High-strength polysaccharide aerogel microsphere, and preparation method and application thereof

A technology of gel microspheres and polysaccharides, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., and can solve problems such as no pressure resistance and low medium flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Blending method to prepare high-strength agarose microspheres with a concentration of 4wt%

[0068] (1) Modification of agarose raw material

[0069] Weigh 4g of agarose powder, add 40mL of water, heat and dissolve to obtain a 10% agarose solution, cool down to about 65°C, slowly add 0.5mL of 40% NaOH solution and bifunctional cross-linking agent allyl glycidyl ether to it 6mL. Among them, the concentration of allyl glycidyl ether in the water phase is 15%, OH - The concentration is 0.21mol / L. After stirring and reacting at 65° C. for 8 h, the reaction was terminated by adjusting the pH value to 7-8 with 60% glacial acetic acid solution, and an allylated agarose solution was obtained. Add 4 times the volume of ethanol to the solution, centrifuge to collect the precipitate, pre-freeze at -70°C for 2 hours, and freeze-dry for 72 hours to obtain the modified agarose raw material.

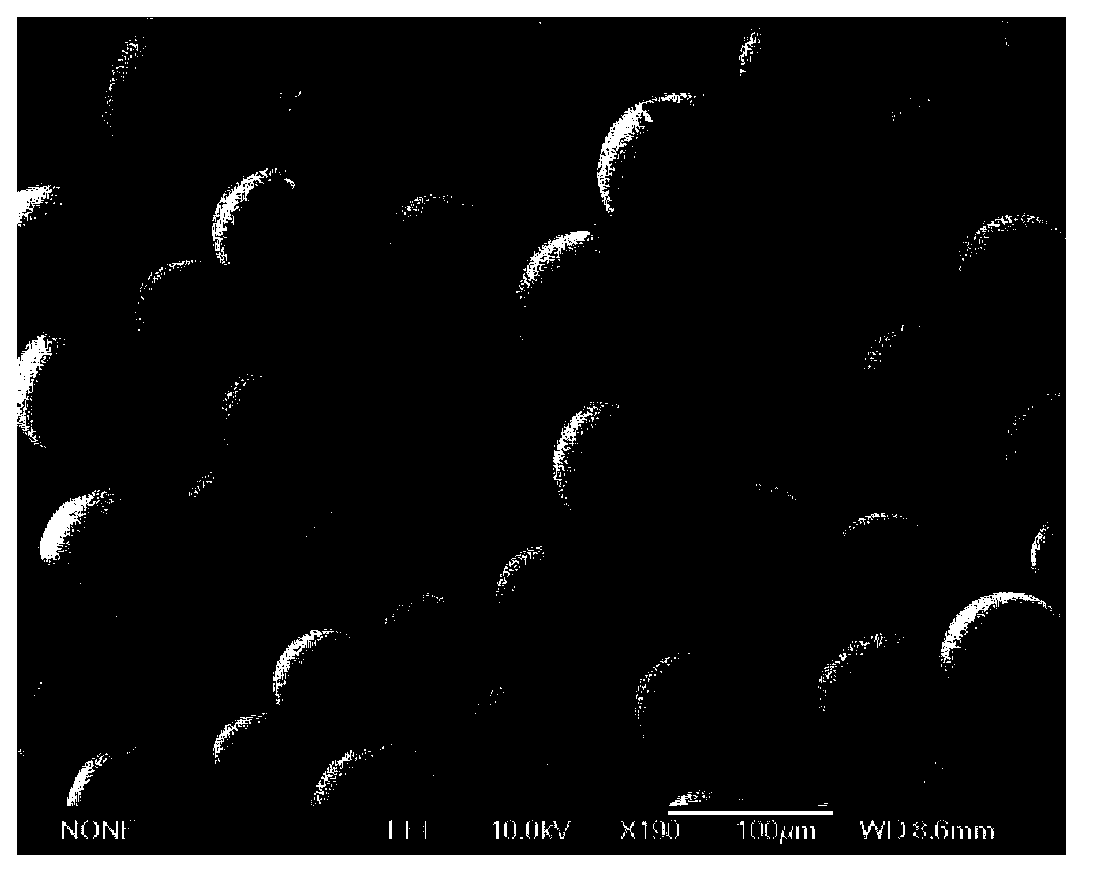

[0070] (2) Preparation of agarose microspheres modified by cross-linking agent...

