Automatic paper feeding and taking machine

A paper machine, automatic technology, applied in thin material handling, object separation, transportation and packaging, etc., can solve the problems of prone to paper jams, paper stop operation, inconvenient collection, etc., to achieve the effect of convenient installation and reduce paper overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

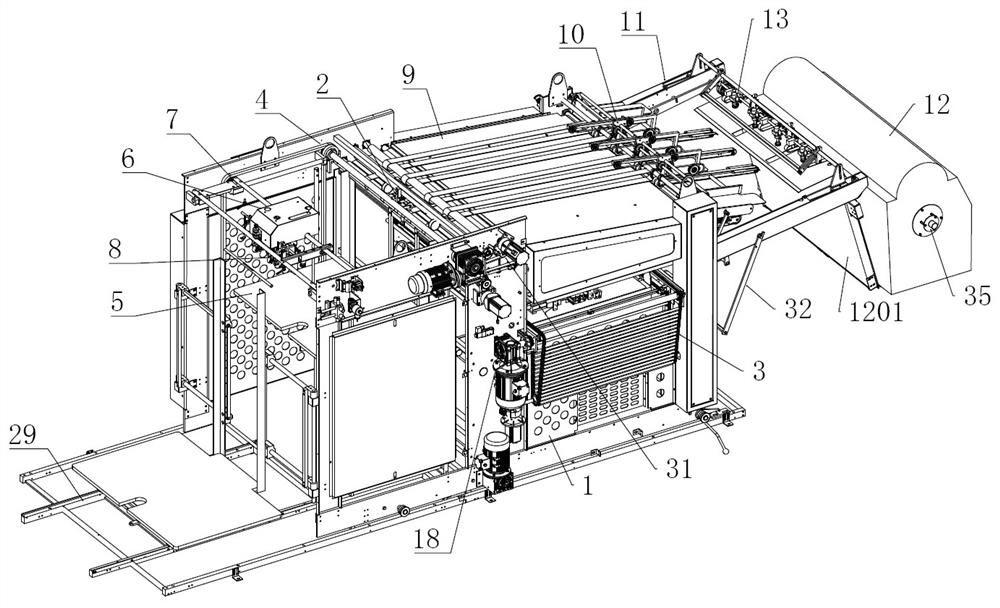

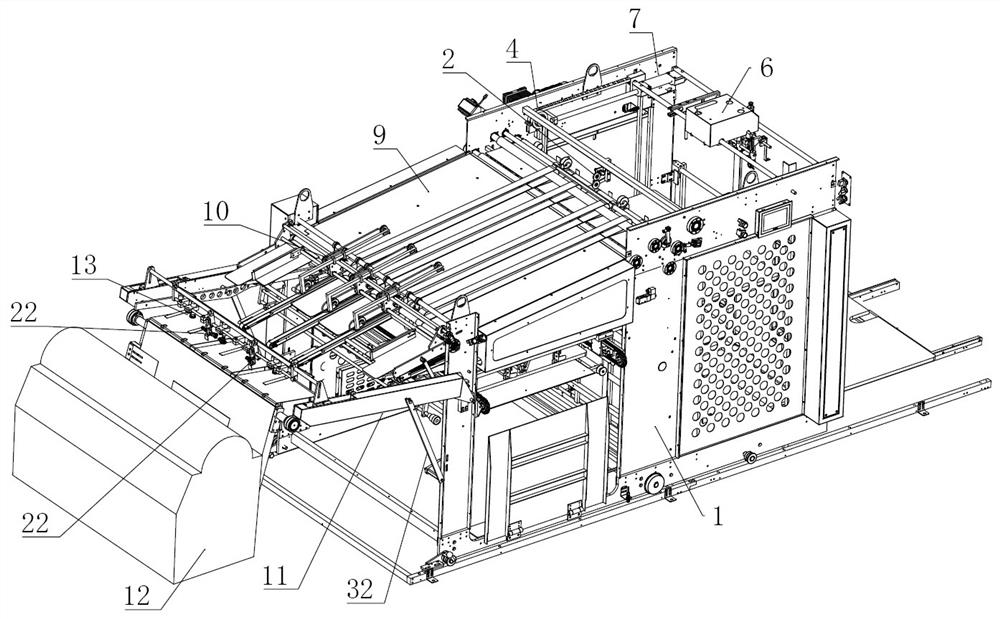

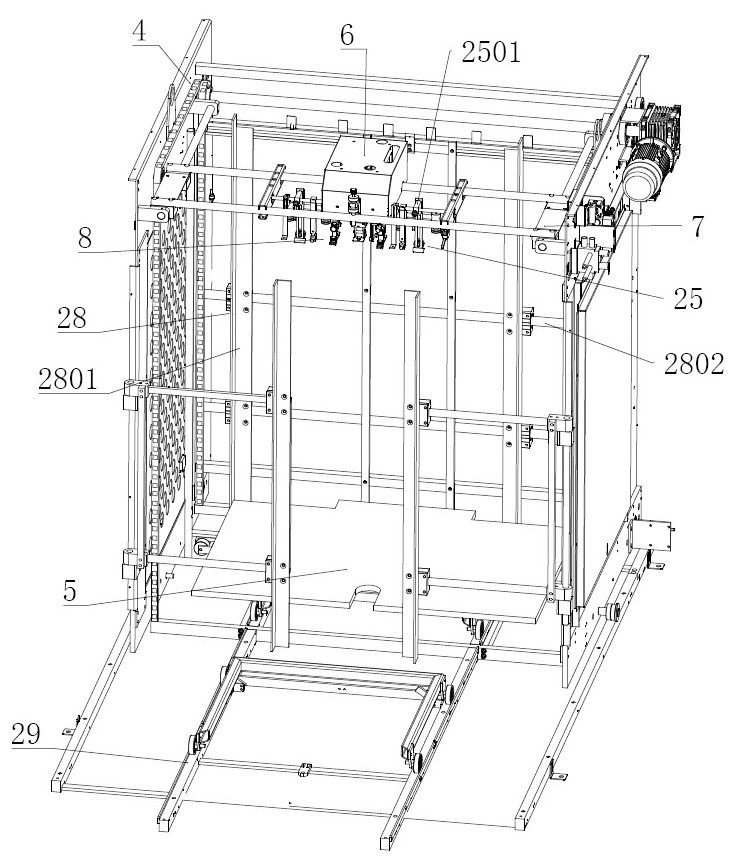

[0063] like Figure 1-Figure 3 and Figure 17-Figure 18 As shown, an automatic paper feeding machine includes a frame 1, and one end of the frame 1 is provided with a paper feeding device, through which the paper can be automatically loaded, and the discharge end of the paper feeding device is connected to The paper quantity detection mechanism 2 can detect the quantity of conveyed paper through the paper quantity detection mechanism 2. When there are more than two overlapping papers, the automatic paper feeding and picking machine is stopped in time to avoid affecting the subsequent paper processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com