Heated air delivery pipe of plastic stretch blowing machine

A technology of air pipes and stretch blowing machines, which is applied in the field of plastic machinery, and can solve problems such as unrealizable, failing to meet product requirements, and prone to white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

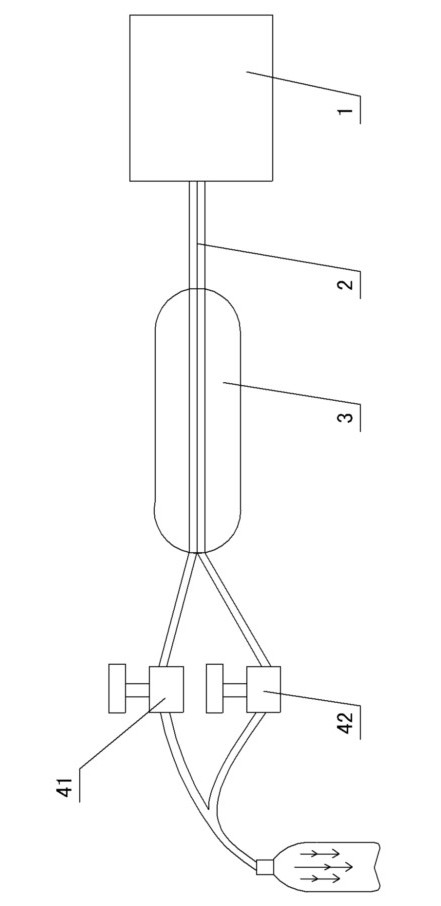

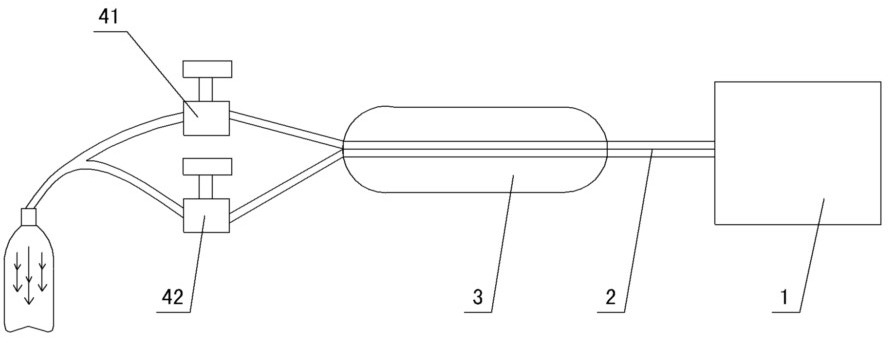

[0008] The invention relates to a heating type air pipe for a plastic stretch blowing machine, such as figure 1 As shown, it includes one end connected to the gas storage tank 1, and the other end connected to the air delivery pipe of the blow valve. The air in the trachea is heated. The air pressurized by the air compressor reaches the air storage tank 1, the air storage tank is connected to the air delivery pipe 2, and the air delivery pipe passes through the air blowing valve and the air blowing pipe to blow the air into the plastic bottle tube, and blow the plastic bottle tube into plastic. bottle. In order to process thin-walled plastic containers, the air blown into the bottle tube is hot air, so an electric heating device 3 is installed outside a section of the air delivery pipe, and the electric heating device controls the compressed air in the air delivery pipe 2 and the air delivery pipe. heating. There are many technical solutions for the electric heating device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com