Stamping device for mobile phone shell production

A punching device, mobile phone casing technology, applied in mechanical equipment, cleaning methods and utensils, forming tools and other directions, can solve the problems of reducing the production efficiency of mobile phone casings, unable to meet the use, complex disassembly, etc., to increase quality, increase stability, The effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

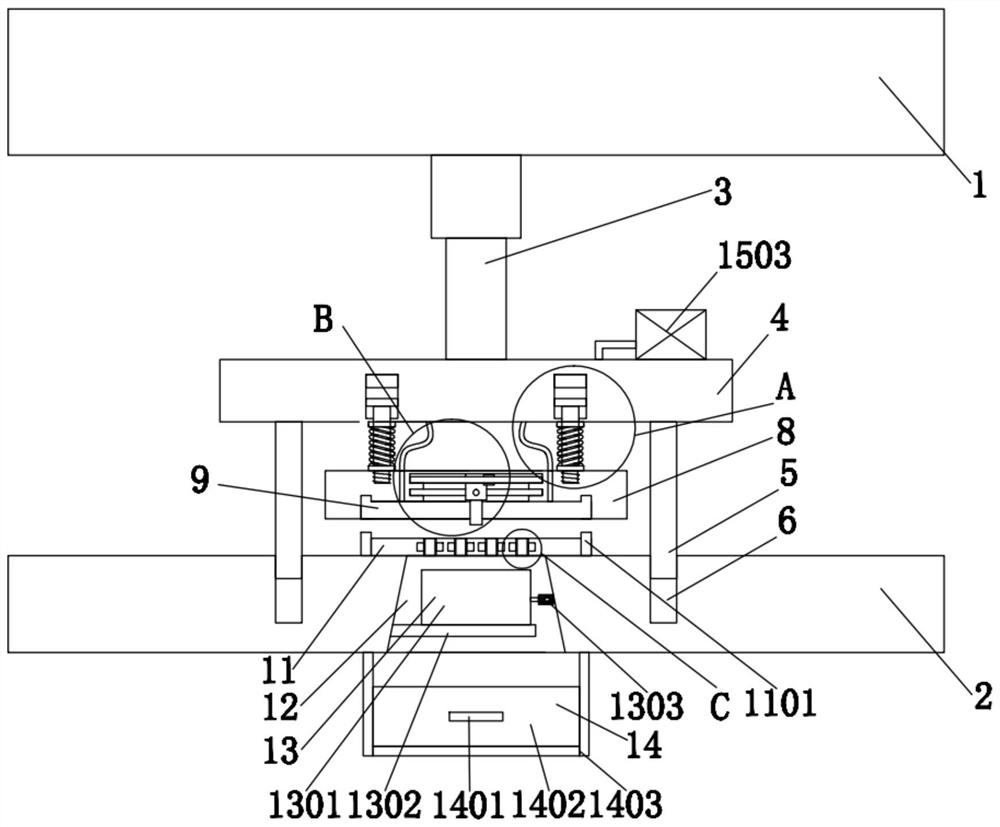

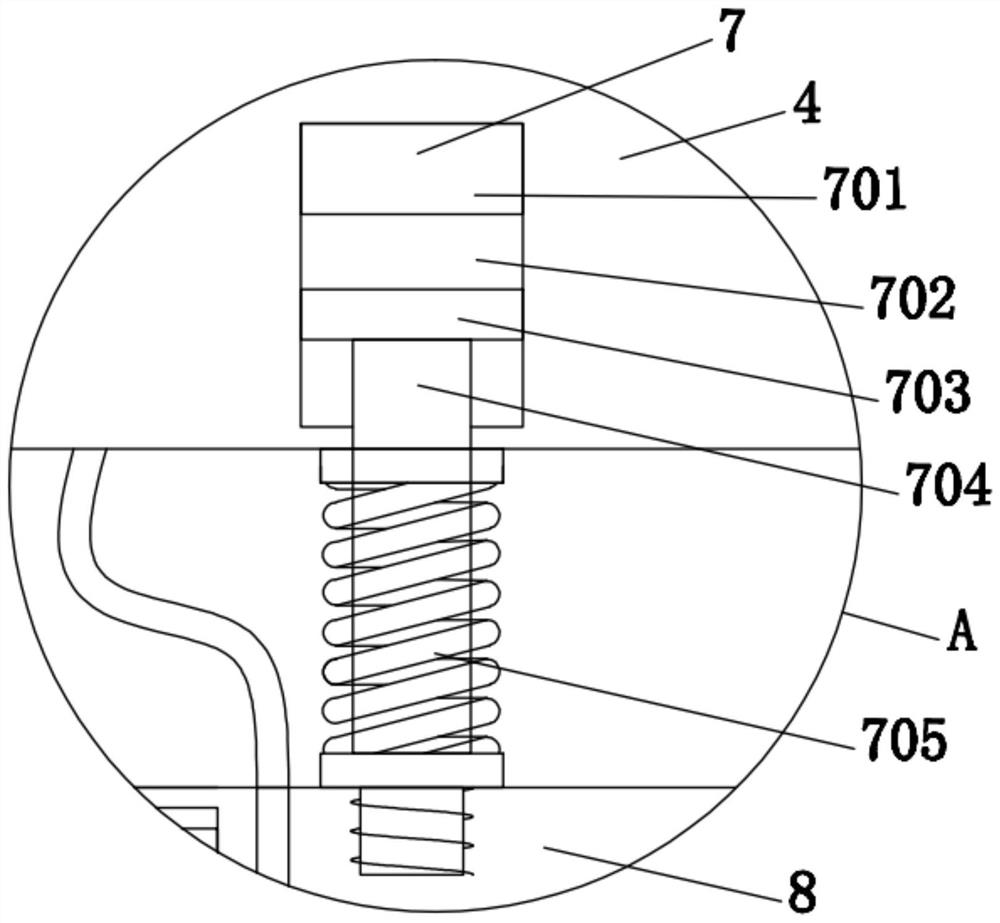

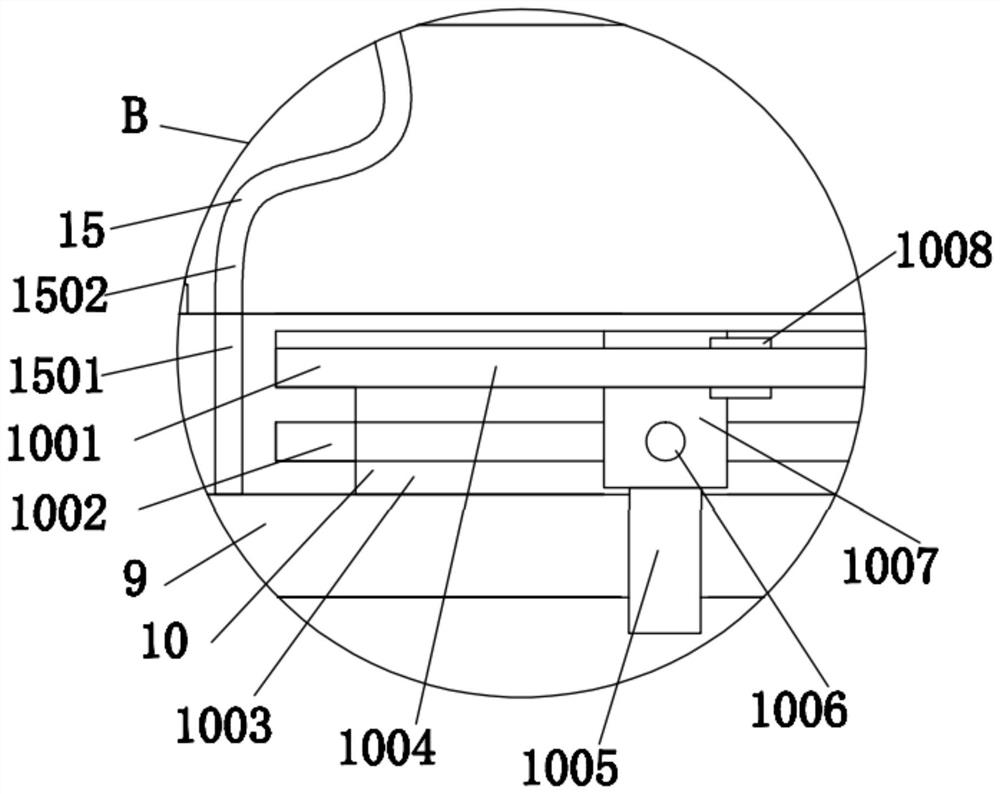

[0033] see Figure 1-4 , a stamping device for mobile phone casing production, comprising a top plate 1 and a bottom plate 2, the bottom of the top plate 1 is bolted to a hydraulic cylinder 3, the bottom of the hydraulic cylinder 3 is bolted to a first mold 4, and the first mold 4 Both sides of the bottom are bolted with a first limiting column 5, and the top of the bottom plate 2 is provided with a first limiting groove 6, and the surface of the first limiting groove 6 slides with the surface of the first limiting column 5. connection, the bottom of the first mold 4 is provided with a shock absorber 7, the bottom of the shock absorber 7 is fixedly connected with a second mold 8, and the bottom of the second mold 8 is provided with a first groove 9, so The top of the first groove 9 is provided with an adjustment device 10, the top of the bottom plate 2 is bolted with a third mold 11, and the top of the bottom plate 2 is provided with a second through hole 12, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com