Portable type valve pipe fitting production device

A technology for valve pipe fittings and production equipment, applied in the field of convenient valve pipe fitting production equipment, can solve the problems of uneven stress on steel pipes, waste of manpower, material resources, affecting work efficiency, etc., to improve precise performance, facilitate maintenance and replacement, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

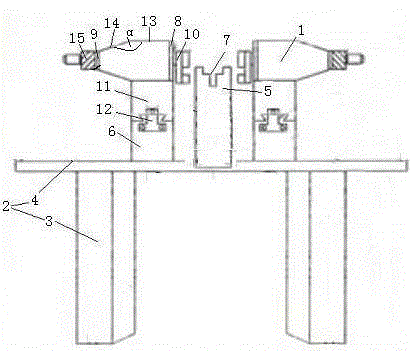

[0009] As shown in the figure, the portable valve and pipe fitting production device includes a machine head 1 and a frame 2. The frame 2 includes a support frame 3 and a workbench 4. The workbench 4 is provided with a first fixed block 5 With the second fixed block 6, there are two second fixed blocks 6, which are axisymmetrically arranged with the center line of the first fixed block 5 as the axis of symmetry, and the first fixed block 5 is provided with a limiting groove 7 One end of the machine head 1 is provided with a front end cover 8, the other end is provided with a rear end cover 9, the front end cover 8 is provided with a swing arm 10, and one side of the machine head 1 is provided with a mounting plate 11, The mounting plate 11 is fixedly connected to the second fixed block 6 through the adjusting block 12, the machine head 1 includes a main shaft end 13, one end of the main shaft end 13 is connected to the front end cover 8, and the other end is passed through an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com