Nickel tin salt coloring and sealing hole recycling coloring agent and reclaimed water utilization method and online configuration

A coloring agent, nickel-tin technology, applied in chemical instruments and methods, neutralization water/sewage treatment, application, etc., can solve problems such as lack of mature and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

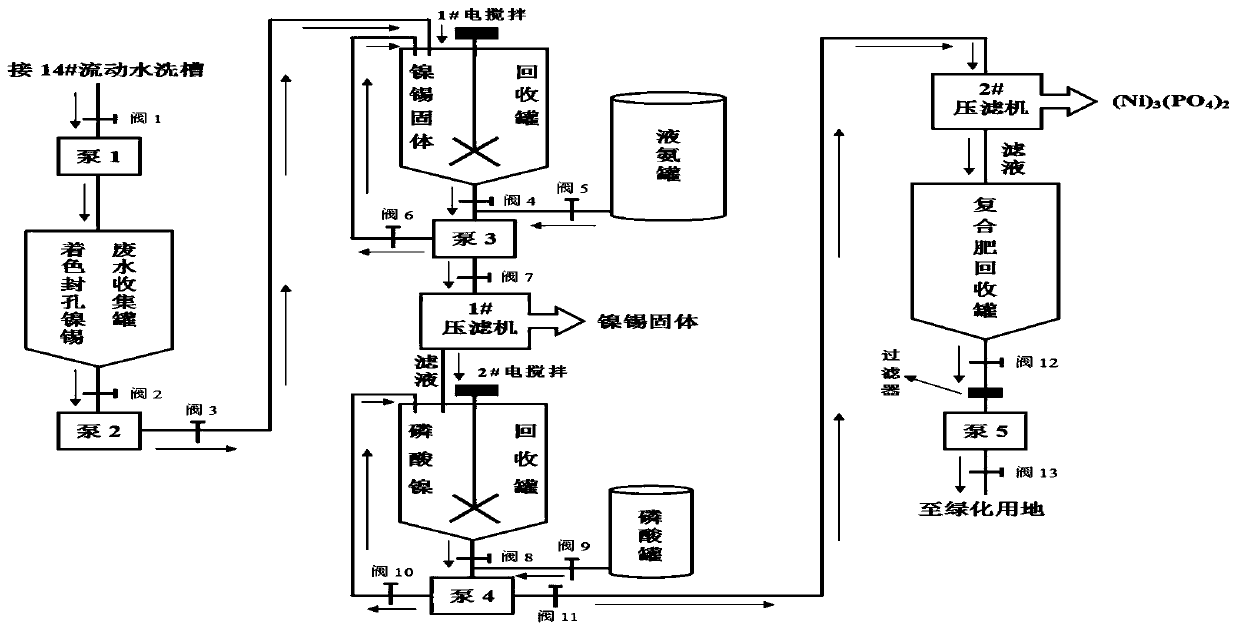

[0158] Nickel-tin salt coloring sealing hole recovery coloring agent and reclaimed water utilization method, including: reverse series water-saving operation, nickel-tin wastewater interception operation, nickel-tin wastewater treatment operation, nickel phosphate recovery operation and N-P compound fertilizer recovery operation;

