Patents

Literature

41results about How to "Adjust operating parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

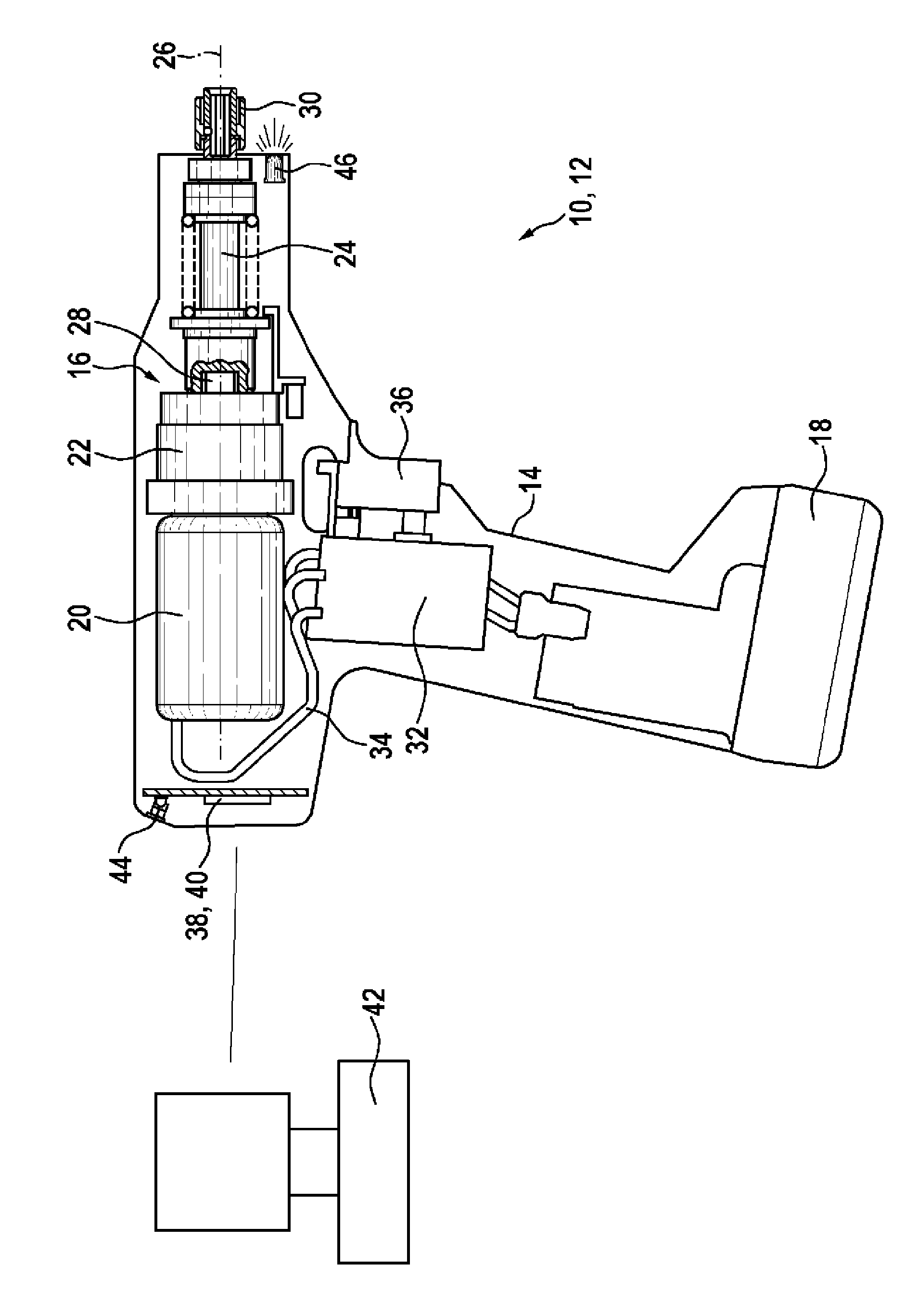

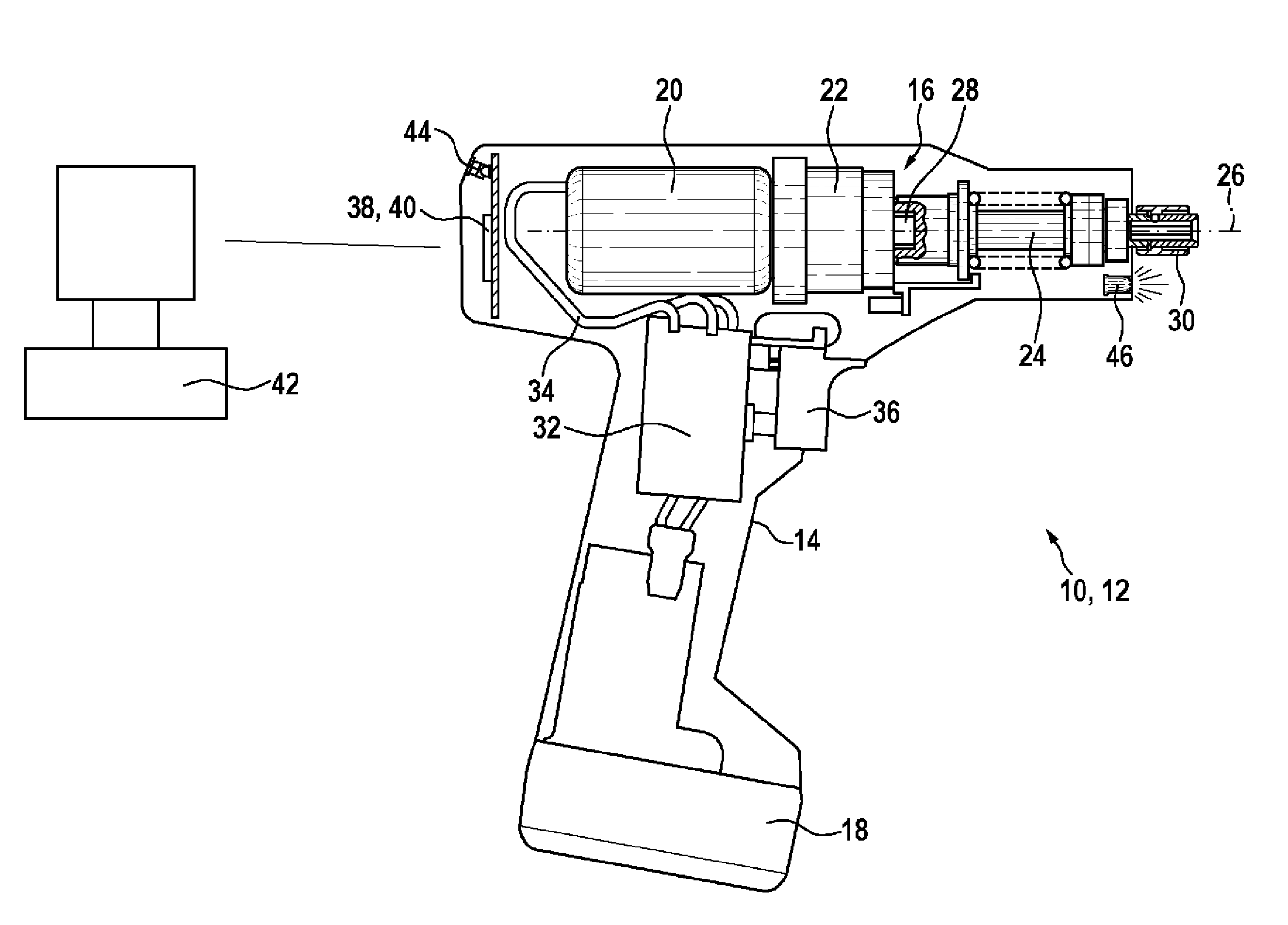

Hand-held power tool

Owner:ROBERT BOSCH GMBH

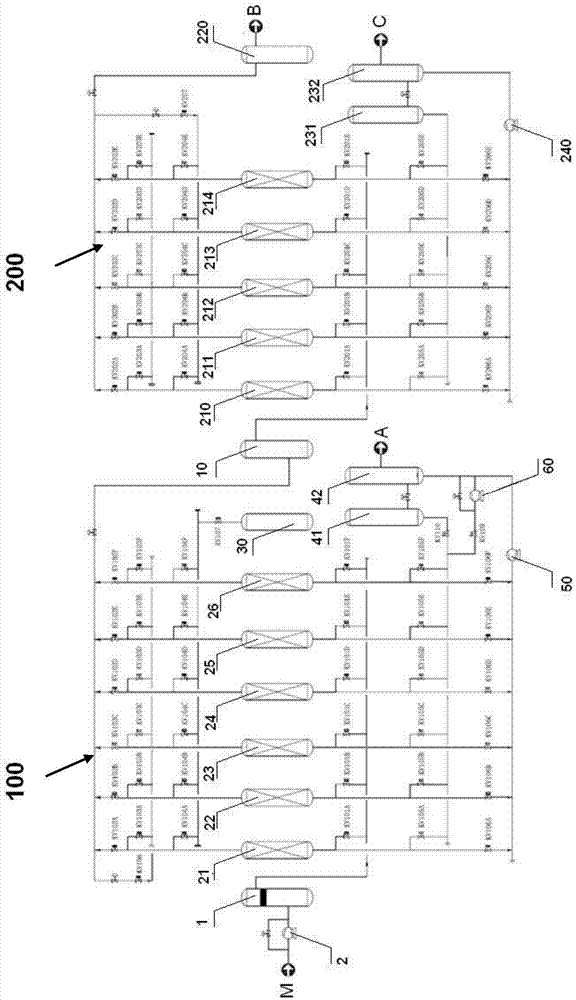

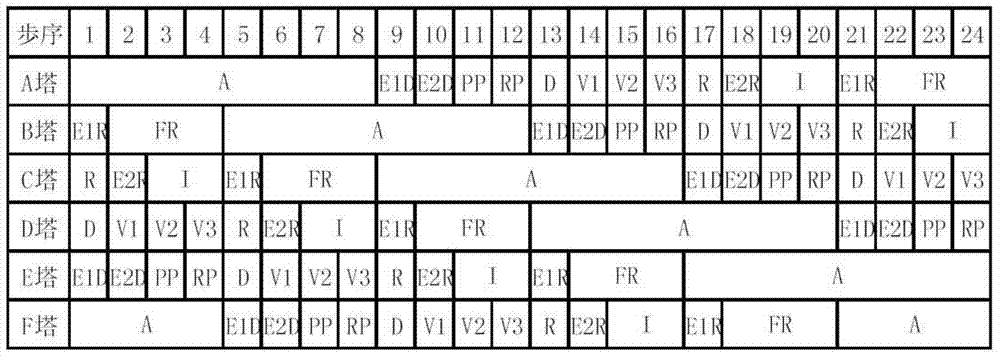

Device and process for separating and recycling non-methane total hydrocarbons and hydrogen gas from refinery dry gas

InactiveCN103752129AAchieve recyclingAchieve separationDispersed particle separationMixed gasMethane

The invention provides a device for separating and recycling hydrocarbon components and hydrogen gas from refinery dry gas and a process for separating and recycling the hydrocarbon components and the hydrogen gas by adopting the device. After treatment by the method, C2 and C2+ light hydrocarbon components in the mixture gas can be recycled, moreover, H2 in the mixture gas can be concentrated and purified, so that the additional value of the mixture gas is maximized, ideal economic benefits can be produced, Chinese energy development strategies are met, and besides, carbon dioxide emissions are reduced.

