Isosorbide preparation method

A technology of isosorbide and sorbitol solution, applied in the direction of organic chemistry, etc., can solve the problems of high cost of isosorbide, high requirements for reaction equipment, environmental pollution, etc., reduce reaction equipment parameters, reduce production costs, avoid The effect of high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This isosorbide preparation method step is as follows:

[0027] 1) solid sorbitol is dissolved in water, is made into the solution that mass fraction is 10%; Add phosphorus modified HZSM-5 molecular sieve in sorbitol solution, the addition amount of phosphorus modified HZSM-5 molecular sieve is sorbitol solution dry matter 15% by weight; at 150 ° C, stirring for 3 hours under the condition that the nitrogen filling pressure is 3Mpa, and dehydration reaction is carried out to obtain a solid-liquid mixture;

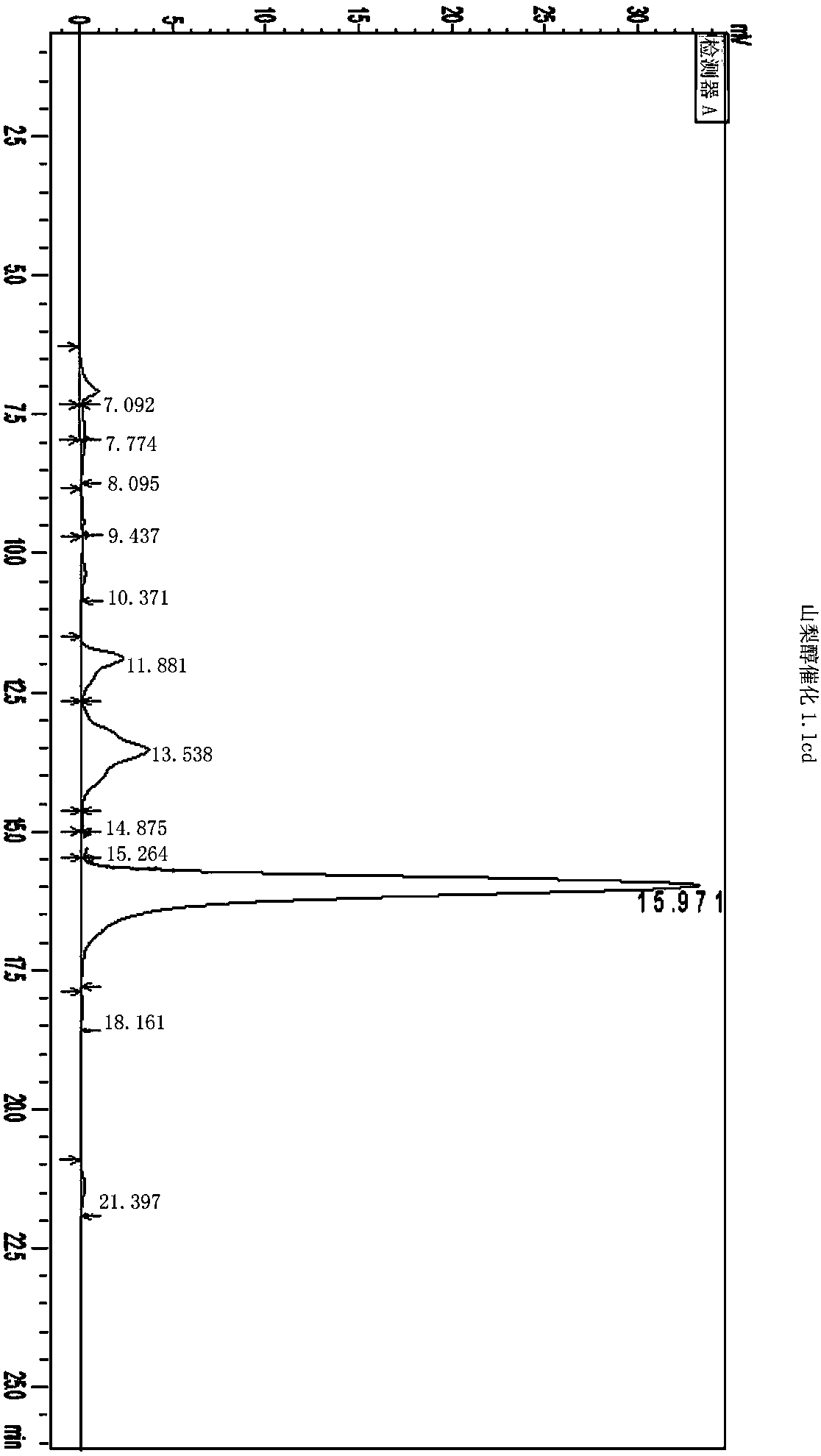

[0028] 2) The solid-liquid mixture is filtered to remove insolubles to obtain the filtrate, which is detected by HPLC, and the purity of isosorbide in the liquid is 77%, as shown in figure 1 and shown in Table 1;

[0029] 3) The filtrate is decolorized with activated carbon, the amount of activated carbon added is 1% of the dry matter weight of the solution, kept at 80° C. for 40 min, and filtered to obtain the filtrate;

[0030] 4) Ion-exchange the filtrate throug...

Embodiment 2

[0036] This isosorbide preparation method step is as follows:

[0037] 1) liquid sorbitol is diluted with water to Brix and be 30% solution; In sorbitol solution, add phosphorus-modified HZSM-5 molecular sieve, the addition of phosphorus-modified HZSM-5 molecular sieve is 8% of sorbitol solution dry matter weight ; Stirring for 5 hours at 220°C under nitrogen filling pressure of 7Mpa, performing dehydration reaction to obtain a solid-liquid mixture;

[0038] 2) Filtrating the solid-liquid mixture to remove insoluble matter to obtain a filtrate, which is detected by HPLC, and the purity of isosorbide in the liquid reaches 81%;

[0039] 3) The filtrate is decolorized with activated carbon, the amount of activated carbon added is 5% of the dry matter weight of the solution, kept at 70° C. for 30 min, and filtered to obtain the filtrate;

[0040] 4) Ion-exchange the filtrate through D301 anion resin, 001×7 cation resin, and D301 anion resin in sequence to obtain an ion-exchange l...

Embodiment 3

[0044] This isosorbide preparation method step is as follows:

[0045] 1) solid sorbitol is dissolved in water, is made into the solution that mass fraction is 50%; Add phosphorus modified HZSM-5 molecular sieve in sorbitol solution, the addition amount of phosphorus modified HZSM-5 molecular sieve is sorbitol solution dry matter 2% by weight; at 300°C, stirring for 7 hours under the condition of nitrogen filling pressure of 10Mpa, dehydration reaction to obtain a solid-liquid mixture;

[0046] 2) Filtrating the solid-liquid mixture to remove insoluble matter to obtain a filtrate, which is detected by HPLC, and the purity of isosorbide in the liquid reaches 78%;

[0047] 3) The filtrate is decolorized with activated carbon, the amount of activated carbon added is 10% of the dry matter weight of the solution, kept at 60° C. for 20 min, and filtered to obtain the filtrate;

[0048] 4) Ion-exchange the filtrate through D301 anion resin, 001×7 cation resin, and D301 anion resin i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com