Patents

Literature

79results about How to "Flexible speed adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

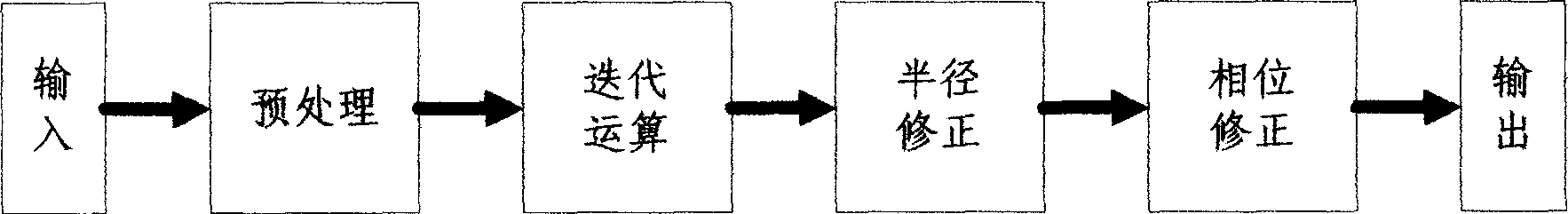

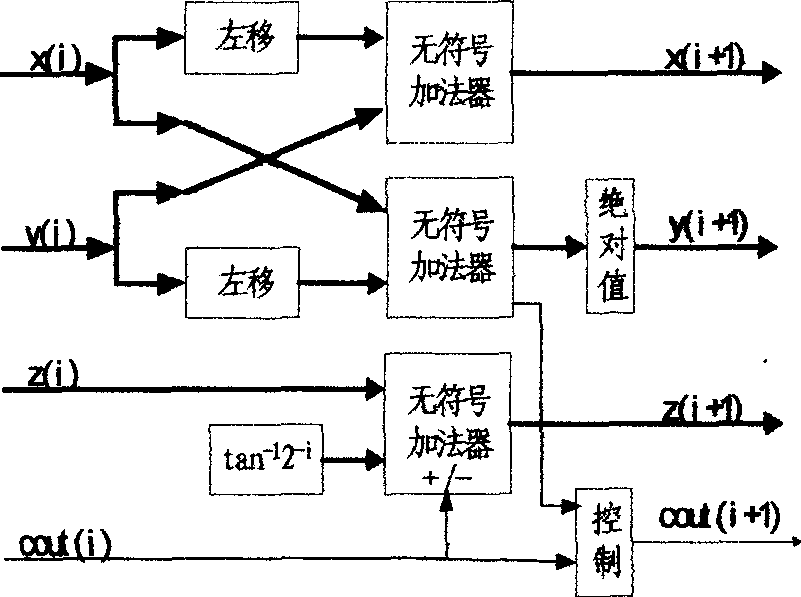

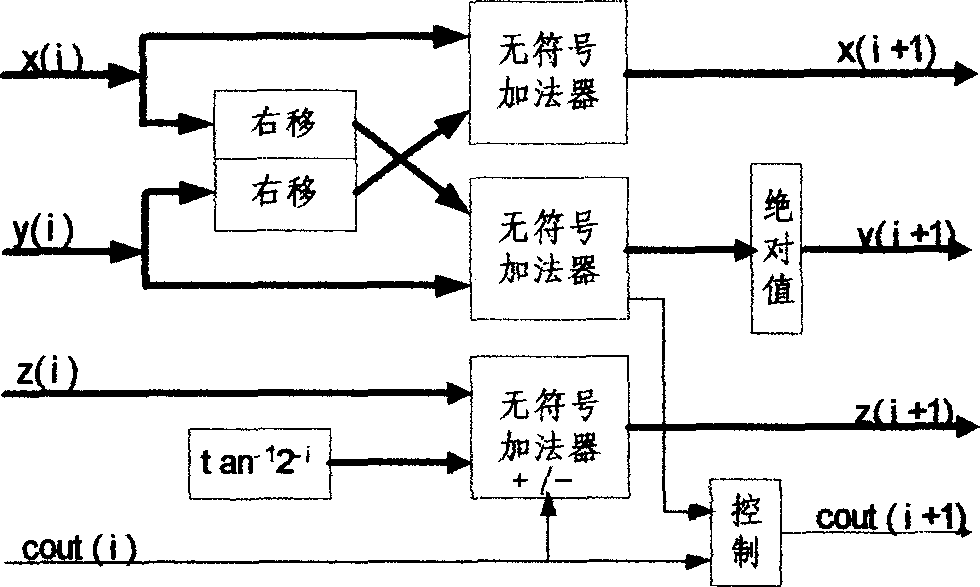

Coordinate transformation method for digital scanning change-over device and processor

InactiveCN1492313AFlexible adjustment of precisionFlexible speed adjustmentUltrasonic/sonic/infrasonic diagnosticsDigital data processing detailsPhase correctionPre treatment

The coordinate transformation method and processor for digital scanning converter is used to transform the rectangular coordinate values (x0, y0) into polar coordinate values (r, p). The transformation method includes initialization; pre-treatment; CORDIC algorithm including a times of left-shift iterative operation and (N-a) times of right-shift iterative operation; radius correction and phase correction. The optimal implementation example of the processor includes input module, pre-treatment module, iterative operation module, radius correction module, phase correction module and output module. The coordinate transformation method and processor may be used in digital scanning converter of B-type ultrasonic imaging instrument for regulating precision, speed and other performance parameters flexibly.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

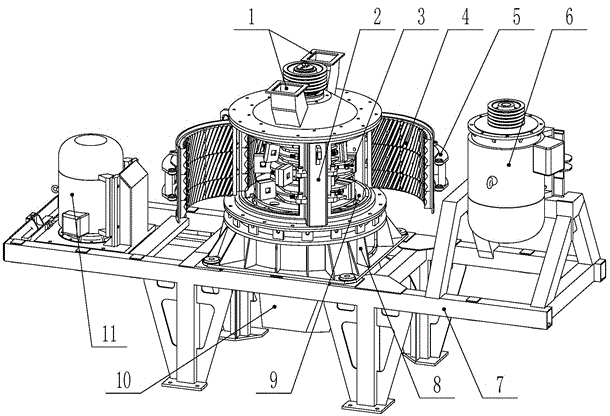

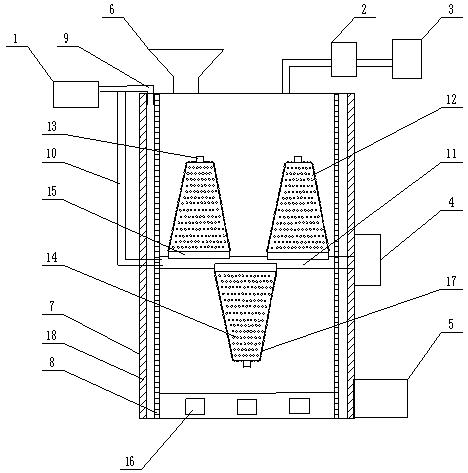

Vertical combined crushing and grinding machine

The invention provides a vertical combined crushing and grinding machine. The vertical combined crushing and grinding machine comprises an integral support, a grinding cavity seat, a cylinder body, a vertical rotor body, a spiral impact plate, a discharge hopper, charge hoppers, a turnover door, a grinding cavity wall lining plate, an electromotor, a crushing mechanism and a grinding mechanism. The vertical combined crushing and grinding machine enables the material crushing and grinding processes to be realized by one machine, is compact in structure and small in occupied area, saves the process, and improves the efficiency. Materials are impacted and crushed at high speed by a hammer head on a tower-shaped hammer seat in a spiral through crushing cavity, are thrown to the turnover door, are rebounded to the hammer head on the tower-shaped hammer seat, and are crushed repeatedly in the way, so as to guarantee relatively sufficient crushing. A centrifugal rotation roller acts on a grinding cavity wall lining plate, the materials are ground and crushed to 1mm below, and the qualified materials discharged from the discharge hopper finally are uniform in granularity and high in crushing ratio. In addition, the crushing and grinding cavity of the through combined crushing and grinding machine of the design is difficult to block, is smooth in material discharge and is long in service life, and the industrial cost is reduced.

Owner:四川皇龙智能破碎技术股份有限公司

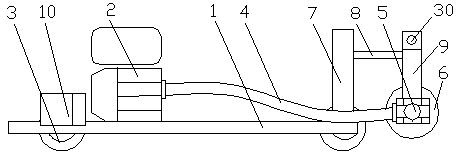

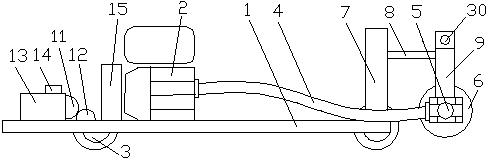

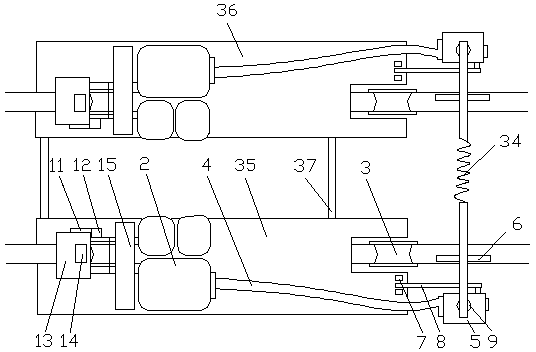

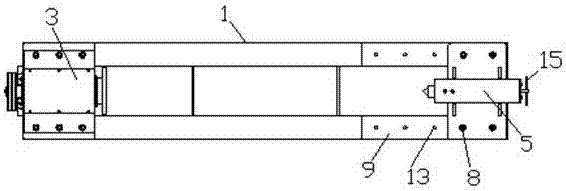

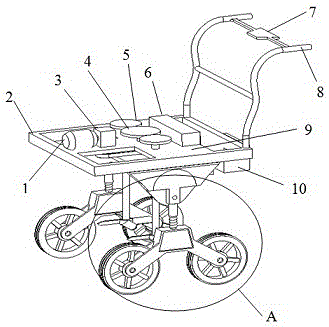

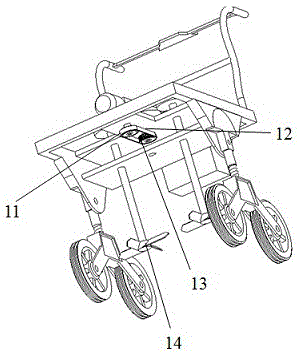

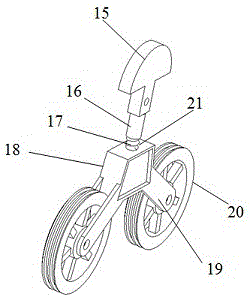

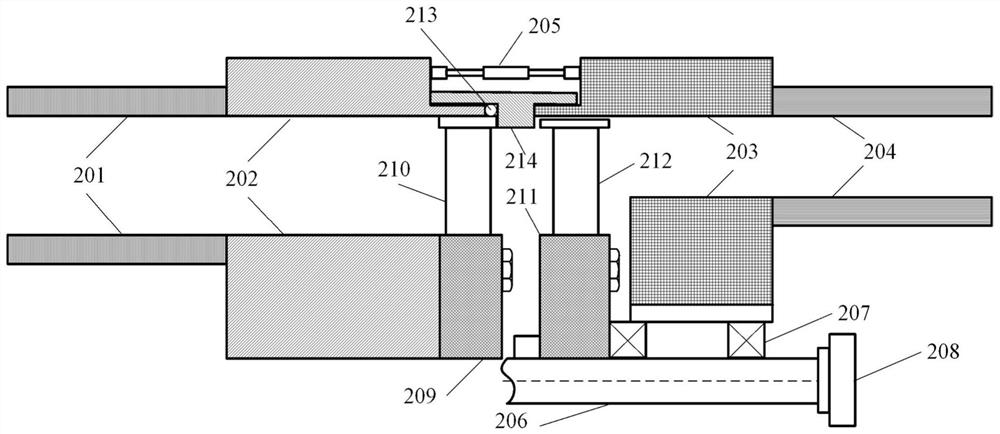

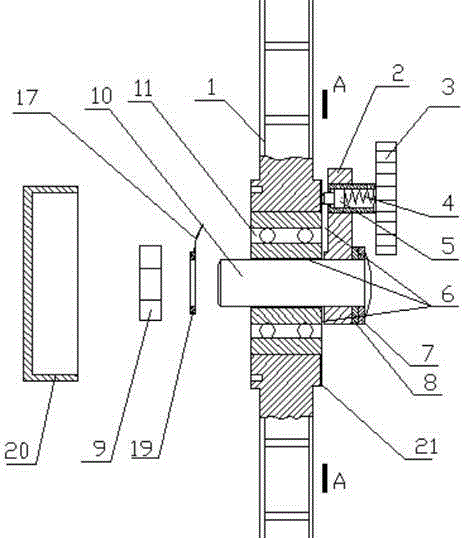

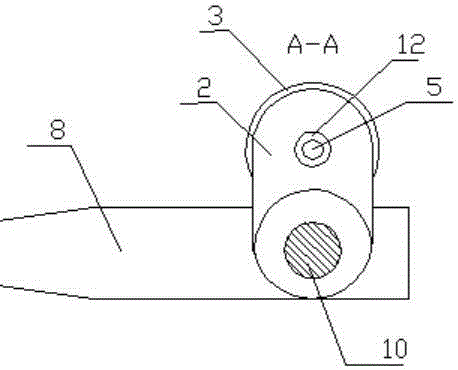

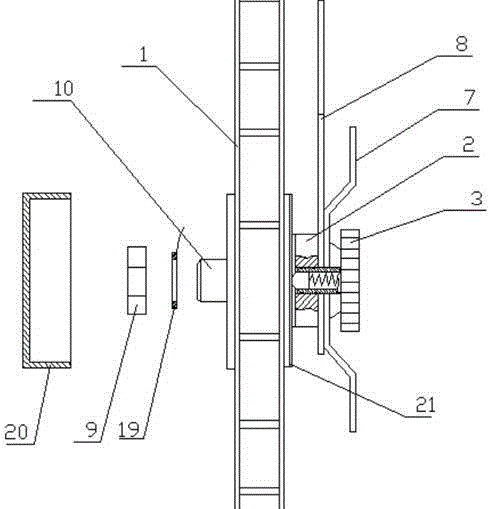

Automatic steel rail duplex rust removing machine

ActiveCN104631234AHard and wear-resistant working surfaceEasy to attachTrack superstructureRailway track constructionCouplingEngineering

The invention discloses an automatic steel rail duplex rust removing machine. The automatic steel rail duplex rust removing machine comprises a rack, engines and wheels connected to the lower portion of the rack, and is characterized in that the two engines are adopted and distributed on steel rails on the two sides respectively, the automatic steel rail duplex rust removing machine further comprises two soft shafts and two steering gears, one ends of the soft shafts are connected with rotating shafts of the engines through couplers, the other ends of the soft shafts are connected with input shafts of the steering gears, output shafts of the steering gears are connected with blade grinding wheels, the rack is fixedly connected with two connecting pieces, vertical adjusting pieces are arranged above the steering gears and elastically connected with the steering gears, connecting rods of the connecting pieces are connected with the vertical adjusting pieces, a transverse spring pull rod is connected between the vertical adjusting pieces of the steel rails on the two sides, and the rack is connected with a drive component. The kinetic energy of the engines is directly transmitted to the blade grinding wheels through the soft shafts, a duplex structure is adopted, synchronous automatic constant-speed rust removing can be carried out on pedal faces of the two steel rails at the same time, and the rust removing quality and efficiency are greatly improved.

