Preparation method of high-temperature proton exchange membrane fuel cell cathode catalyst

A fuel cell cathode and proton exchange membrane technology, which is applied in the field of materials science, can solve the problems of low utilization rate, poor stability and high loading of noble metal catalysts, and achieves the improvement of oxygen reduction activity, electrochemical stability, and electrochemical activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a high-temperature proton exchange membrane fuel cell cathode catalyst, comprising the following steps:

[0036] 1) Preparation of black phosphorus nanosheets: Weigh 1-3g red phosphorus (RP), put it in a reaction kettle together with 15-25mL deionized water, and heat it at 160-180°C for more than 15h to remove the surface oxide layer. Dry and grind into powder, mix 400-600mg RP, 18-24mg Sn and 10-15mg SnI 4 Add to the quartz tube to vacuumize and seal, at 5°C min -1The heating rate is heated to 650°C for 2-3h, then cooled to 450-500°C, kept for 5-7h and then cooled to room temperature. The obtained black phosphorus (BP) crystals were washed several times with hot toluene and acetone, and placed in a glove box with Ar for use. In an argon-filled glove box, weigh 200 mg of blocky BP crystals, grind them into powder with an agate mortar, add to 50-70 mL of NMP (N-methylpyrrolidone) solution, and grind in a cell pulverizer at ...

Embodiment 1

[0047] A preparation method of black phosphorus-activated graphene composite material loaded platinum nanoparticles, specifically comprising the following steps:

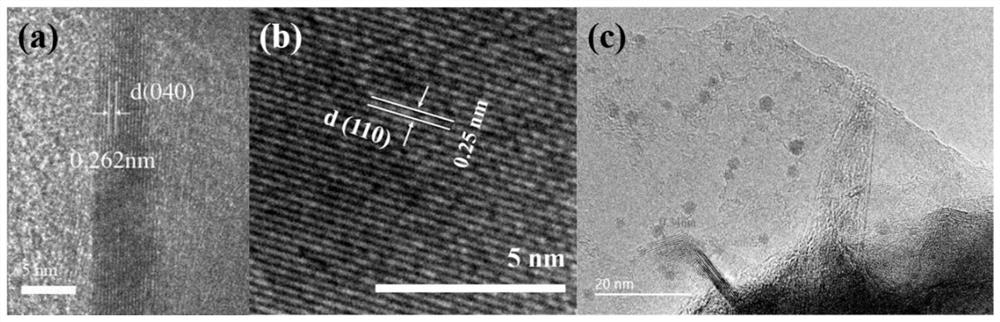

[0048] (1) Preparation of black phosphorus-activated graphene composites

[0049] ①Preparation of black phosphorus nanosheets: Weigh 2g of red phosphorus (RP), put it in a reaction kettle together with 25mL of deionized water, and heat it at 160-180℃ for more than 15h to remove the surface oxide layer. Dry and grind into powder, mix 400-600mg RP, 18-24mg Sn and 10-15mg SnI 4 Add to the quartz tube to vacuumize and seal, at 5°C min -1 The heating rate is heated to 650°C for 3h, then cooled to 500°C, kept for 6h and then cooled to room temperature. The obtained black phosphorus (BP) crystals were washed several times with hot toluene and acetone at 70 °C, and placed in a glove box filled with Ar for use. In a glove box filled with argon gas, weigh 200 mg of bulk BP crystals, grind them into powder with an agate mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com