High-speed rapier loom

A rapier loom, high-speed technology, used in looms, textiles, textiles, and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

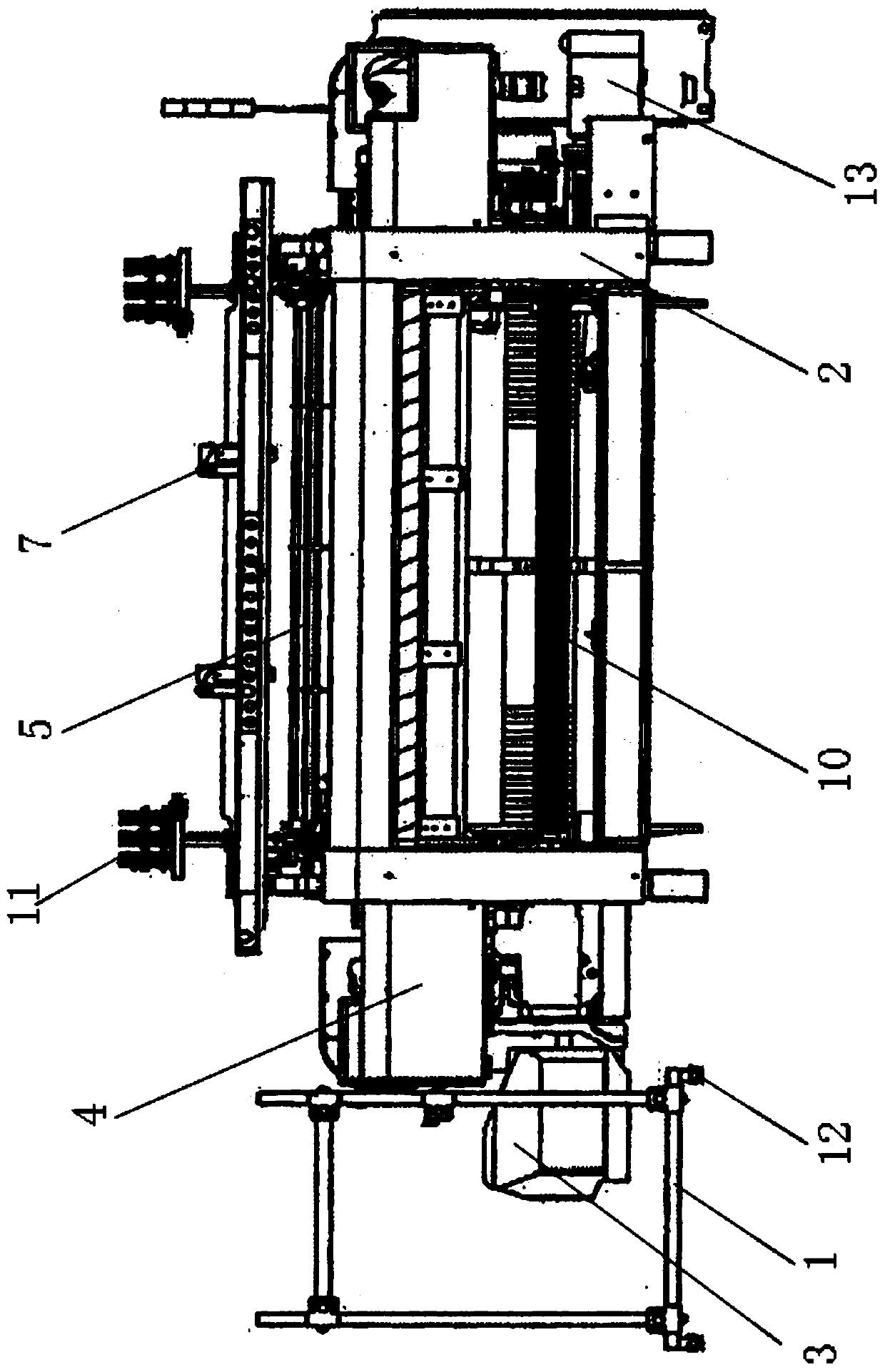

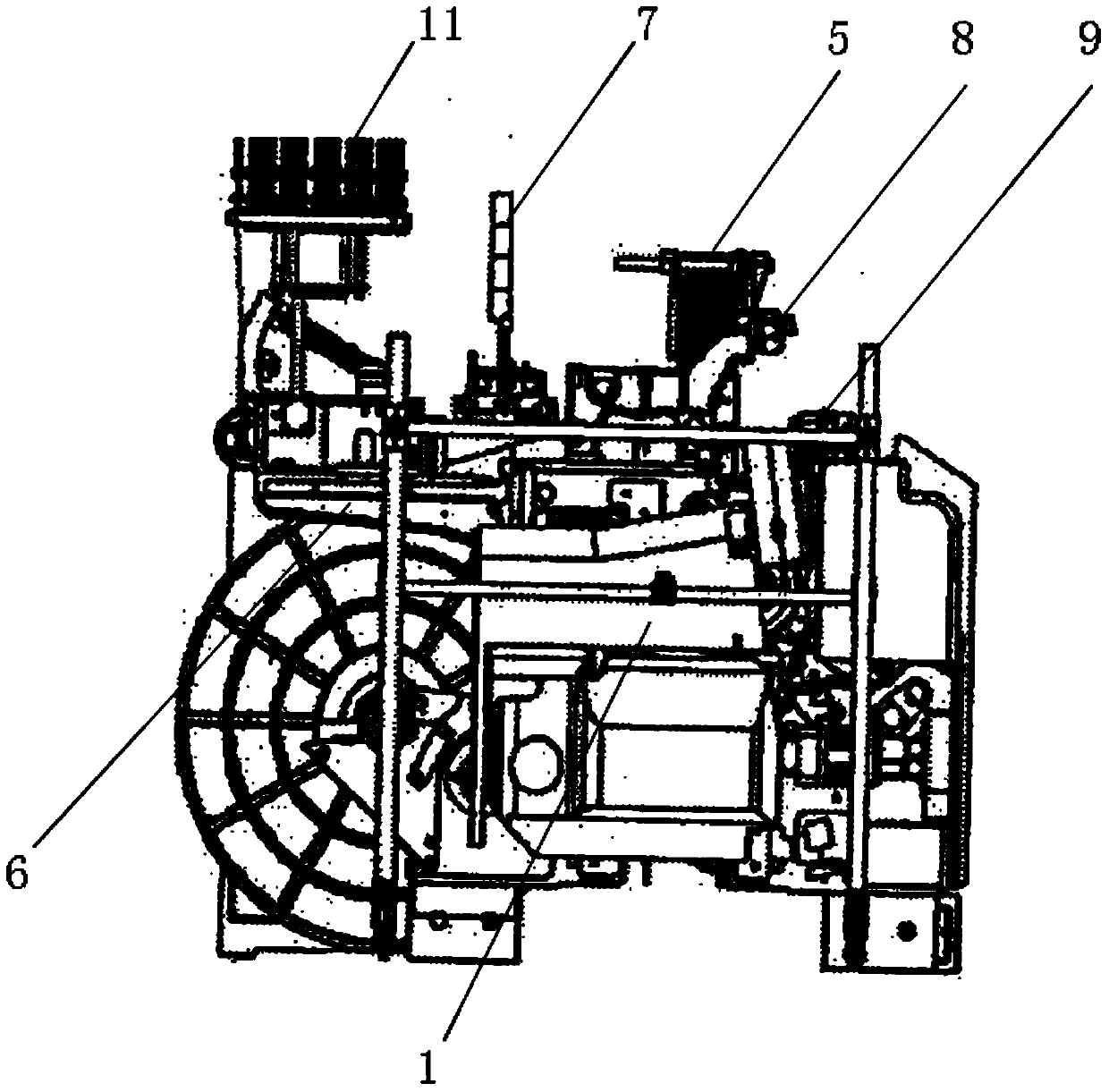

[0031] Please refer to the instruction manual figure 1 Attached Figure 7 As shown, the present invention is a high-speed rapier loom, which consists of a weft frame 1, a frame 2, a shedding mechanism 3, a weft insertion box 4, a beat-up mechanism 5, a warp frame 6, a heald frame 7, and a selvedge scissors mechanism 8. Temple structure 9, winding mechanism 10 and selvage creel 11 are assembled from several parts.

[0032] Wherein, the weft creel 1 is placed on one side of the frame 2 on which weft threads can be placed, and the bottom of the weft frame 1 is provided with a movable roller 12 so as to be movable relative to the frame 2.

