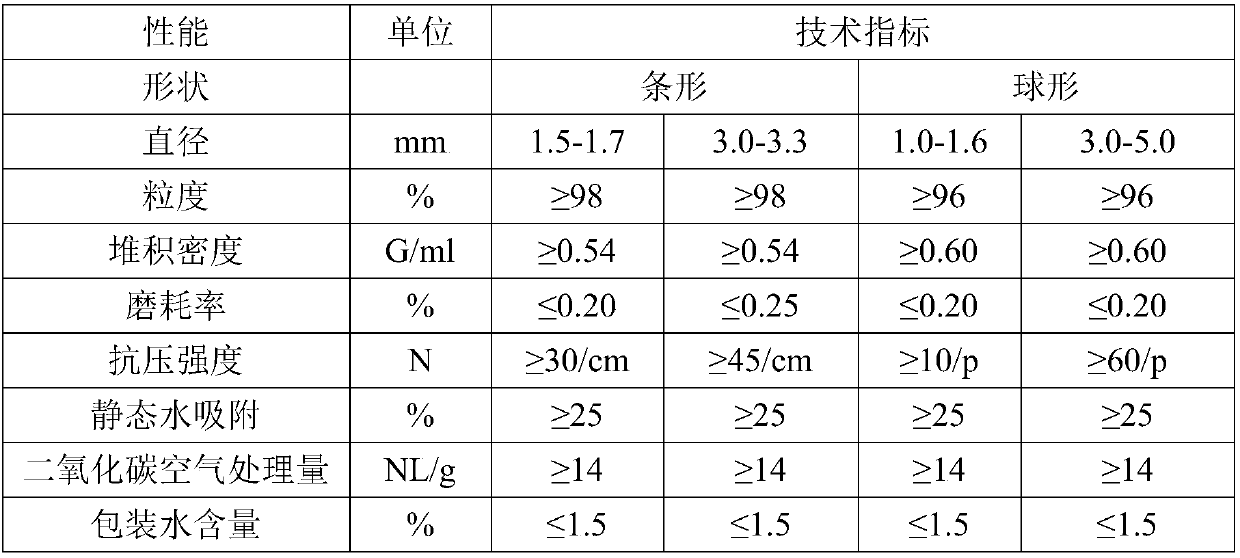

[0035] The performance parameters of 13x molecular sieve are shown in Table 2

[0036] Table 2

[0037]

[0038] The adsorption de-alkyne reaction of the C5 fraction is carried out in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com