Owner:上海同利环境科技有限公司

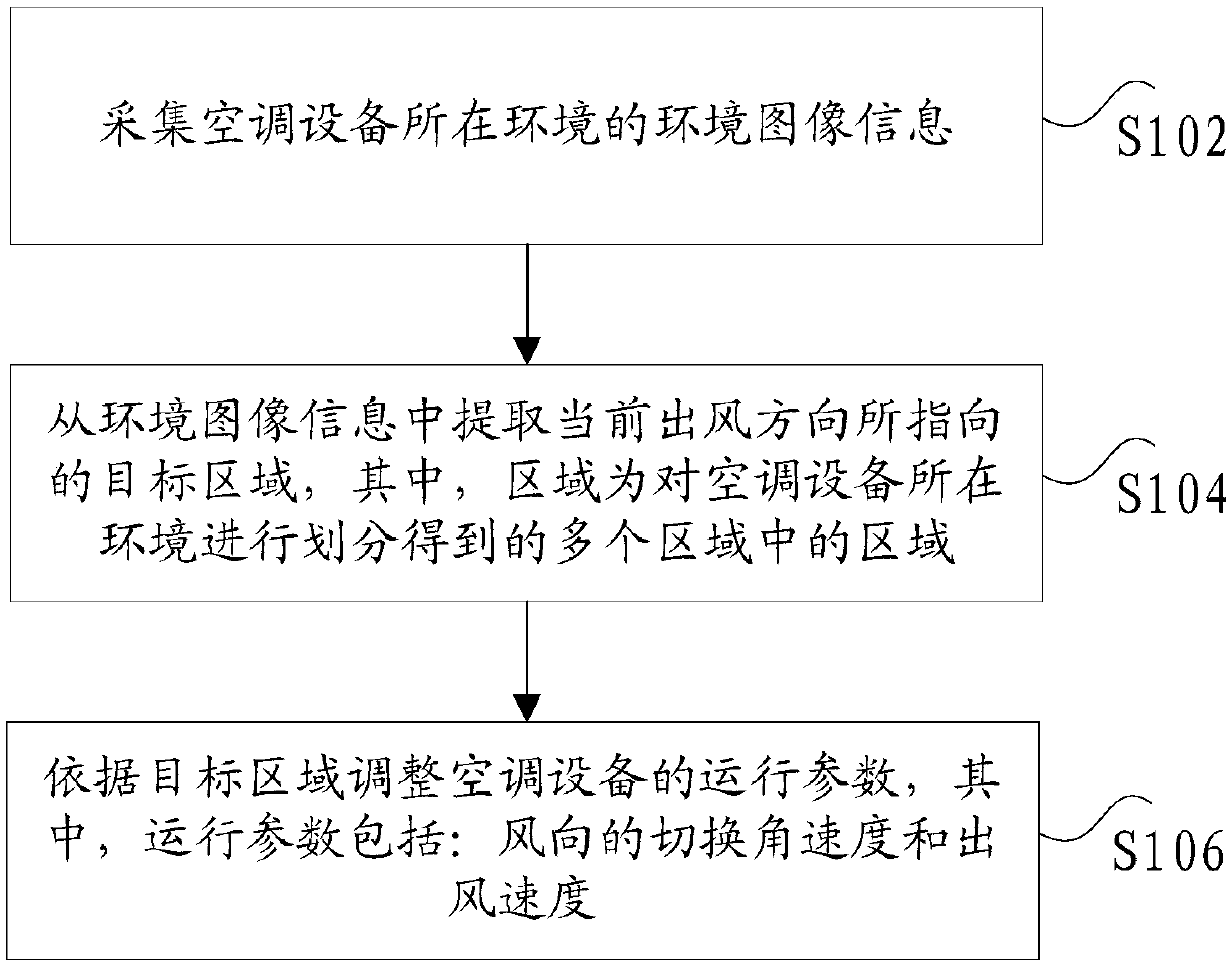

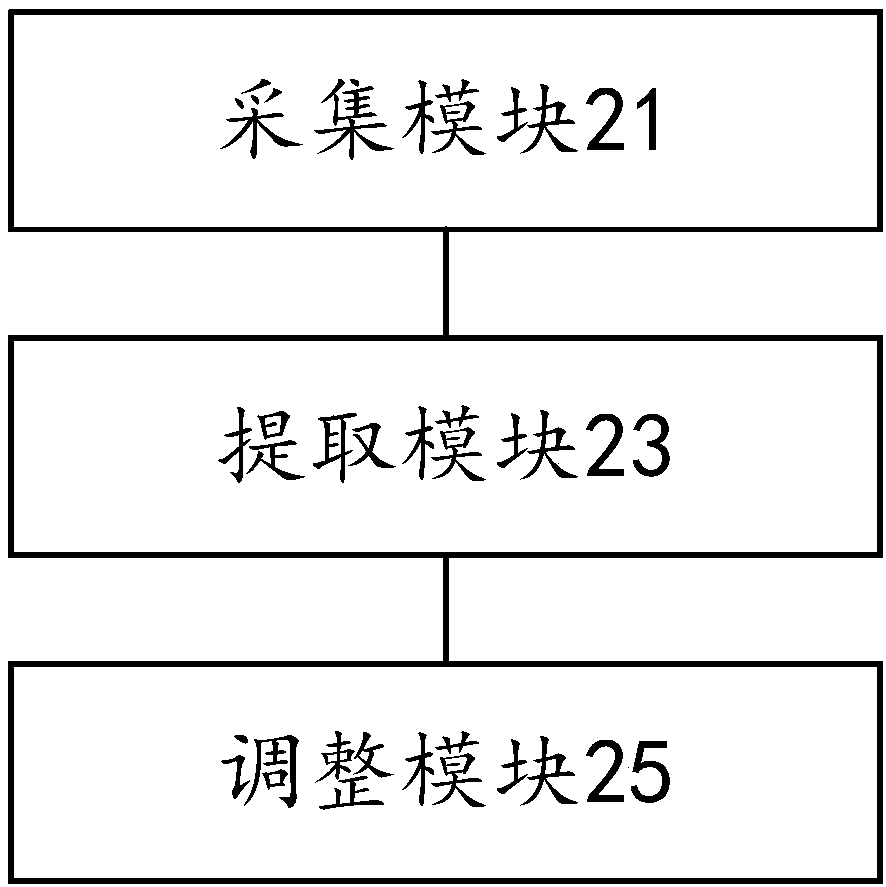

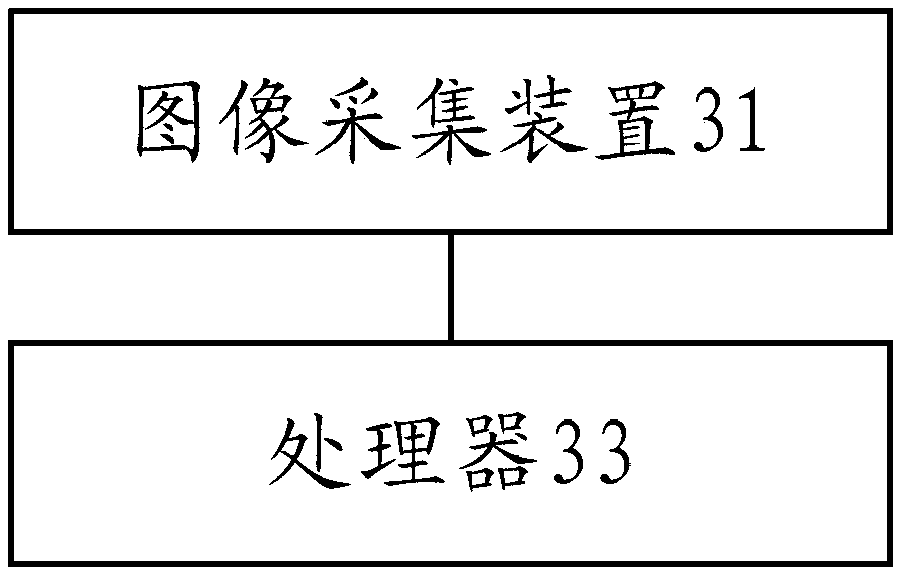

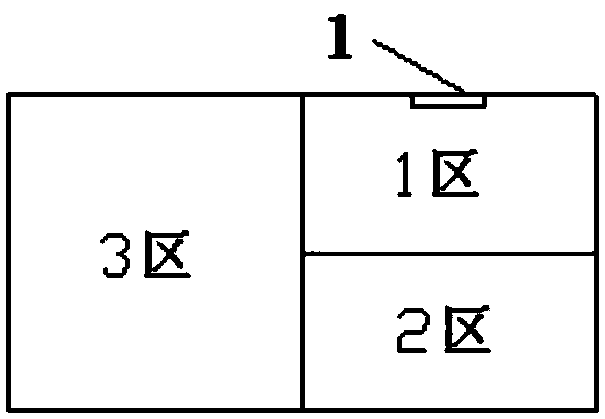

Air conditioner air outlet control method and terminal

InactiveCN107860100AAdjust operating parametersFlexible adjustment of operating parametersMechanical apparatusSpace heating and ventilation safety systemsAir conditioningWind direction

The invention discloses an air conditioner air outlet control method and a terminal. The method comprises the steps that environment image information of an environment where air conditioning equipment is located is acquired; a target area pointed by the current air outlet direction is extracted from the environment image information, wherein the area is one of a plurality of areas obtained afterthe environment where the air conditioning equipment is located is partitioned; and operating parameters of the air conditioning equipment are adjusted according to the target area, wherein the operating parameters include the air direction switching angular speed and the air outlet speed. By adopting the air conditioner air outlet control method and the terminal, the technical problems that the air direction and air speed control of an air conditioner in a relevant art are simplex, and consequentially, the experience when a user uses the air conditioner is poor are solved.