Owner:德阳路安恒轨道技术开发有限公司

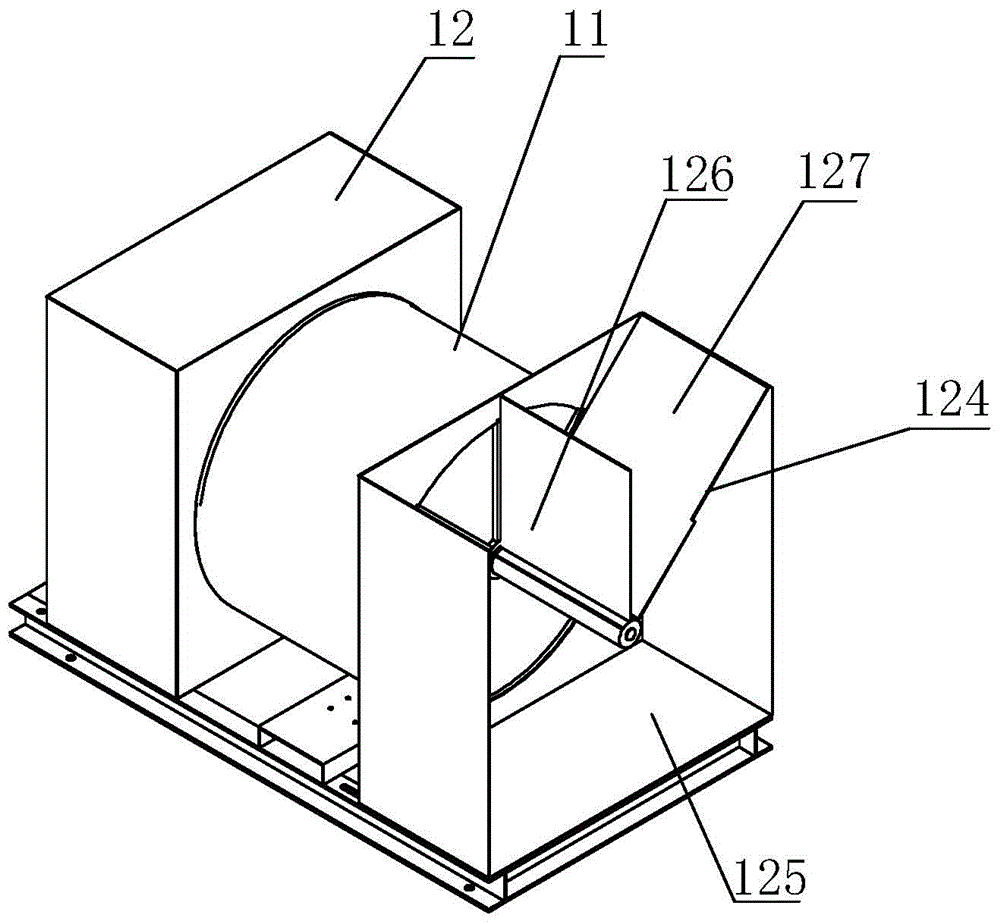

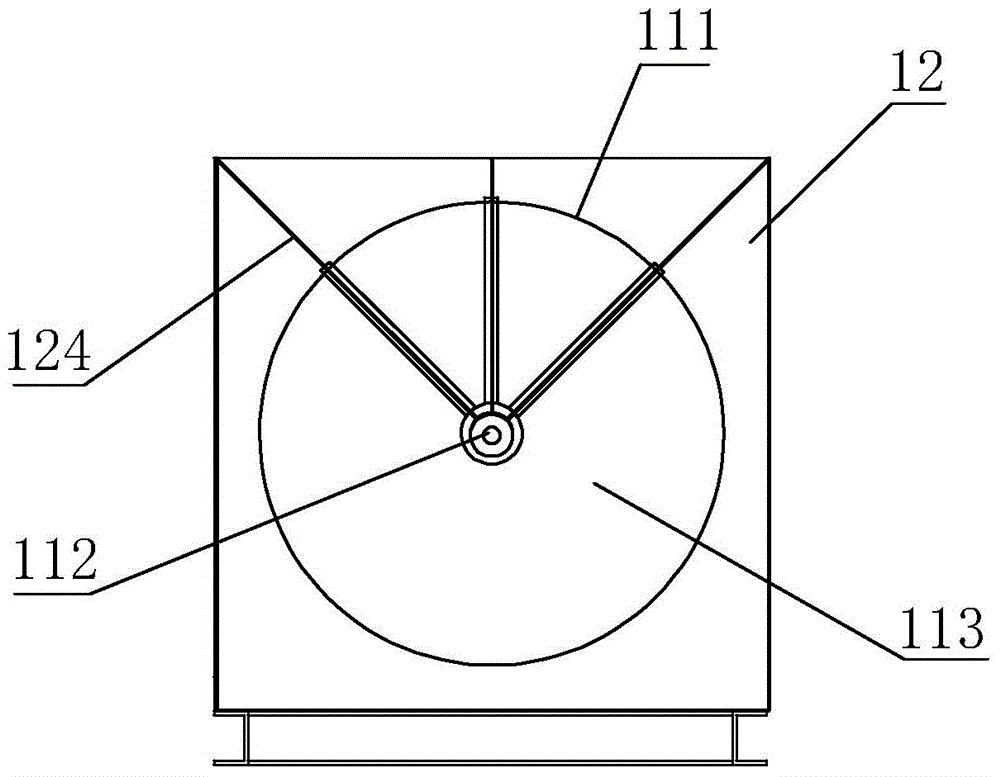

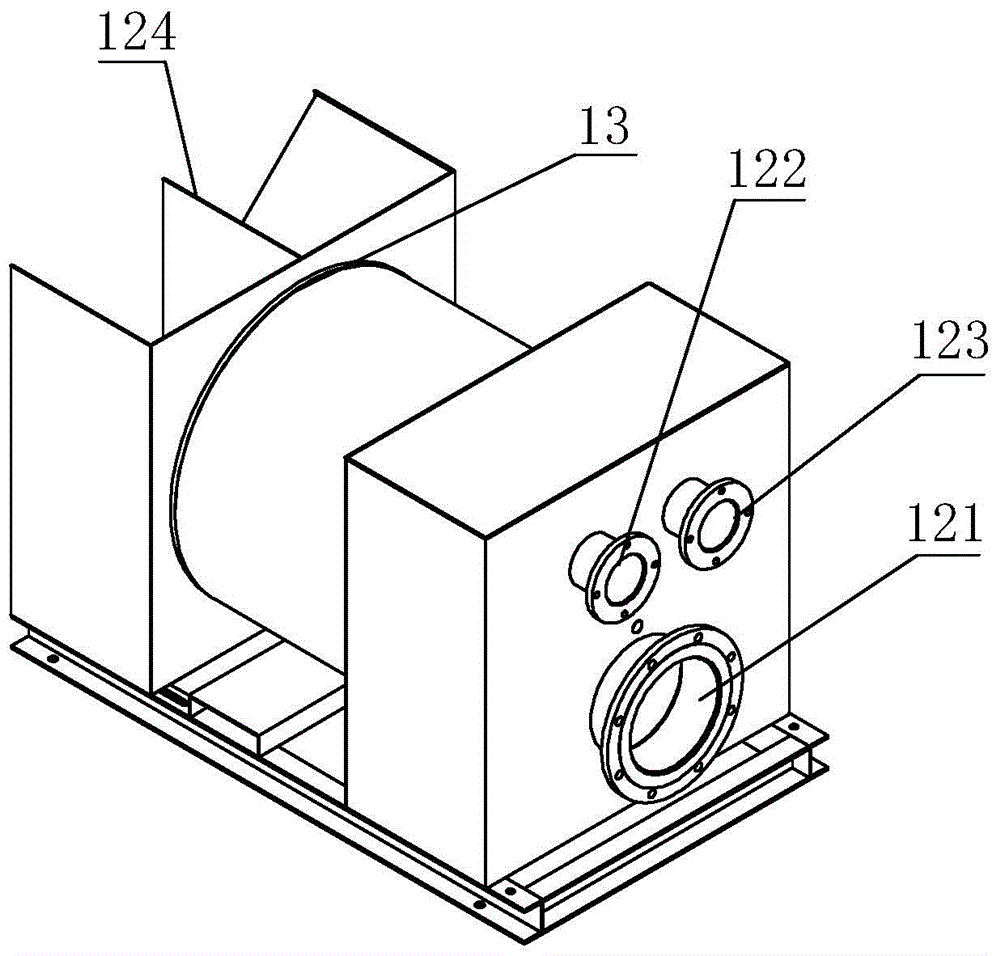

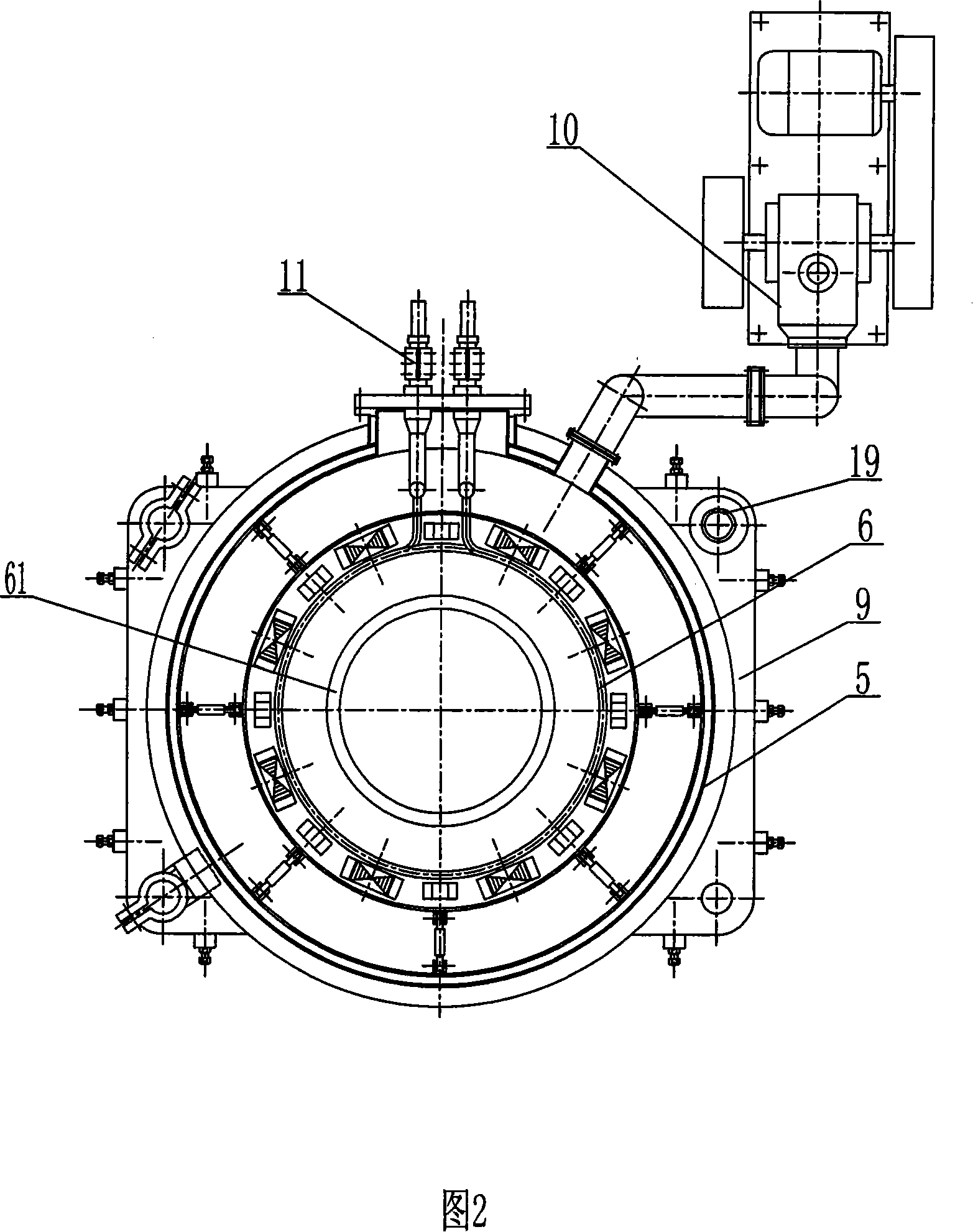

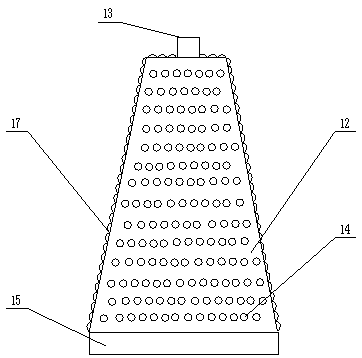

Absorption type rotating wheel gas purifying device

ActiveCN103599676AImprove adsorption efficiencyImprove adsorption utilizationDispersed particle separationActivated carbonDesorption

The invention discloses an absorption type rotating wheel gas purifying device. The absorption type rotating wheel gas purifying device comprises a rotating wheel and two gas partitioning boxes, wherein the rotating wheel comprises a shell, a core shaft, a partitioning leaves and honeycomb active-carbon modules, wherein the shell rotates around the core shaft by virtue of mechanical driving; the shell is averagely divided into a plurality of areas by virtue of the partitioning leaves; a plurality of layers of small active-carbon honeycomb bodies are respectively embedded into each area; gas channels on the active-carbon honeycomb bodies are distributed along the length direction of the active-carbon honeycomb bodies; two gas partitioning boxes are respectively arranged at the two sides of the rotating wheel; each gas partitioning box comprises a box body; one side of the box body is connected with a gas inlet and outlet pipeline, and the other side of the box body is provided with a round opening with the diameter equal to that of the shell of the rotating wheel; the box body is internally divided into 6 areas (an absorbing area, a desorbing area, a cooling area and three isolating areas without being adjacent) by virtue of partitioning plates; the end surface, which is contacted with the rotating wheel, of each isolating area is sealed. The absorption type rotating wheel gas purifying device disclosed by the invention has the advantages that the absorption and the desorption can be finished simultaneously, the problem that the adsorbability of active carbon is reduced along with the accumulation of the absorbing amount is avoided, the volume is small, the weight is light and the structure is compact.

Owner:青岛纳博科环保科技有限公司

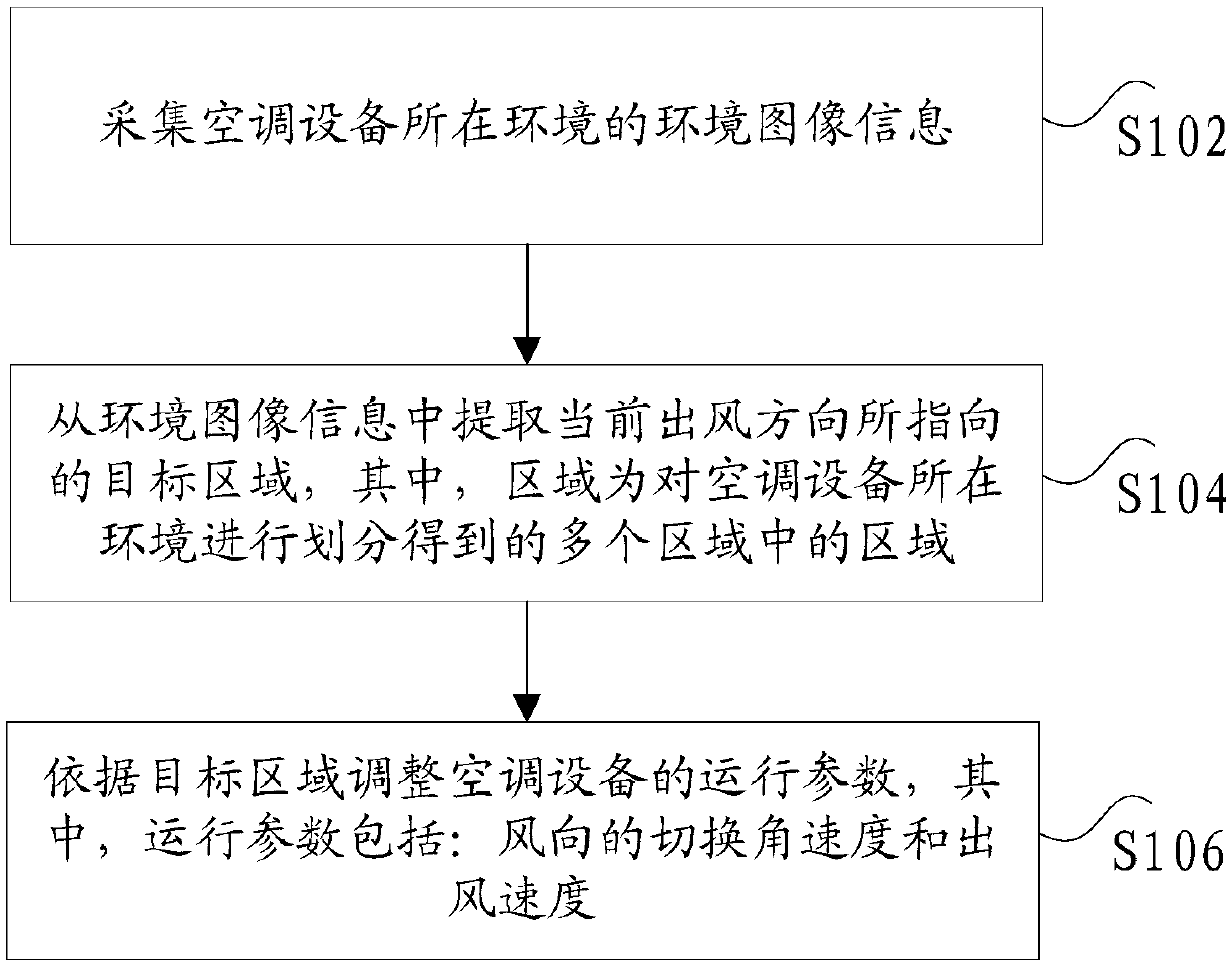

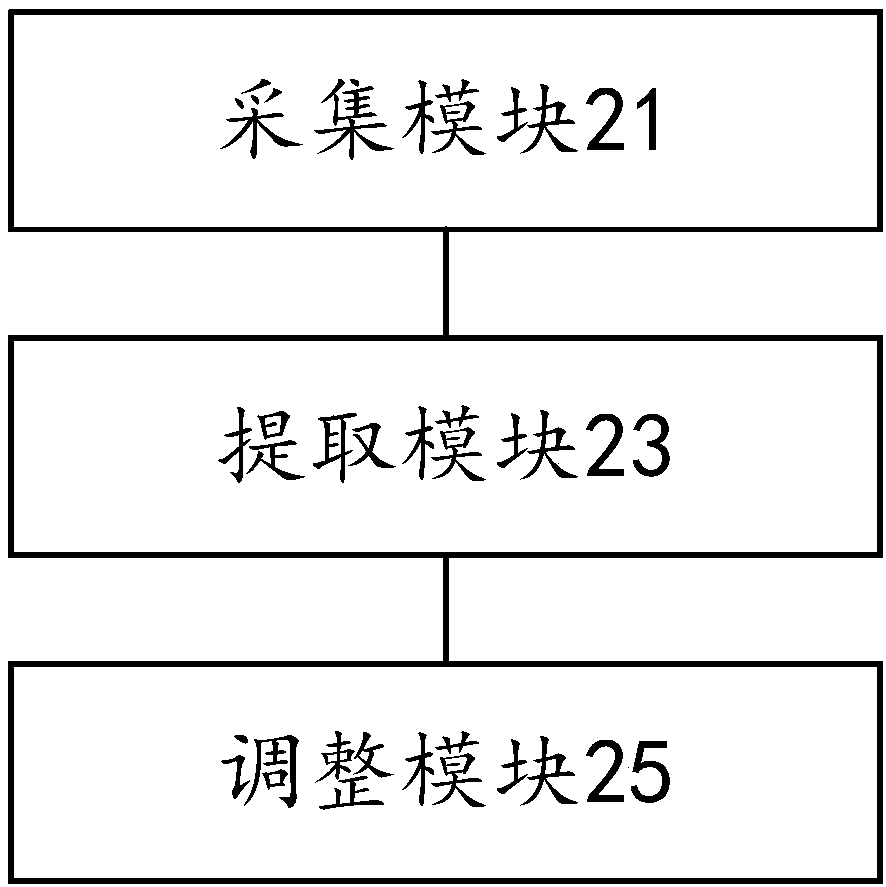

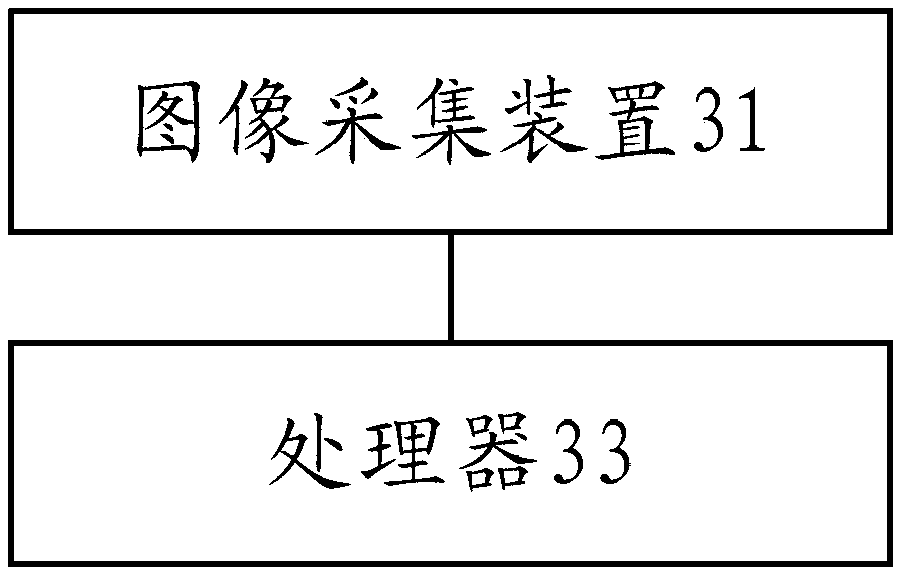

Air conditioner air outlet control method and terminal

InactiveCN107860100AAdjust operating parametersFlexible adjustment of operating parametersMechanical apparatusSpace heating and ventilation safety systemsAir conditioningWind direction

The invention discloses an air conditioner air outlet control method and a terminal. The method comprises the steps that environment image information of an environment where air conditioning equipment is located is acquired; a target area pointed by the current air outlet direction is extracted from the environment image information, wherein the area is one of a plurality of areas obtained afterthe environment where the air conditioning equipment is located is partitioned; and operating parameters of the air conditioning equipment are adjusted according to the target area, wherein the operating parameters include the air direction switching angular speed and the air outlet speed. By adopting the air conditioner air outlet control method and the terminal, the technical problems that the air direction and air speed control of an air conditioner in a relevant art are simplex, and consequentially, the experience when a user uses the air conditioner is poor are solved.

