Automatic pipeline channeling machine and channeling method thereof

A grooving machine and pipeline technology, applied in the field of pipeline grooving, can solve the problems of cumbersome adjustment, low production efficiency, unstable quality of grooving, etc., and achieve the effects of simple adjustment, improved production efficiency, and quick selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

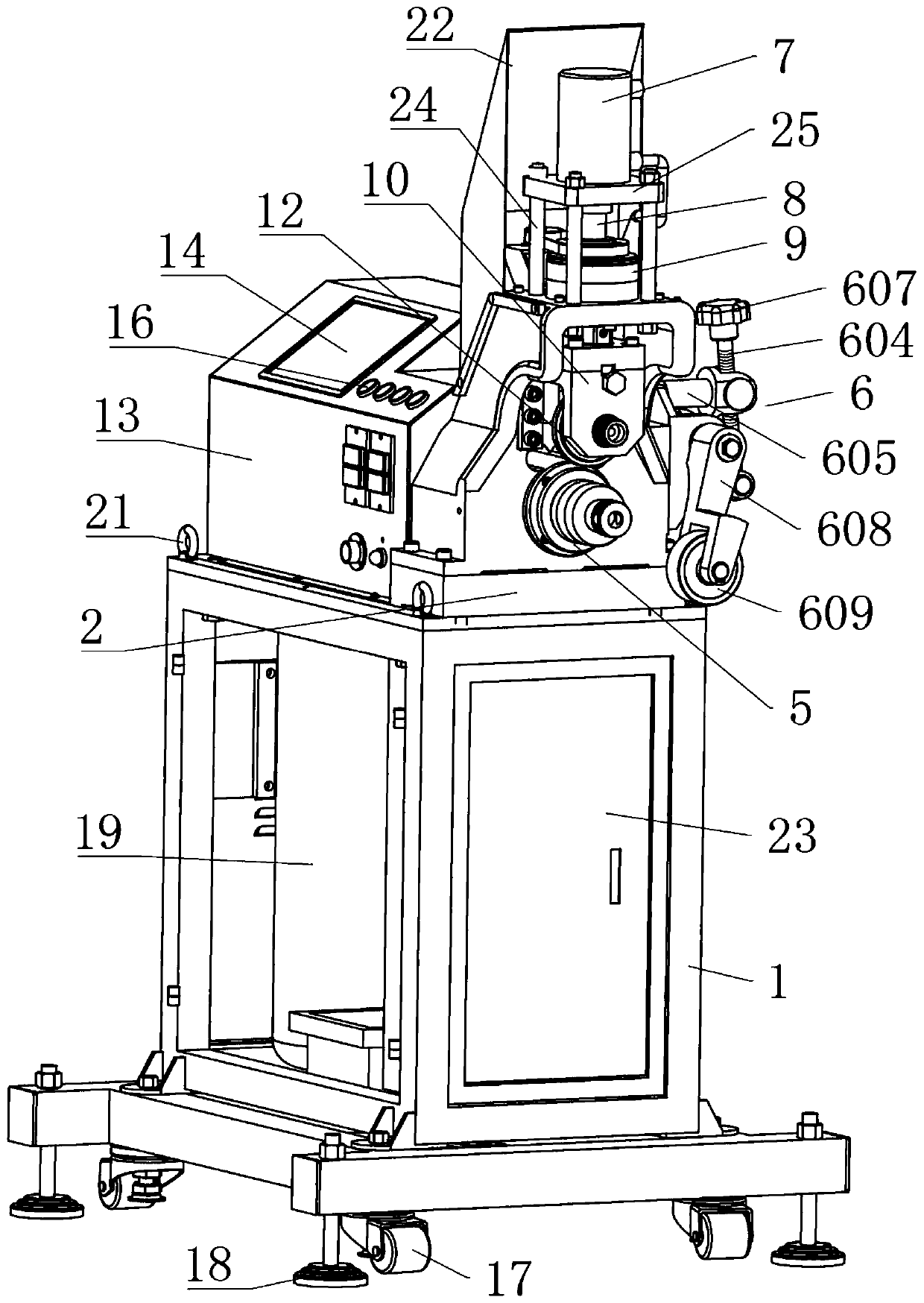

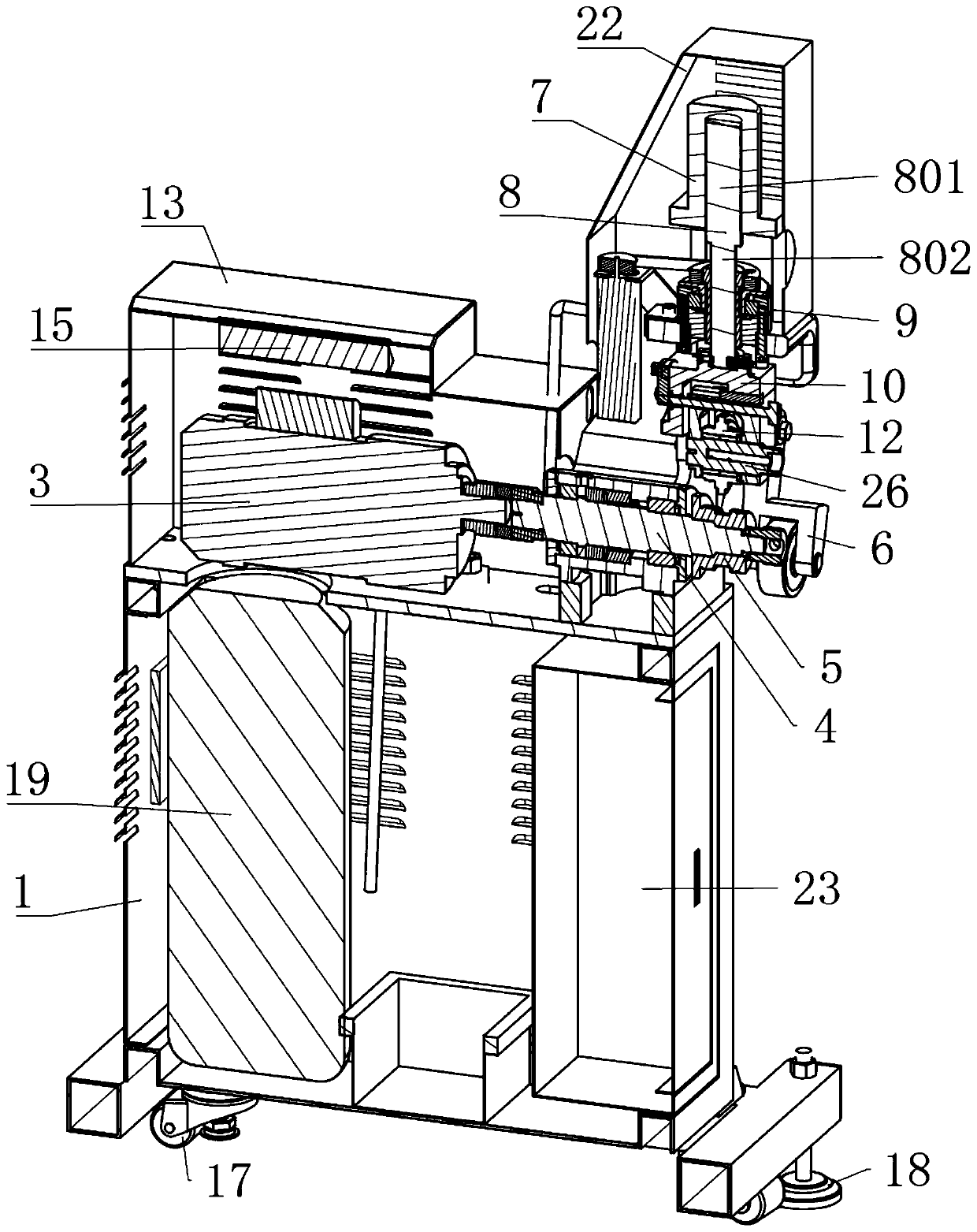

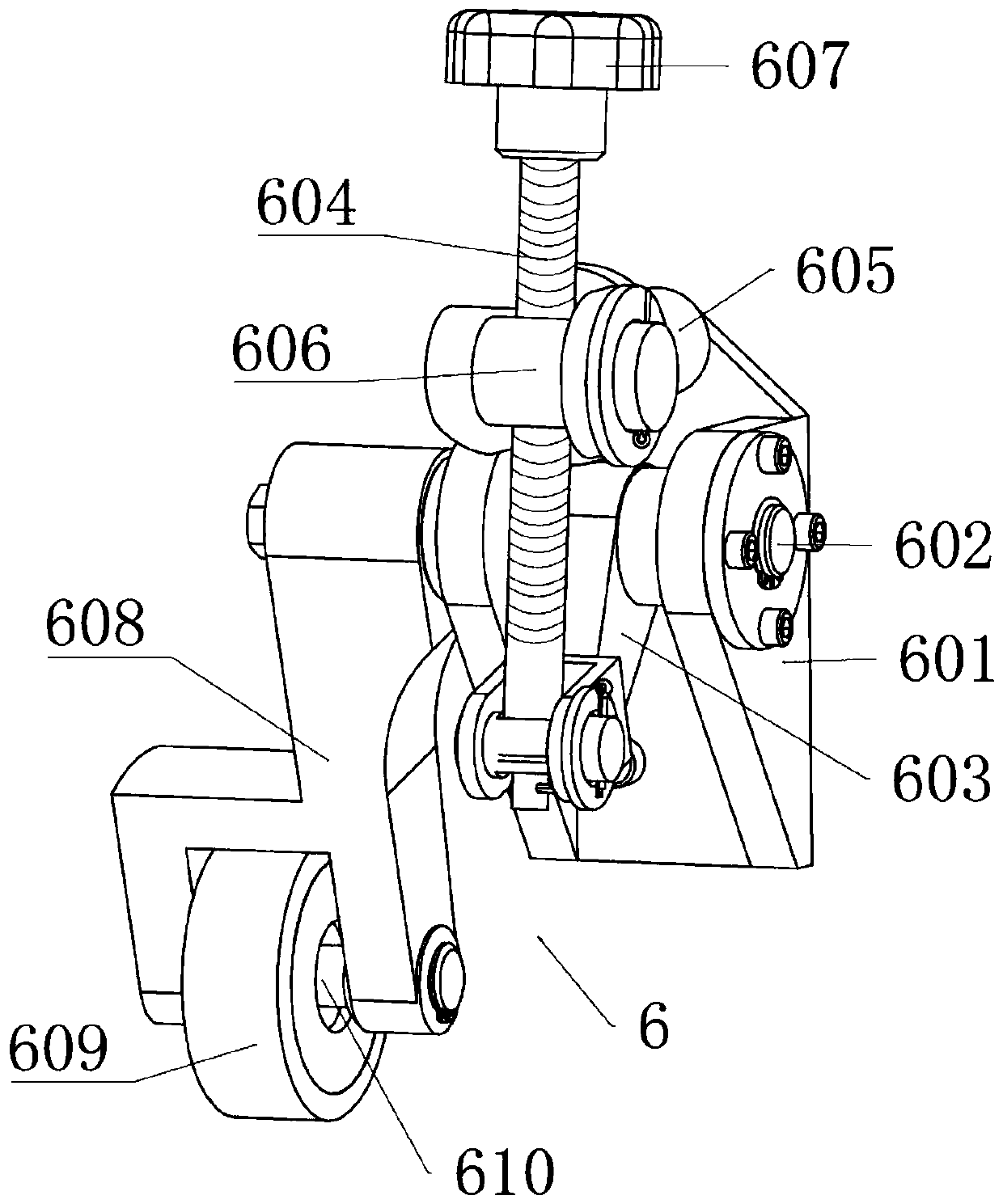

[0049] In this example, combined with figure 1 and figure 2 As shown, the present invention provides an automatic pipe grooving machine, comprising a fuselage 1, the top bolt of the fuselage 1 is mounted with an organic base 2, and the base 2 is mounted with a main shaft 4 driven by a geared motor 3 through bearing rotation, the main shaft 4 The end far away from the deceleration motor 3 extends to the outside of the machine base 2 and the lower pressure wheel 5 is installed with bolts. On the machine base 2 and close to the lower pressure wheel 5, there is an auxiliary support mechanism 6 for stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com