Owner:GREE ELECTRIC APPLIANCES INC

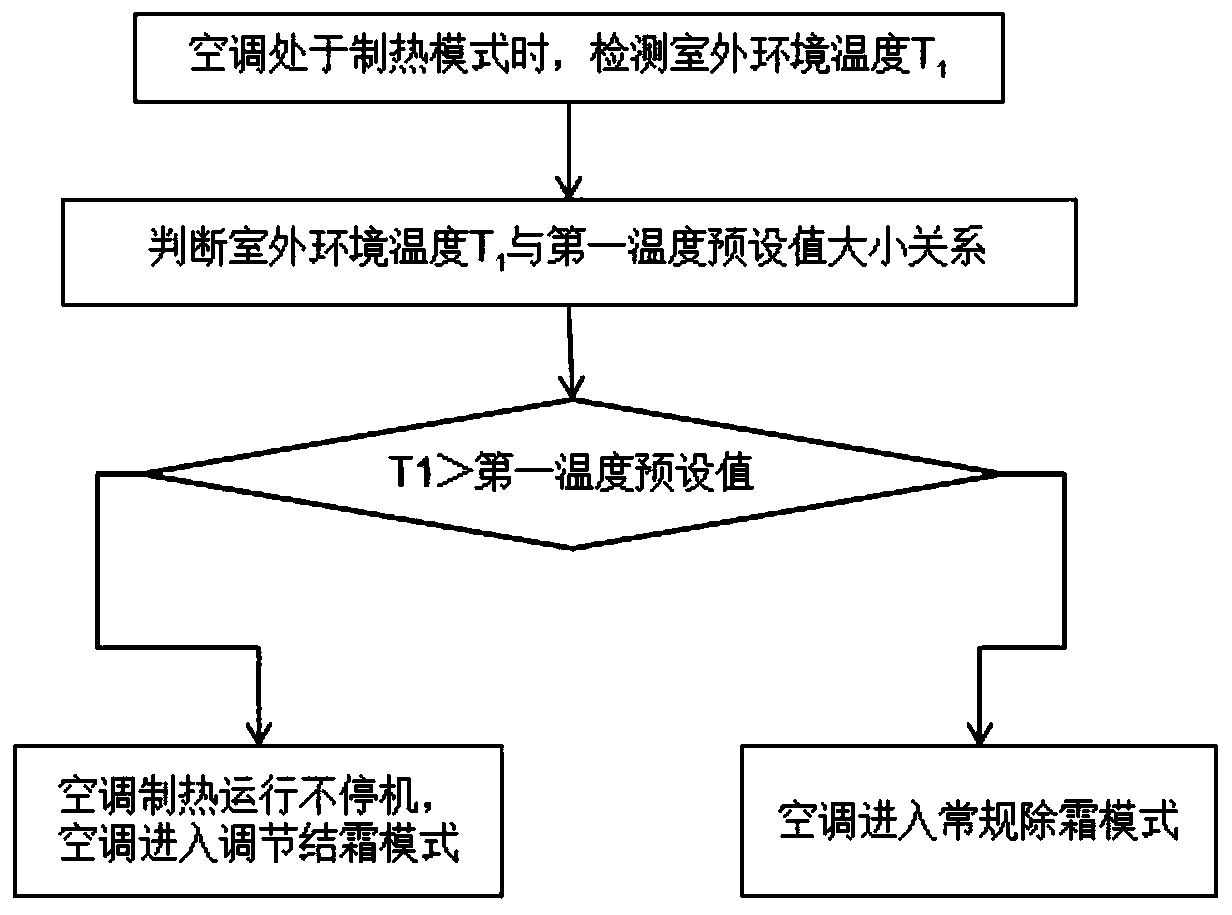

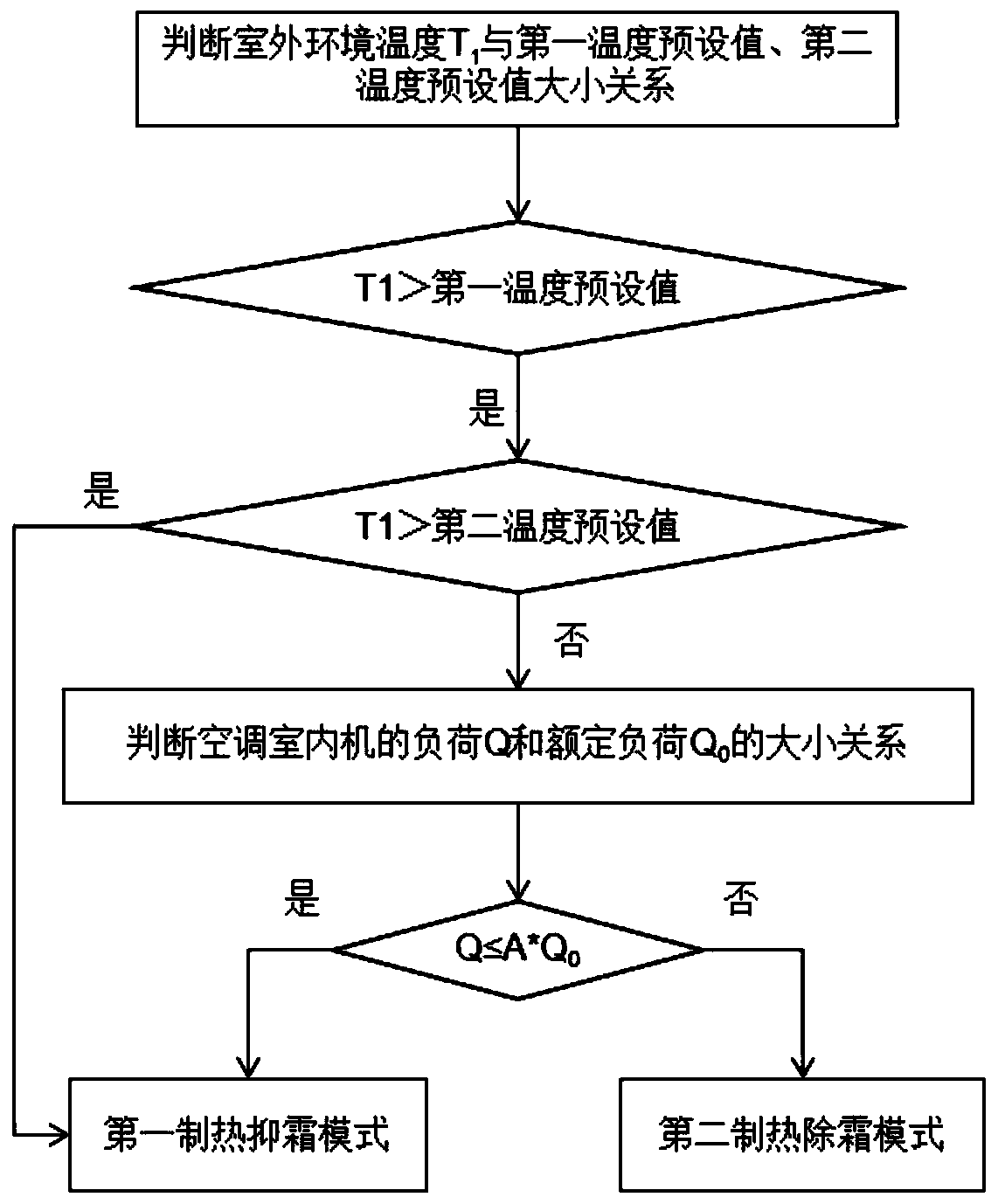

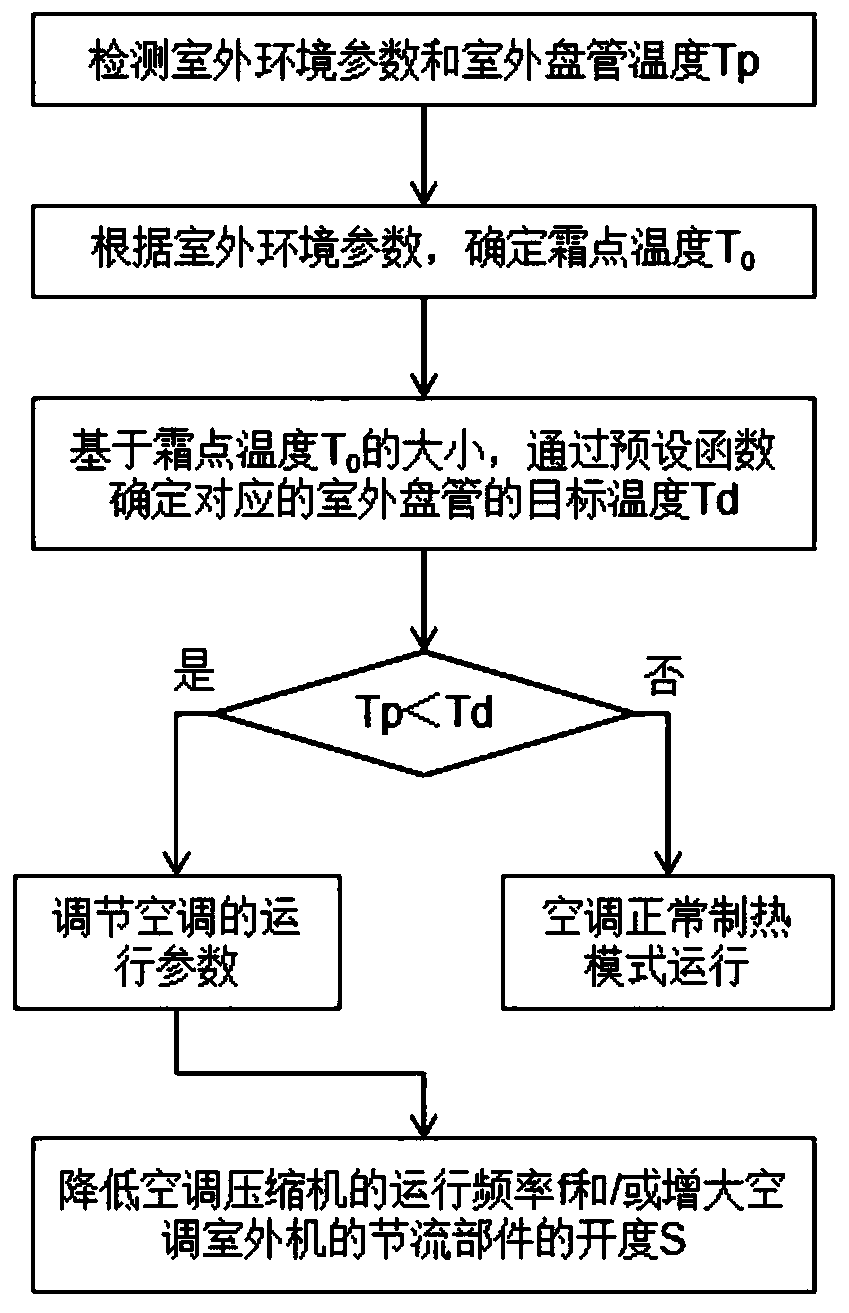

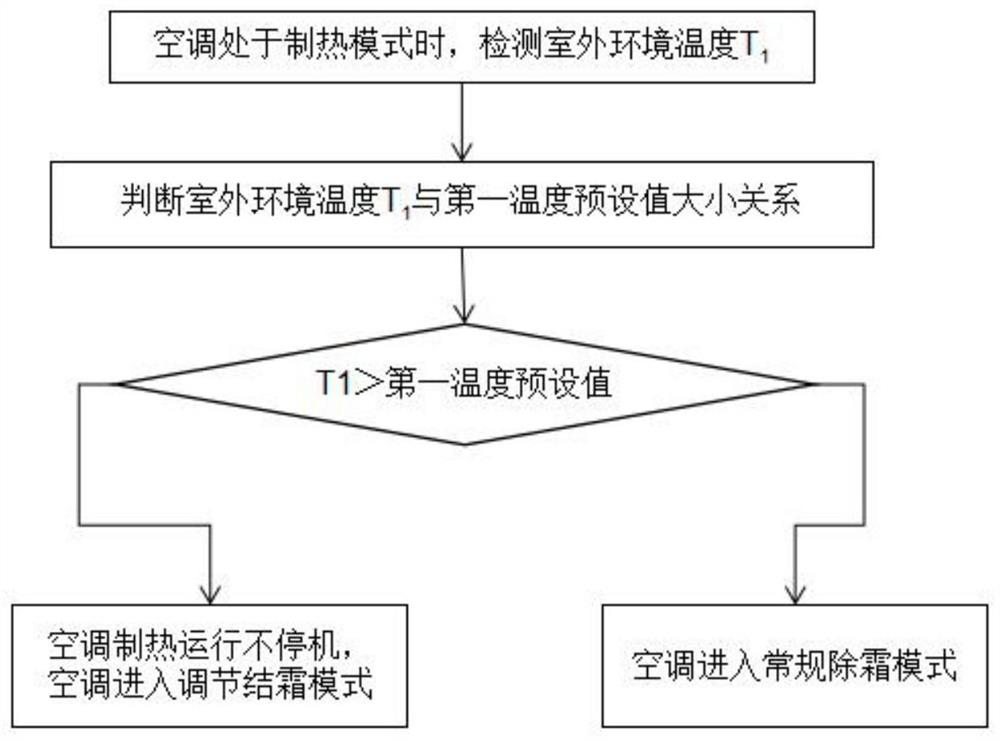

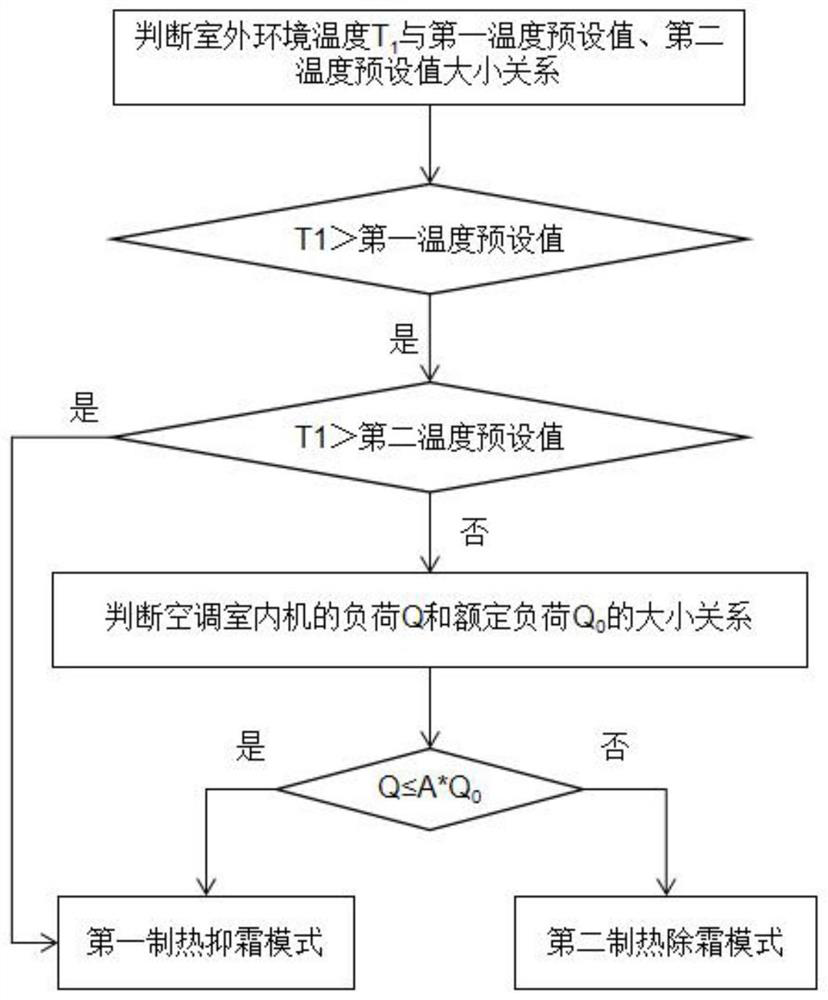

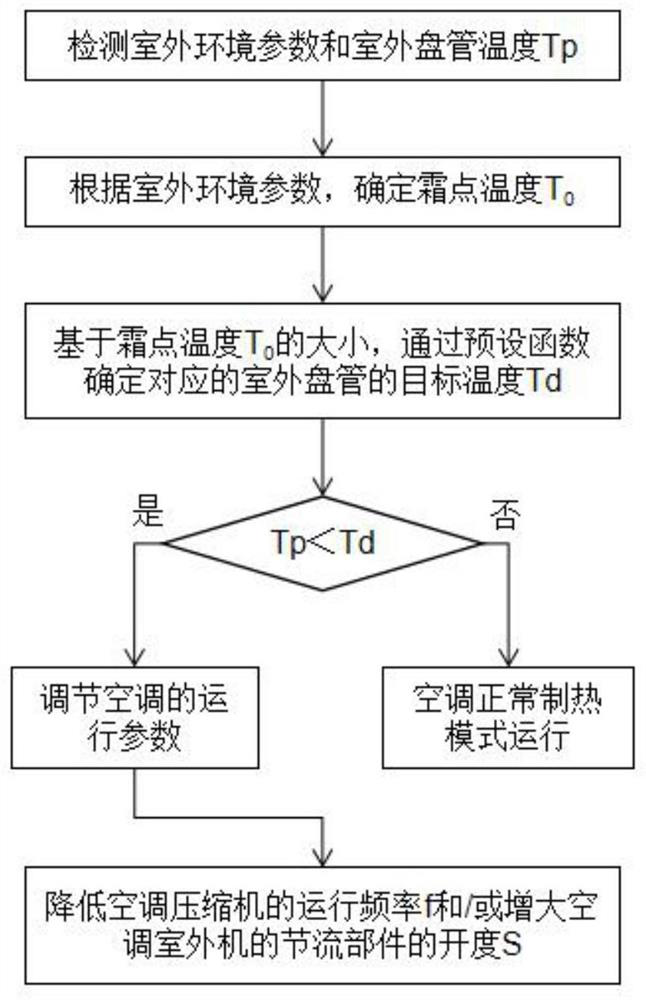

Control method and control system for adjusting frosting of air conditioner and air conditioner

ActiveCN111141007AAvoid reliabilityAvoid lifeMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsControl system

The invention relates to a control method and control system for adjusting the frosting of an air conditioner and an air conditioner. The control method for adjusting the frosting of the air conditioner comprises the steps that when the air conditioner is in a heating mode, the outdoor environment temperature T1 is detected; the relationship between the outdoor environment temperature T1 and the first temperature preset value is judged; and when the outdoor environment temperature T1 is greater than the first temperature preset value, the air conditioner enters an adjusting frosting mode. According to the control method, the situation that the outdoor environment temperature meets certain conditions is set, the heating operation of the air conditioner does not stop, the air conditioner enters the heating and defrosting or heating and anti-frosting mode, a frost layer is prevented from weakening the heating capacity of the air conditioner, and the situation that in a traditional methodof refrigerating and defrosting, the reliability and service life of a compressor are affected because the compressor accumulates too much refrigerants is avoided; and defrosting or anti-defrosting isconducted in the process of heating, the reduction of indoor temperature cannot be caused, the comfort of a room is improved, and the user experience is improved.

Owner:NINGBO AUX ELECTRIC

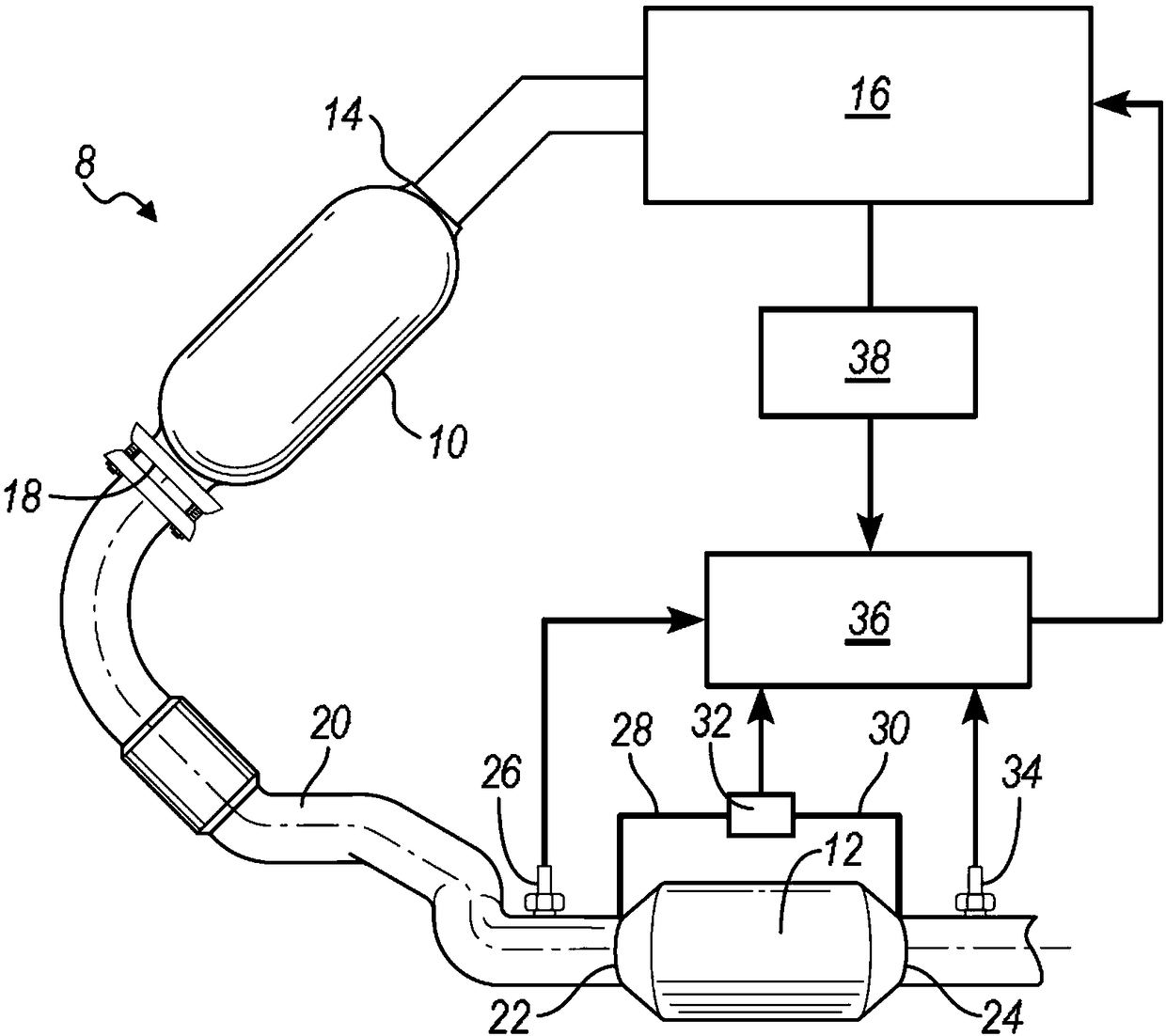

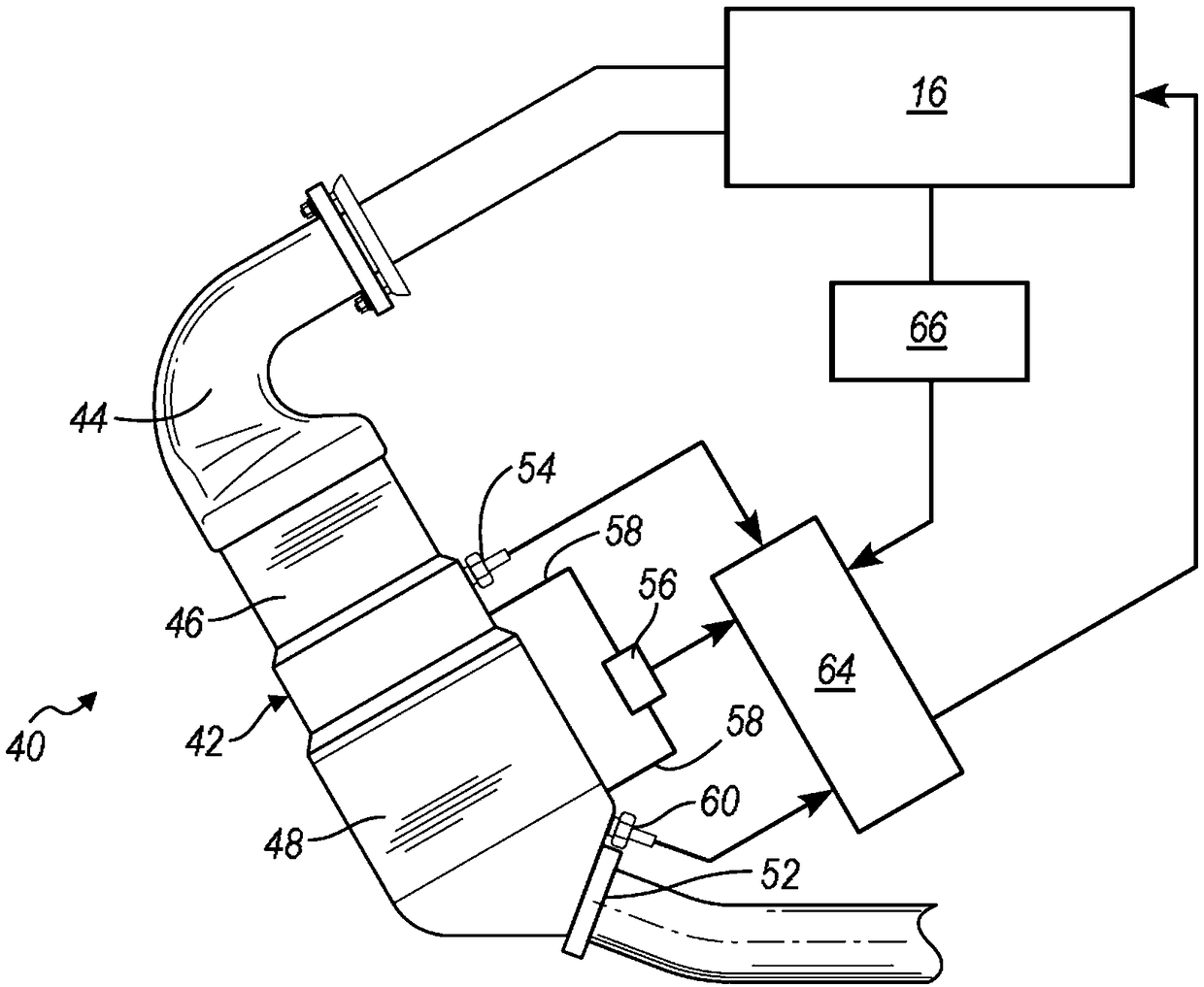

Gasoline particulate filter regeneration strategy

ActiveCN108952909AAdjust operating parametersEfficient combustionElectrical controlInternal combustion piston enginesGasolineDiesel particulate filter

The method determines whether soot loading of a gas particulate filter (GPF) requires regeneration. If it does, the temperature of the GPF is read to determine whether it is sufficiently high to achieve particulate (soot) burning. If it is not, an engine control module is commanded to adjust variables such as spark timing, fuel injection timing and valve timing. If the temperature of the particulate filter is sufficiently high that regeneration can occur, other variables may be adjusted such as leaning the air / fuel mixture, retarding the spark timing, the fuel injection and valve timing. Because the latter adjustments may limit or reduce either engine speed or power, messages in a message center are provided indicating, first, that the driver should continue driving for GPF regeneration and, subsequently, under certain conditions, that the engine power has been reduced. Operation of the motor vehicle proceeds until, based upon sensed conditions or pre-determined experimental or empirical data, the filter has been regenerated.