Owner:GREE ELECTRIC APPLIANCES INC

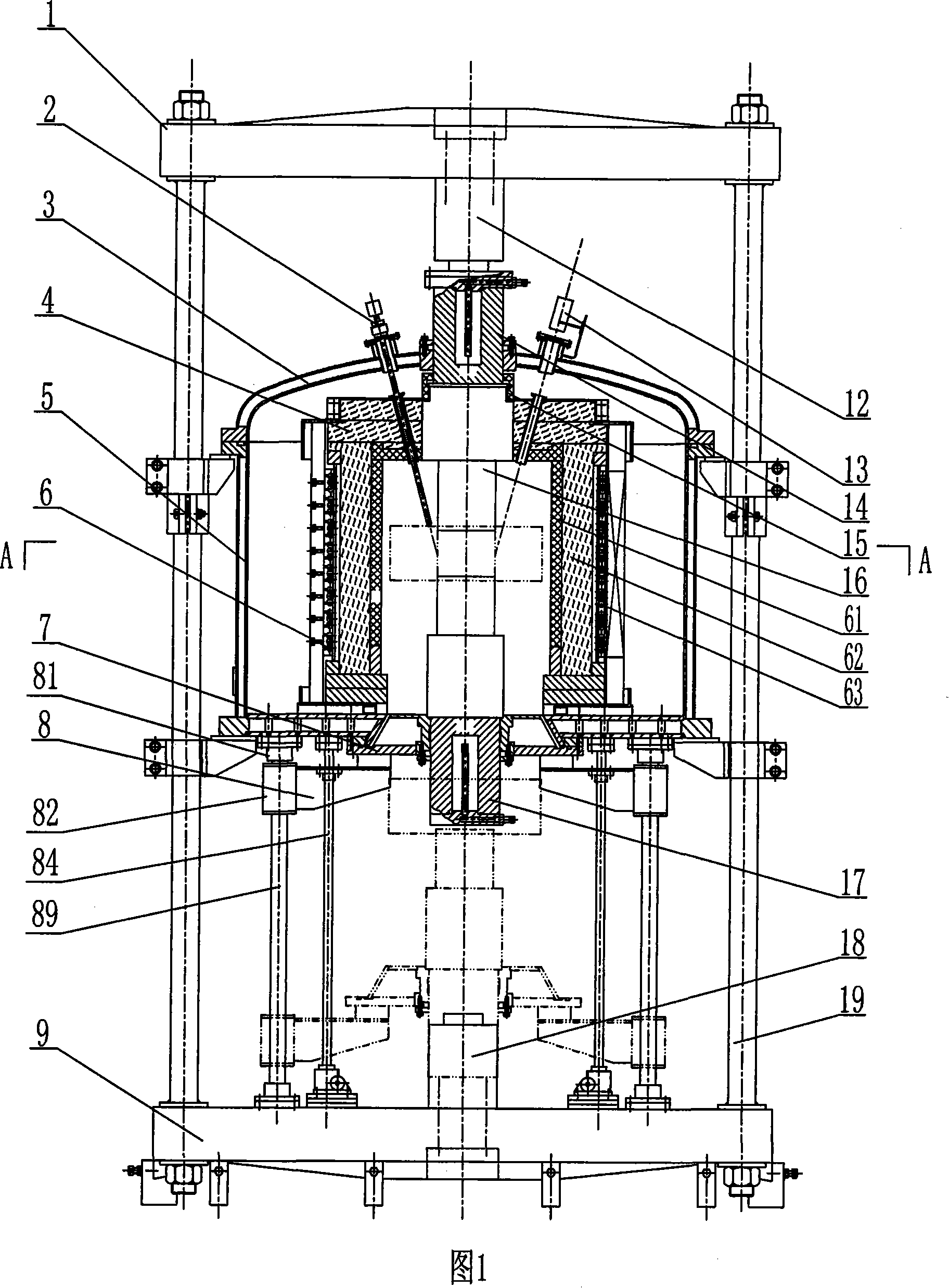

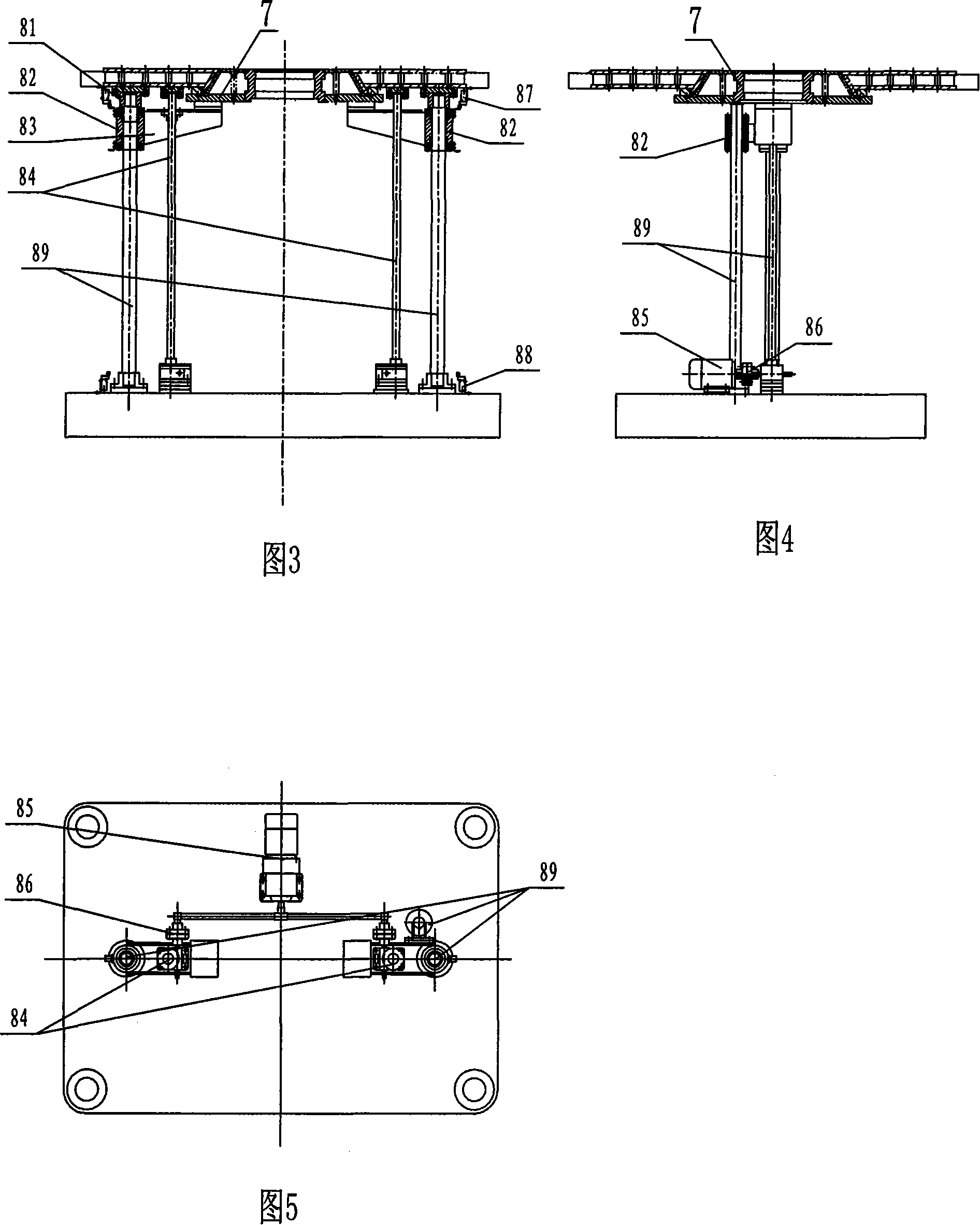

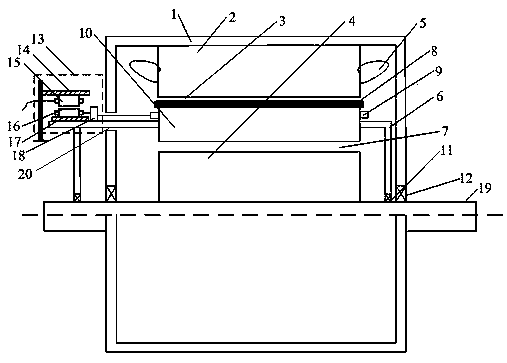

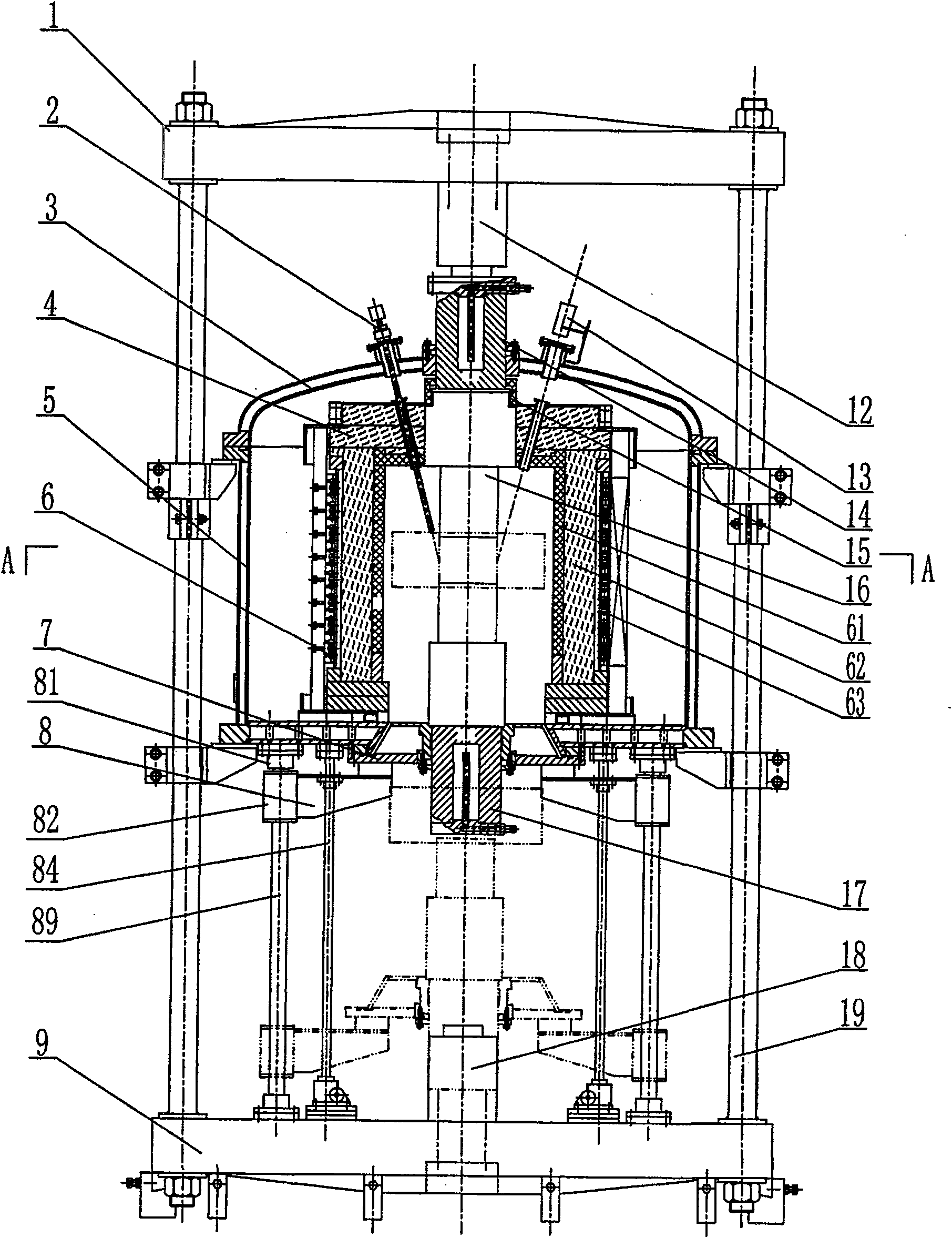

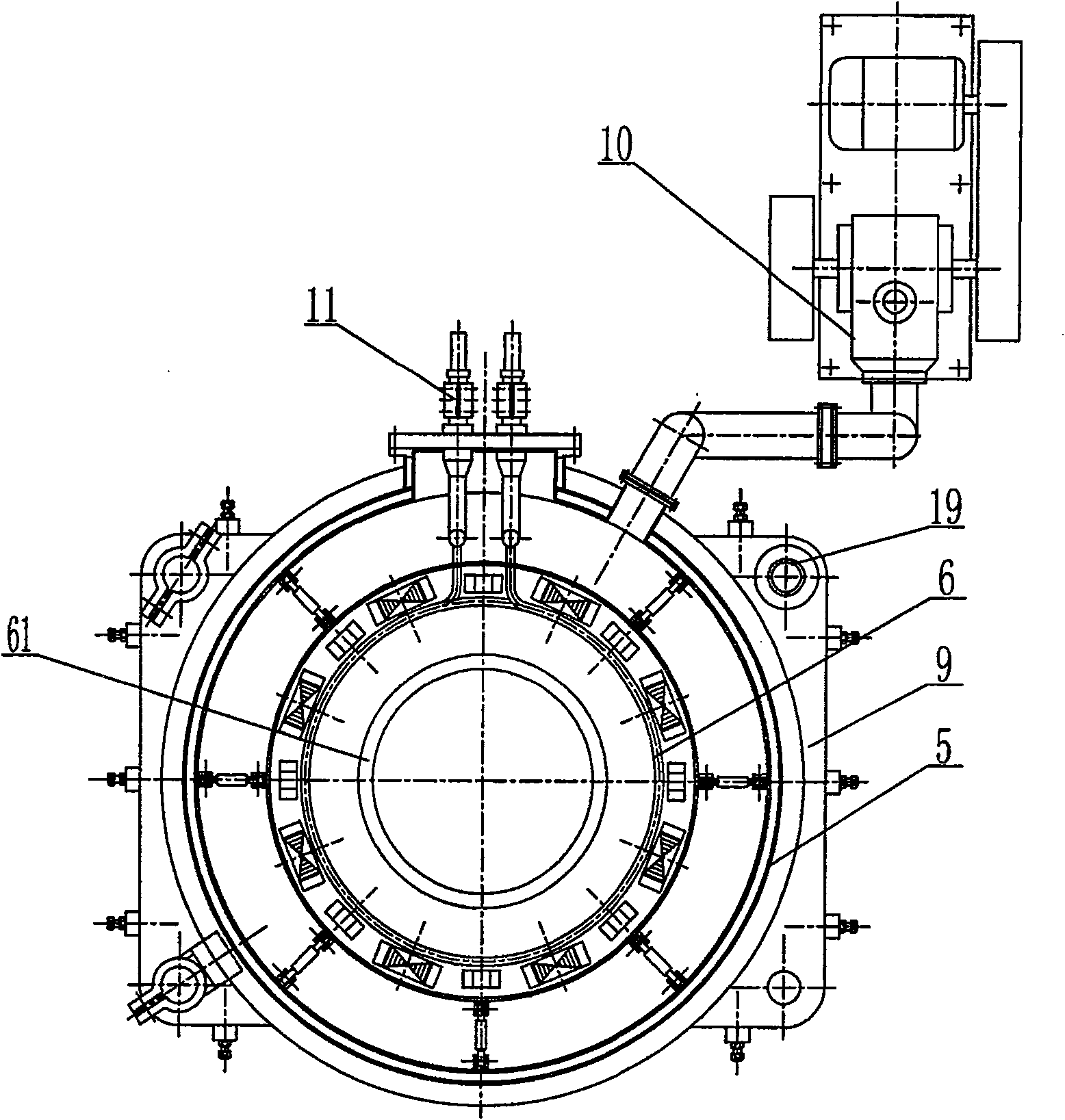

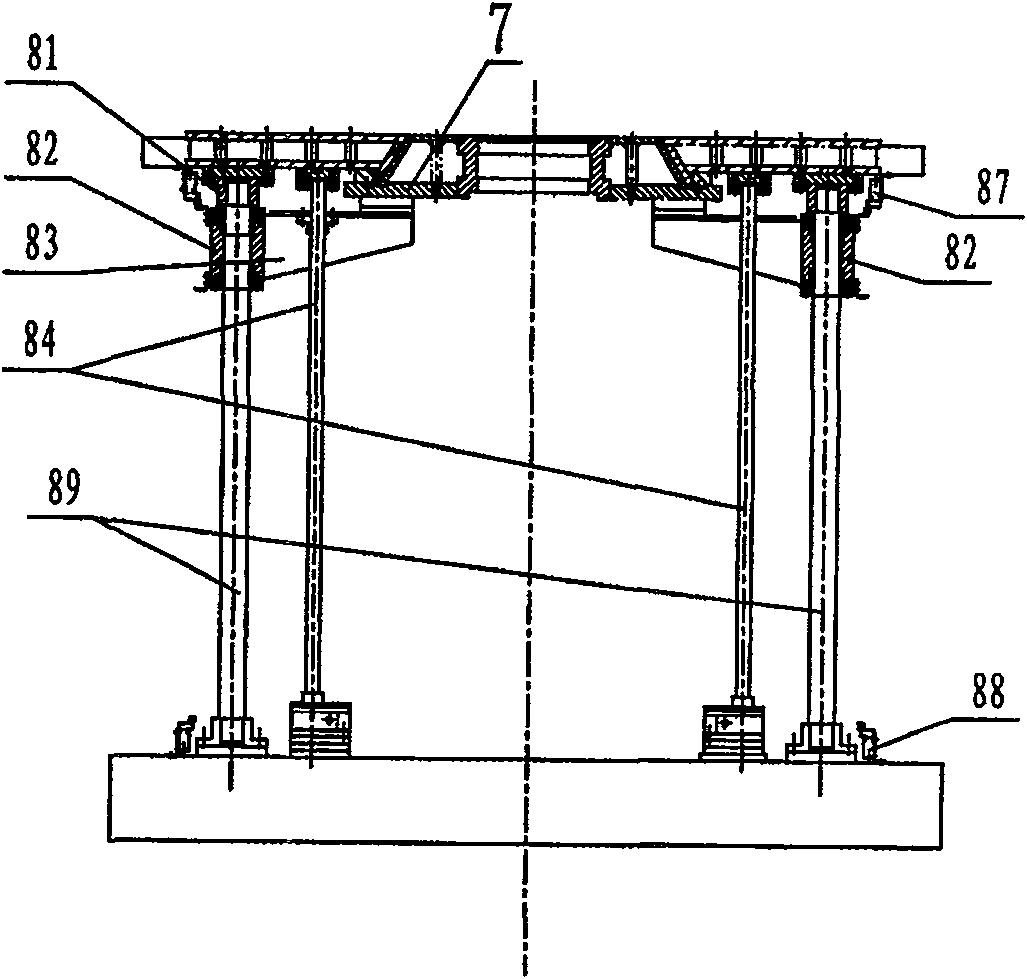

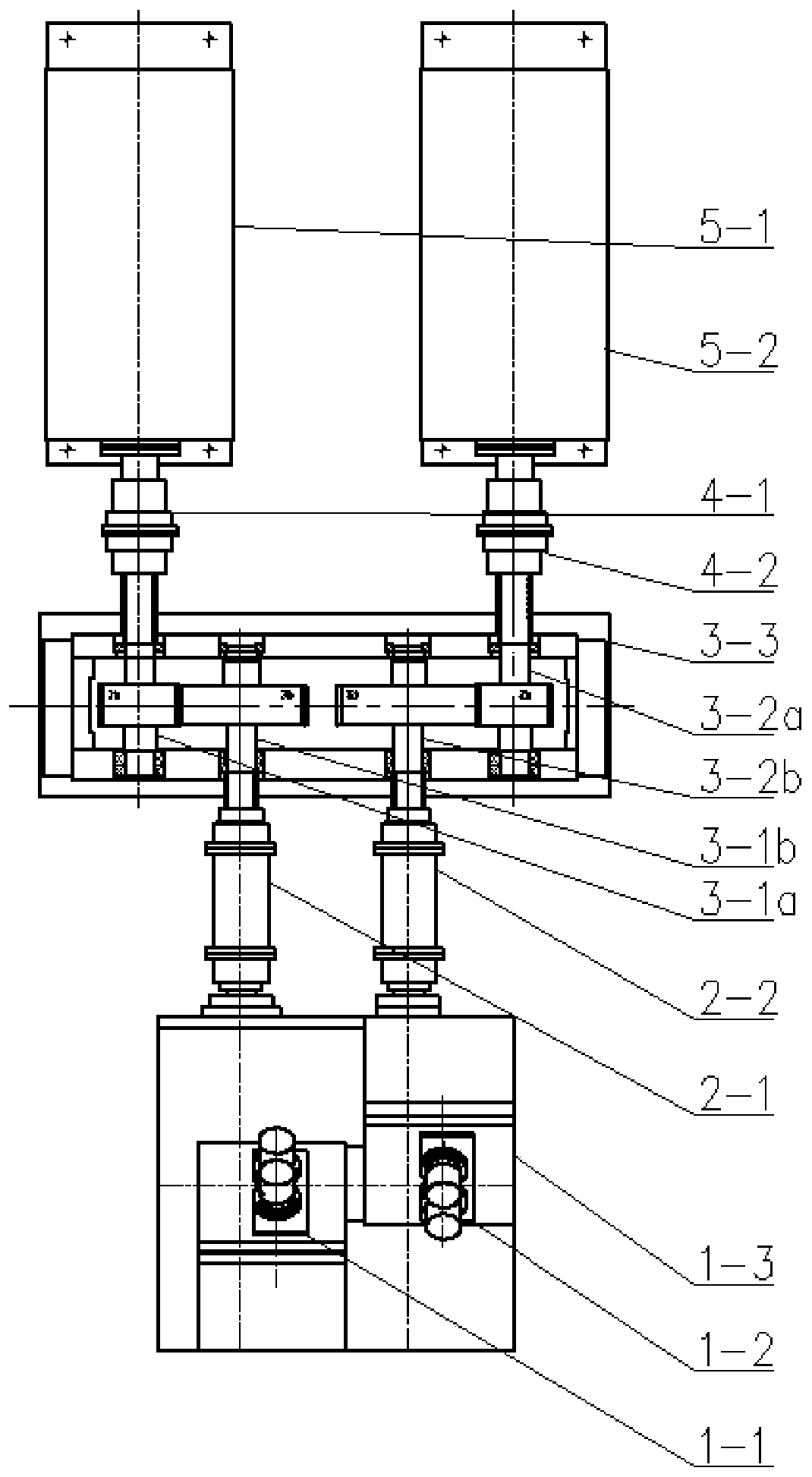

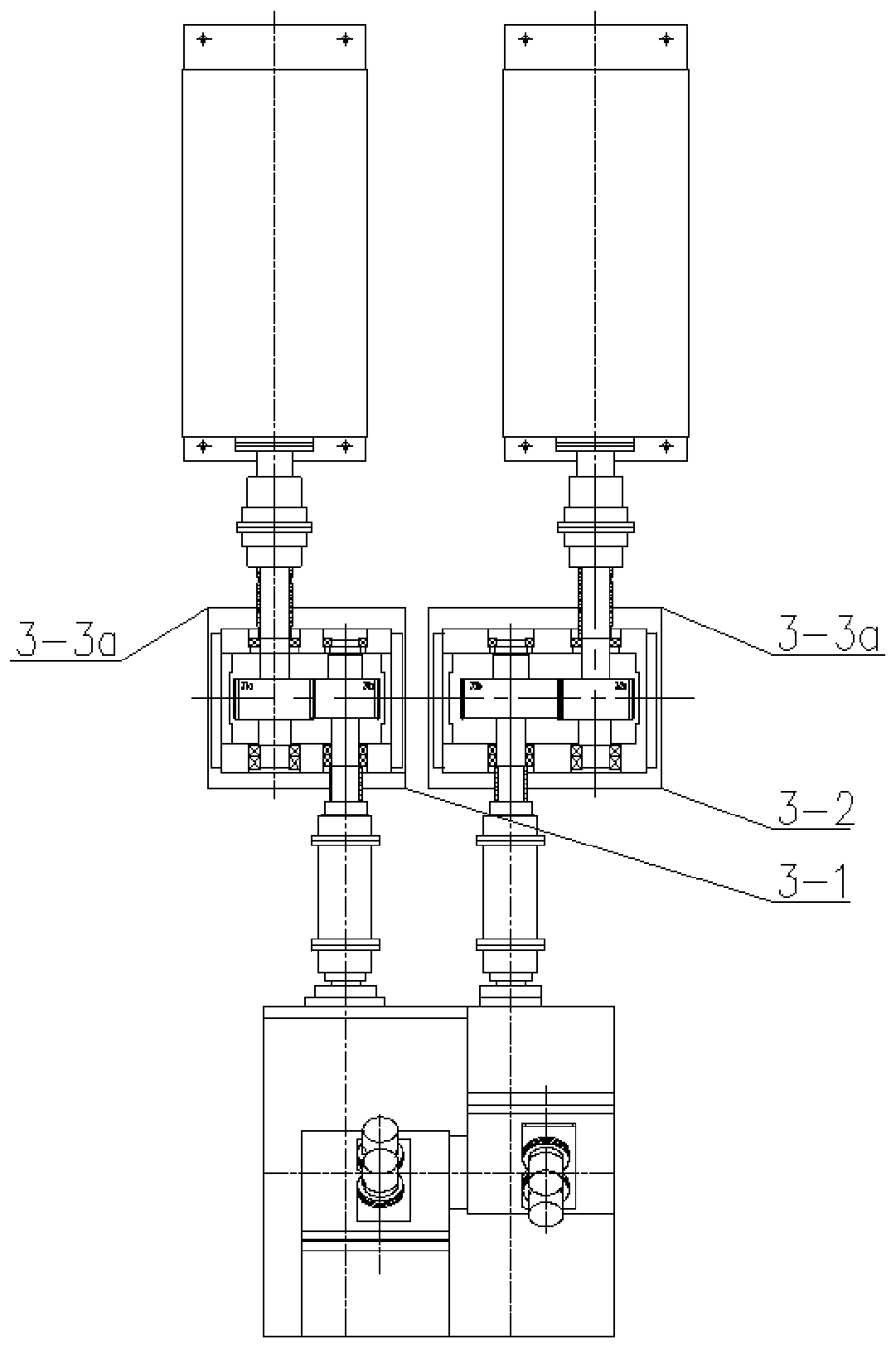

Large-sized vacuum hotpressing stove

InactiveCN101118112AGuaranteed synchronicityLifting height can be adjusted at willMuffle furnacesInduction heatingSusceptorGraphite

The present invention relates to a large vacuum hot pressing furnace, which comprises an electric furnace main body. The electric furnace main body comprises a furnace casing, a furnace casing bottom elevating device and an induced heating device; the furnace casing bottom elevating device comprises a material loading elevating platform, an electrical motor, three plane guideposts supported on the bottom part of the material loading elevating platform, and two adjusting screw rods driven by the same electrical motor; the induced heating device comprises an inductor and a furnace lining; a fire-resisting heat-insulating layer and an electric insulation later are arranged around the furnace lining structure arranged between the induction coil and the graphite heating cylinder of the inductor. The vacuum hot pressing furnace can make the material feeding and discharging process more safe and reliable, and meets requirements of the vacuum sealing performance and improves the planeness of the material loading elevating platform evidently. The adaptation of the induction heating method can make the temperature-rising speed improved significantly, and because the heating element is a graphite susceptor cylinder, which has strong intensity under high temperature, even if the graphite mold breaks under the pressing condition, the heating element can not be damaged.