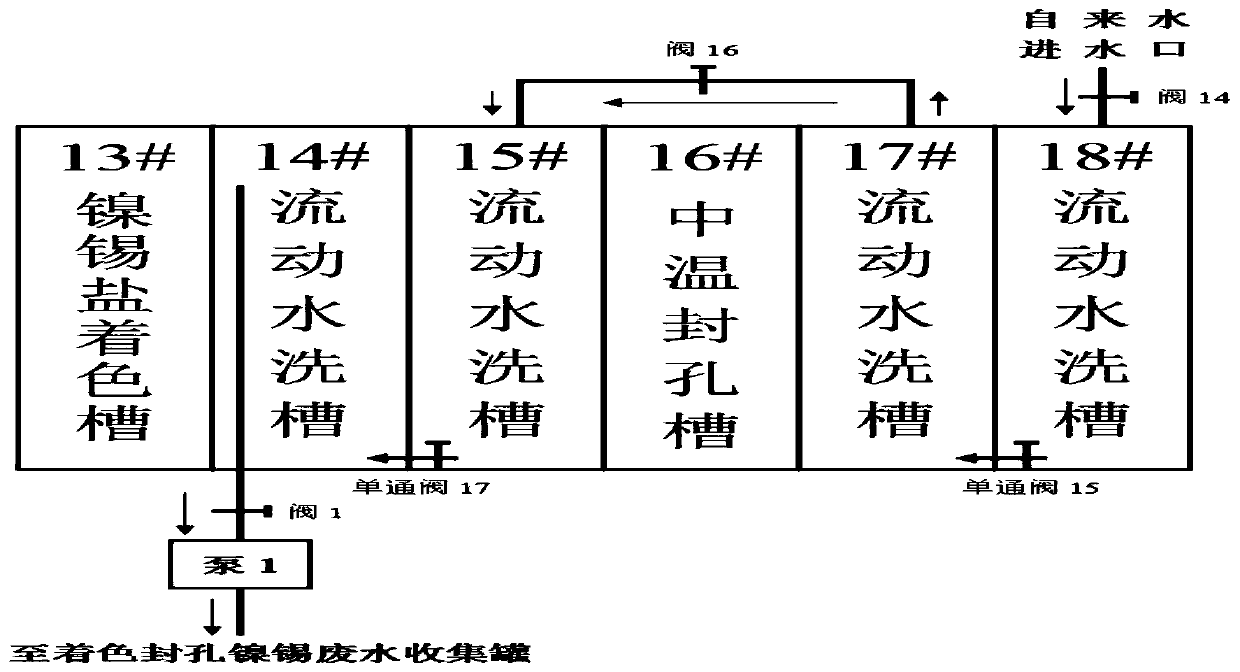

[0159] (1) The reverse series water-saving operation includes: open valve 14, feed tap water from the tap water inlet to the 18# flowing water washing tank, enter the 17# flowing water washing tank through the valve 15, and enter the 15# flowing water washing tank through the valve 16 , enter the 14# flowing water washing tank through valve 17, and enter the colored and sealed nickel-tin wastewater collection tank through valve 1 and pump 1; the reverse series water-saving operation is responsible for collecting the colored and sealed nickel-tin wastewater collection tank; greatly reducing the nickel content The amount of tin wastewater collected can...

Embodiment 2

[0197] Embodiment 2 (the nickel-tin salt coloring liquid working ability detection that reclaims production)

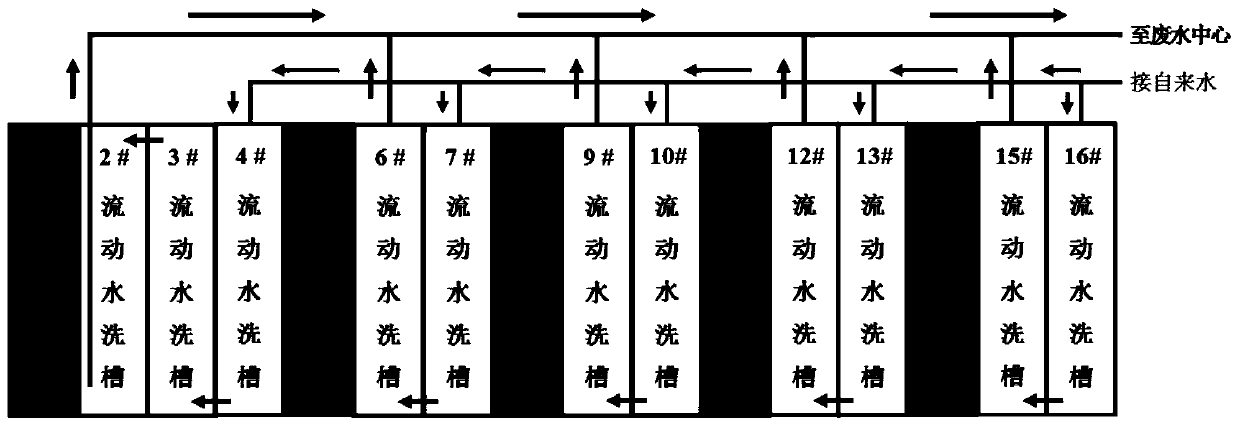

[0198] according to image 3 , continuous production of colored aluminum, 13# nickel-tin salt coloring tank is continuously added the coloring solution recovered and produced by the present invention according to the control index of formula (1); take the coloring solution pH = 1.0, temperature 25 ° C, stannous sulfate 5-10g / L (Other ingredients are calculated by (12) formula); It is 15 microns to get oxide film thickness, and coloring time is 10 minutes, and the result is as shown in table 3 below:

[0199] Table 3 The coloring effect of different concentrations of stannous sulfate on aluminum

[0200]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com