Owner:GM GLOBAL TECH OPERATIONS LLC

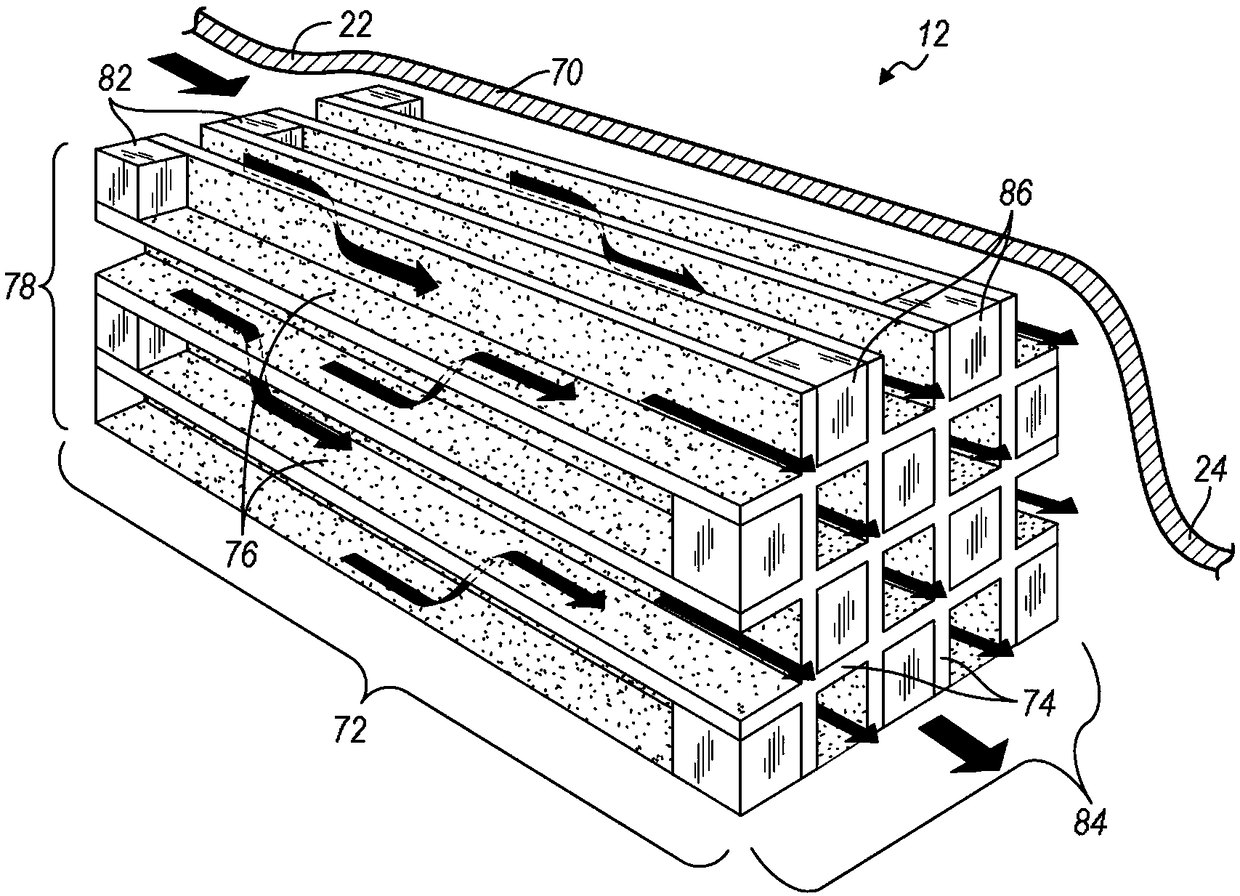

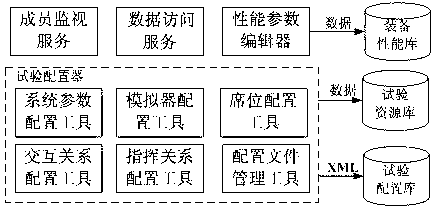

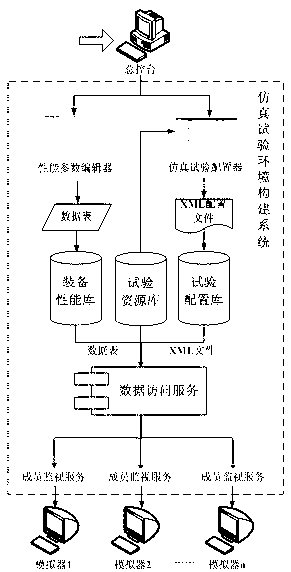

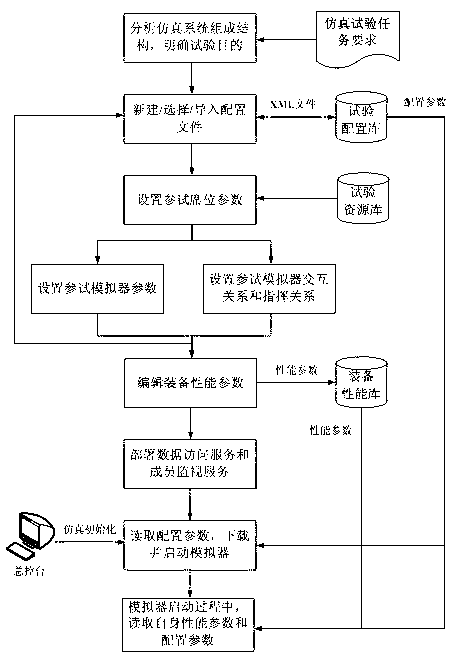

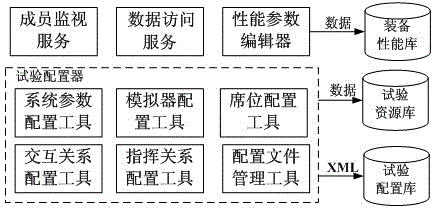

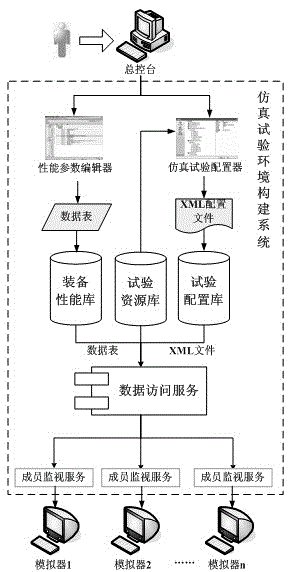

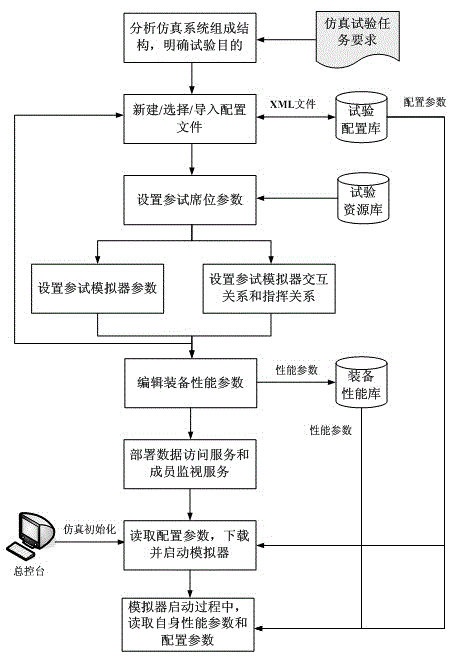

System simulation test environment building and configuring system and method based on extensive markup language (XML)

ActiveCN102799709AImprove efficiencyShorten the preparation processSpecial data processing applicationsControl tableSystems simulation

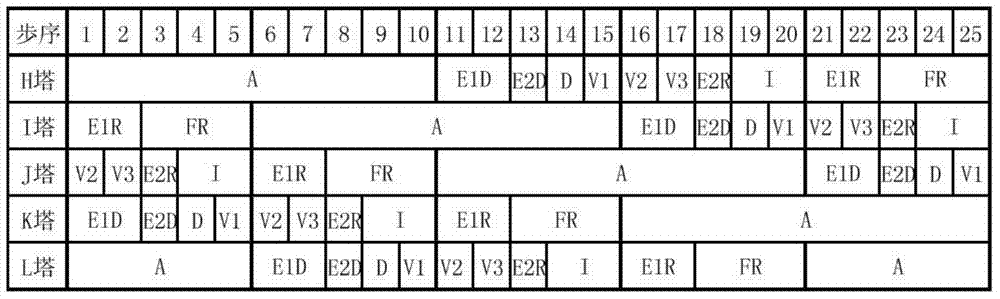

The invention discloses a system simulation test environment building and configuring system and a system simulation test environment building and configuring method based on extensive markup language (XML). The system comprises a simulation test configurator, a performance parameter editor, a member monitoring service, a data access service, a test configuration library, a test resource library and an equipment performance library. According to the method, a test manager uses a simulation test configurator to perform position configuration, simulator working parameter configuration, interactive relation configuration, command relation configuration and the like on a master control table; the master control table broadcasts and sends an initialization command; members on each position monitor the service and receive the initialization command; a corresponding simulator program is downloaded and started from a database; the performance parameters which are required for operation are read from the equipment performance database by a data access service when the simulator is started; a configuration file in the XML format is downloaded from the test configuration library and the operation parameters are read by the data access service; and completing the initialization work after the system completes the starting, and waiting the start of a simulation test.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

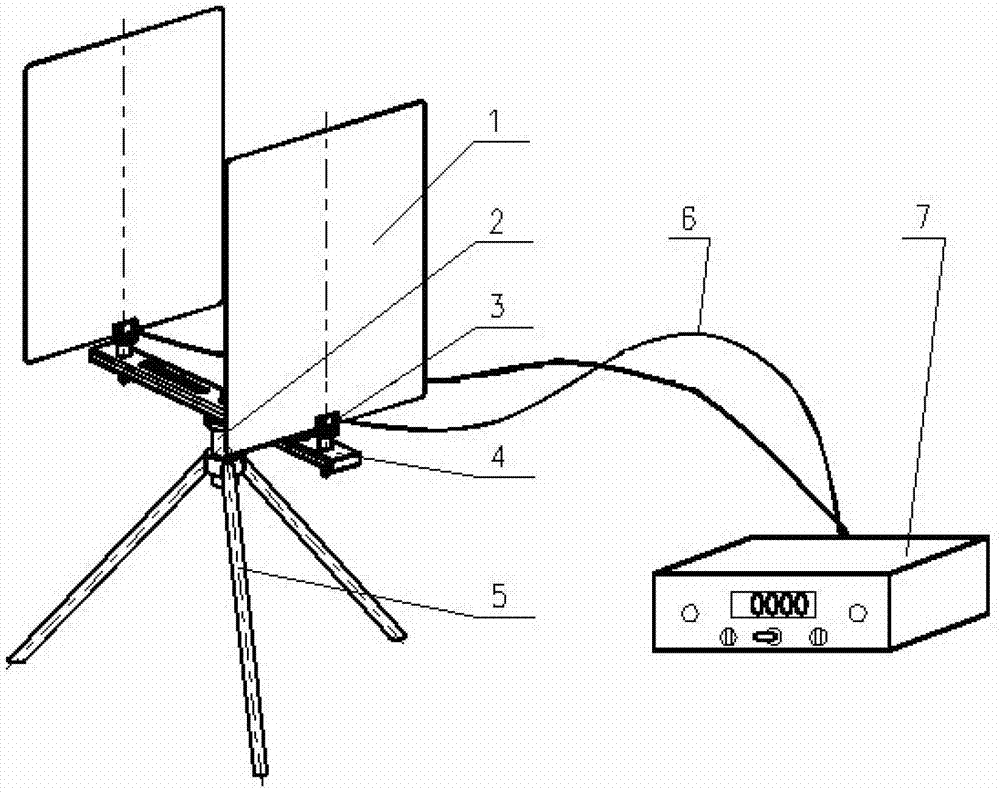

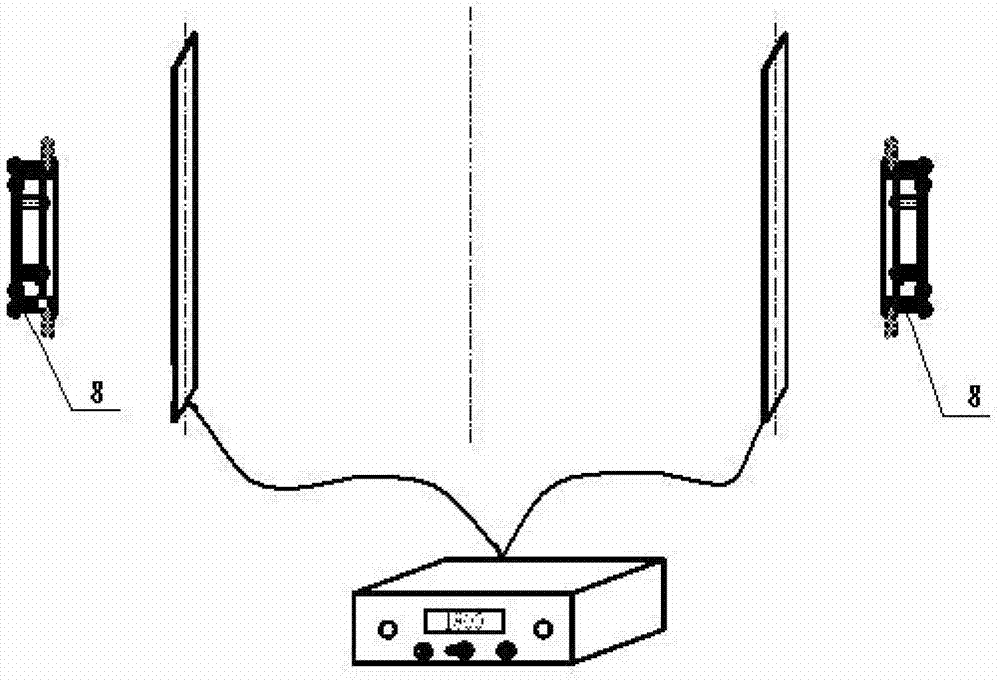

Electrostatic detection calibrator

InactiveCN102736051AMeet performance requirementsAdjust operating parametersElectrical measurementsControl parametersTesting equipment

The invention discloses an electrostatic detection calibrator. The electrostatic detection calibrator comprises a calibration power supply and calibration polar plates, wherein two calibration polar plates are arranged in pairs; the two calibration polar plates are connected with the calibration power supply through a lead; the calibration polar plates are fixed through an insulation support; the insulation support is in sliding fixation on a cross beam; and a bracket is connected below the cross beam. The invention has the beneficial effects that when the electrostatic detection calibrator is used for calibrating an electrostatic detection system, various performance requirements of the electrostatic detection system are met; operation parameters and control parameters of electric control system software are modulated and optimized; and meanwhile, the electrostatic detection calibrator can be used as an important tool for testing and acceptance inspection of electrostatic testing equipment as well.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

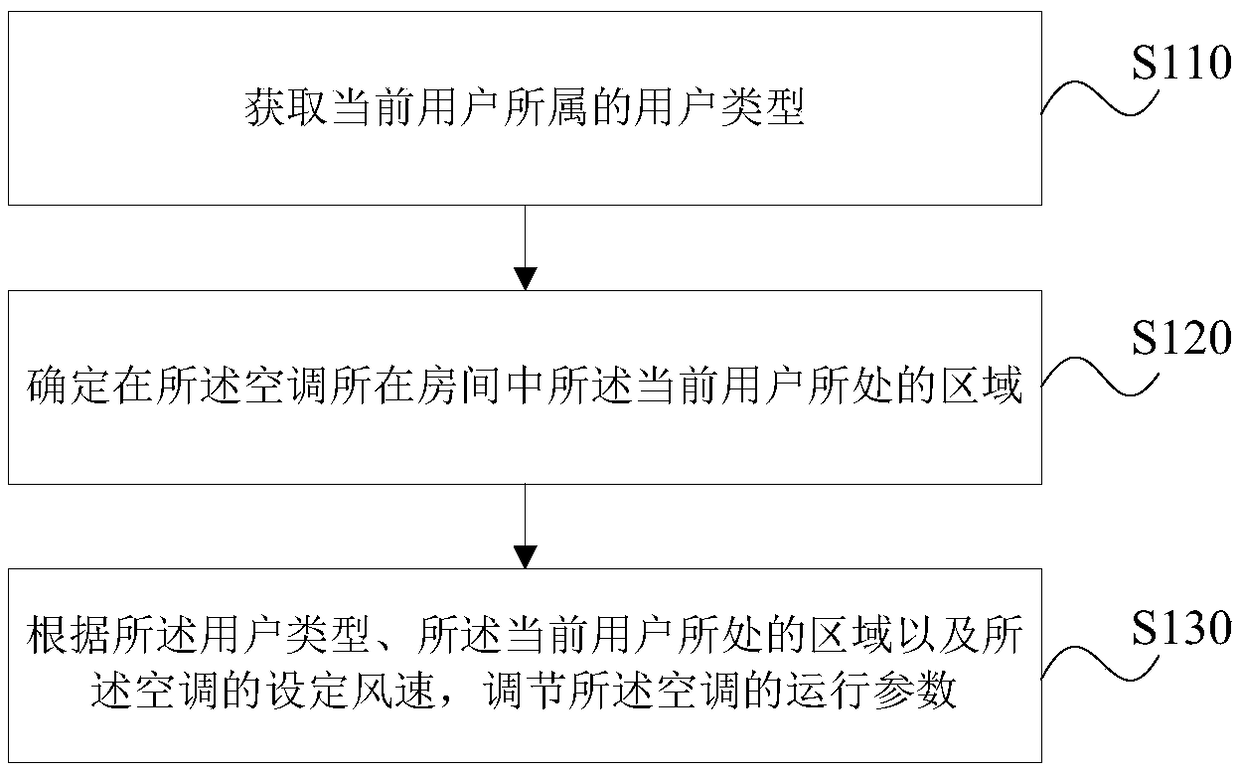

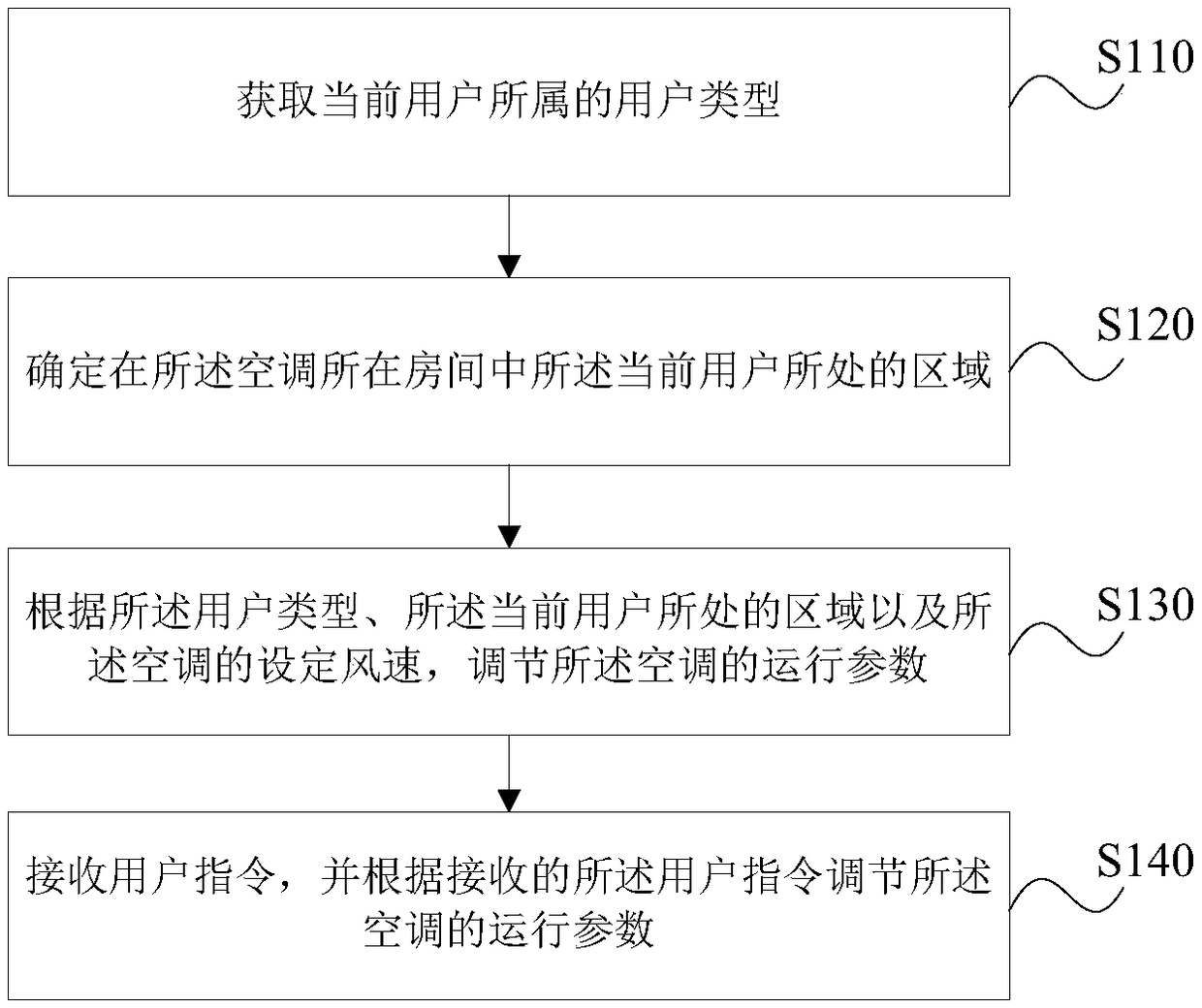

Air conditioner control method and device, storage medium and air conditioner

InactiveCN109442688AAdjust operating parametersAvoid discomfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringAirspeed

The invention provides an air conditioner control method and device, a storage medium and an air conditioner. The method comprises the following steps that a type of a user to which a current user belongs is acquired; an area where the current user is located in a room where the air conditioner is located is determined; and according to the user type, the area where the user located and a set airspeed of the air conditioner, the operation parameters of the air conditioner are adjusted. According to the scheme, the problem that uncomfortable is caused due to individual difference and room areadifference in the process of using the air conditioner can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

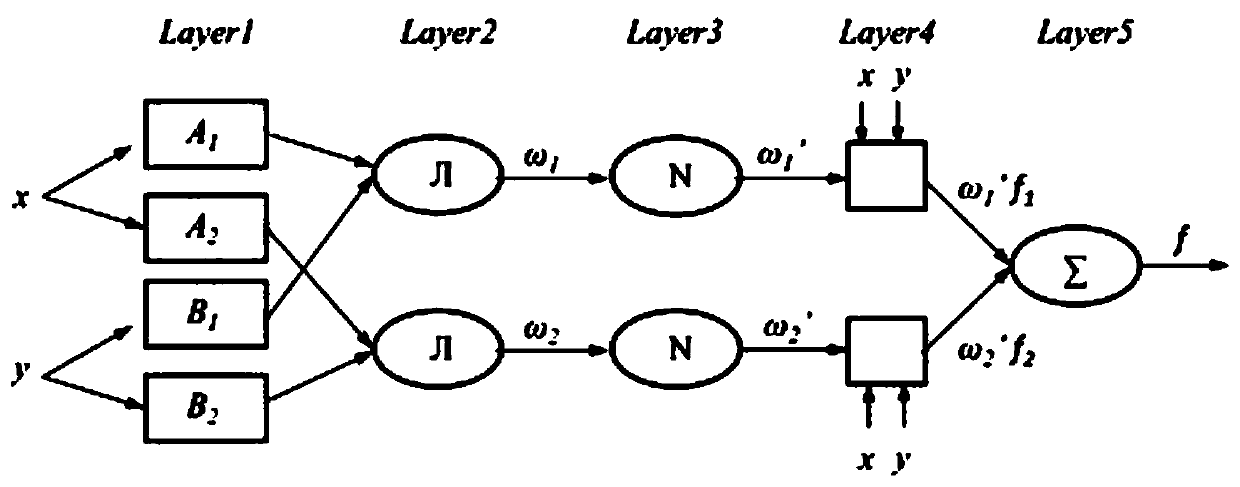

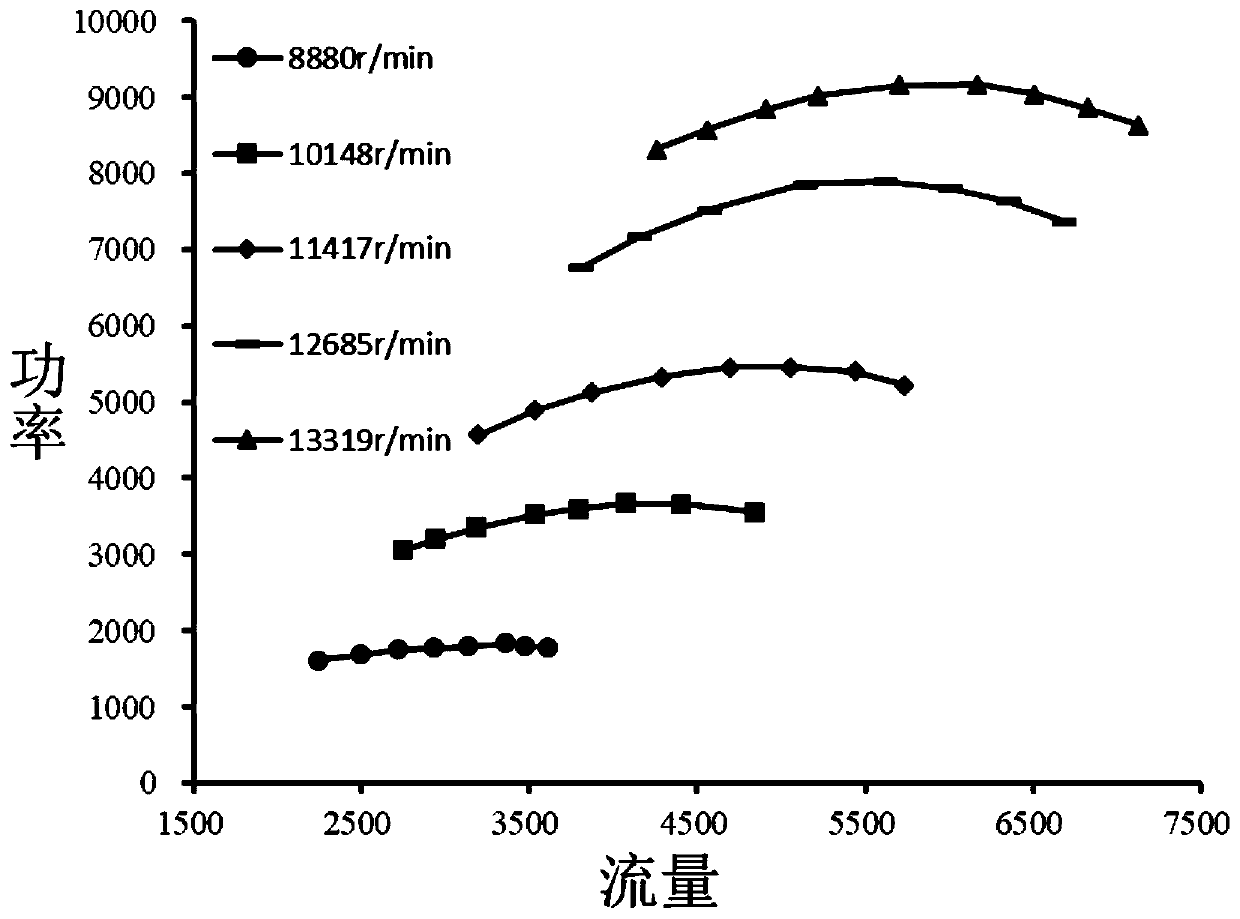

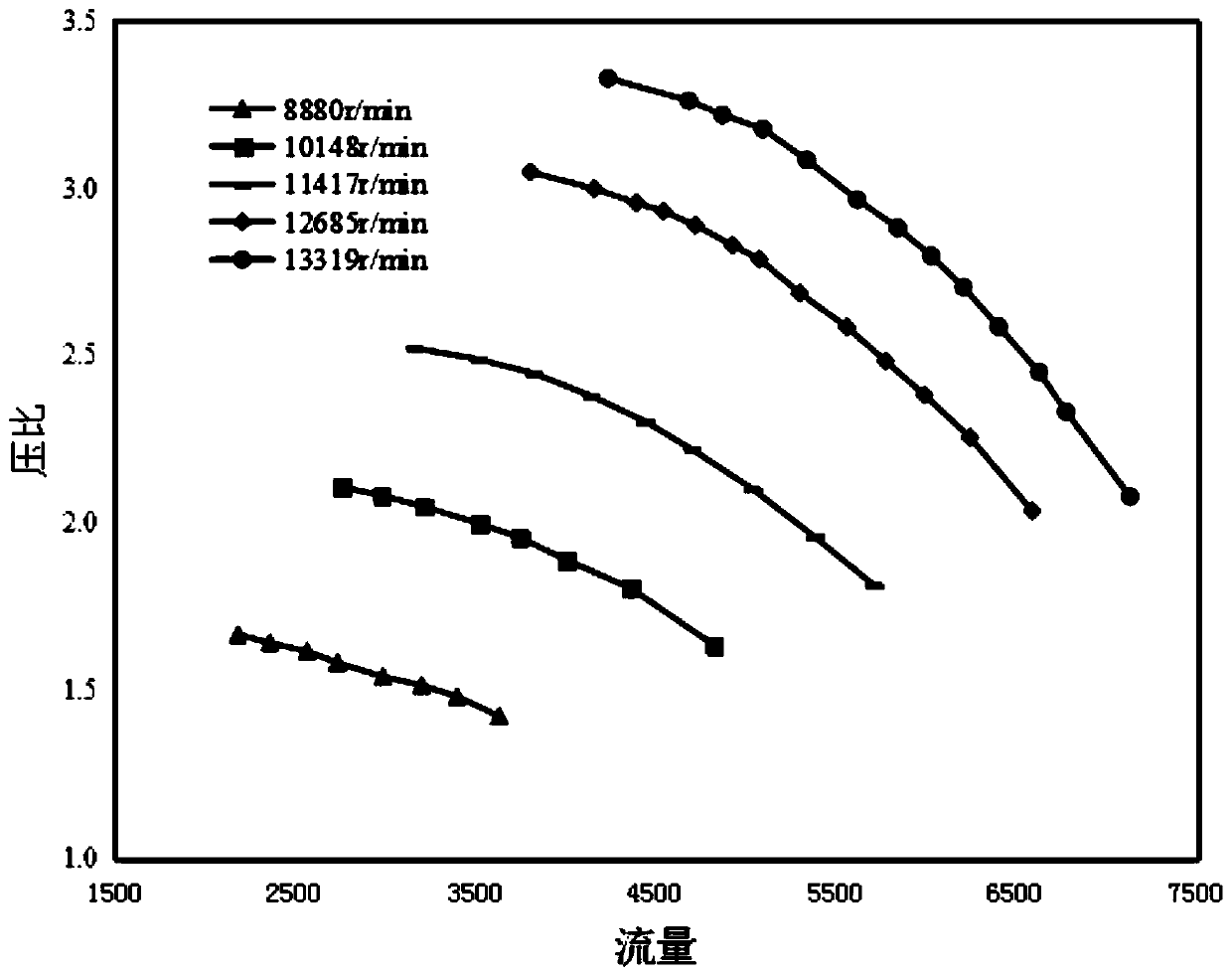

Compressor adaptive performance curve generation method

InactiveCN110110424AAdjust operating parametersDesign optimisation/simulationSpecial data processing applicationsSimulationLeast squares

The invention discloses a compressor adaptive performance curve generation method. The method comprises: obtaining a centrifugal compressor design performance curve and converting the centrifugal compressor design performance curve into a numerical form; obtaining theoretical performance parameters under actual working conditions by utilizing a similarity theory; establishing a performance curve mapping relation according to an ANFIS algorithm, and calculating theoretical performance parameters of all rotating speeds; combining historical operation data of the compressor, introducing a performance curve degradation factor, performing calculating by using a least square method to obtain a value of the degradation factor, and correcting theoretical performance parameters of all rotating speeds through the degradation factor; determining a stable working parameter range of the centrifugal compressor to obtain a compressor surge and blockage boundary curve; and finally generating actual performance curves of all rotating speeds of the centrifugal compressor under actual working conditions. Performance curves of all rotating speeds of the centrifugal compressor under actual working conditions can be accurately obtained, a stable working interval of the centrifugal compressor in actual operation is determined, and operation parameters of the compressor are adjusted according to the stable working interval.

Owner:CHINA PETROLEUM & CHEM CORP +2

System simulation test environment building and configuring system and method based on extensive markup language (XML)

ActiveCN102799709BImprove build efficiencyOptimizationSpecial data processing applicationsData accessControl table

The invention discloses a system simulation test environment building and configuring system and a system simulation test environment building and configuring method based on extensive markup language (XML). The system comprises a simulation test configurator, a performance parameter editor, a member monitoring service, a data access service, a test configuration library, a test resource library and an equipment performance library. According to the method, a test manager uses a simulation test configurator to perform position configuration, simulator working parameter configuration, interactive relation configuration, command relation configuration and the like on a master control table; the master control table broadcasts and sends an initialization command; members on each position monitor the service and receive the initialization command; a corresponding simulator program is downloaded and started from a database; the performance parameters which are required for operation are read from the equipment performance database by a data access service when the simulator is started; a configuration file in the XML format is downloaded from the test configuration library and the operation parameters are read by the data access service; and completing the initialization work after the system completes the starting, and waiting the start of a simulation test.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

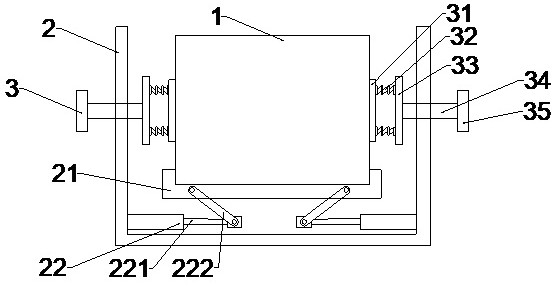

An energy-saving offshore wind power transformer with short-circuit resistance

ActiveCN113808814BAvoid Balance EffectsMaster the balanceTransformers/reacts mounting/support/suspensionElectric component structural associationTransformerControl cell

The present invention relates to an energy-saving short-circuit impact-resistant offshore wind power transformer, which includes: a housing for accommodating the main body of the transformer; a shock absorbing mechanism arranged at the bottom of the housing for maintaining the balance of the transformer; the control unit, They are respectively connected with the shock absorbing mechanism and the wind speed sensor to receive the data measured by the position sensor, the wind speed sensor and the weight sensor, and calculate the balance degree of the transformer according to the height of the bearing platform, and the control unit according to Compare the transformer balance degree with the preset value and judge whether the transformer balance degree meets the standard according to the result, and when the transformer balance degree does not meet the standard, correct the operating parameters of the shock absorbing device according to the actual transformer balance degree, and control the The unit adjusts the parameters of the damping device, while effectively increasing the anti-shock performance of the transformer, it can effectively avoid the occurrence of short circuits and accidents, thereby effectively increasing the safety of the transformer.