Owner:SHANGHAI ZHONGJIA ELECTRIC FURNACE

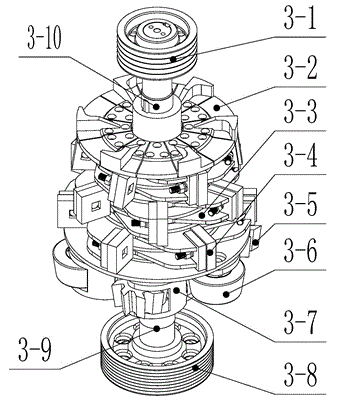

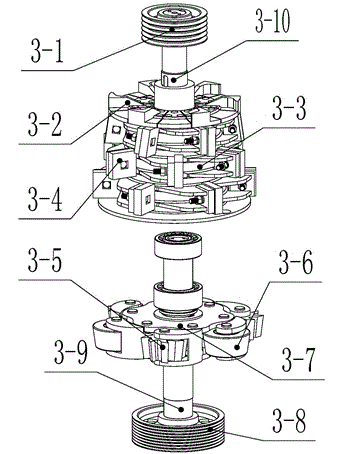

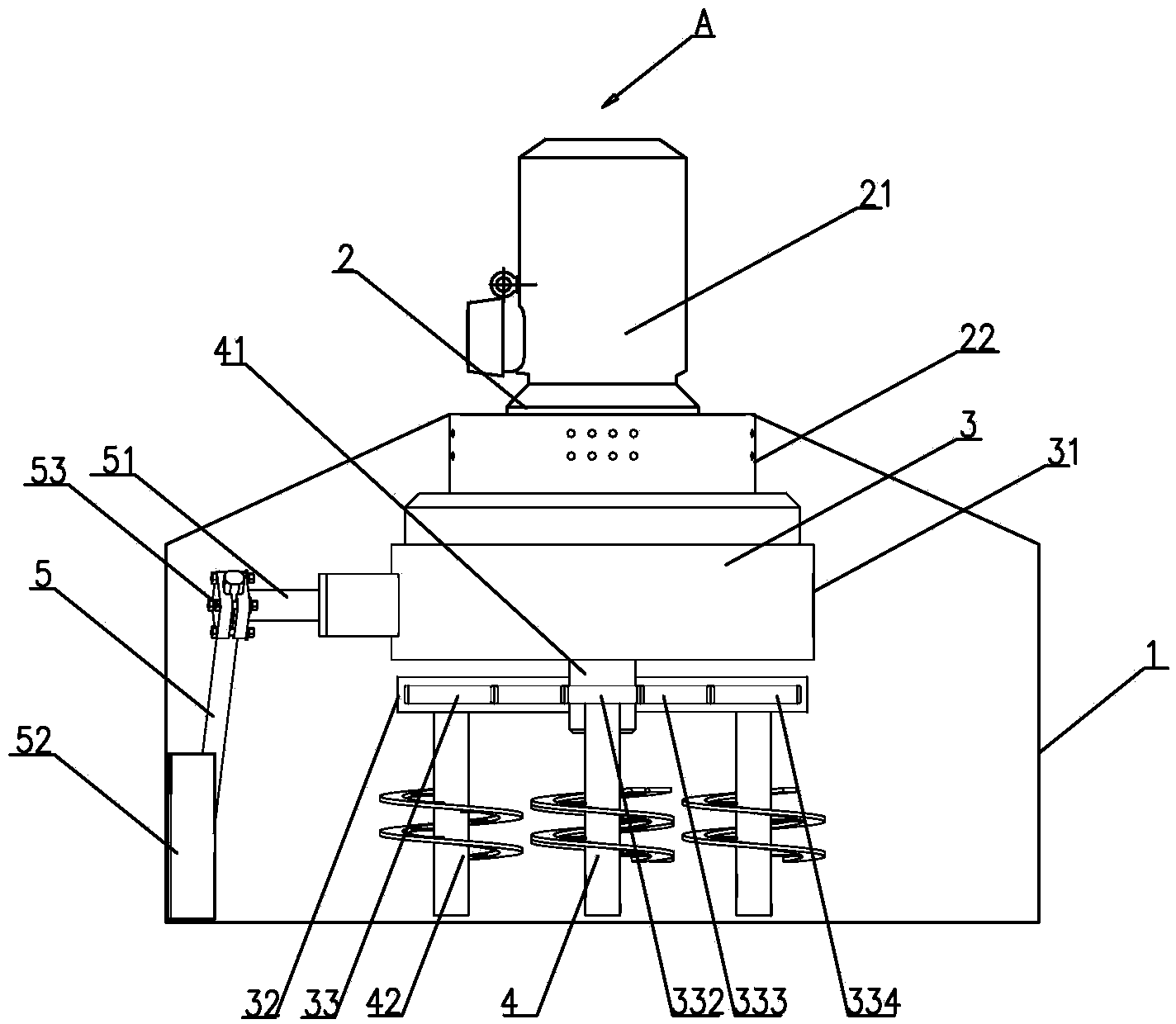

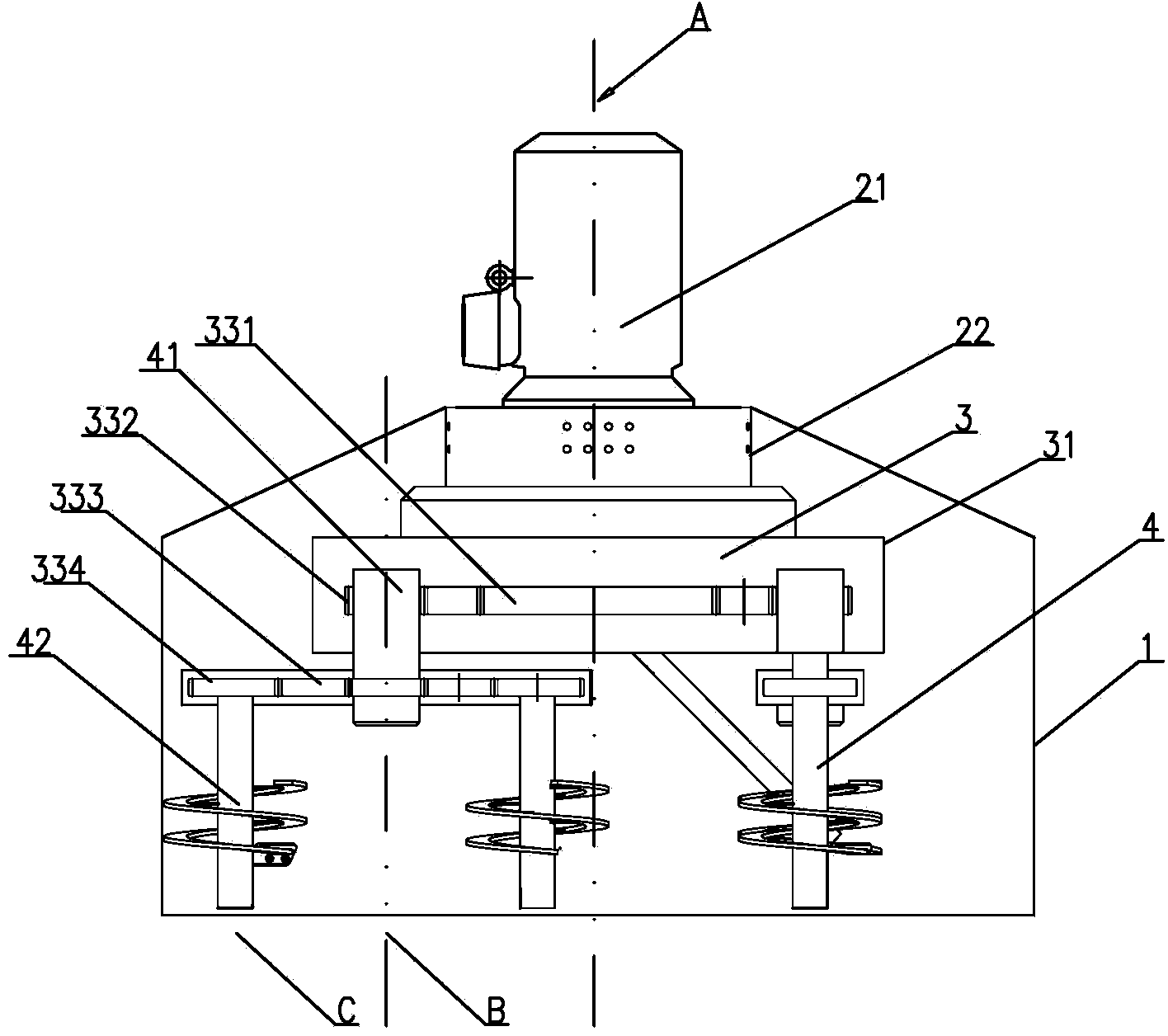

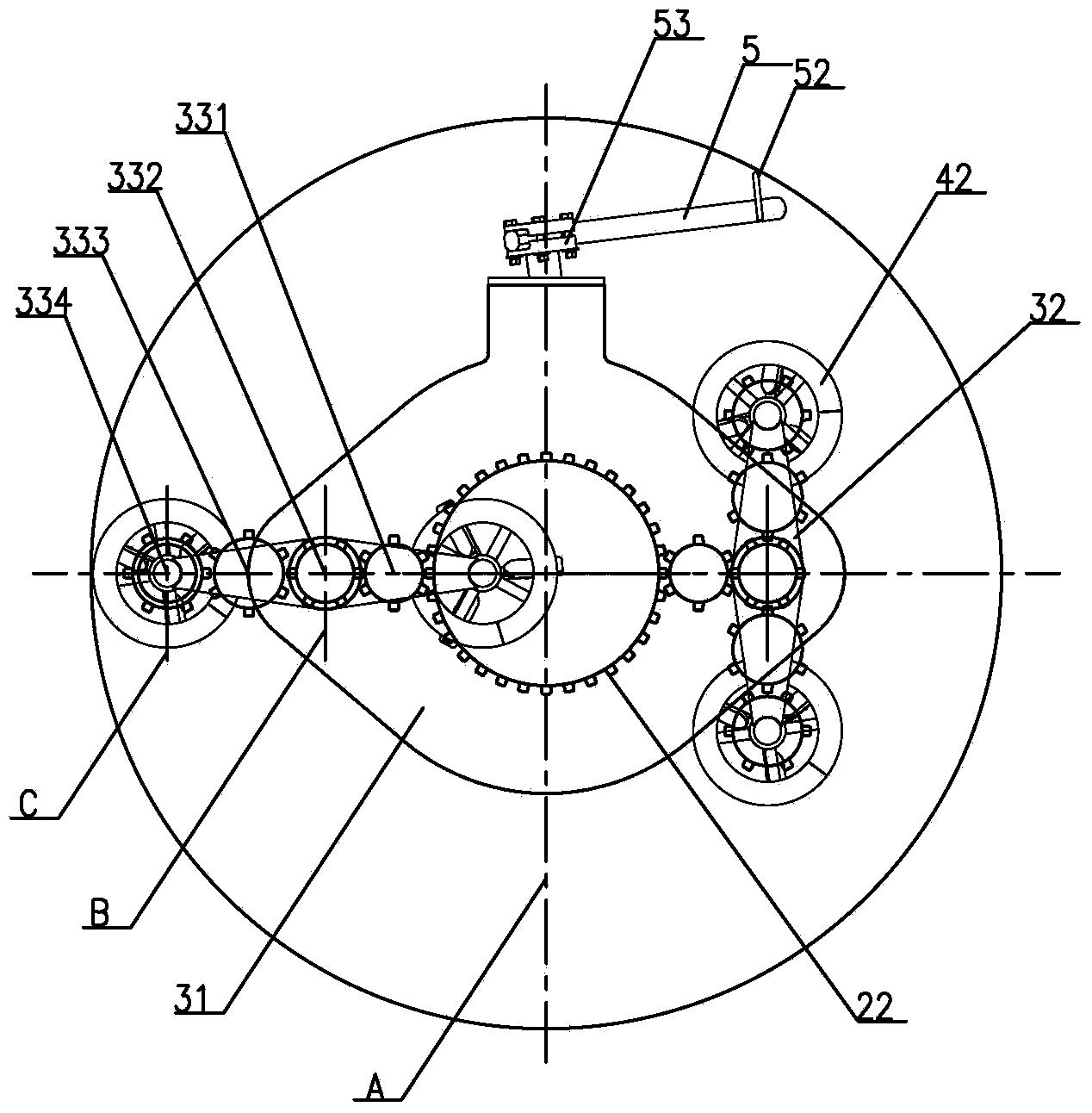

Multi-track vertical-shaft planetary mixer

ActiveCN103817797AFlexible speed adjustmentStir vigorouslyCement mixing apparatusGear wheelEnergy consumption

The invention relates to the technical field of concrete mixing, in particular to a multi-track vertical-shaft planetary mixer. The multi-track vertical-shaft planetary mixer comprises a barrel, a driving mechanism arranged on the barrel as well as a transmission mechanism and a mixing mechanism which are arranged in the barrel, wherein the driving mechanism drives the mixing mechanism through the transmission mechanism. The multi-track vertical-shaft planetary mixer is characterized in that the transmission mechanism comprises a primary revolution rotary disk, a secondary revolution rotary disk and a gear set; and the mixing mechanism comprises mixing shafts and mixing arms. According to the multi-track vertical-shaft planetary mixer, the transmission mechanism and the mixing mechanism adopt combination of two groups of autorotation and revolution forms, so that the rotating speeds of the mixing arms and the mixing shafts can be regulated flexibly, complicated motion track can be achieved in the barrel, a mixing dead angle is not formed in the barrel, materials are mixed violently, sufficiently and uniformly, further, the mixing time is shortened, energy consumption is reduced, and the mixing efficiency is increased.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

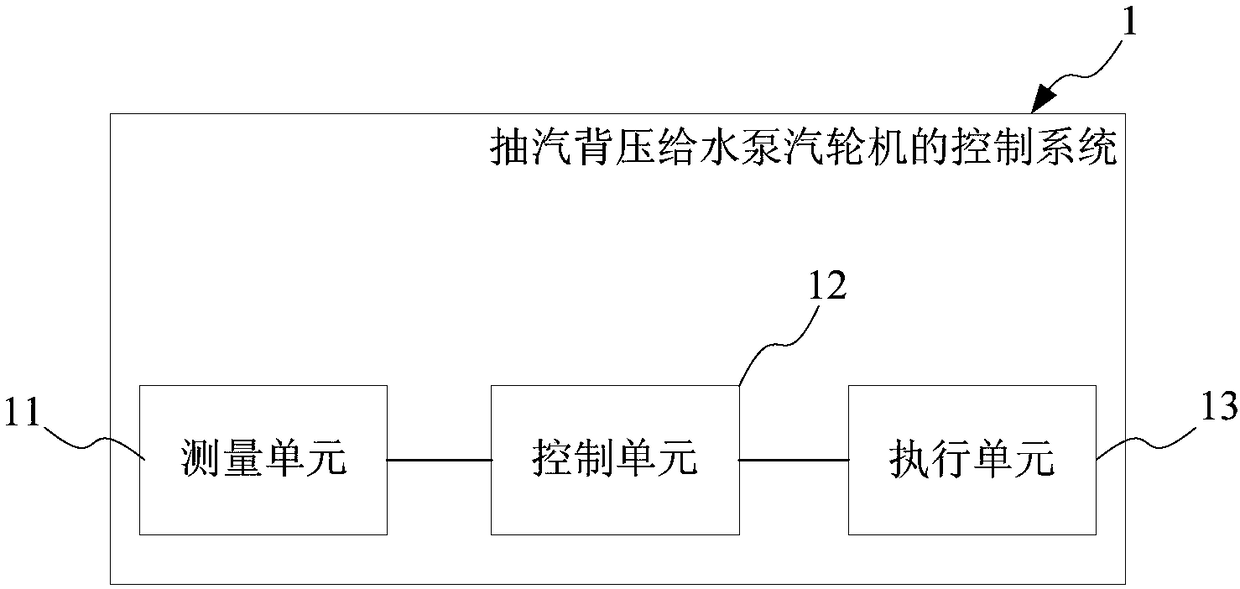

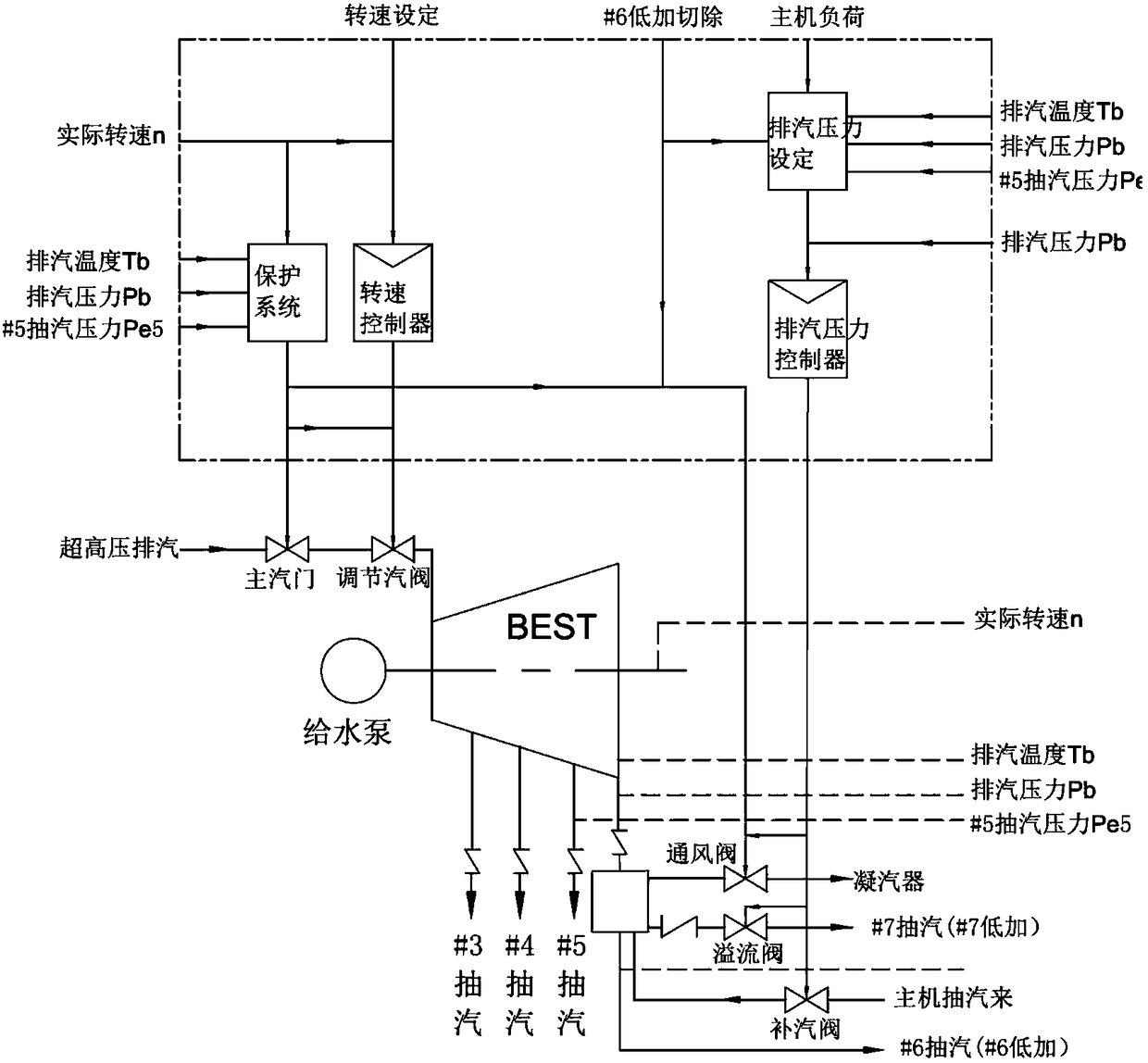

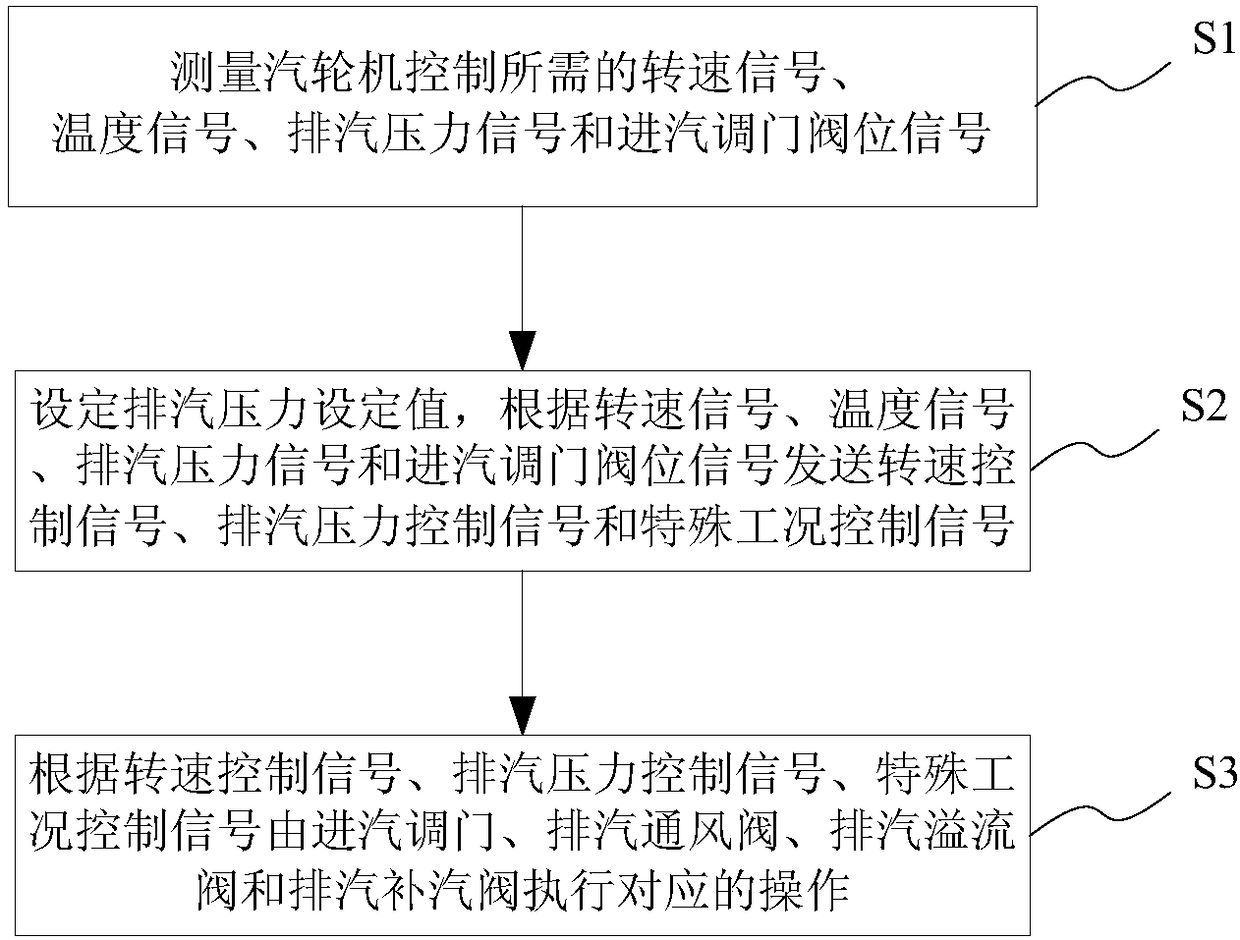

Control system and control method of backpressure extraction steam water-feeding pump turbine and turbine

ActiveCN108240238AMeet the requirements of water supply speedSatisfy extractionMachines/enginesEngine componentsControl signalControl system

The invention provides a control system and a control method of a backpressure extraction steam water-feeding pump turbine and a turbine. The control system of the backpressure extraction steam water-feeding pump turbine comprises a measuring unit, a controlling unit and an executing unit, wherein the measuring unit is used for measuring a rotation speed signal, a temperature signal, a steam exhaust pressure signal and a steam feeding gate valve position adjusting signal; the controlling unit is used for setting a steam exhaust pressure setting value and sending a rotation speed controlling signal, a steam exhaust pressure controlling signal and a special working condition controlling signal to the executing unit according to the rotation speed signal, the temperature signal, the steam exhaust pressure signal and the steam feeding gate valve position adjusting signal sent by the measuring unit; and the executing unit is used for executing corresponding operations according to the rotation speed controlling signal, the steam exhaust pressure controlling signal and the special working condition controlling signal sent by the controlling unit. According to the control system and the control method of the backpressure extraction steam water-feeding pump turbine and the turbine disclosed by the invention, a requirement on water feeding rotation speed of a boiler can be met, and requirements on sucking and exhausting the steam to a heater also can be met.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

