Equipment for producing brick-making sand by use of construction waste with separation light materials

A construction waste, lightweight material technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as energy consumption, large dust, and impact on staff health, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

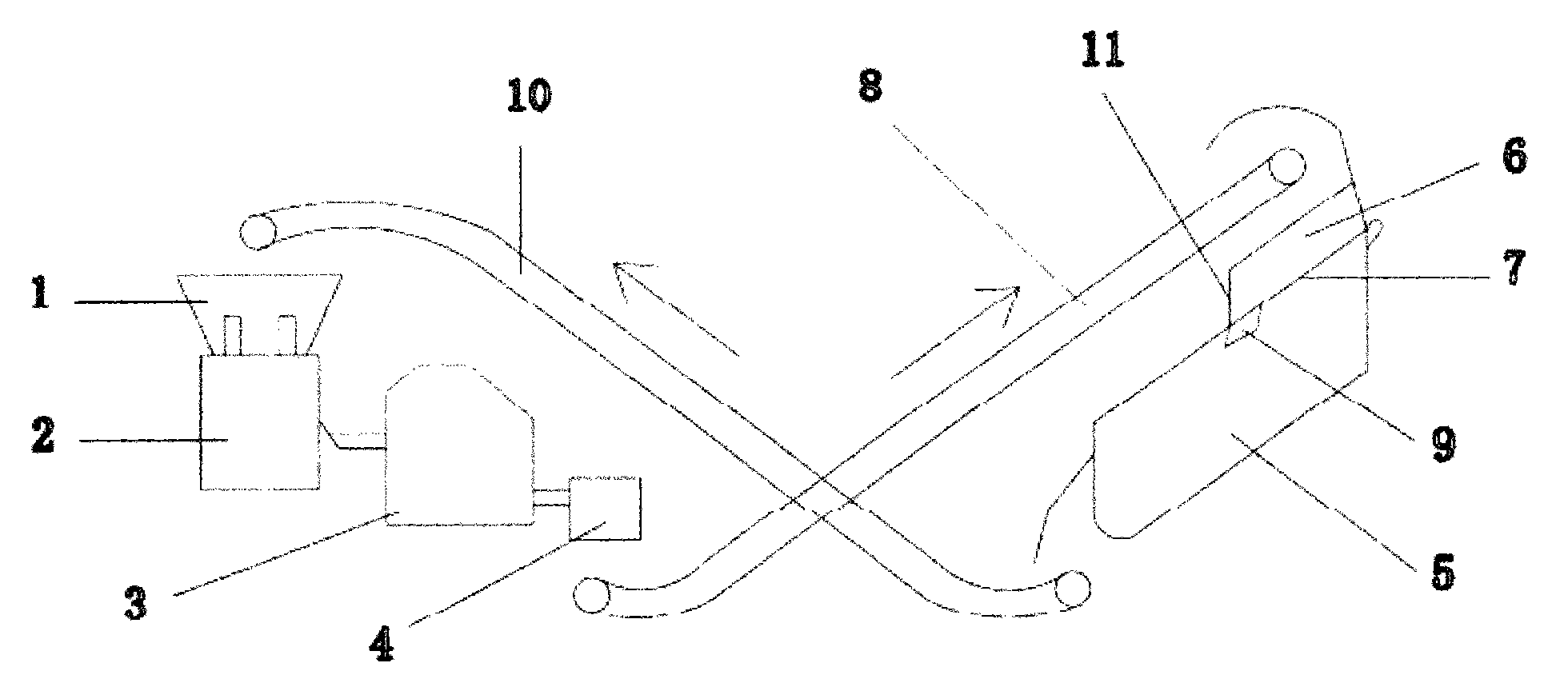

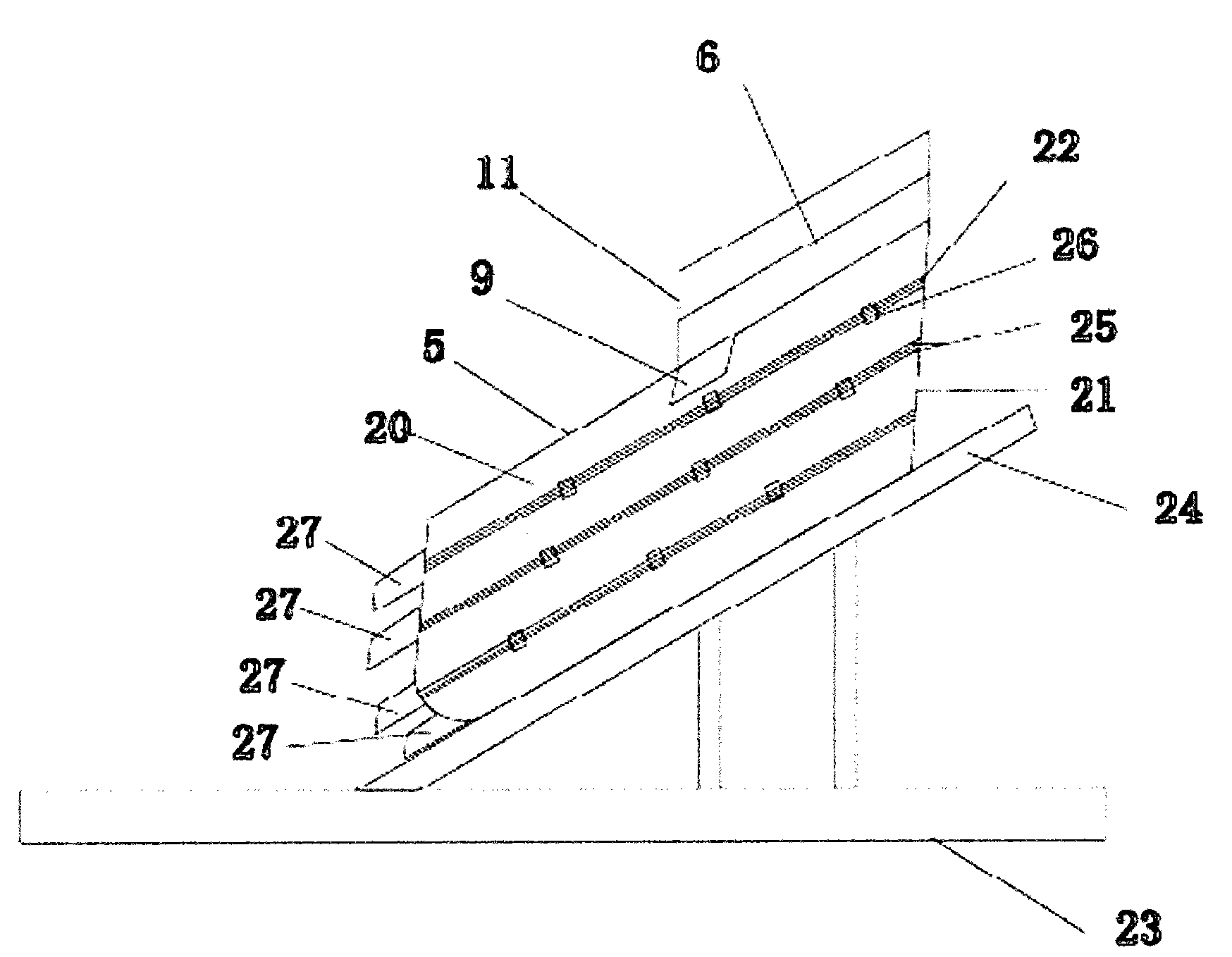

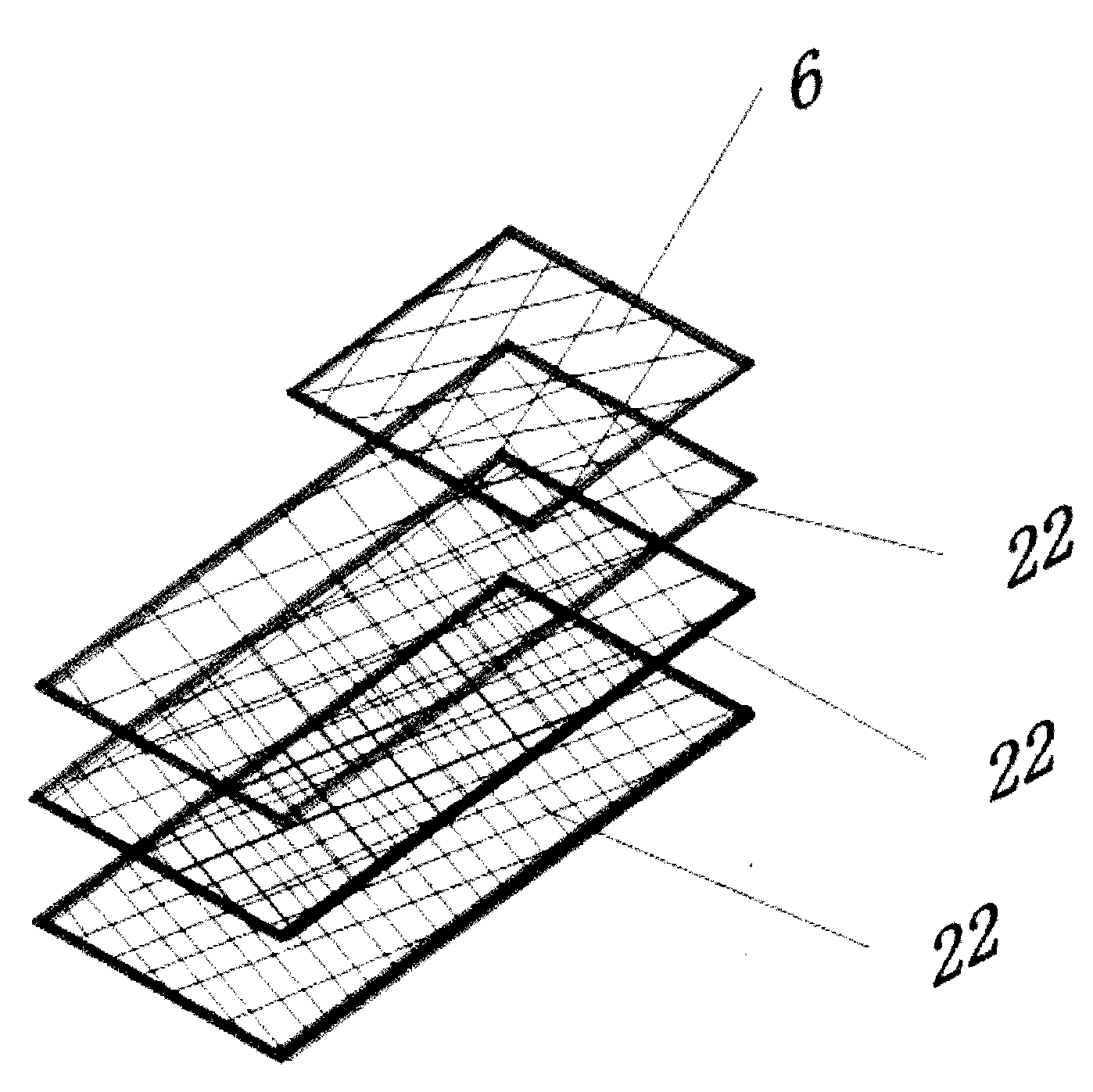

[0023] like figure 1 , figure 2 and image 3 As shown, an equipment for producing brick-making sand from construction waste that separates lightweight materials, including a silo 1, a vibrating feeder 2, a crusher 3, a self-unloading iron remover 4, and a vibrating screen 5; a silo 1 The lower part is equipped with a vibrating feeder 2, the feed hopper of the crusher 3 is connected