Owner:山东晨宇电气股份有限公司

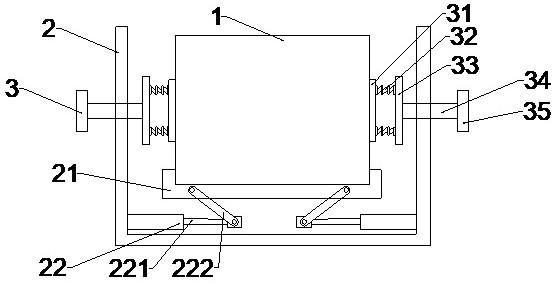

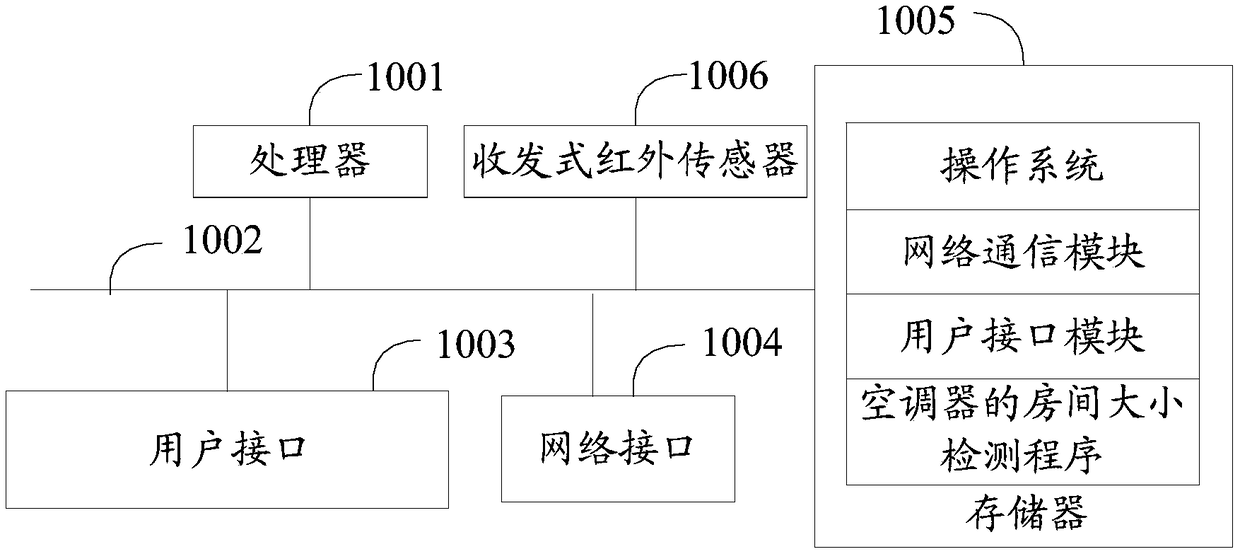

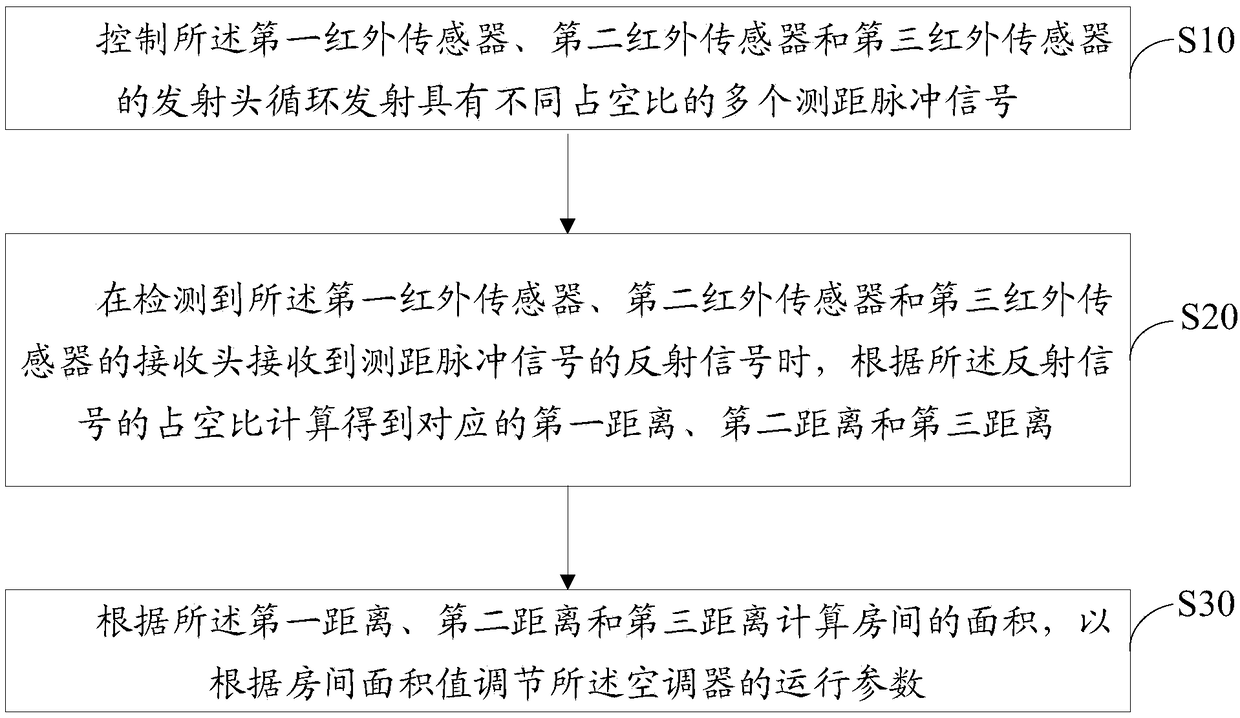

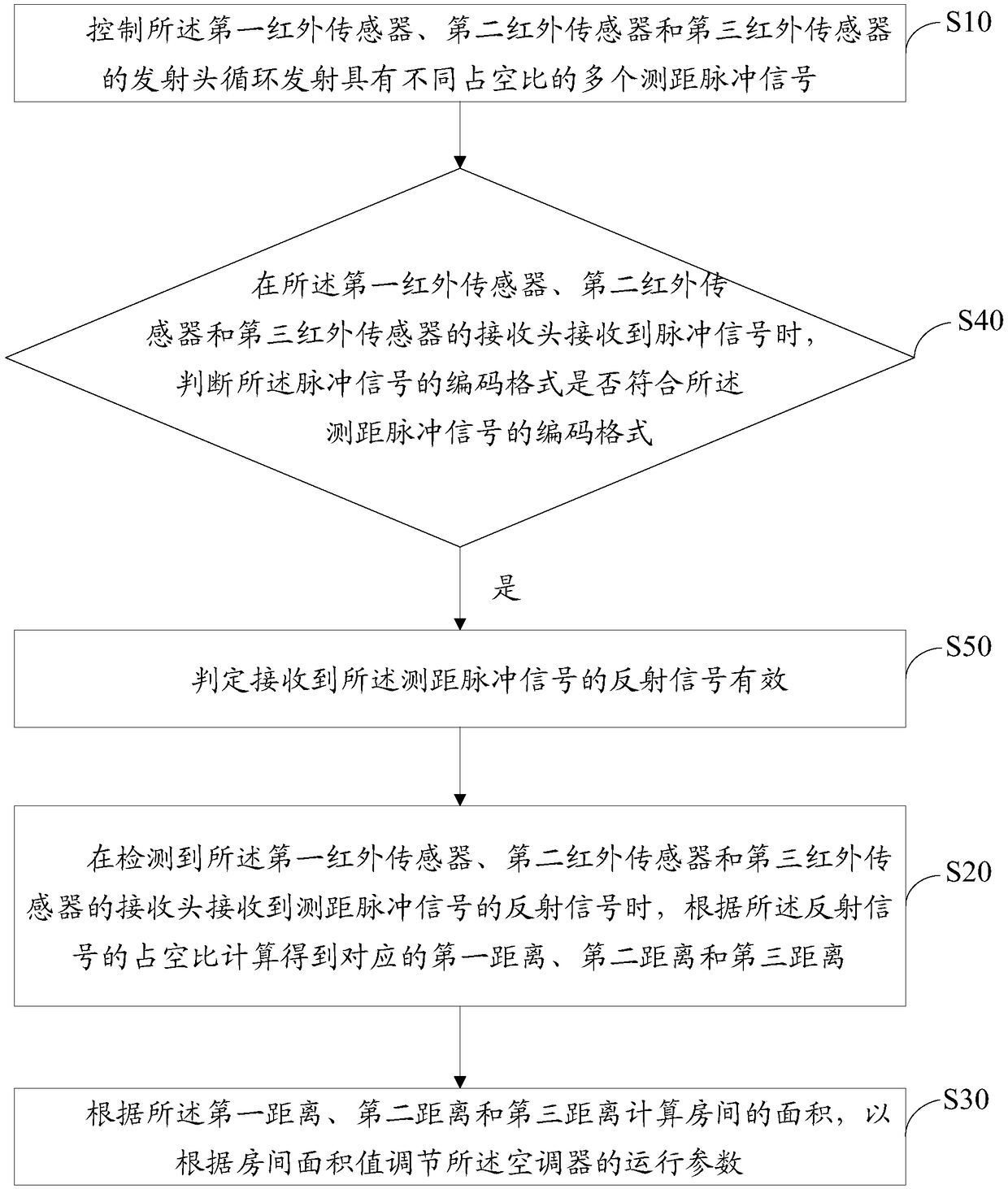

Air conditioner room size detection method, air conditioner and computer storage medium

InactiveCN108761473AAdjust operating parametersMechanical apparatusElectromagnetic wave reradiationElectrical and Electronics engineeringDuty cycle

The present invention discloses an air conditioner room size detection method. The air conditioner is built in a transmit-receive first infrared sensor, a second infrared sensor and a third infrared sensor. The method comprises the steps of: controlling transmitting heads of the first infrared sensor, the second infrared sensor and the third infrared sensor to circularly transmit a plurality of ranging pulse signals with different duty ratios; when detecting that the receiving heads of the first infrared sensor, the second infrared sensor and the third infrared sensor receive reflection signals of the ranging pulse signals, calculating and obtaining corresponding first, second and third distances according to the duty ratio of the reflection signals; and calculating the area of the room according to the first, second and third distances to regulate the operation parameters of the air conditioner according to the area value of the room. The present invention further discloses an air conditioner and a computer storage medium. Therefore, the area of the room is detected and the operation parameters of the air conditioner are regulated according to the area.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