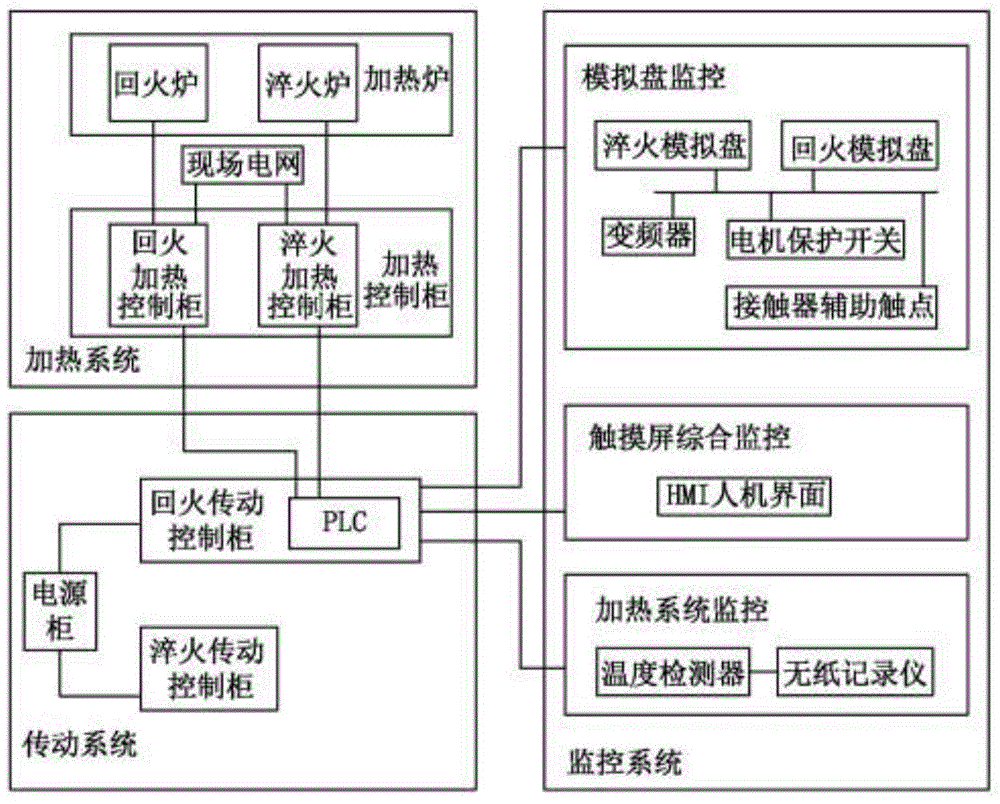

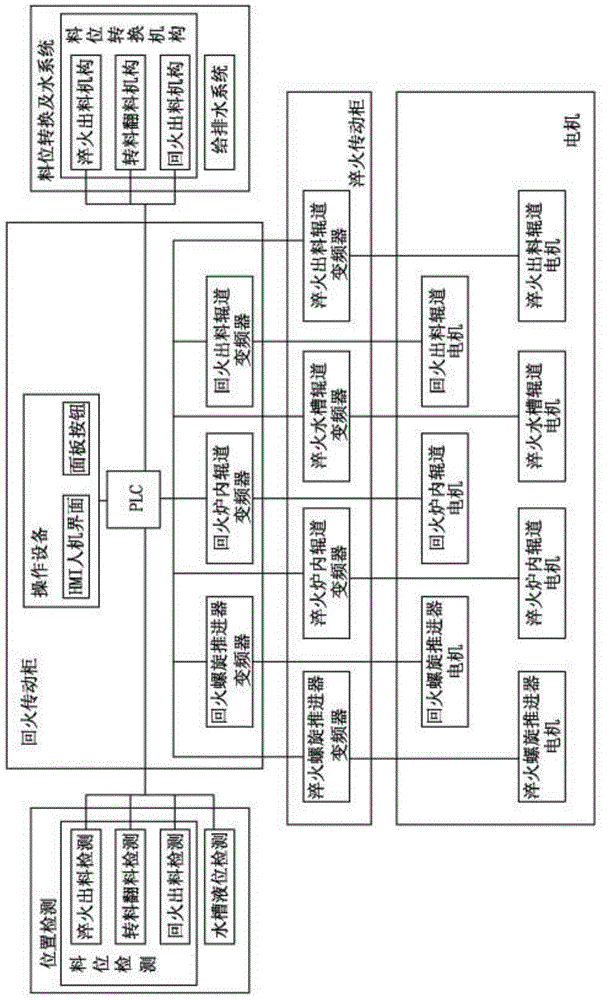

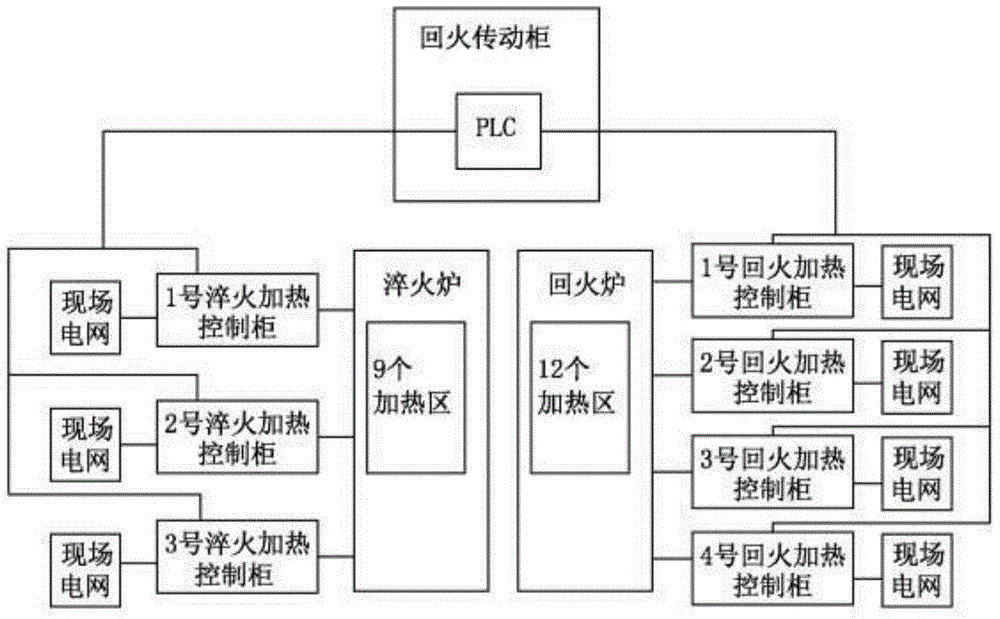

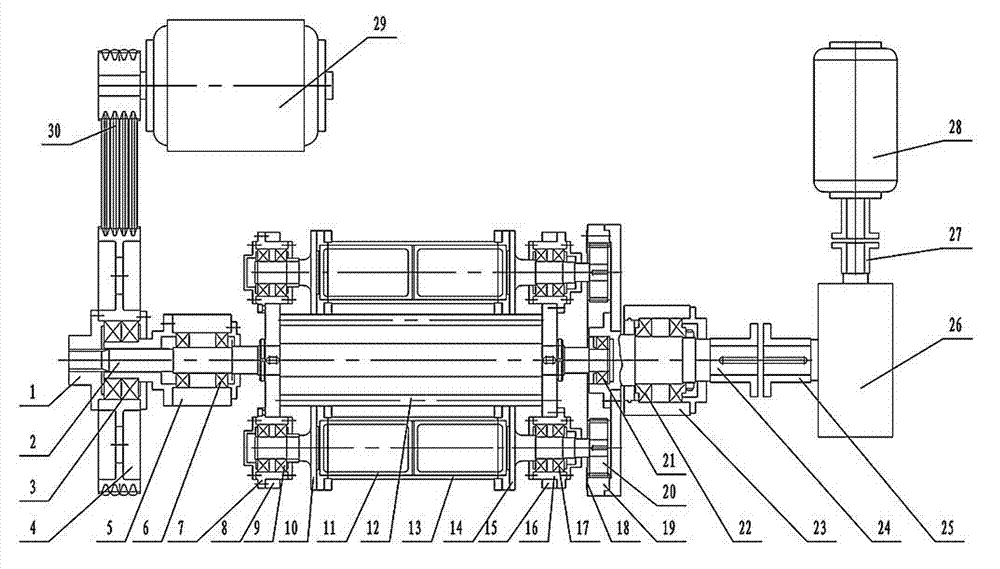

Electrical control system for long bar heating furnace

InactiveCN105112646AImprove versatilityPrecise control of heating timeFurnace typesHeat treatment process controlFrequency changerQuenching

The invention provides an electrical control system for a long bar heating furnace. The system comprises a transmission system, a heating system and a monitoring system, wherein the transmission system comprises a power cabinet, a tempering transmission cabinet, a quenching transmission cabinet, a position detector, a material position switching and water system and motors, wherein a transducer, a PLC and an operating device are arranged in the tempering transmission cabinet and sequentially connected; the transducer is connected with the corresponding motor; the heating system comprises a heating control cabinet and a heating furnace; the monitoring system comprises a simulating plate monitor, a touch screen integral monitor and a heating system monitor; the transmission system, the heating system and the monitoring system are connected through the PLC. According to the system, the heating, quenching and tempering of a workpiece can be automatically carried out; the workpiece heating time can be accurately controlled and adjusted, so that the operators can be greatly decreased, and the labor intensity can be reduced; meanwhile, an automatic production line of the long bar heating furnace can be monitored in real time and remotely diagnosed.

Owner:LUOYANG XINSILU ELECTRIC

Digital printing transparent tipping paper and making method

InactiveCN106436483AHigh glossHigh digital printing precisionSpecial paperDuplicating/marking methodsPrinting inkWork in process

The invention provides digital printing transparent tipping paper and a making method, and belongs to the technical field of printing. The tipping paper comprises a transparent tipping paper raw paper layer, an underpainting layer, a coating layer, a digital ink layer and a gold stamping substance layer. The making method of the tipping paper comprises a step before printing, wherein transparent tipping paper sample manuscript designing and transparent tipping paper raw paper pretreating are conducted; a printing step, wherein a designed transparent tipping paper sample manuscript is input into digital printing equipment, and printing is conducted on transparent tipping paper raw paper; a step after printing, wherein gold stamping, die cutting and winding treating are conducted on a semi-finished transparent tipping paper product. According to the digital printing method of the transparent tipping paper, a printing plate does not need to be manufactured, therefore, the cost of materials and dies is reduced, and environmental pollution brought by an electroplating technology in the plate manufacturing process is eliminated; the transparent tipping paper is printed by adopting digital printing, the printed ink layer is thin and uniform in distribution, relatively less ink is consumed, patterns and characters are fine and exquisite, and the advantages of being bright in appearance and high in glossiness and smoothness of the transparent tipping paper are reasonably utilized.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY +1

High energy horizontal planetary ball milling equipment for production of nanometer traditional Chinese medicine powder

InactiveCN102773134AImprove work efficiencyReduce manufacturing costGrain treatmentsGear transmissionHigh energy

The invention relates to a high energy horizontal planetary ball milling equipment for production of nanometer traditional Chinese medicine powder. The equipment comprises a main motor, a driving belt, belt wheels, a main shaft, a left wheel disc, a left half axle, a right half axle, ball milling jar sleeves, a right wheel disc, a planetary gear, an internal gear, an internal gear transmission shaft, a first shaft coupling, a worm and gear speed reducer, a second shaft coupling and a vice-motor, wherein the main shaft is horizontally disposed, a plurality of the ball milling jar sleeves are horizontally disposed and are circumferentially and uniformly arranged around the main shaft and between the left wheel disc and the right wheel disc, the main motor is driven by the driving belt and drives the main shaft to rotate, circular rotation of the ball milling jar sleeves around the axis of the main shaft is realized through the rotation of the main shaft, the left wheel disc and the right wheel disc, the ball milling jar sleeves are connected with the right half axle, the planetary gear on the right half axle is engaged with the internal gear, the internal gear is arranged on the internal gear transmission shaft, and the vice-motor drives the internal gear to rotate through the worm and gear speed reducer.

