A process for producing membrane electrodes

A process method and membrane electrode technology, applied to battery electrodes, circuits, fuel cells, etc., can solve the problems of difficult automatic production, complex membrane electrode production process, low efficiency and quality, etc., to achieve waste reduction, simple process, and high production efficiency The effect of high efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

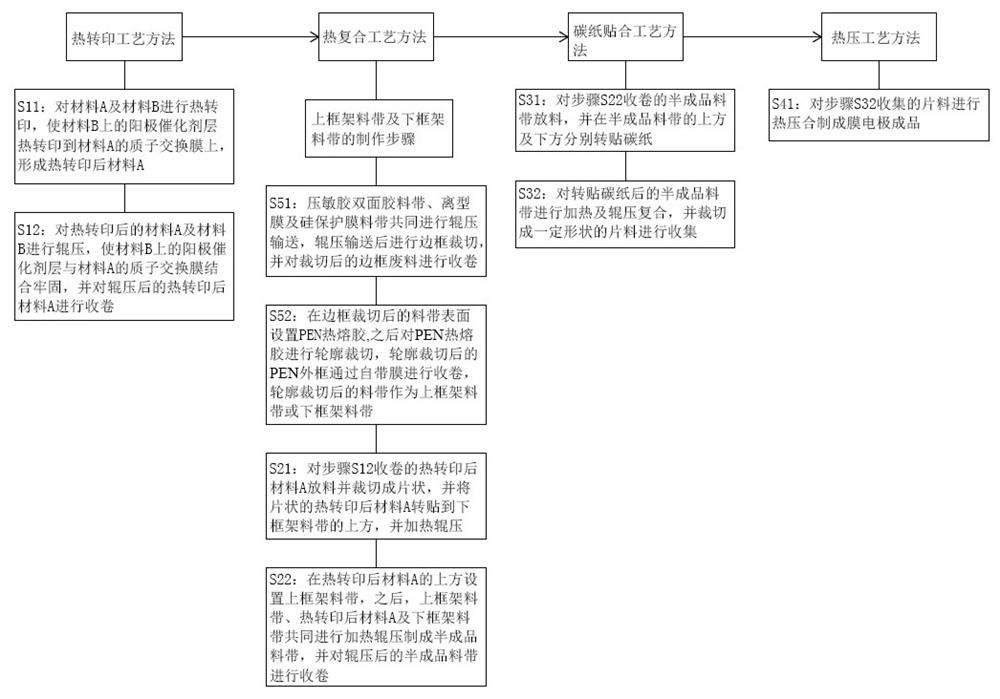

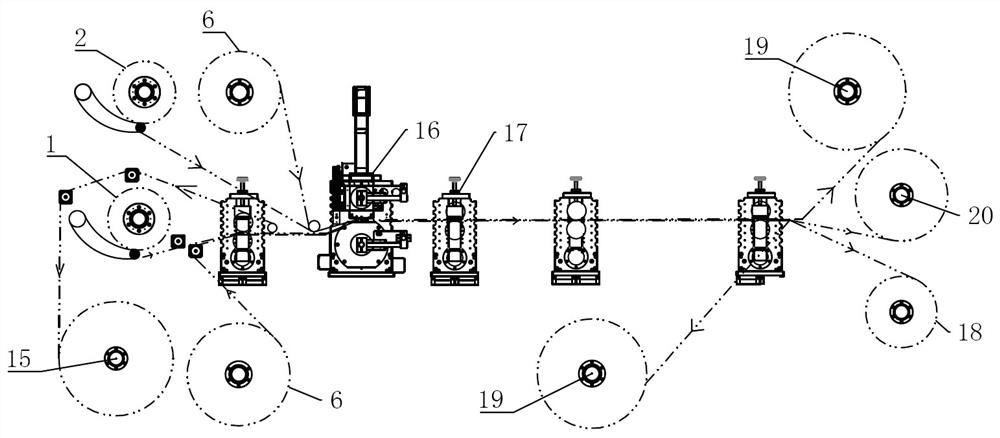

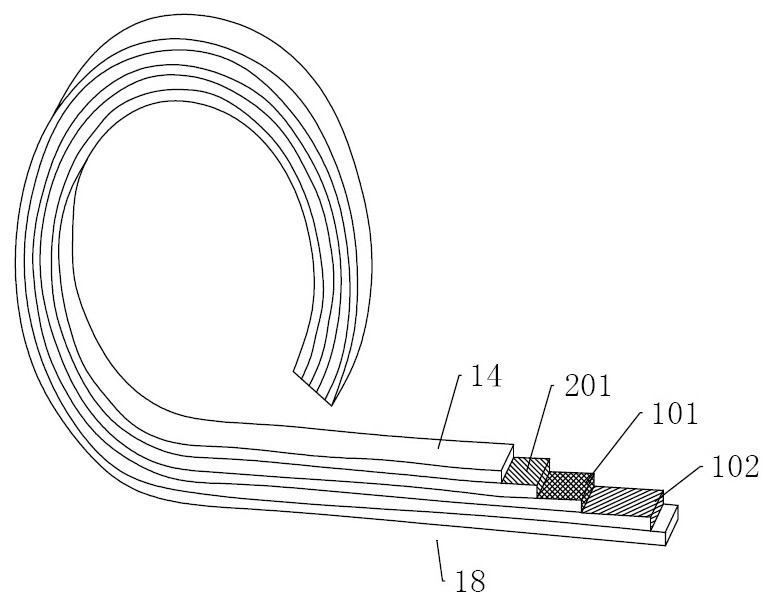

[0054] like Figure 1-Figure 8 As shown, a process method for producing a membrane electrode, the process method includes a thermal transfer process method, a thermal composite process method, a carbon paper 5 bonding process method, and a hot pressing process method;

[0055] Wherein, the thermal transfer process method includes the following steps:

[0056] S11: Before thermal transfer printing, place material A and material B on the material shaft respectively, and pull material A through the rolling knife seat 17. The material A lining film on the side is removed, and the material A lining film r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com