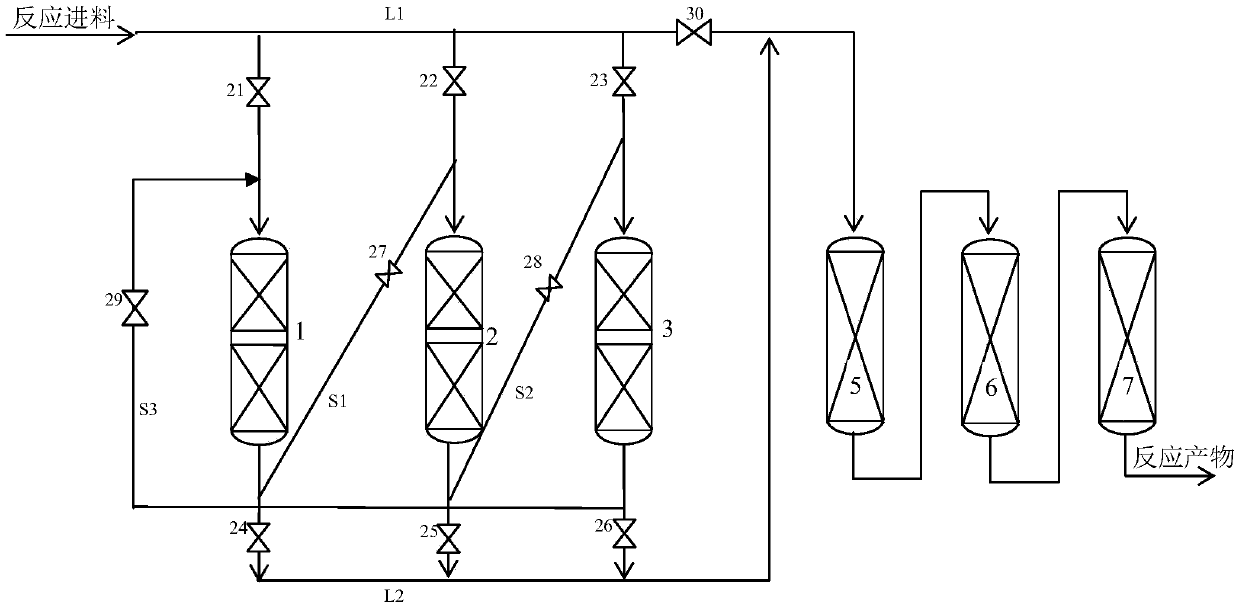

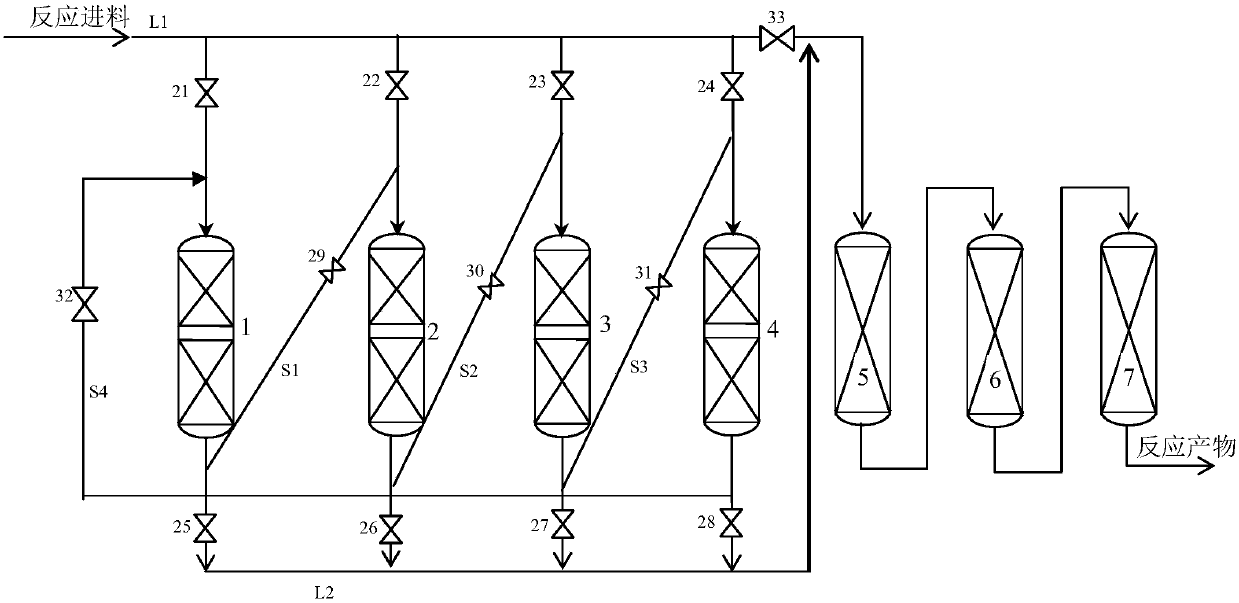

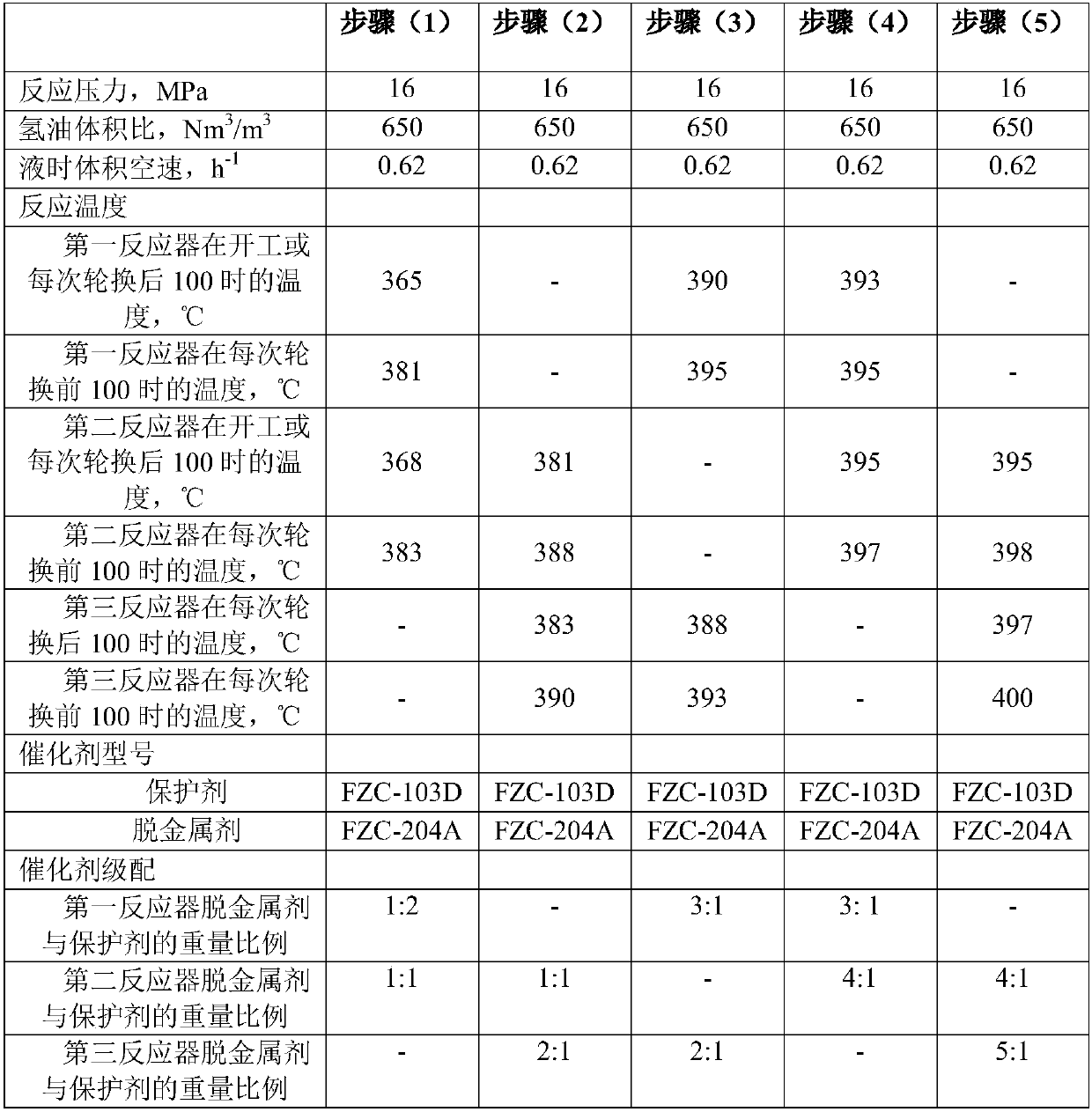

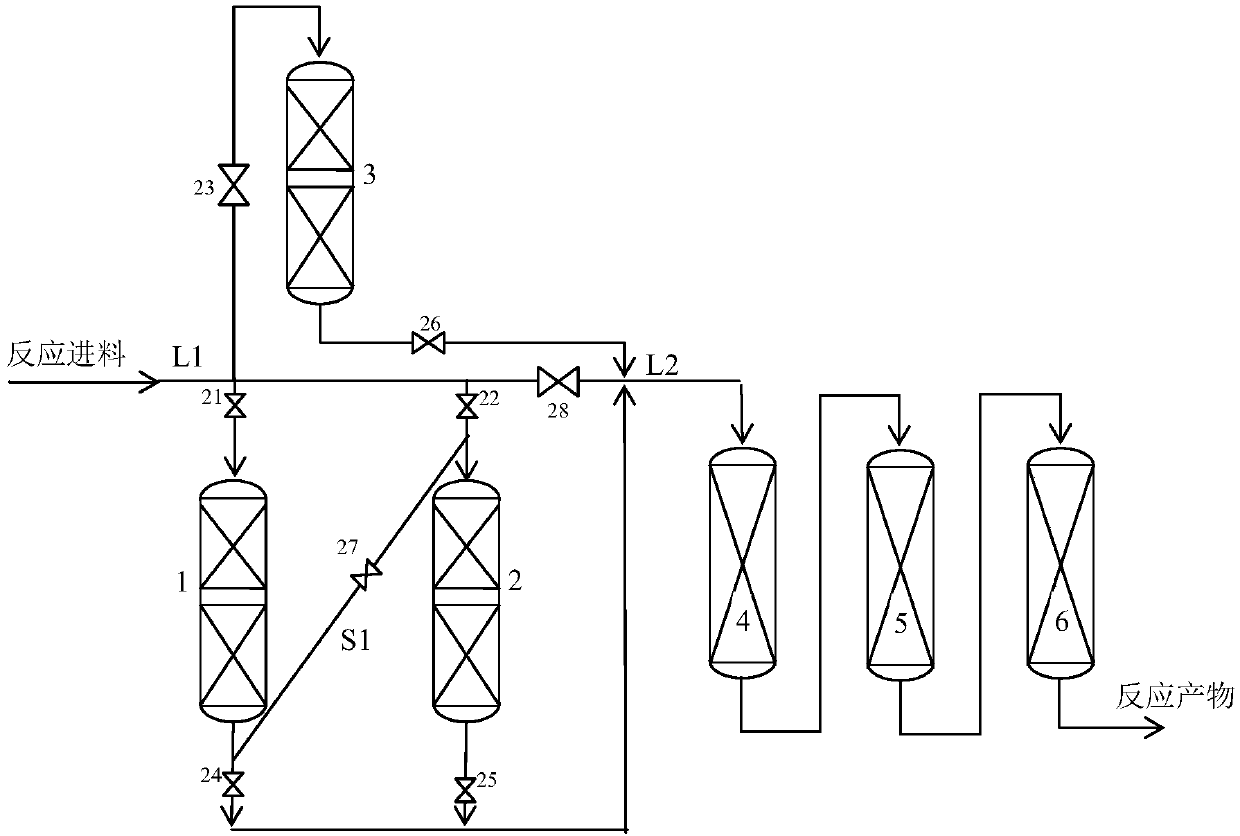

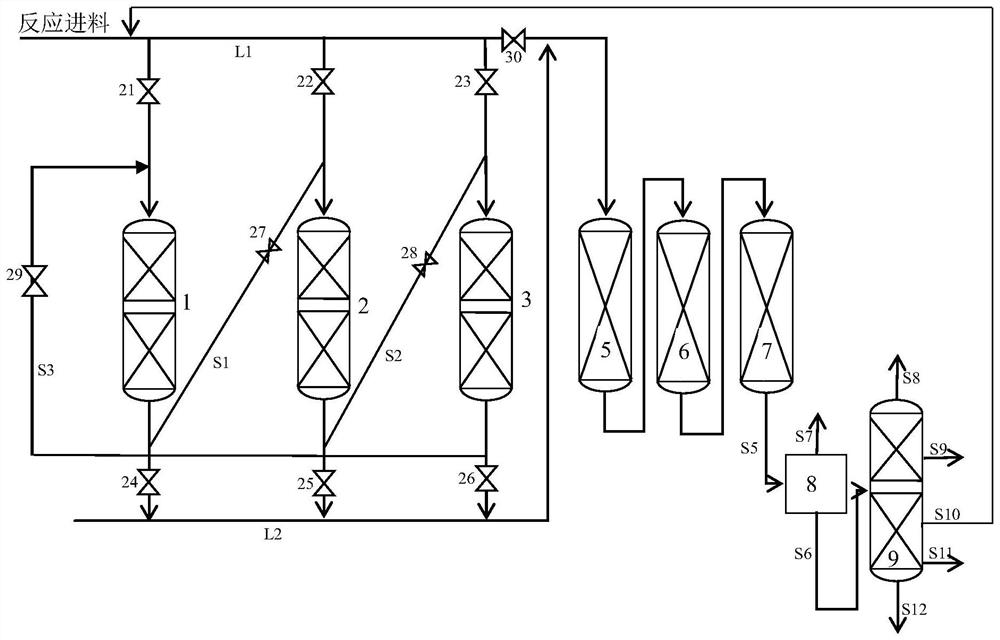

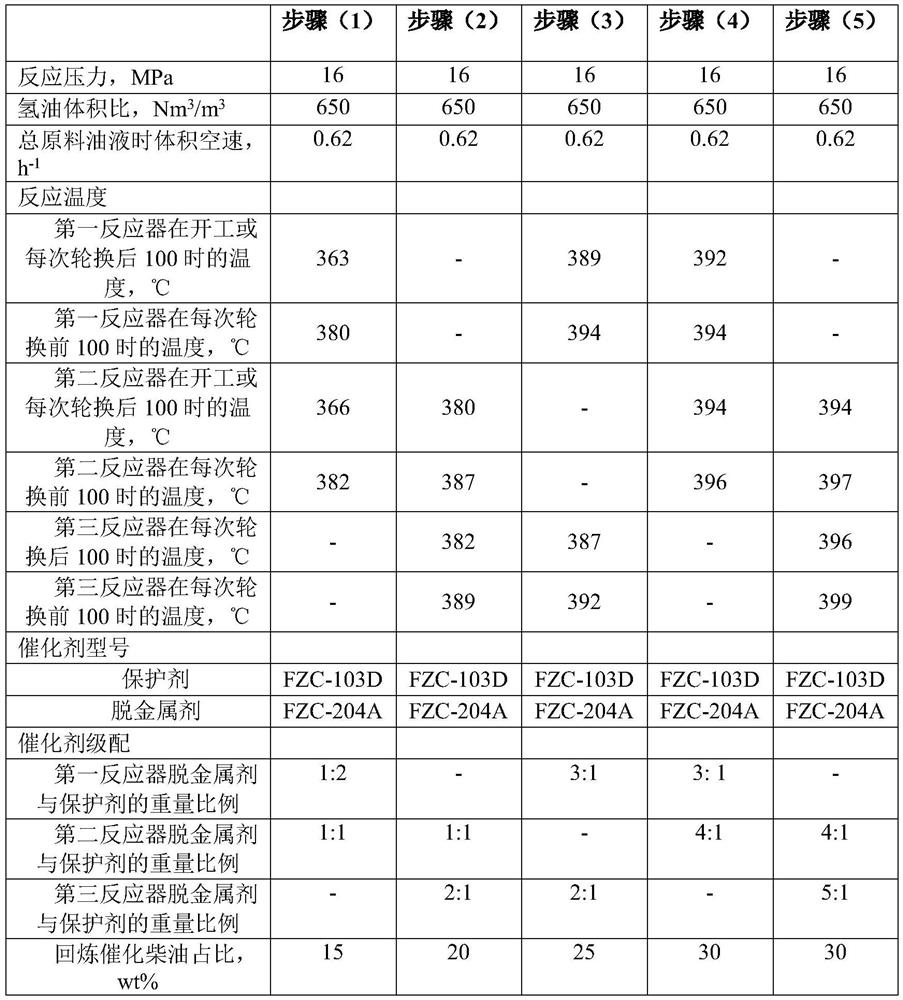

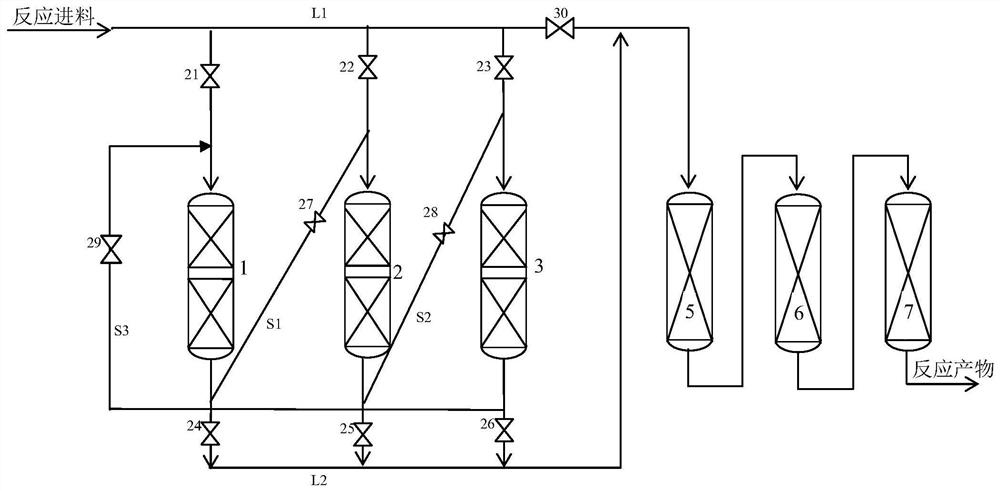

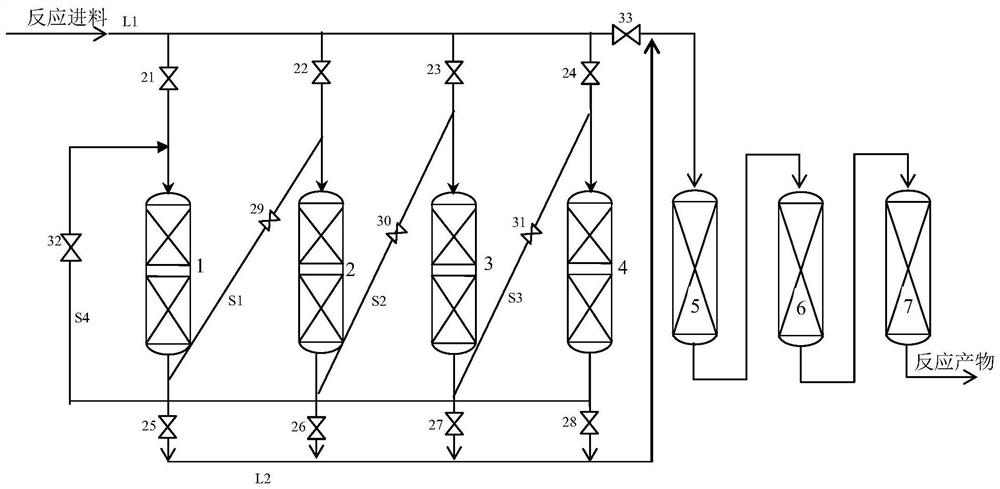

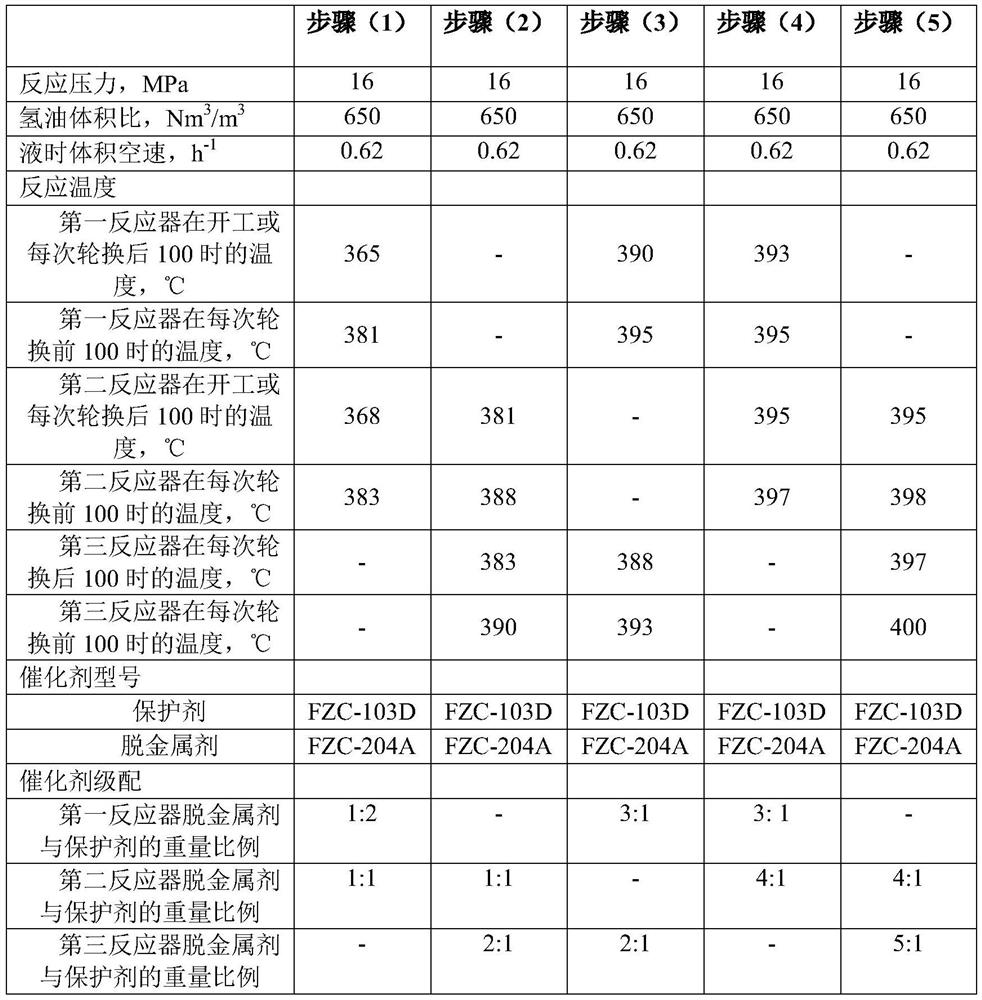

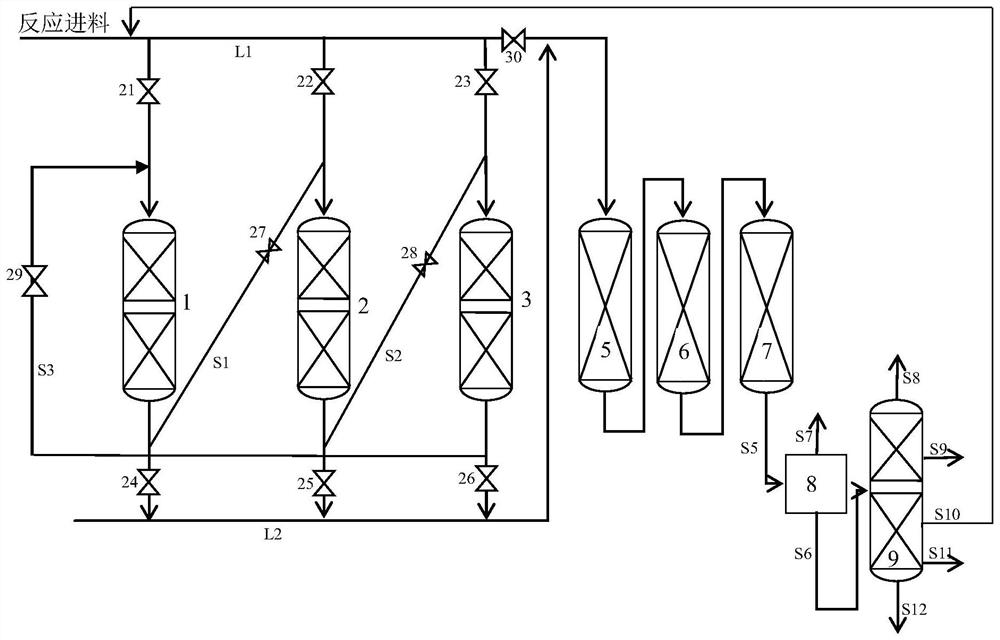

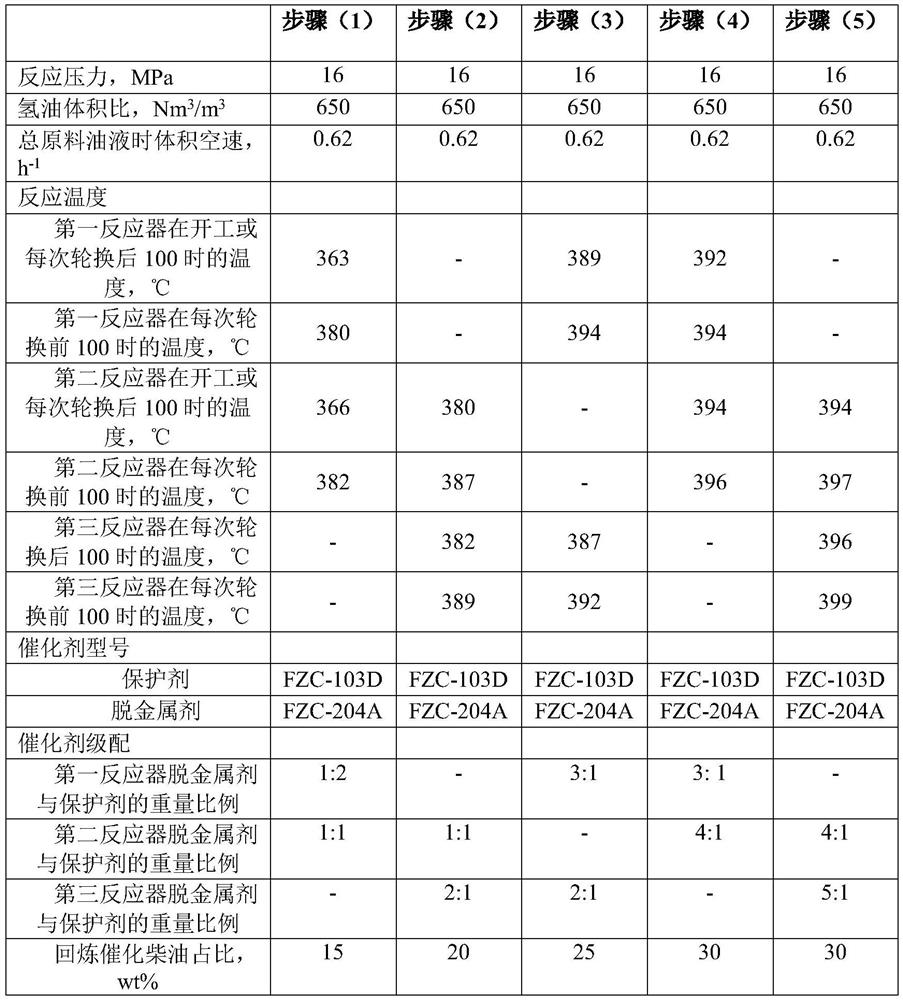

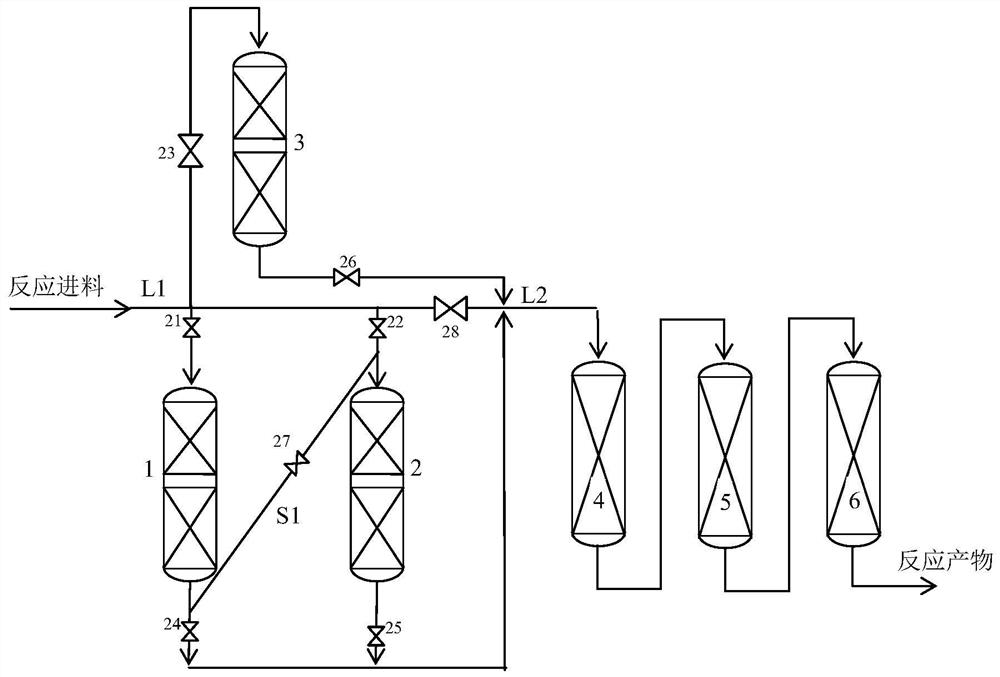

In-series alternated hydrotreating method and system for fixed-bed residue oil

ActiveCN110499188ARealize long-term operationExtended run timeTreatment with hydrotreatment processesFixed bedReaction zone

The invention discloses an in-series alternated hydrotreating method and system for fixed-bed residue oil. The method comprises the following steps: a hydropretreating reaction zone and a hydrotreating reaction zone are arranged in series for residue oil hydrotreating, and the hydropretreating reaction zone comprises N hydropretreating reactors, wherein the reactors from a first hydropretreating reactor to a (N-1)th hydropretreating reactor are sequentially connected in series to be used as an (N-1)-stage online hydropretreating reactor, and a Nth hydropretreating reactor is used as an off-line hydropretreating reactor; when pressure drop in the first hydropretreating reactor rises to a designed upper limit of pressure drop or the activity of a catalyst is lower than a required value, thefirst hydropretreating reactor is switched out, and the Nth hydropretreating reactor is used as the (N-1)-stage online hydropretreating reactor; and switching is performed according to the above manner, so that an uninterrupted (N-1)-stage hydropretreating reaction can be realized. The method provided by the invention can improve the utilization efficiency of a main catalyst and the operation stability of a device, and greatly extend the operating time of a hydrotreating reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy-saving and anti-short-circuit-impact offshore wind power transformer

ActiveCN113808814AAvoid Balance EffectsMaster the balanceTransformers/reacts mounting/support/suspensionElectric component structural associationMarine engineeringTransformer