Owner:CHANGCHUN CHAOWEI PHARMA TECH DEV

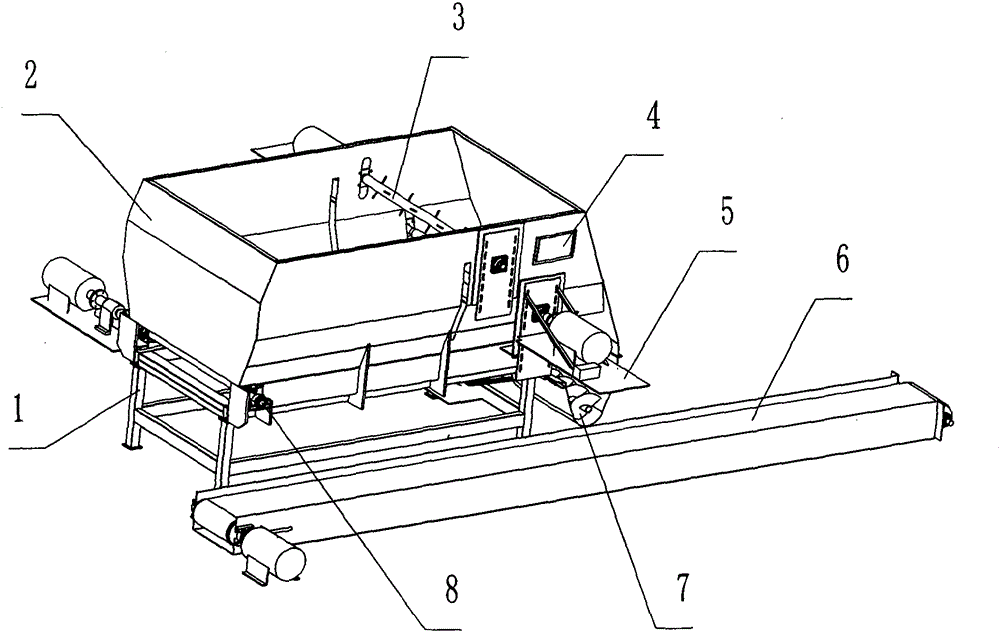

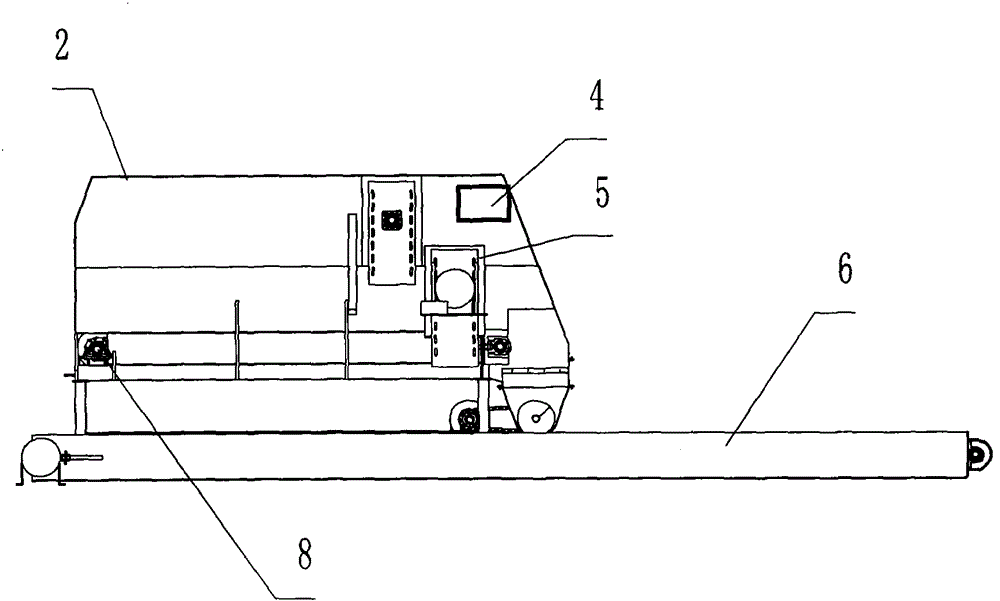

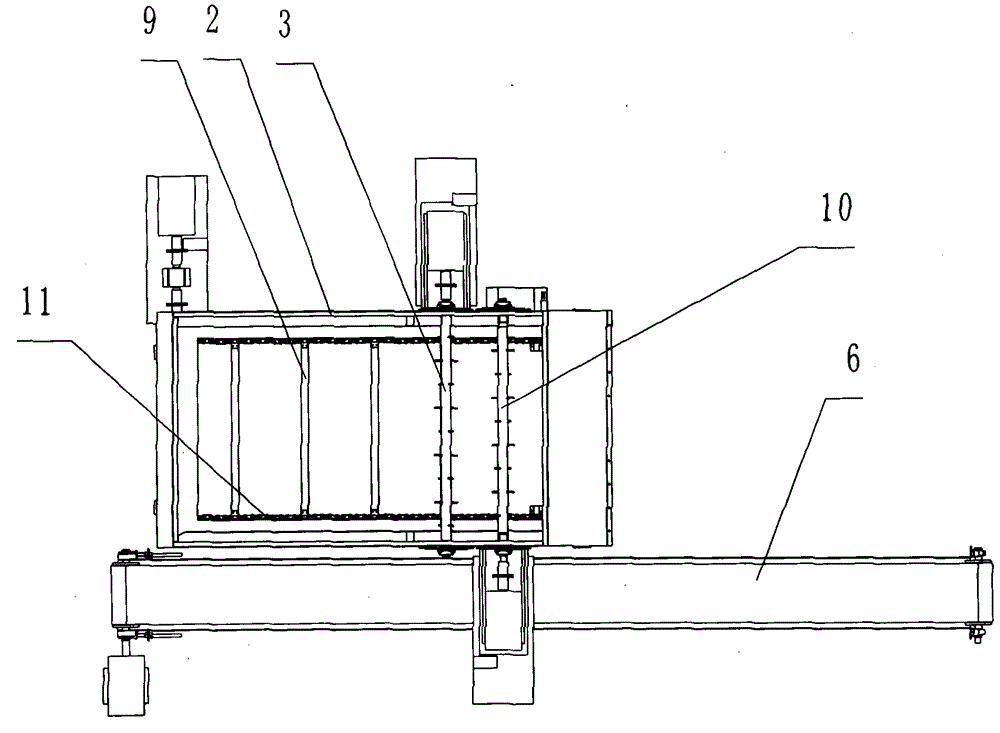

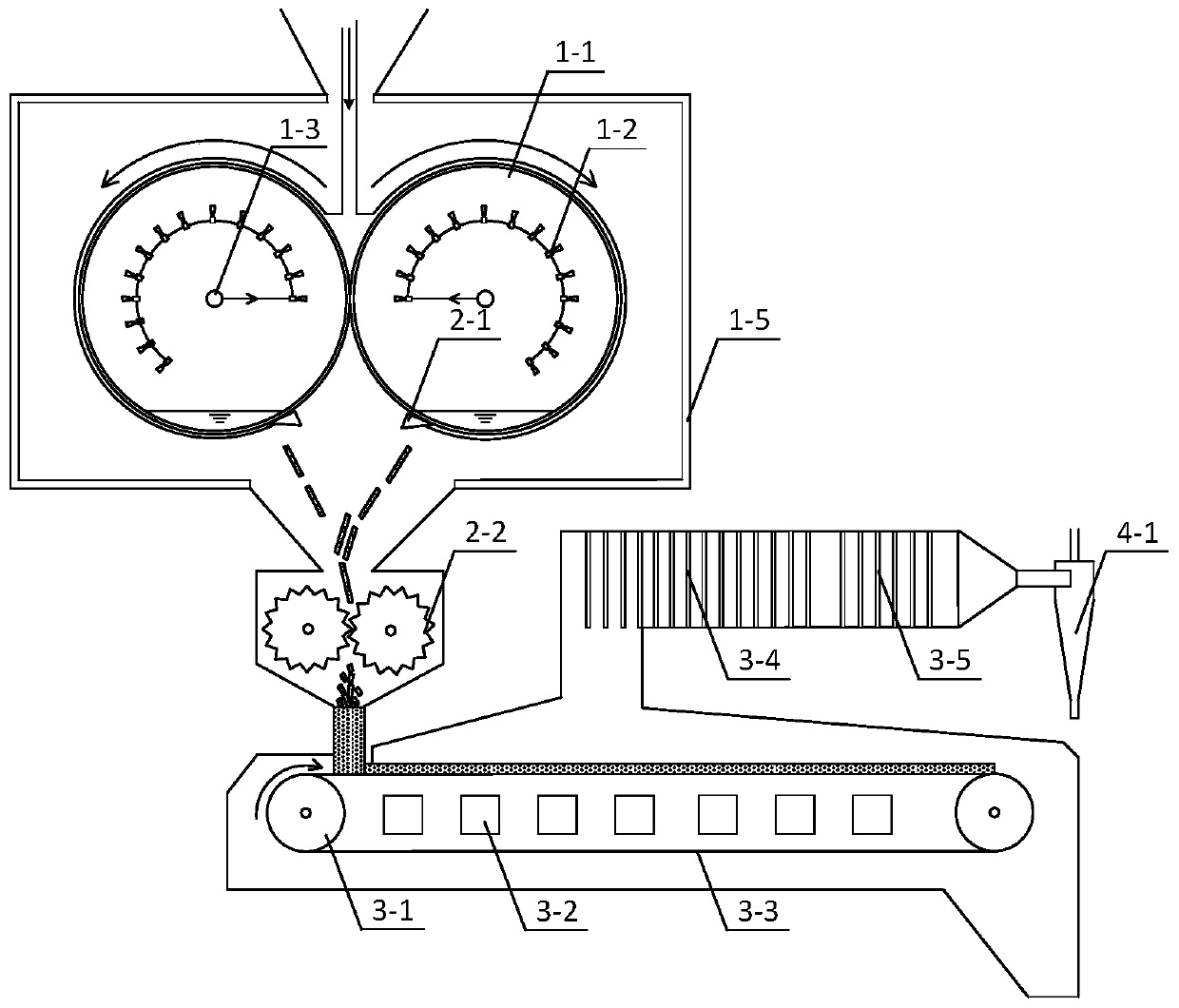

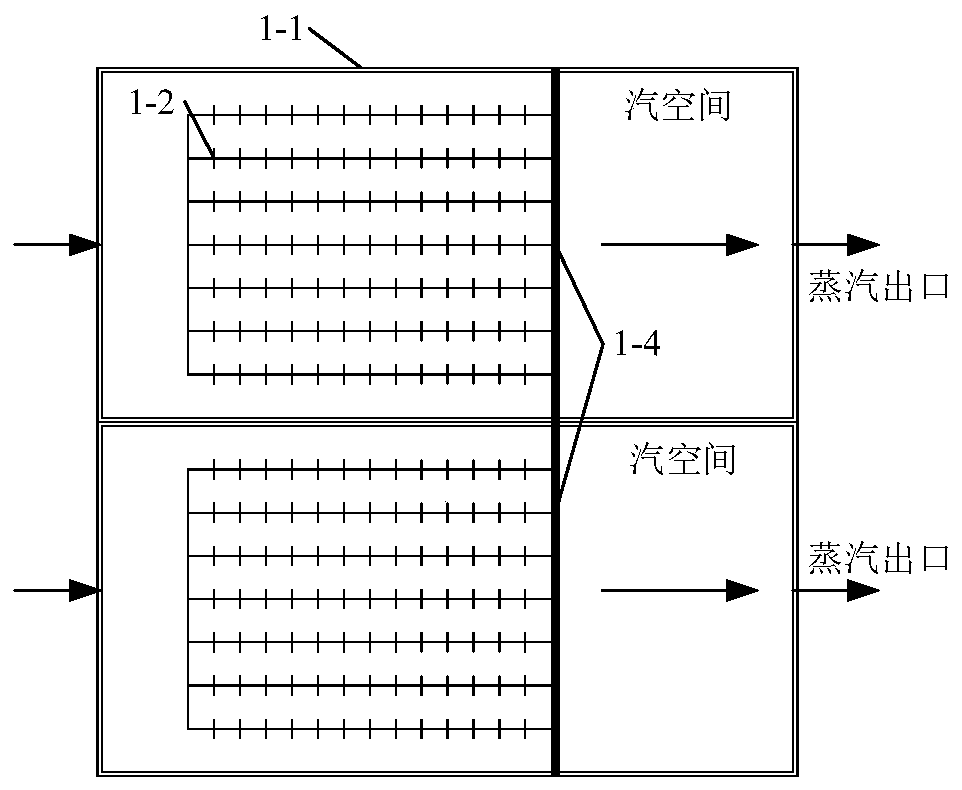

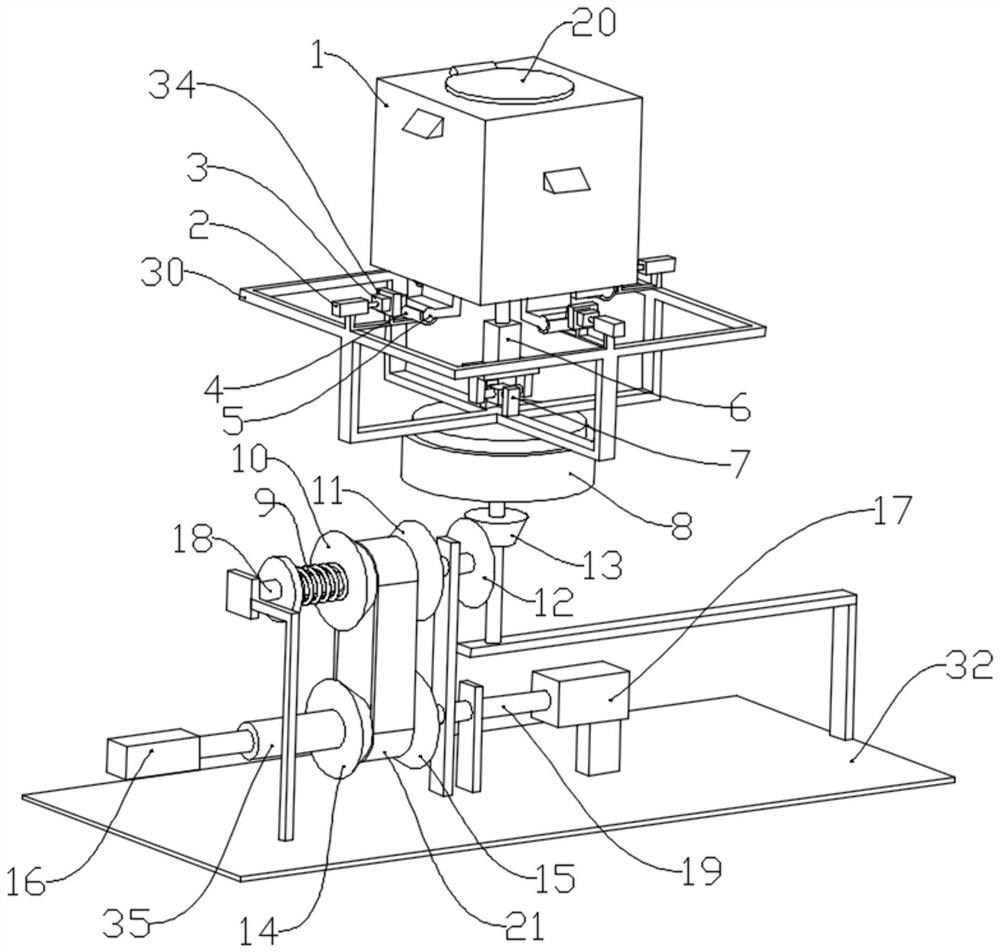

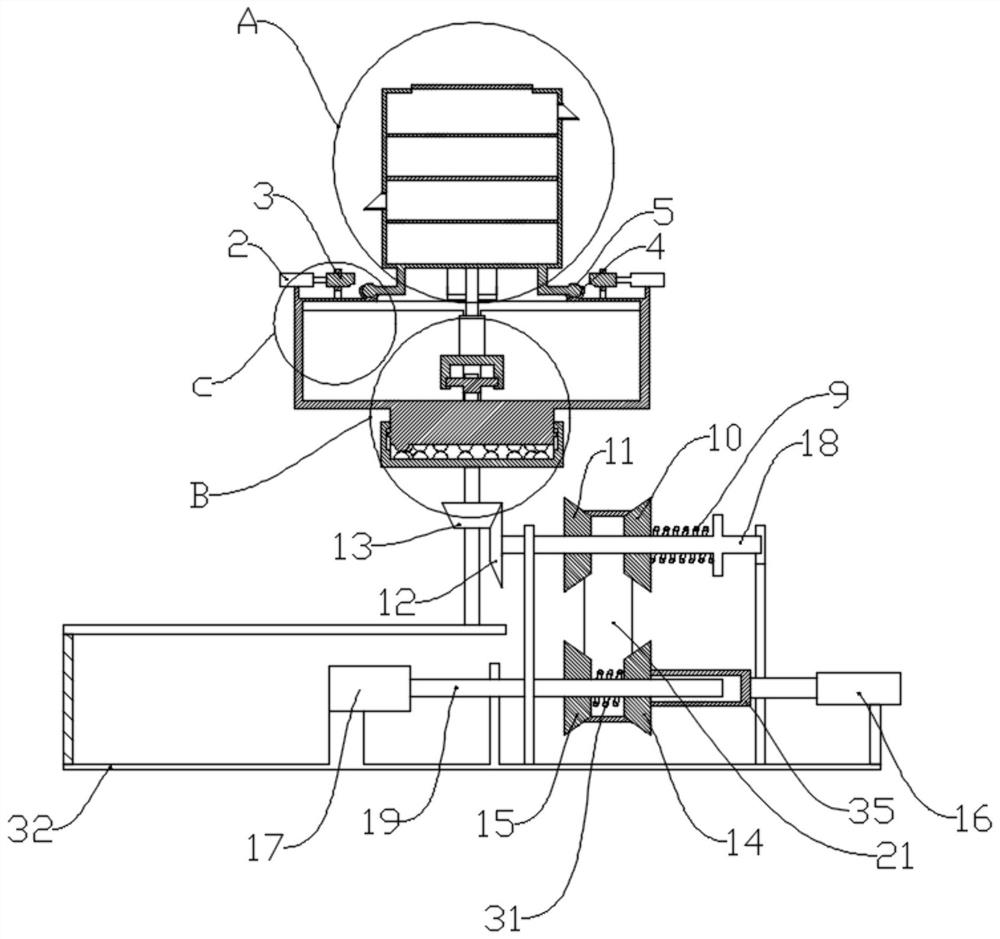

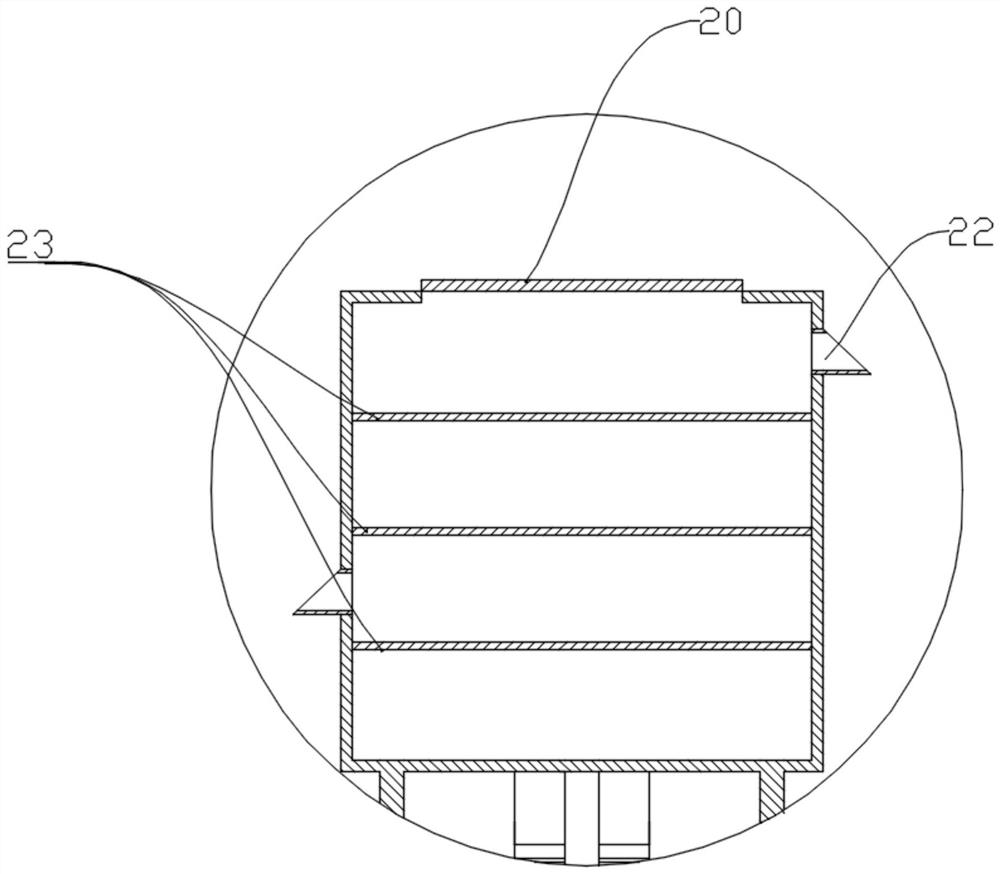

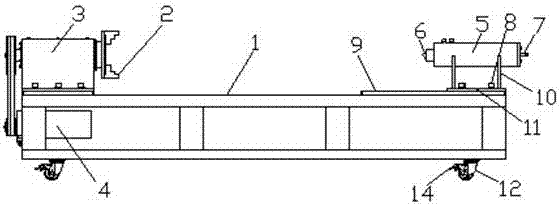

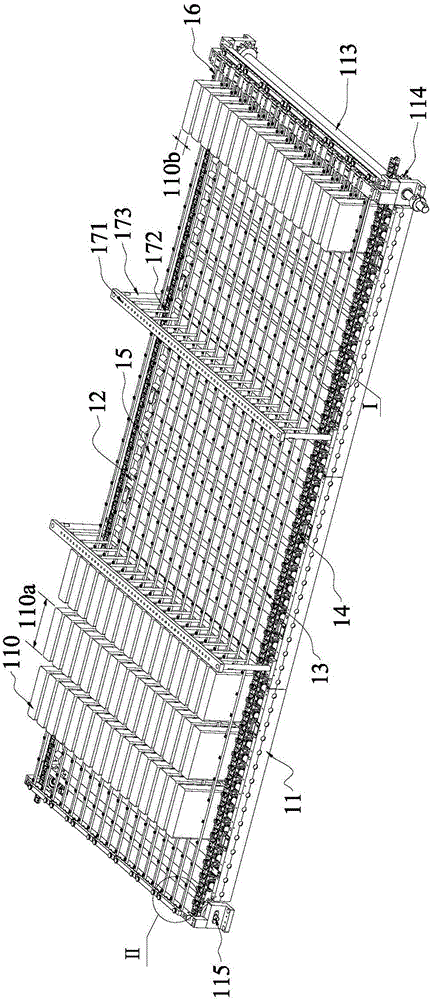

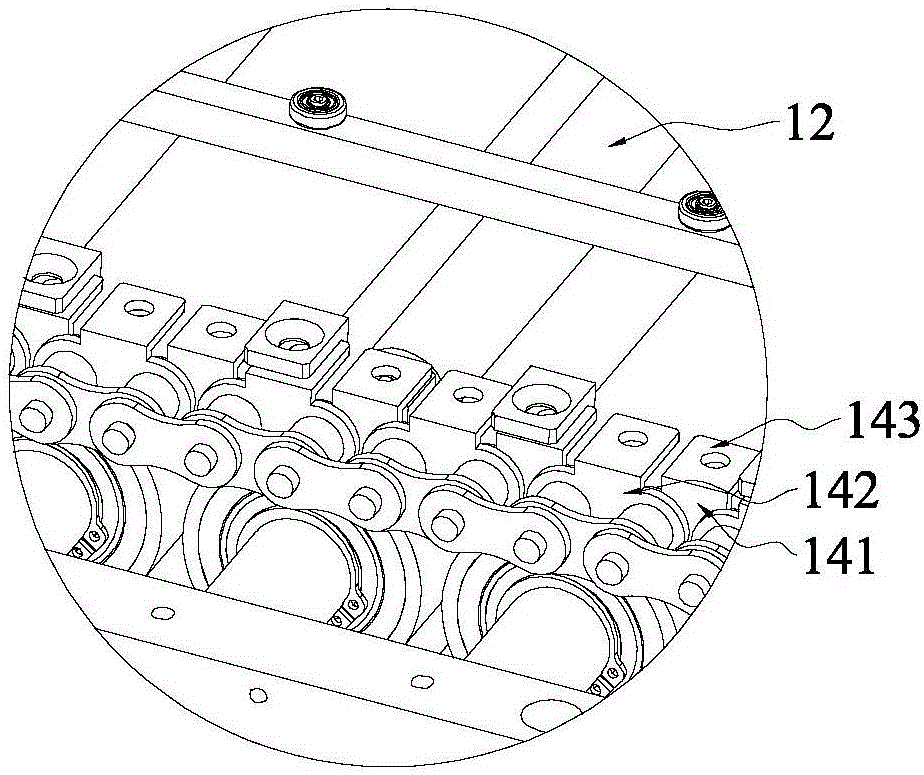

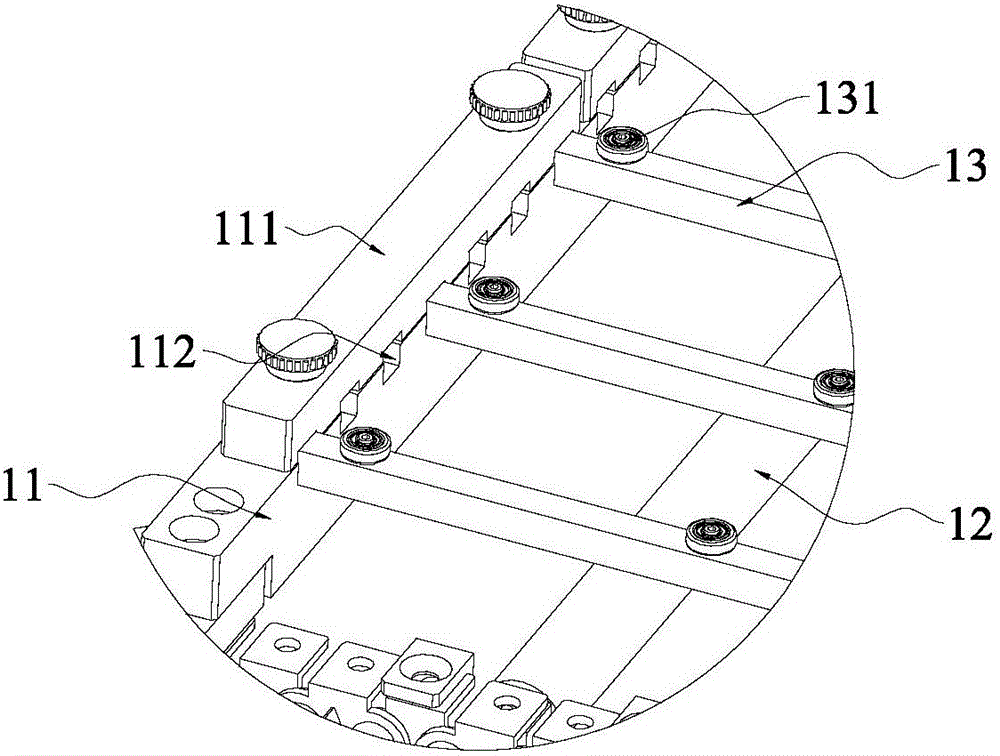

Livestock feed casting test stand

InactiveCN105059962AFlexible speed adjustmentFlexible adjustment of spacingConveyorsLoading/unloadingHeifer calfRelative motion

The invention relates to a livestock feed casting test stand. The livestock feed casting test stand is characterized in that the test stand comprises a support; a material box is arranged on the support; scrapers are arranged inside the material box; a driving chain is arranged at the two ends of the scrapers; the rear part of the inside of the material box is provided with a baffle roller, a shifting roller and a feed casting auger sequentially from top to bottom; a weighing sensor is arranged between the support and the material box; a weighing display screen is disposed on the wall of the material box. The livestock feed casting test stand is a feed casting test stand of a cattle and sheep feeding car; the test stand can flexibly adjust rotating speeds of a scraper conveyor spindle, a feeding auger, the baffle roller and the shifting roller through a frequency converter; the interval of the scrapers can be adjusted through selection of different chain lugs; the position height of the baffle roller and the shifting roller of a feed casting car can be flexibly adjusted through moving of a device support; traveling feed casting of the feed casting car is simulated through relative motion of a static rack and belt conveyor driving.

Owner:SHIHEZI UNIVERSITY +1

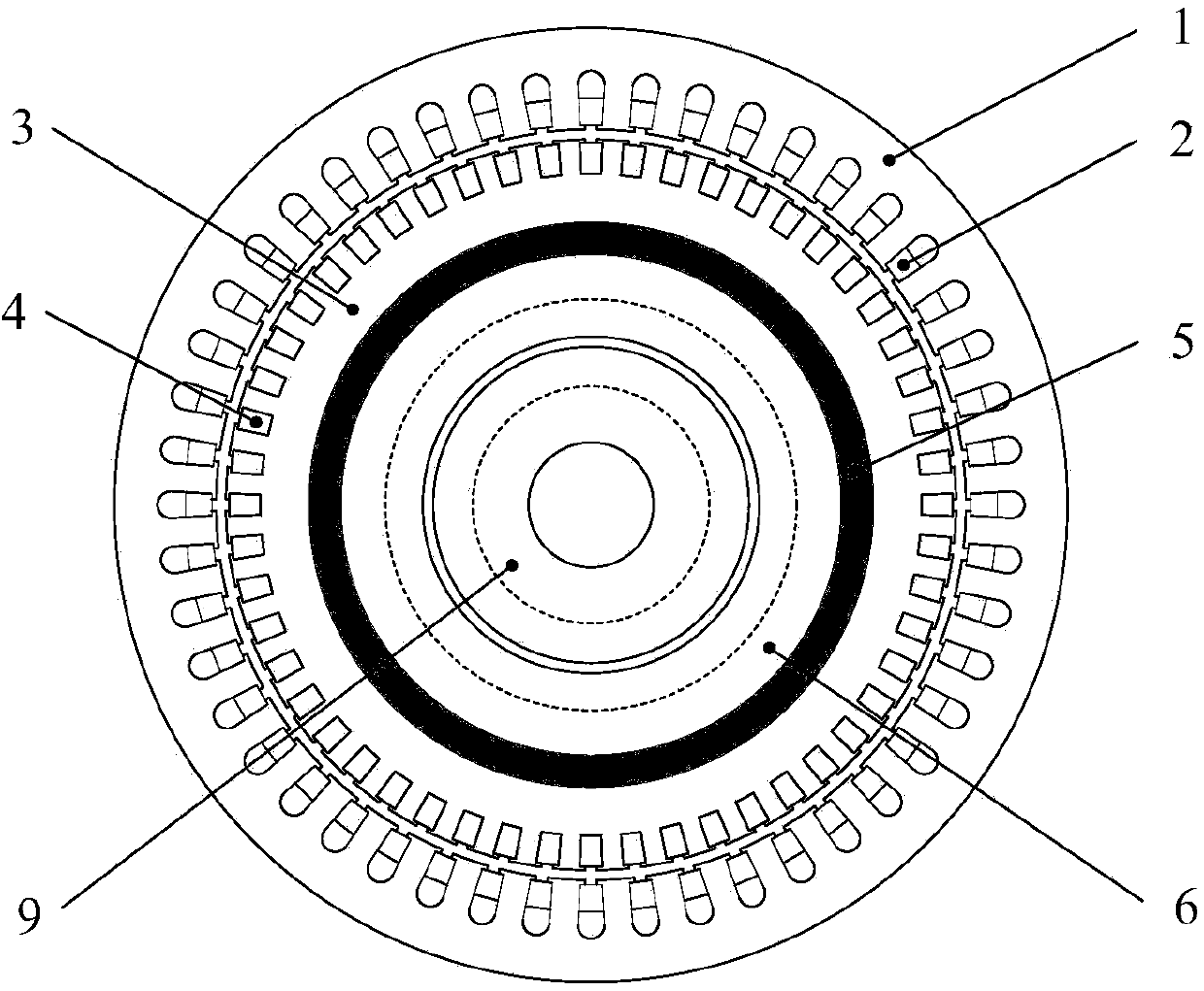

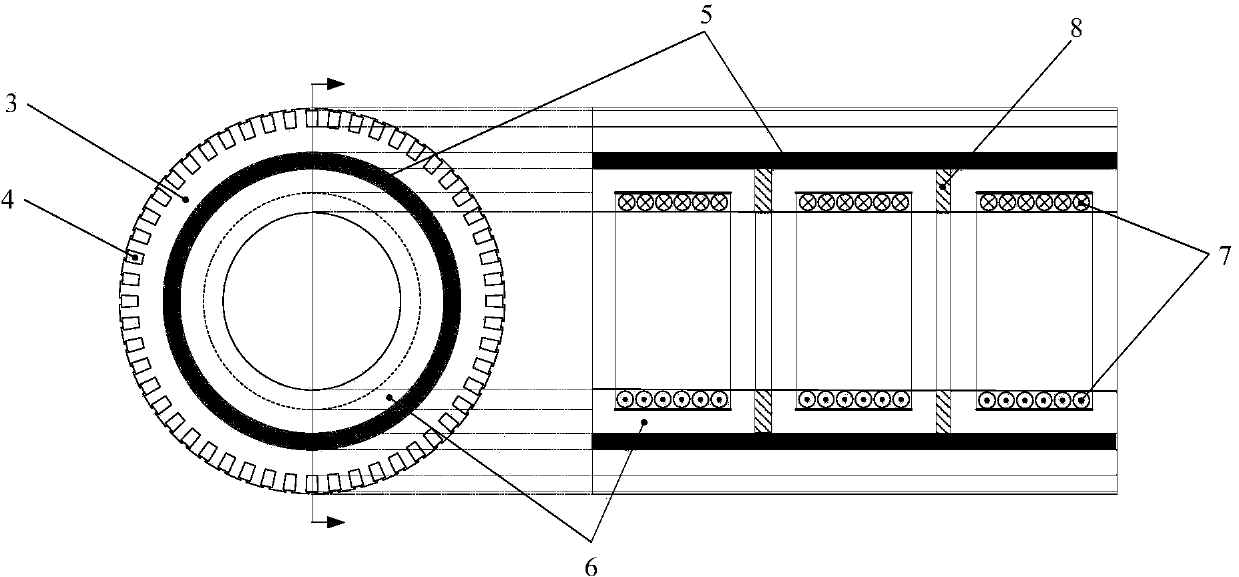

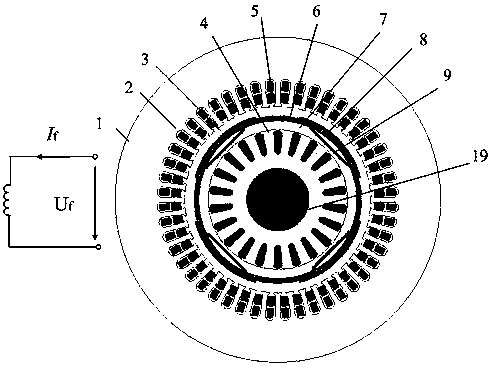

Separable transformer type double-stator brushless double-fed motor

InactiveCN104201849AImprove reliabilityFlexible speed adjustmentDynamo-electric machinesTransformerElectric machine

The invention discloses a separable transformer type double-stator brushless double-fed motor which comprises an outer stator, a cup-type rotor, an inner stator and a rotating shaft sequentially from outside to inside. The outer stator, the cup-type rotor and the inner stator are coaxial and independent from one another, the rotor is fixed on the rotating shaft, an outer air gap is formed between the outer stator and the cup-type rotor, and an inner air gap is formed between the rotor and the inner stator. The separable transformer type double-stator brushless double-fed motor is of a novel motor structure provided based on a brush double-fed motor operating principle through structural equivalence. A separable transformer composed of the inner layer of the rotor and the inner stator transmits rotor current and voltage of the double-fed motor to the side of the inner stator in a contactless mode, and accordingly functions of an existing brush double-fed motor are realized completely; however, an electric brush slip ring, low in reliability and needing scheduled maintenance, in the brush double-fed motor is omitted, thus the separable transformer type double-stator brushless double-fed motor has high application value in high-reliability, maintenance-free, low-cost variable-frequency speed control occasions.

Owner:SOUTHEAST UNIV

High-temperature waste heat recovery system adopting two-roller method

PendingCN109750127ARealize cascade utilizationFlexible speed adjustmentEnergy inputCalcium carbideProcess engineeringThermal energy

The invention discloses a high-temperature waste heat recovery system adopting a two-roller method. The high-temperature waste heat recovery system is composed of a cooling solidification unit, a peeling and crushing unit, a moving bed waste heat recycling unit and a gas purification unit. The high-temperature waste heat recovery system has the effects that industrial high-temperature waste heat is efficiently utilized, and a product is formed while high waste heat recovery efficiency and system flexibility and the high cooling speed are guaranteed; the double-roller method and a moving bed waste heat recycling device are combined, compared with a traditional waste heat recovery technology adopting the two-roller method, the temperature of the final product can be significantly decreased,and the utilization efficiency of heat energy is improved; a crusher is additionally arranged, and thus under the premise of guaranteeing the heat exchange efficiency of a moving bed, the product is crushed to be formed; and the gas purification unit is additionally arranged, and thus particulate matter in exhaust gas is removed.