[0033] The opening mechanism 3 and the weft insertion box 4 are installed on one side of the frame 2. The opening mechanism 3 and the weft insertion box 4 are all prior art and have nothing to do with the inventive point of this creation, so they will not be repeated here.

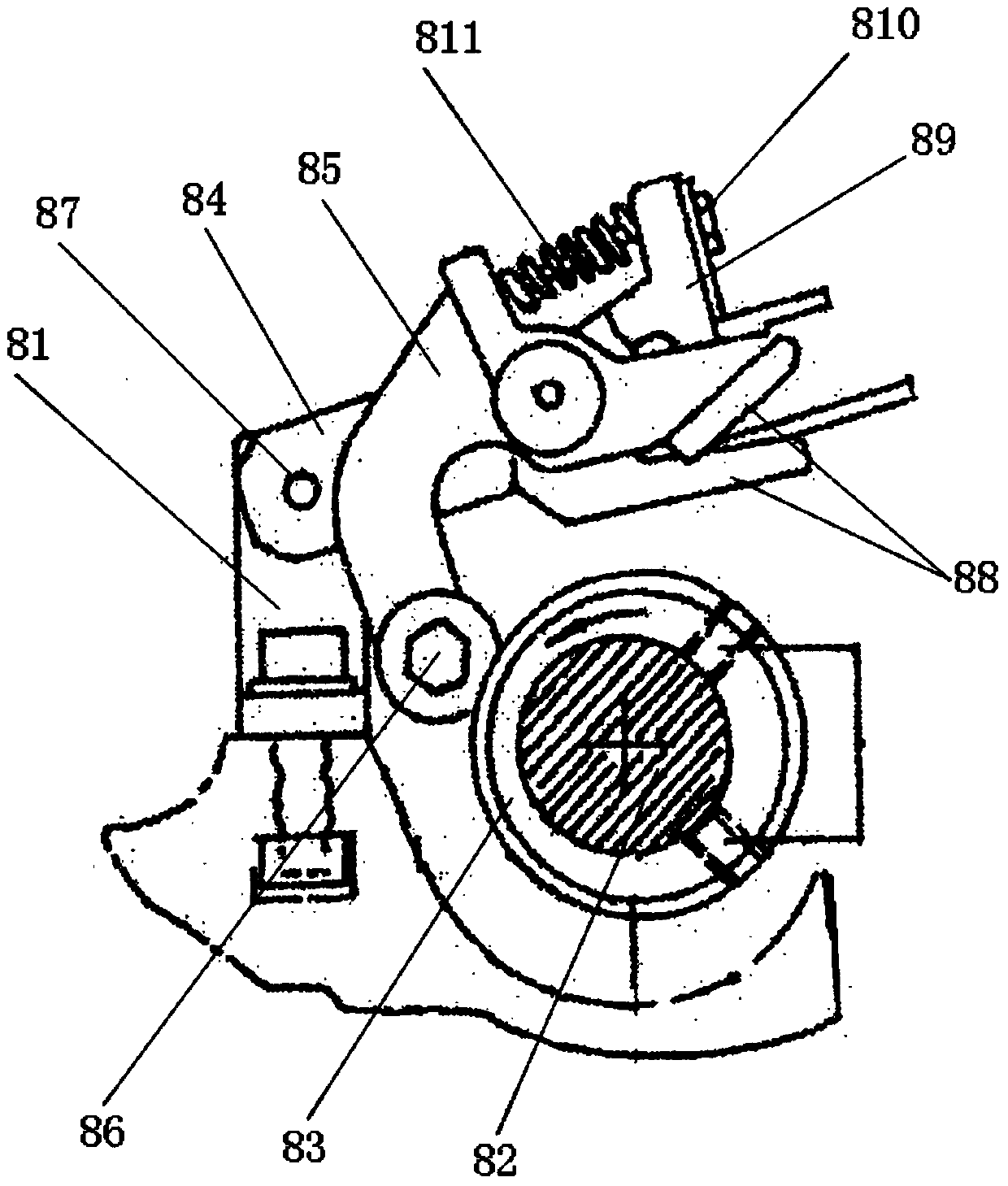

[0034] The beating-up mechanism 5, heald frame 7, selvedge scissors mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com