with the vibrating feeder 2, and the discharge hopper is connected with the self-unloading iron remover 4 through a belt; the entrance of the sorting device 6 passes through the self-unloading iron remover 4 The conveyor belt 8 is connected, and a sundry conveyor belt is set under the waste port 9 to transport light sundries to the designated position for stacking; the feed port 7 of the vibrating screen 5 is directly connected to the sorting device 6, and the lower part is provided with a movable return belt 10 , the other end of the return belt 10 leads to the feed bin 1.

[0024] The sorting ...

Embodiment 2

[0028] like figure 1 , figure 2 and image 3As shown, an equipment for producing brick-making sand from construction waste that separates lightweight materials, including a silo 1, a vibrating feeder 2, a crusher 3, a self-unloading iron remover 4, and a vibrating screen 5; a silo 1 The lower part is equipped with a vibrating feeder 2, the feed hopper of the crusher 3 is connected with the vibrating feeder 2, and the discharge hopper is connected with the self-unloading iron remover 4 through a belt; the entrance of the sorting device 6 passes through the self-unloading iron remover 4 The conveyor belt 8 is connected, and a sundry conveyor belt is set under the waste port 9 to transport light sundries to the designated position for stacking; the feed port 7 of the vibrating screen 5 is directly connected to the sorting device 6, and the lower part is provided with a movable return belt 10 , the other end of the return belt 10 leads to the feed bin 1.

[0029] The sorting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com