Owner:XI AN JIAOTONG UNIV

Sieve shaker

The invention discloses a sieve shaker. The sieve shaking machine comprises a storage cavity and a supporting frame; the storage cavity is of a hollow cavity structure, and a filter screen is arrangedin the storage cavity; the interior of the storage cavity is divided into a plurality of cavities by the filter screen, and the mesh number of the filter screen is gradually increased from top to bottom; four rotating shafts A are arranged at the bottom of the storage cavity; the supporting frame is provided with a supporting block, a pressing block and a first hydraulic cylinder corresponding tothe rotating shafts A; a through groove A is arranged on the supporting block, the inner wall of the through groove A is in sliding fit with the side walls of the rotating shafts A; a cylinder body of the first hydraulic cylinder is connected with the supporting frame, and a piston rod of the first hydraulic cylinder is connected with the pressing block; the supporting frame is provided with a second hydraulic cylinder, a piston rod of the second hydraulic cylinder is coaxial with the storage cavity, a cylinder body of the second hydraulic cylinder is connected with the supporting frame through a universal joint coupling, and the piston rod of the second hydraulic cylinder is connected with the storage cavity through a spherical universal joint, so that the storage cavity rotates around acertain rotating shaft A; a discharging channel is arranged in the storage cavity; and a sieve shaking mechanism is arranged at the bottom of the supporting frame. The device of the invention can perform multi-stage screening at the same time.

Owner:四川大学锦城学院

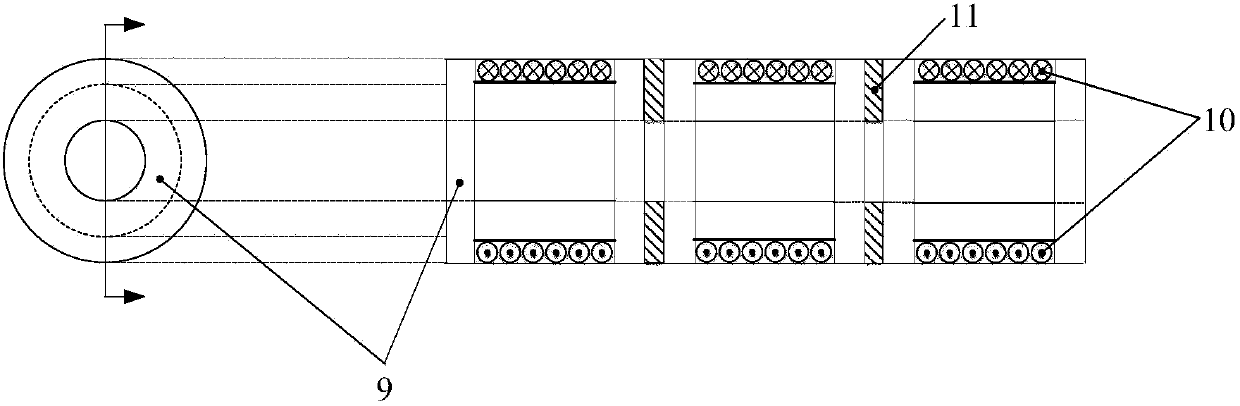

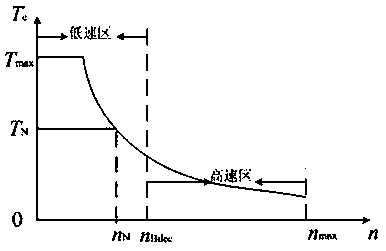

Double-rotor generator and control method thereof

ActiveCN110492710ASmall currentChanging the air gap flux densitySynchronous machinesGenerator control by field variationPermanent magnet rotorPower factor

A double-rotor generator includes a machine shell that is rotationally connected with a rotating shaft. A stator is fixedly connected into the machine shell, wherein the rotating shaft is fixedly connected with an inner squirrel-cage rotor, an outer permanent magnet rotor is arranged between the stator and the inner squirrel-cage rotor, the outer permanent magnet rotor is rotatably connected withthe rotating shaft, an outer air gap is arranged between the outer permanent magnet rotor and the stator, and an inner air gap is arranged between the inner squirrel-cage rotor and the outer permanentmagnet rotor. The outer permanent magnet rotor is added in a traditional squirrel-cage induction generator. The outer permanent magnet rotor provides adjustable excitation; therefore, an operating power factor and power density of the generator are improved, the rotating speed of the generator can be adjusted within a wide range, the outer permanent magnet rotor can rotate freely, the rotating speed of the outer permanent magnet rotor and a synchronous rotating magnetic field generated by a stator winding are overlapped, and the current of the stator winding of the generator is reduced.

Owner:QILU UNIV OF TECH

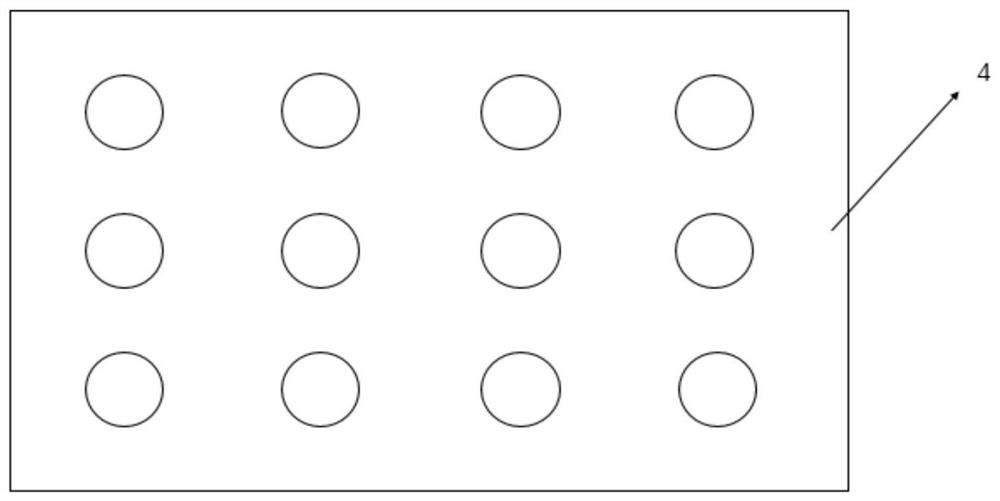

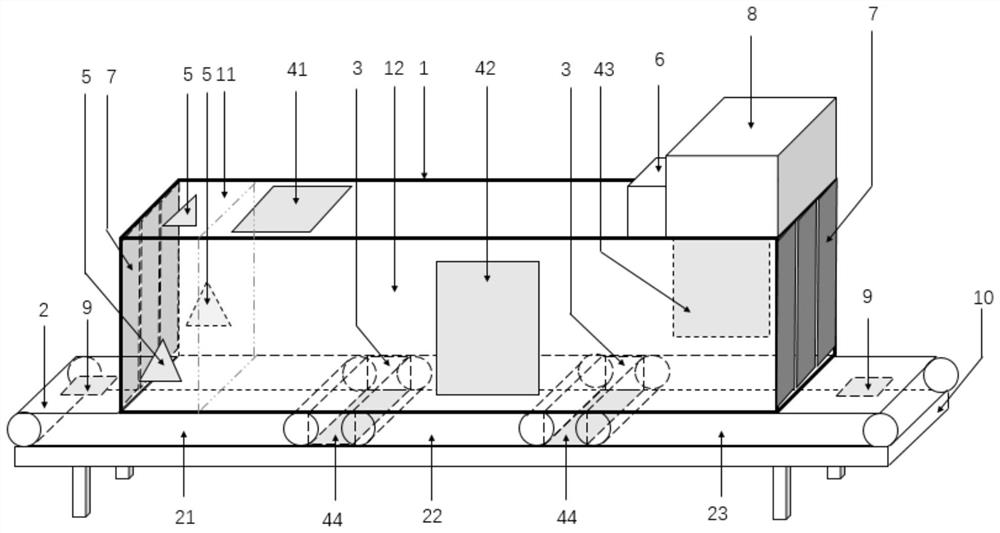

Deep ultraviolet-based all-directional disinfection device for cold chain cargoes

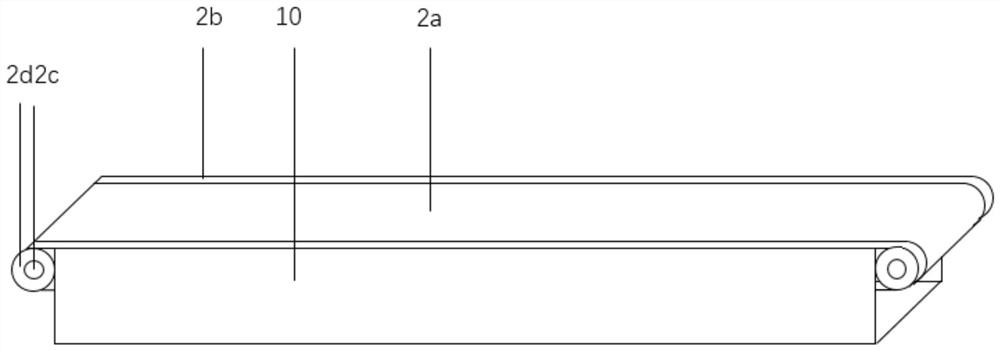

InactiveCN113117106AImprove disinfection effectFlexible speed adjustmentConveyorsLavatory sanitoryCold chainUltraviolet lights

The invention discloses a deep ultraviolet-based all-directional disinfection device for cold chain cargoes, and relates to cold-chain cargo disinfection. The all-directional disinfection device comprises a housing, conveying belts, grooves, deep ultraviolet light source lamp arrays, distance measuring sensors, a main control chip, safety curtains, a power box, a gravity sensor and a base; the safety curtains are installed on two sides of the housing correspondingly; three conveying belts are installed under the housing and a groove is formed by a gap between every two conveying belts; the distance measuring sensors are mounted on the upper surface and left and right side surfaces of a distance measuring region; the power box is installed on the upper side face of the housing; and the main control chip is placed at the left side of the power box. The all-directional disinfection device is safe, and has no toxicity and pollution; the deep ultraviolet light source lamp arrays are mounted in the grooves correspondingly, and can have a very good disinfection effect on bottoms of the cargoes; on and off of the conveying belts and lamps are controlled through gravity sensors, so that energy consumption when no cargoes are present on the conveying belts can be reduced; and the distance between the cargoes and upper and side deep ultraviolet light source lamp arrays is measured through the distance measuring sensors, the speed of the conveying belts can be flexibly adjusted, efficiency is improved, and a safety guarantee is provided for transportation of the cold chain cargoes.

Owner:XIAMEN UNIV

Expulsion type simulation mechanical bird

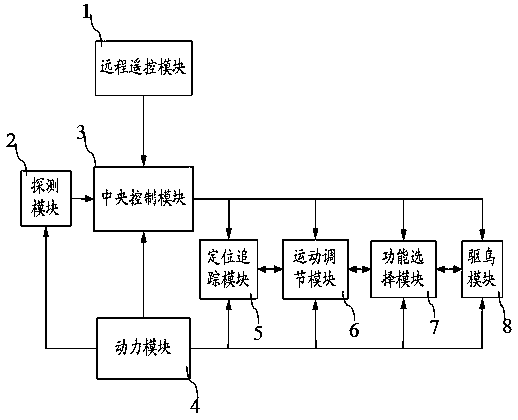

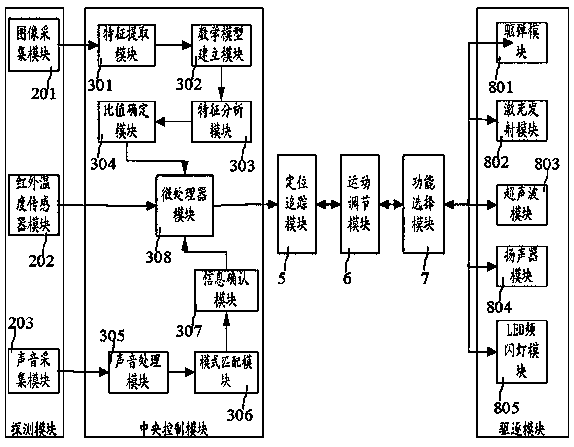

InactiveCN108077236AStrong targetingRepelling is effectiveProgramme controlComputer controlRemote controlComputer module

The invention discloses an expulsion type simulation mechanical bird. The simulation mechanical bird includes a central control module, and a remote control module, a detection module, a power module,a positioning tracking module, a motion adjustment module, a function selection module and a bird repelling module which are separately connected with the central control module. The expulsion type simulation mechanical bird provided by the invention can accurately find the position of flying birds, and has a large repelling range and a diversified repelling function, thereby realizing a targetedbird repelling effect.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

Spraying assisting device universal for long shaft parts

PendingCN107185751AIncrease the scope of applicationFlexible speed adjustmentSpraying apparatusSlide plateIndustrial engineering

The invention discloses a spraying assisting device universal for long shaft parts. The device comprises an installation support. The installation support is provided with a gearbox and a moving apex assembly. An output shaft of the gearbox is provided with a chuck opposite to the moving apex assembly. The moving apex assembly comprises an apex with the front end horizontally pointing to the center position of the chuck. The bottom of the moving apex assembly is provided with a sliding plate located above the installation support. The installation support is provided with a sliding strip located below the sliding plate. Multiple adjusting thread holes are formed in the sliding strip in the axial direction at intervals. The sliding plate is provided with bolts corresponding to the adjusting thread holes. In this way, according to the spraying assisting device universal for the long shaft parts, the chuck can be adjusted to adapt to the diameters of the shaft parts, the position of the moving apex assembly can be horizontally adjusted so as to adapt to the lengths of the shaft parts, the rotating speed of the gearbox can be flexibly adjusted, movement is convenient, and university is good.

Owner:JIANGSU RAILTECO EQUIP CO LTD

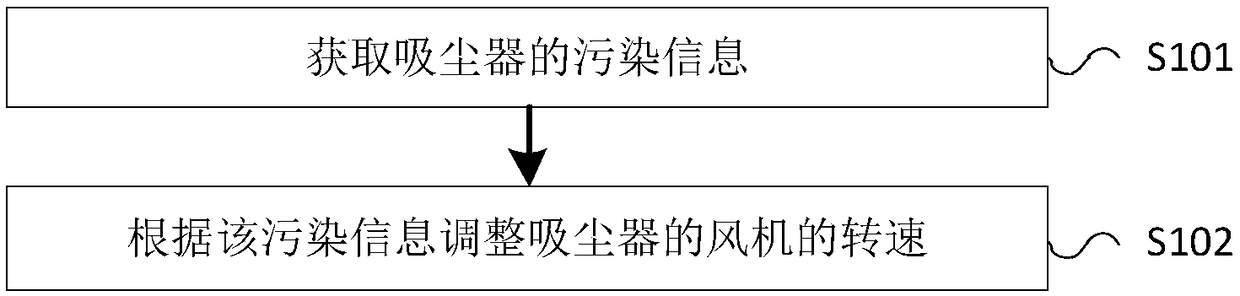

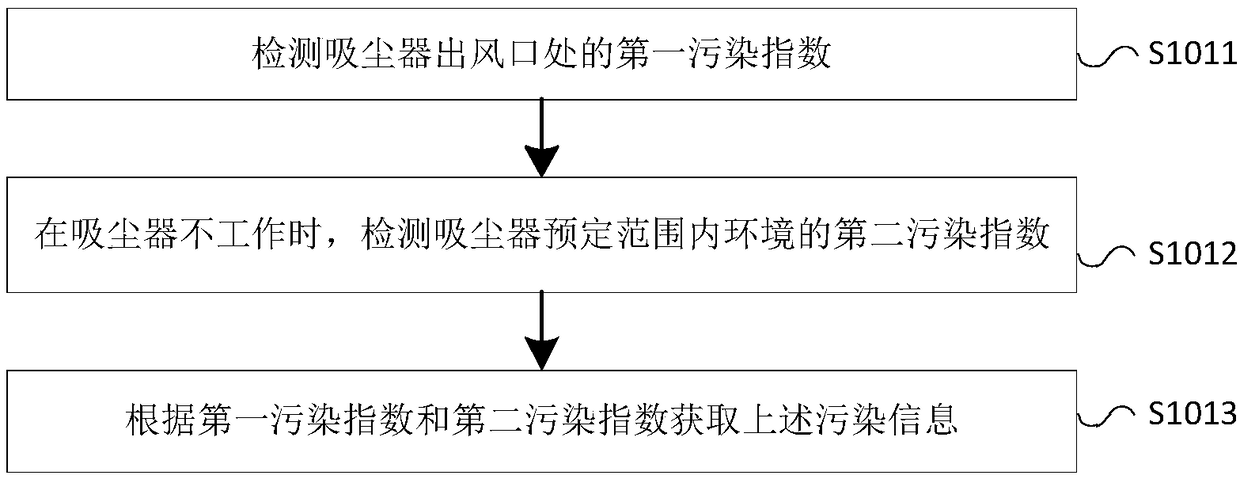

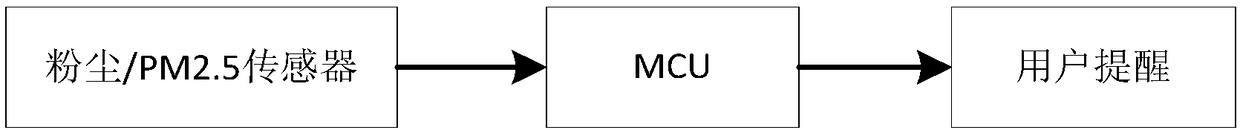

Vacuum cleaner speed adjusting method, device and speed control system and storage medium

ActiveCN108968806ASolve the problem of low dust collection efficiencyFlexible speed adjustmentElectric equipment installationSpeed control systemPulp and paper industry

The invention provides a vacuum cleaner speed adjusting method, device and speed adjusting system and a storage medium. The vacuum cleaner speed adjusting method includes: acquiring pollution information of a vacuum cleaner, wherein the pollution information is used for indicating the pollution status of a filter screen of the vacuum cleaner relative to the pollution status of the environment within the predetermined range of the vacuum cleaner; adjusting the rotating speed of a fan of the vacuum cleaner according to pollution information. With the speed adjusting method of the vacuum cleaner,the pollution information of the vacuum cleaner is detected, whether the amount of dust on the filter screen is accumulated to a certain extend compared with the amount of dust in the surrounding environment can be known, the rotating speed of the fan of the vacuum cleaner is adjusted according to the pollution information, the fan of the vacuum cleaner can adjust the rotating speed flexibly according to the pollution condition of the filter screen of the vacuum cleaner, and the problem that the fan of the vacuum cleaner running at a constant speed with setting speed in an existing vacuum cleaner can cause low dust collection efficiency of the vacuum cleaner is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Hand-push two-station mowing device

The invention provides a hand-push two-station mowing device. Before the device is working, the working staff checks whether all components are fixed reliably, and pushes the device to a flat lawn. Then, the working staff starts a main variable-frequency motor through a control panel, and determines the frequency of the main variable-frequency motor according to the needed efficiency and the thickness and density of grass. The main variable-frequency motor drives a small belt pulley to rotate after started, the small belt pulley drives a drive gear to rotate through a belt and a large belt pulley, and the drive gear drives a mowing blade to mow the lawn through a mowing gear. When the lawn is too rugged, mechanisms can play a buffering role and help cross obstacles, so that the device is not overturned due to too large angle of tilt during working. By adopting the device, the defects of a traditional mowing device, such as low degree of automation and high labor intensity of staff, are overcome. The hand-push two-station mowing device has the advantages of simple operation and high adaptability to terrains.

Owner:徐州瑞益晟机械有限公司

Tea roasting equipment

InactiveCN108703233AImprove qualityAvoid stickingPre-extraction tea treatmentElectricityThermal insulation

The invention provides tea roasting equipment which comprises a tea roasting drum, an air blower, a dehumidifier, a drying device, a variable frequency motor and a control device, wherein the tea roasting drum comprises an outer drum and an inner drum; the outer drum is provided with an electric heating layer; the inner drum comprises a thermal insulation mesh sieve; the air blower is provided with a first air outlet pipe and a second air outlet pipe; the first air outlet pipe is connected to the inner and outer drums; a feed hopper, a dehumidifying pipe, the dehumidifier and the drying deviceare arranged at the top of the inner drum; the variable frequency motor is connected with a rotary shaft; multiple tea roasting turning plates are arranged on the rotary shaft; a humidity sensor is arranged at the tail end of each tea roasting turning plate; the rotary shaft is a hollow rotary shaft; the second air outlet pipe is connected with the interior of the rotary shaft; multiple air ventsare formed in the tea roasting turning plate; an electromagnetic valve is arranged at the joint between the rotary shaft and the tea roasting turning plate; the lower drum wall of the tea roasting drum is a transparent drum wall, and an industrial camera is arranged on the lower drum wall; the control device is electrically connected with the electric heating layer, the air blower, the dehumidifier, the humidity sensor, the variable frequency motor and the industrial camera respectively. The tea roasting equipment provided by the invention can adjust the tea roasting temperature and power inreal time, and thus is favorable to improving the tea roasting quality.

Owner:安吉溪龙茗岙茶场

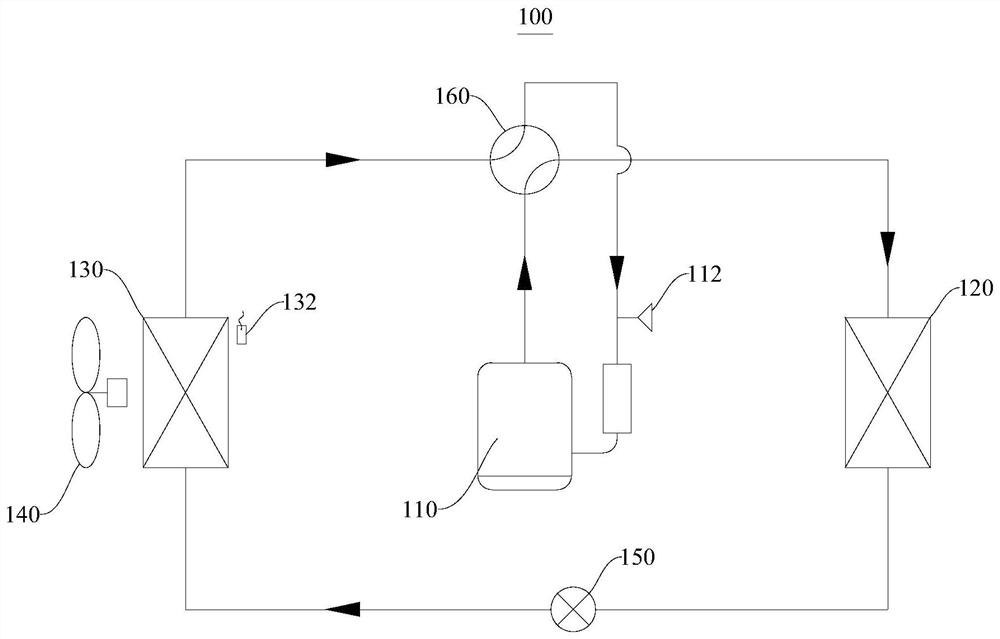

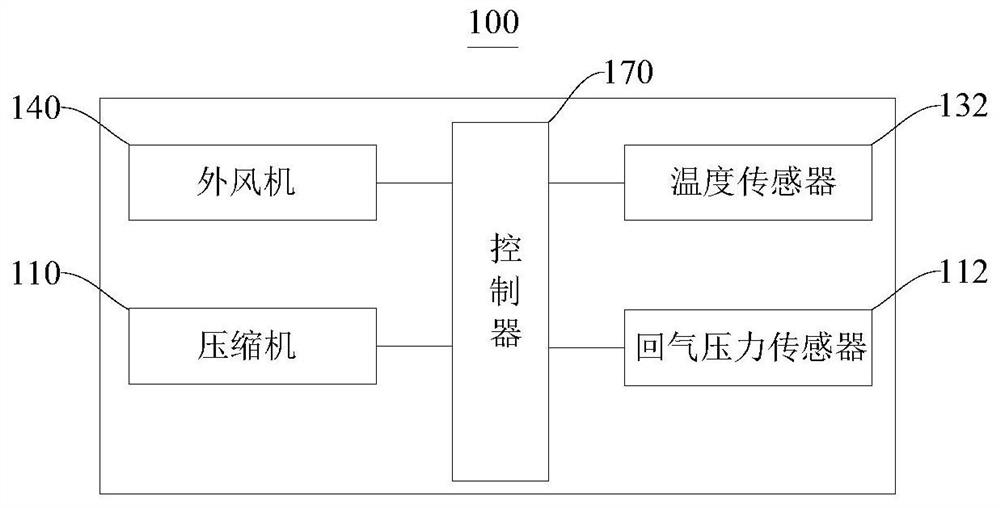

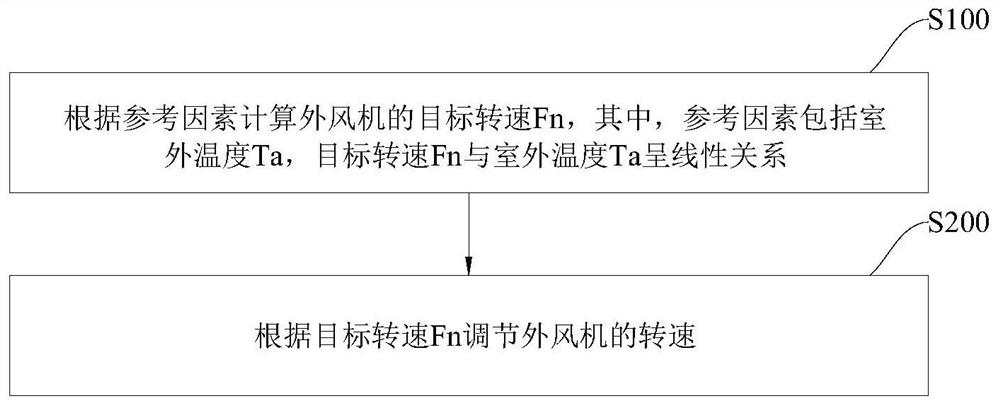

External fan control method and air conditioning system

InactiveCN112797601AMeet needsFlexible speed adjustmentMechanical apparatusSpace heating and ventilation safety systemsControl engineeringOutdoor temperature

The embodiment of the invention provides an external fan control method and an air conditioning system, and relates to the technical field of air conditioners. According to the external fan control method, a target rotating speed is calculated according to reference factors comprising outdoor temperature, then an external fan is controlled to be adjusted according to the target rotating speed, due to the fact that the target rotating speed and the outdoor temperature are in the linear relation, the rotating speed of the external fan can be linearly adjusted, compared with existing multi-gear adjustment, the adjustment is more flexible, and the load requirement of an air conditioner can be better met. The air conditioning system can realize the external fan control method, so that the air conditioning system also has the beneficial effects.

