Matrix asphalt production method

A production method and technology of base asphalt, which is applied in the direction of distillation processing of tar pitch/petroleum pitch/natural pitch, petroleum industry, and only multi-stage serial refining process, can solve the problems that industrial production is difficult to realize, and achieve reduction Operating severity, ensuring qualification and stability, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

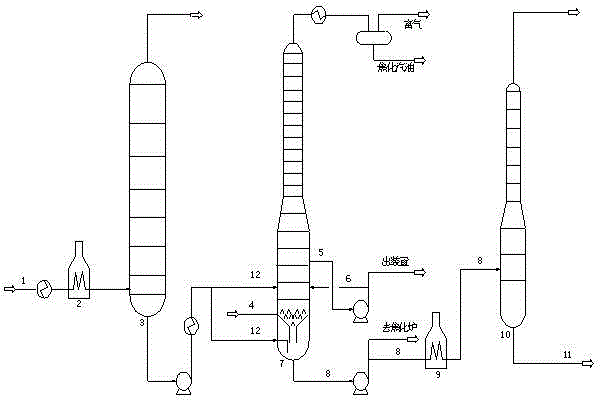

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, Tahe crude oil is produced matrix asphalt experiment according to the method of the present invention.

[0033] The properties of Tahe crude oil are shown in Table 1. It can be seen from the table that Tahe crude oil is a heavy intermediate base crude oil with high metal content and residual carbon value, low light oil yield, and its atmospheric residue and vacuum residue Not suitable for catalytic cracking process.

[0034] Table 1 Properties of Tahe crude oil.

[0035] Analysis Project Tahe 2012-1 Heavy Crude Oil API° 18.0 Density (20℃), g / cm 3 0.9434 Kinematic viscosity (50℃), mm 2 / s 360.6 Kinematic viscosity (80℃), mm 2 / s 69.99 Freezing point / ℃ -8 Pour point / ℃ -6 Carbon residue value / wt% 15.00 Ash content / wt% 0.050 Carbon content / wt% 85.76 Hydrogen content / wt% 11.29 Sulfur content / wt% 2.00 Nitrogen content / wt% 0.32 Chlorine content / wt% 0.12 Flash point (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com