Embodiment 2

[0076] Example 2 Blending method to prepare high-strength agarose microspheres with a concentration of 4wt%

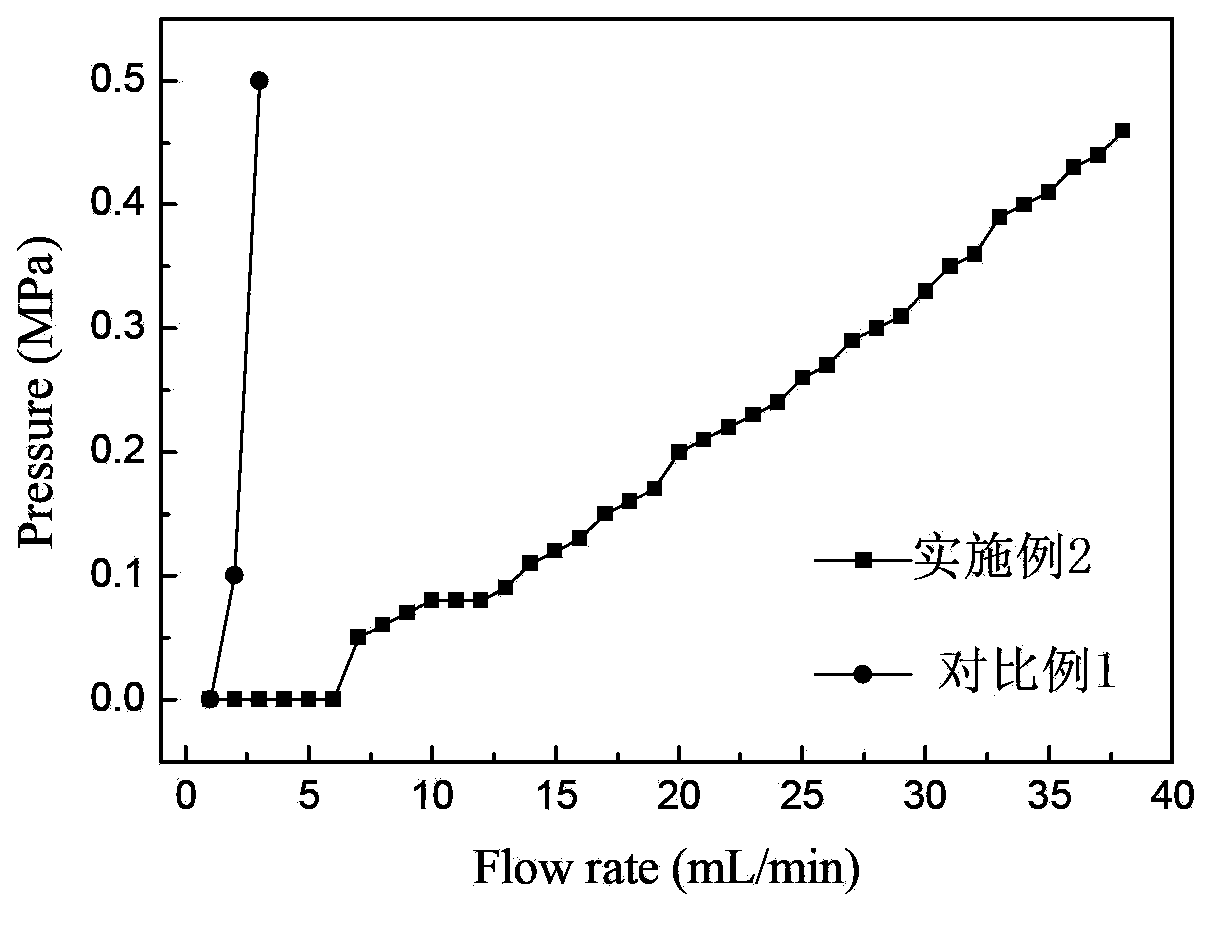

[0077] In order to further increase the strength of the agarose gel microspheres, on the basis of the cross-linking process described in Example 1, the traditional method was used to continue cross-linking once. That is, take 20 g of cross-linked agarose microspheres obtained in step (3) of Example 1, disperse them in 40 mL of deionized water, and gradually raise the temperature to 47.5° C. for 2 hours. After that, 1.6 mL of epichlorohydrin and 2.4 mL of 40% NaOH solution (containing 3% NaBH 4 ), and continued to react for 12h in a constant temperature water bath shaker. After the cross-linking was completed, it was washed with water until neutral, and the obtained 4wt% highly cross-linked agarose microspheres had an average particle size of 86.41 μm and a maximum flow rate of 2980 cm / h in the linear range. The pressure flow rate curve is as figure 2 shown.