Owner:NINGBO AUX ELECTRIC +1

Battery conveying line

ActiveCN106025325AIncrease the number ofFlexible adjustment of movement speedPrimary cell manufactureConveyorsElectrical batteryElectrical and Electronics engineering

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

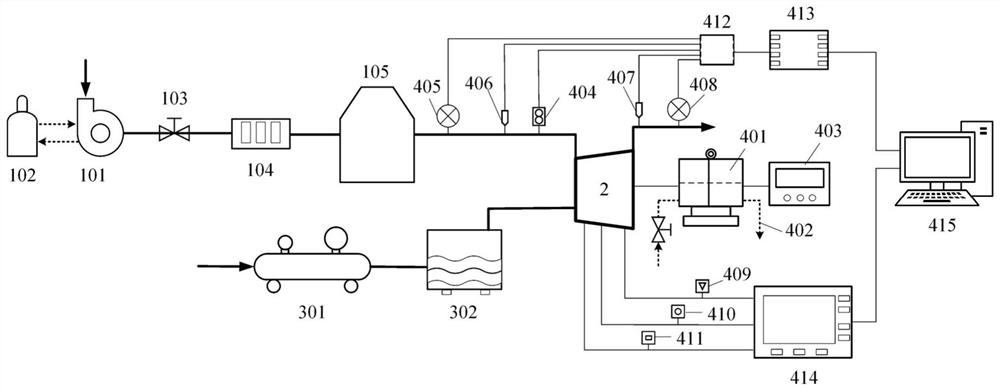

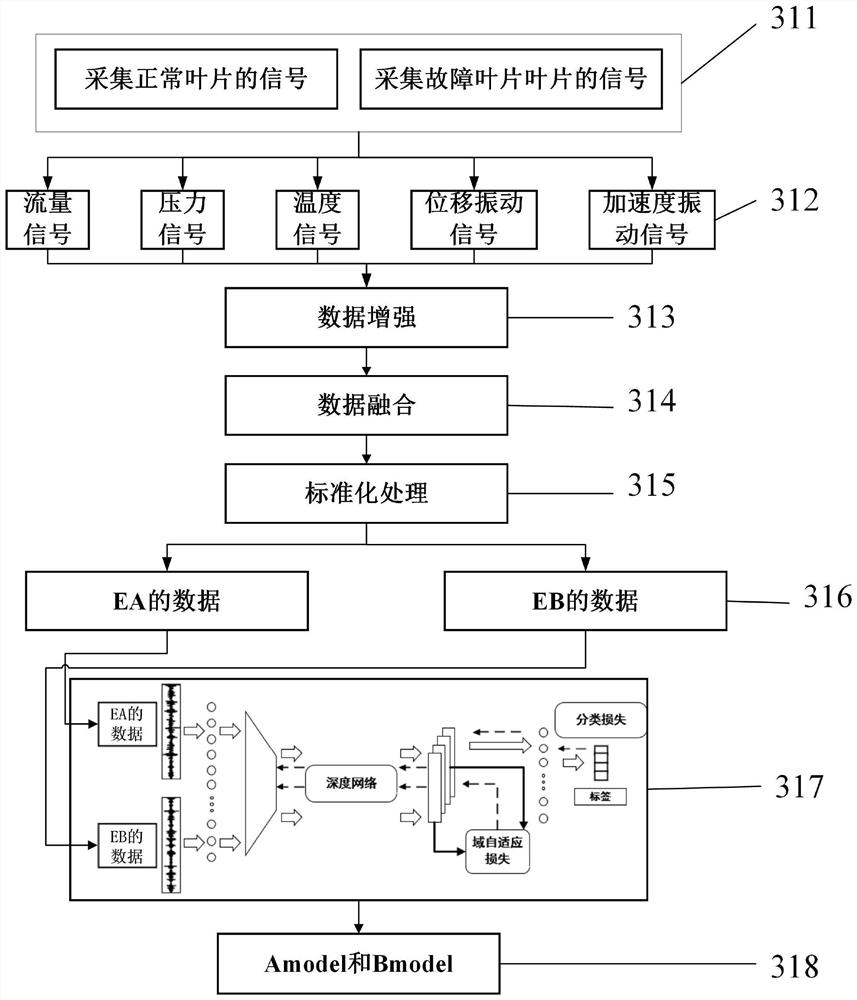

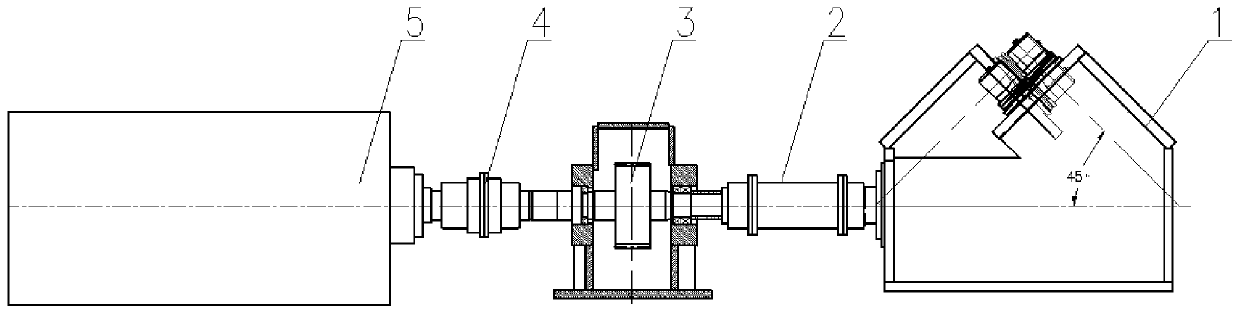

Turbine blade fault test system and intelligent fault diagnosis method thereof

ActiveCN112761740AEasy to replaceFlexible flow adjustmentMachines/enginesNeural architecturesNerve networkTurbine blade

The invention discloses a turbine blade fault test system and an intelligent fault diagnosis method thereof. The test system comprises a gas supply system, a turbine main body system, a lubricating system and a measurement control system. When the turbine blade fault test system runs, the gas supply system provides a gas source for the turbine main body system, the lubricating system provides a lubricating working medium for the turbine main body system, and the measurement control system is used for controlling the running safety of the whole system and measuring required performance parameters. The turbine blade fault test system is established to achieve accurate measurement of pneumatic parameters and vibration parameters during turbine operation, a large amount of test data of fault blades are obtained, and a fault diagnosis model based on a convolutional neural network and deep transfer learning is established. Pneumatic signals and vibration signals of the fault blades are learned, trained and tested, and are migrated and applied to a real turbine unit, so that a foundation is laid for online fault diagnosis of the turbine blades of a large-scale generator set.

Owner:XI AN JIAOTONG UNIV

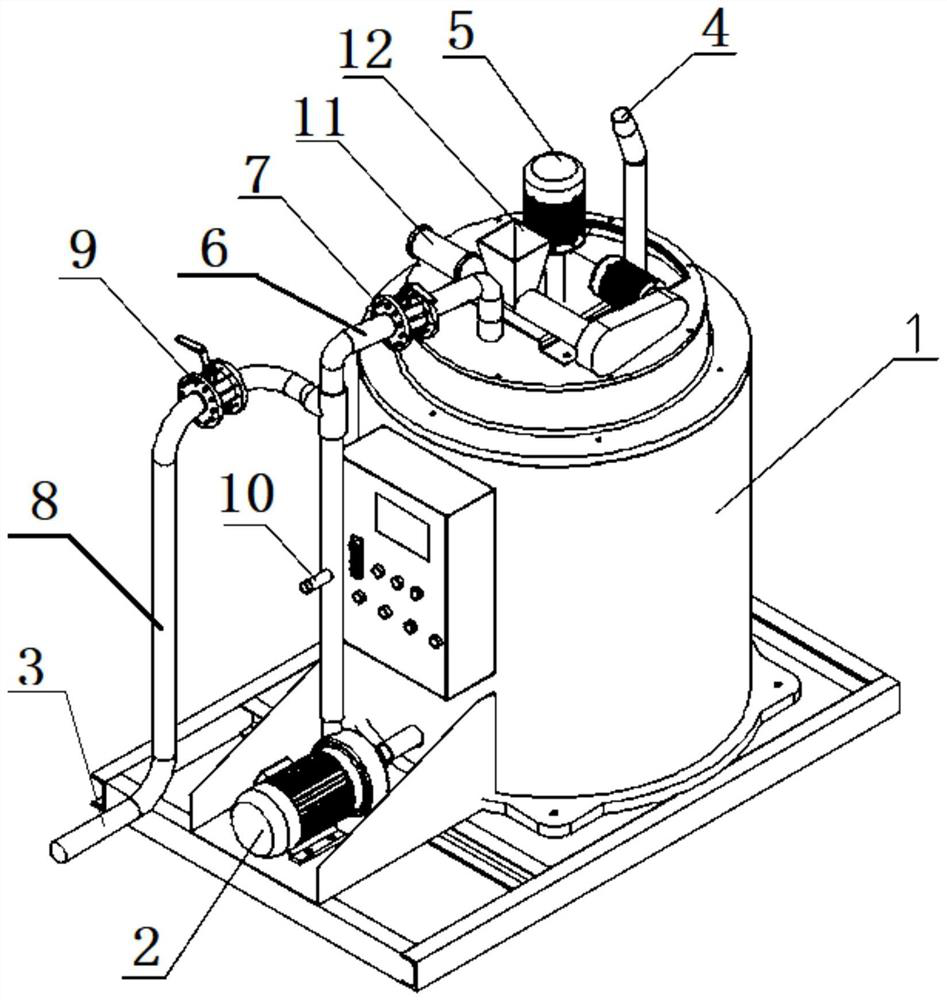

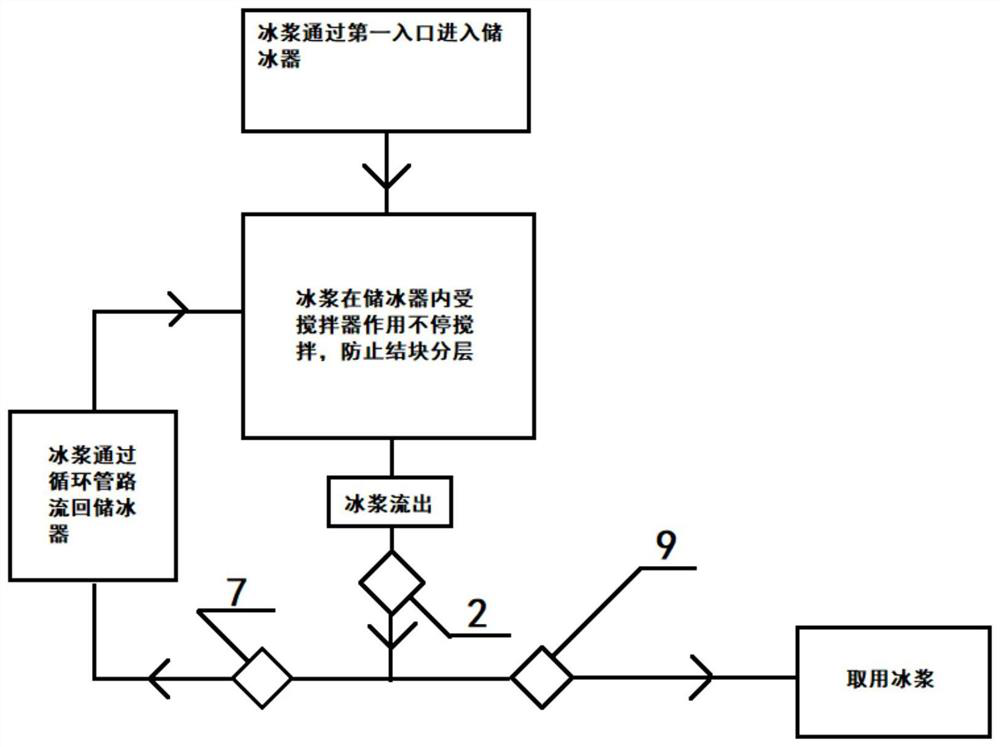

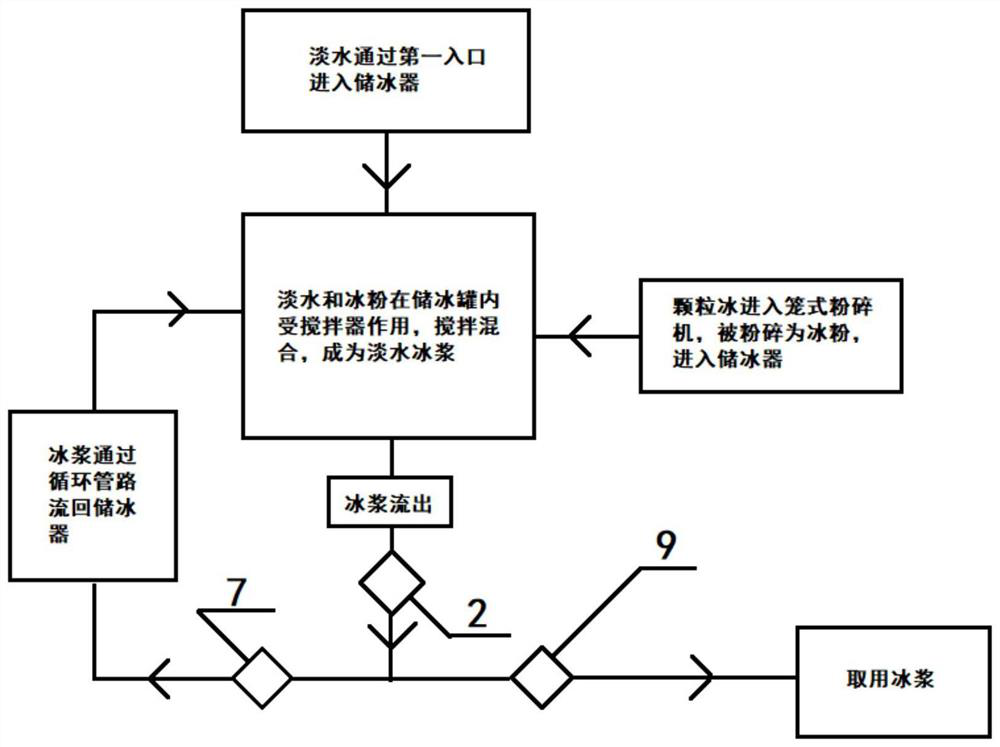

Multifunctional ice slurry storing, stirring and pumping system

PendingCN112781291AInhibition of agglomerationAvoid condensationLighting and heating apparatusIce productionIce storagePetroleum engineering

The invention discloses a multifunctional ice slurry storing, stirring and pumping system. The system comprises an ice storage tank, an ice slurry pump and an ice slurry outlet; the ice slurry pump is correspondingly connected with the ice storage tank and the ice slurry outlet in a sealing manner; and the ice storage tank is provided with a first inlet and a stirrer. The system has the beneficial effects that the ice slurry is continuously stirred by the stirrer in the ice storage tank, so that the situation that even if the ice slurry is stored for a long time, the ice slurry cannot be used due to agglomeration, layering, gathering and condensation is avoided.

Owner:GUANGZHOU KOLLER REFRIGERATION EQUIP

Large-sized vacuum hotpressing stove

InactiveCN100592835CGuaranteed synchronicityLifting height can be adjusted at willMuffle furnacesInduction heatingSusceptorGraphite

The present invention relates to a large vacuum hot pressing furnace, which comprises an electric furnace main body. The electric furnace main body comprises a furnace casing, a furnace casing bottomelevating device and an induced heating device; the furnace casing bottom elevating device comprises a material loading elevating platform, an electrical motor, three plane guideposts supported on thebottom part of the material loading elevating platform, and two adjusting screw rods driven by the same electrical motor; the induced heating device comprises an inductor and a furnace lining; a fire-resisting heat-insulating layer and an electric insulation later are arranged around the furnace lining structure arranged between the induction coil and the graphite heating cylinder of the inductor. The vacuum hot pressing furnace can make the material feeding and discharging process more safe and reliable, and meets requirements of the vacuum sealing performance and improves the planeness ofthe material loading elevating platform evidently. The adaptation of the induction heating method can make the temperature-rising speed improved significantly, and because the heating element is a graphite susceptor cylinder, which has strong intensity under high temperature, even if the graphite mold breaks under the pressing condition, the heating element can not be damaged.

Owner:SHANGHAI ZHONGJIA ELECTRIC FURNACE

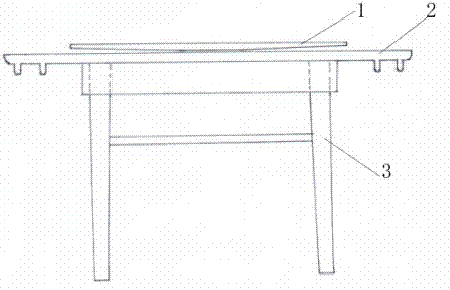

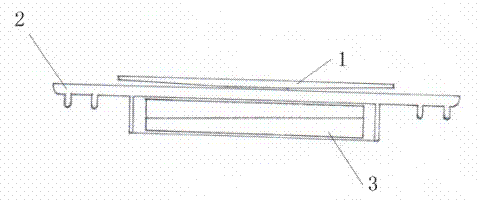

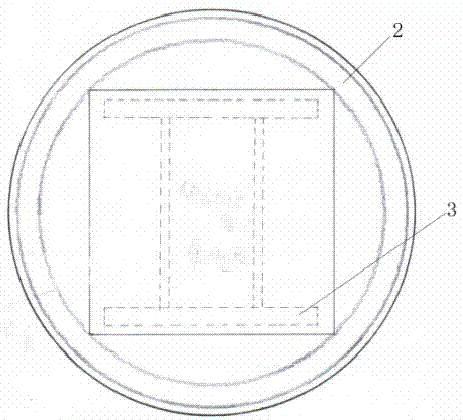

Hangable table

The invention relates to a hangable table comprising a table facet and table legs arranged below the table facet. The table legs are rotatably arranged on the lower surface of the table facet, rotating points of the table legs are arranged at joints of the table legs and the lower surface of the table facet, clamping grooves are formed in the lower surface of the table facet, and each clamping groove fixes each table leg in shape when the table leg rotates to the clamping groove. The hangable table can have different functions and is convenient to fold when not used.

Owner:赵子凯

Modularized independent transmission rolling mill and unit thereof

PendingCN110842030AEasy to repair and replaceEasy to installRolling mill drivesMetal rolling arrangementsGear wheelControl engineering

The invention discloses a modularized independent transmission rolling mill and a unit thereof, and belongs to the field of metallurgical rolling equipment. The modularized independent transmission rolling mill comprises a module rolling mill body, a gear box and a motor, wherein the rolling mill body comprises two mutually independent machine frames arranged in a box body; the gear box comprisestwo mutually independent gear trains; and the two machine frames on the module rolling mill body are connected with two mutually independent motor bodies through the two gear trains on the gear box. The unit comprises one or more modular independent transmission rolling mills, wherein each machine frame of the single or multiple module rolling mill bodies is capable of adjusting an extension coefficient between the machine frames based on the speed change of the corresponding motor bodies. The modularized independent transmission rolling mill can solve the problems that the speed ratio betweenthe two machine frames in a single module rolling mill cannot be flexibly adjusted, and solves the problems that the equipment structure is complex and the dead-load power consumption is high and thelike in the prior art.

Owner:CISDI RES & DEV CO LTD

Spiral force adjustment and force grading type anti-locking elastic brake eight-diagram wheel turning gear capable of being controlled with single hand

ActiveCN105165751AAvoid disconnectionSolve problems that require fine resistanceReelsSpiral of TheodorusEngineering

A spiral force adjustment and force grading type anti-locking elastic brake eight-diagram wheel turning gear capable of being controlled with a single hand comprises a turning gear body installed on a spindle, a wire guiding arm, a wheel seat and other necessary common parts, wherein a brake base is arranged on the inner side of the turning gear body and provided with at least two holes which are the spindle hole and the elastic brake threaded hole, and elastic brake devices are installed in the elastic brake threaded hole. The turning gear has the advantages that 1, the micro-force elastic brake device arranged on the outer side of the turning gear body is suitable for situations where only slight resistance is needed; 2, the spring force of the elastic brake device arranged on the inner side of the turning gear body is quite high, an elastic brake pad in the micro-force elastic brake device arranged on the outer side of the turning gear body acts after being pressed to the bottom so as to provide intermediate elastic pressure to prevent or slow the rotation of the turning gear body, and rigid pressure is provided to stop the rotation of the turning gear body when the compression stroke of a spring is completed; 3, due to the fact that the spring or the elastic brake pad is elastic, the turning gear body can not be locked suddenly, and wire breaking is avoided.

Owner:陈东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com