Method for removing soil and impurities from fresh yellow ginger

A technology of turmeric and flotation agent, applied in chemical instruments and methods, wet separation, solid separation and other directions, can solve the problems of large labor, low efficiency, unsatisfactory soil and impurities removal effect, etc., achieve uniform cleaning, improve cleaning Efficiency, the effect of reducing the amount of cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

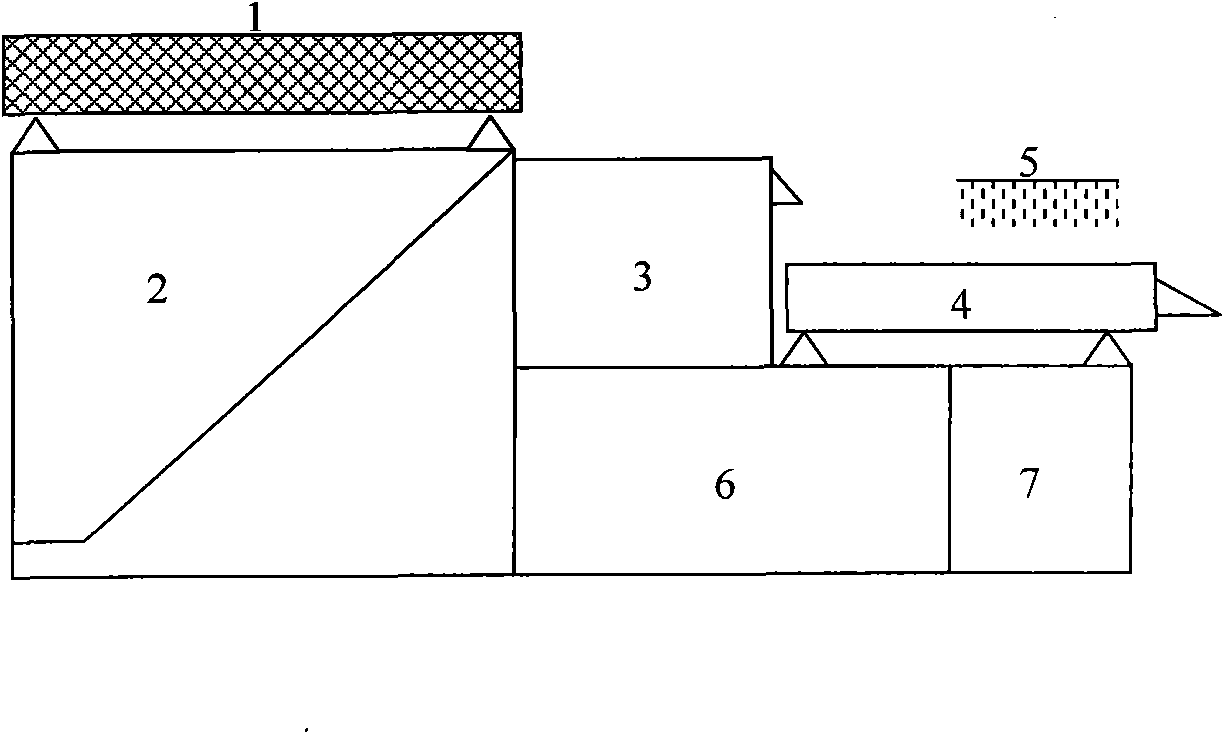

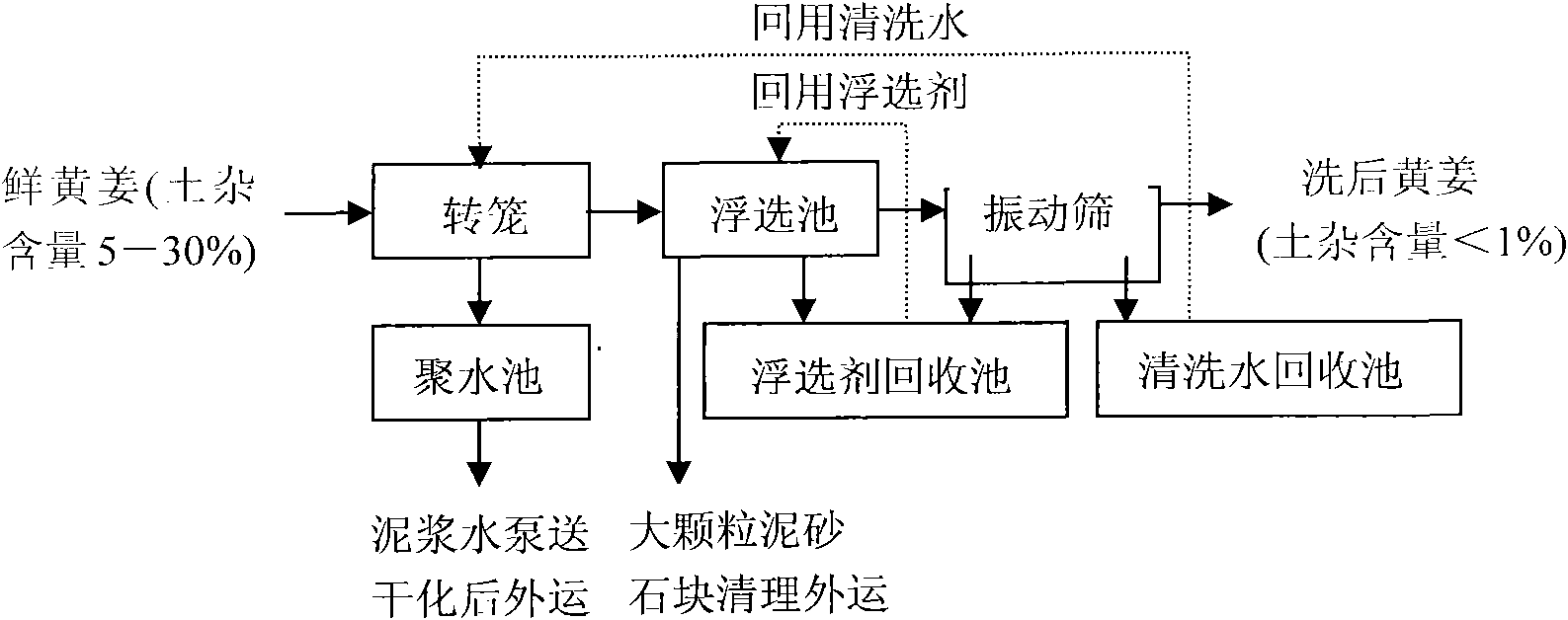

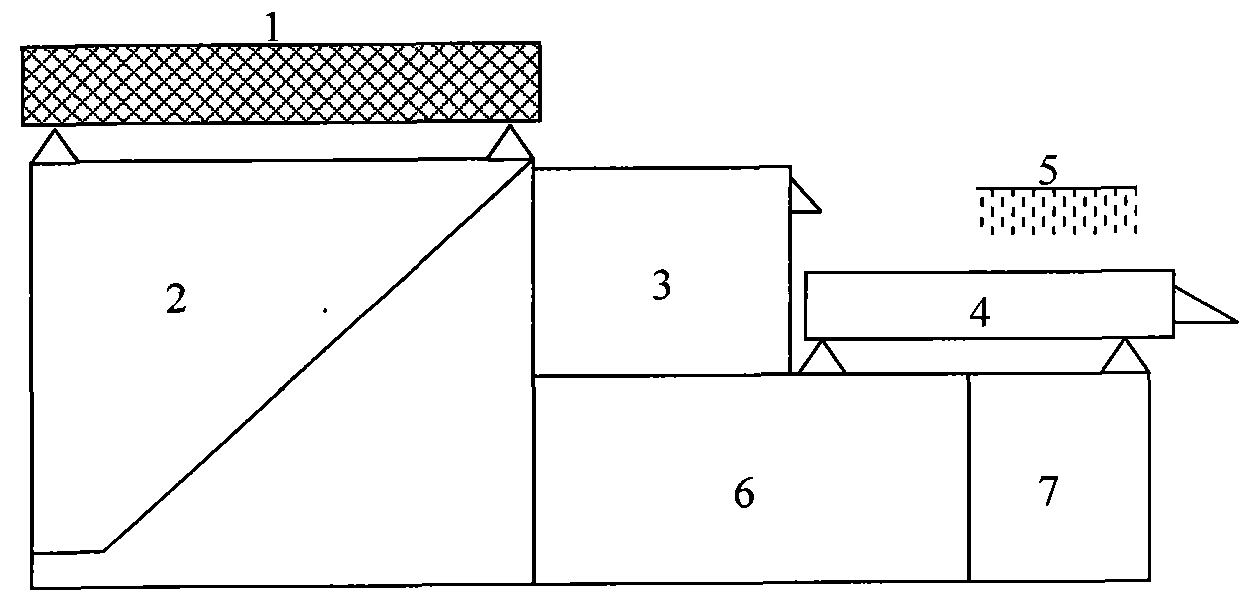

[0016] like figure 2 Shown, a kind of method of removing dirt in fresh turmeric, it comprises the steps:

[0017] 1) The fresh turmeric enters the tumbler first, and the device uses a pressurized nozzle to spray water onto the surface of the turmeric in two stages at high speed to reduce the amount of cleaning water. At the same time, it cooperates with the rotation of the tumbler to make the cleaning even and improve the cleaning efficiency.

[0018] The processing capacity of a single tumbler is about 4t / h, and multiple tumblers can be erected at the same time as needed to meet the needs of different production volumes.

[0019] 2) Smaller particles of mud, sand, and soil impurities in fresh turmeric can be removed during the cleaning process of the tumbler cage. After the removed mud, sand, and soil impurities sink into the lower pool, they are pumped into the sludge drying tank by the mud sand pump. The cleaned turmeric Enter the flotation pool under the rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com