Embodiment 3

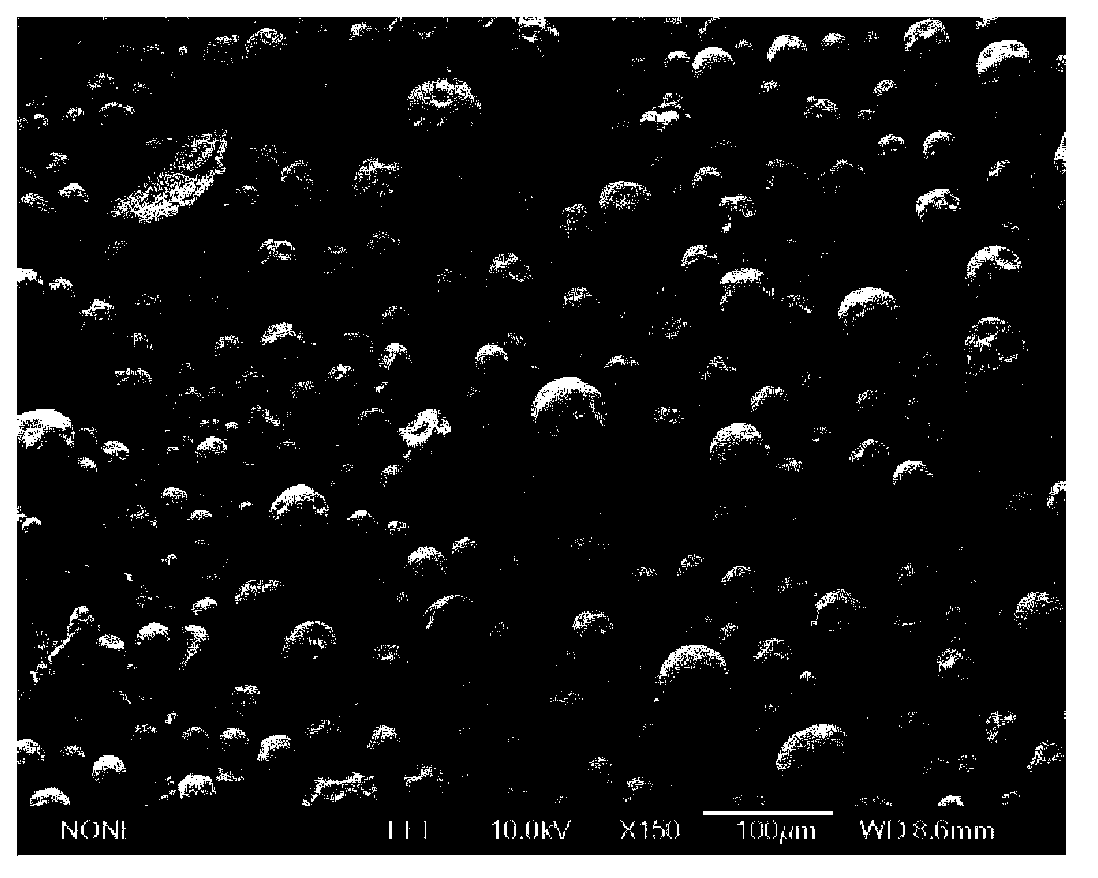

[0087] Example 3 Blending method to prepare high-strength agarose microspheres with a concentration of 6wt%

[0088] (1) Modification of agarose raw material

[0089] Prepare 40 mL of agarose solution with a concentration of 18%, cool down to about 80 °C, and slowly add 3 mL of 40% NaOH solution and 8 mL of cross-linking agent allyl glycidyl ether into it. Among them, the concentration of allyl glycidyl ether in the aqueous phase is 20%, OH - The concentration is 1.25mol / L. After stirring and reacting at 80° C. for 3 h, the reaction was terminated by adjusting the pH value to 7-8 with 60% glacial acetic acid solution, and an allylated agarose solution was obtained. Add 4 times the volume of ethanol to the solution, centrifuge to collect the precipitate, pre-freeze at -70°C for 2 hours, and freeze-dry for 72 hours to obtain the modified agarose raw material.

[0090] (2) Preparation of agarose microspheres modified by cross-linking agent by blending

[0091] Accurately weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com