The invention relates to an energy-saving and anti-short-circuit-impact offshore wind power transformer. The transformer comprises a shell which is used for containing a transformer body; a damping mechanism which is arranged at the bottom of the shell and used for maintaining the balance of the transformer; and a control unit which is connected with the damping mechanism and a wind speed sensor and is used for receiving data measured by a position sensor, the wind speed sensor and a weight sensor, calculating the balance degree of the transformer according to the height of a bearing table, comparing the balance degree of the transformer with a preset value, judging whether the balance degree of the transformer meets the standard or not according to the comparison result, and correcting the operation parameters of the damping device according to the actual balance degree of the transformer if the balance degree of the transformer does not meet the standard. The parameters of the damping device are adjusted through the control unit, the shock resistance of the transformer is effectively improved, meanwhile, short circuit and accidents can be effectively avoided, and then the safety of the transformer is effectively improved.

Owner:山东晨宇电气股份有限公司

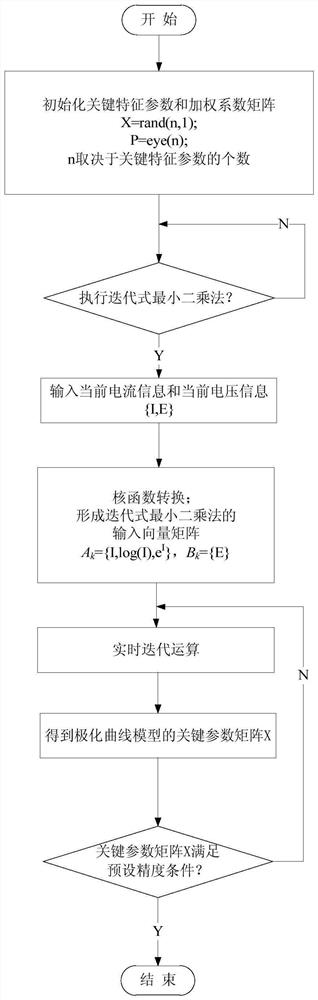

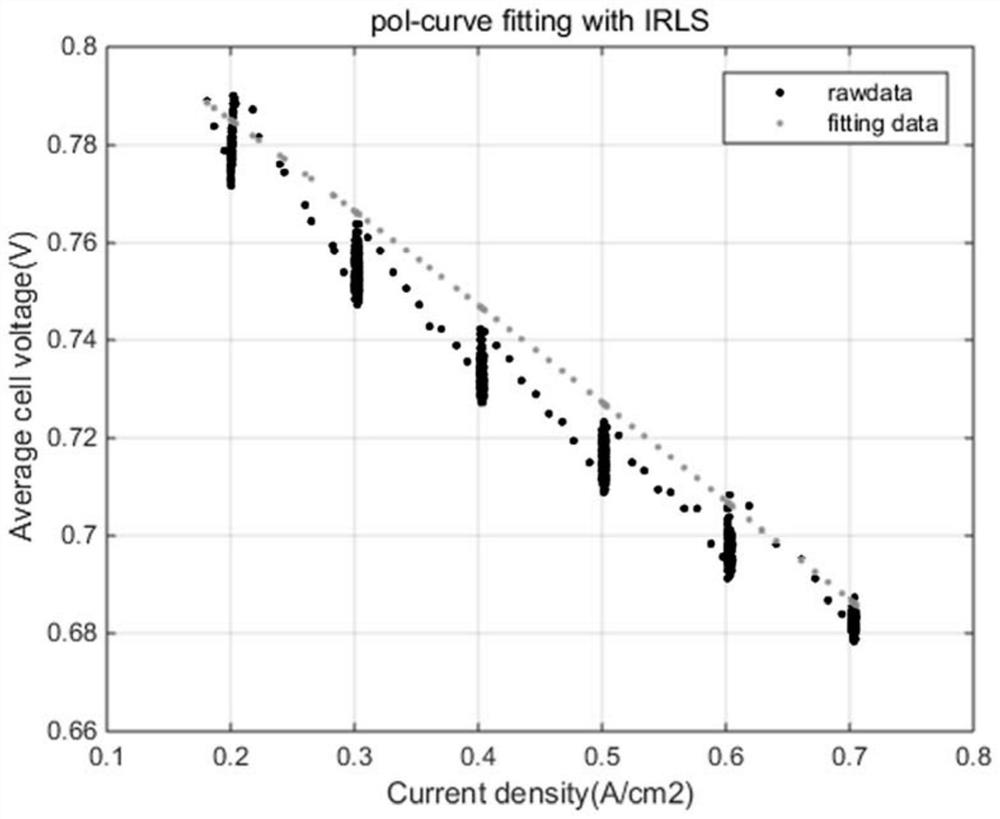

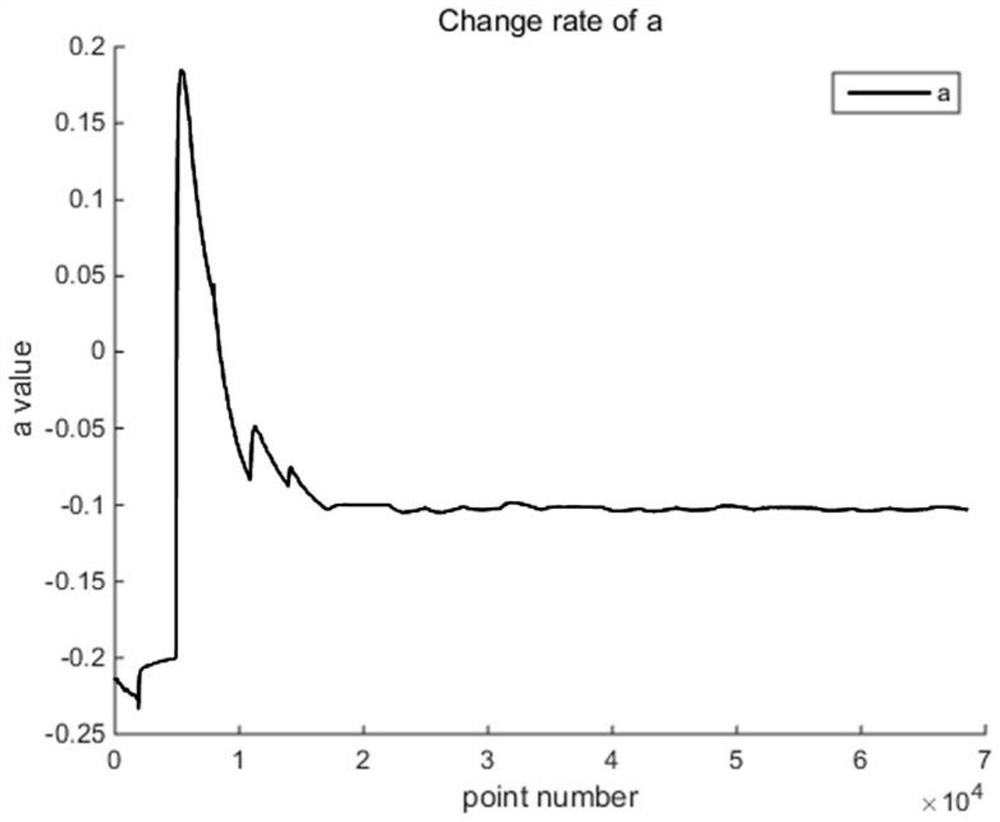

Non-storage online iterative estimation method of polarization curve and fuel cell system

PendingCN114335628AEasy to monitor status changesAdjust operating parametersFuel cell controlProcess engineeringControl engineering

The invention provides a non-storage type online iterative estimation method of a polarization curve and a fuel cell system. The method comprises the following steps: establishing a polarization curve model of a fuel cell; acquiring current current information and current voltage information of the fuel cell in real time; identifying key characteristic parameters of the polarization curve model through a parameter identification system based on the current current information and the current voltage information, forming a new polarization curve model based on the key characteristic parameters, deleting the historical current information and the historical voltage information, and updating the new polarization curve model into a controller of the fuel cell, the method is based on the iterative least square method, the requirement for a controller of the fuel cell is small, the polarization curve model can be updated more accurately in real time, so that the state change of the fuel cell can be monitored conveniently, the operation parameters of the fuel cell can be adjusted conveniently, the operation process is simple, and the operation cost is low.

Owner:SHANGHAI CHONGSU ENERGY TECH CO LTD

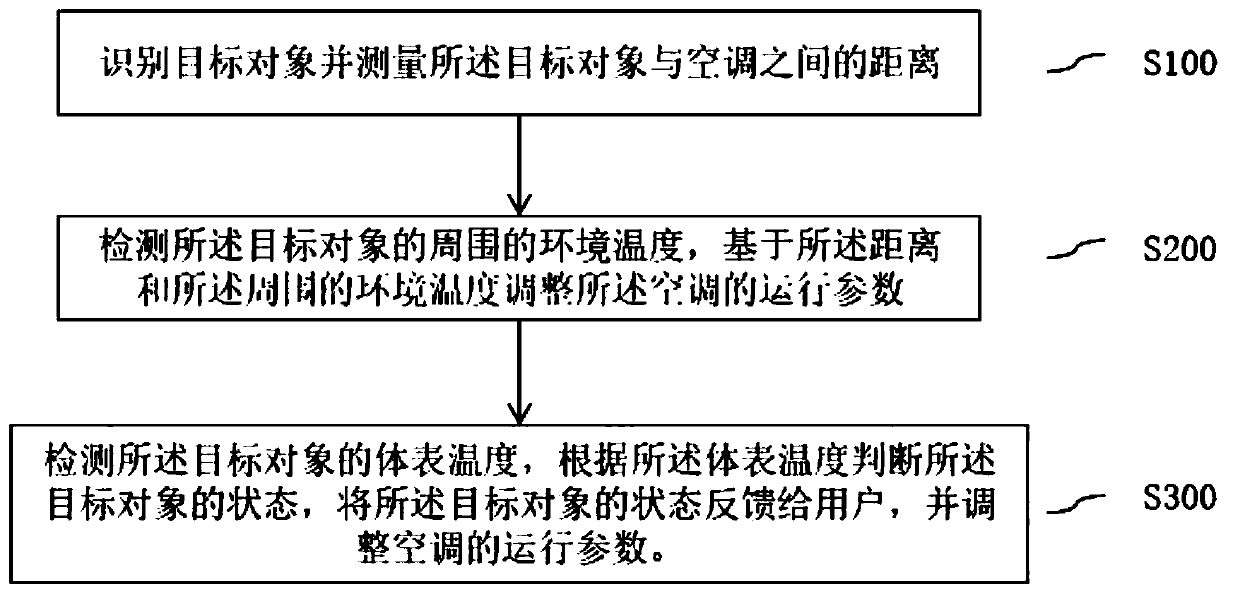

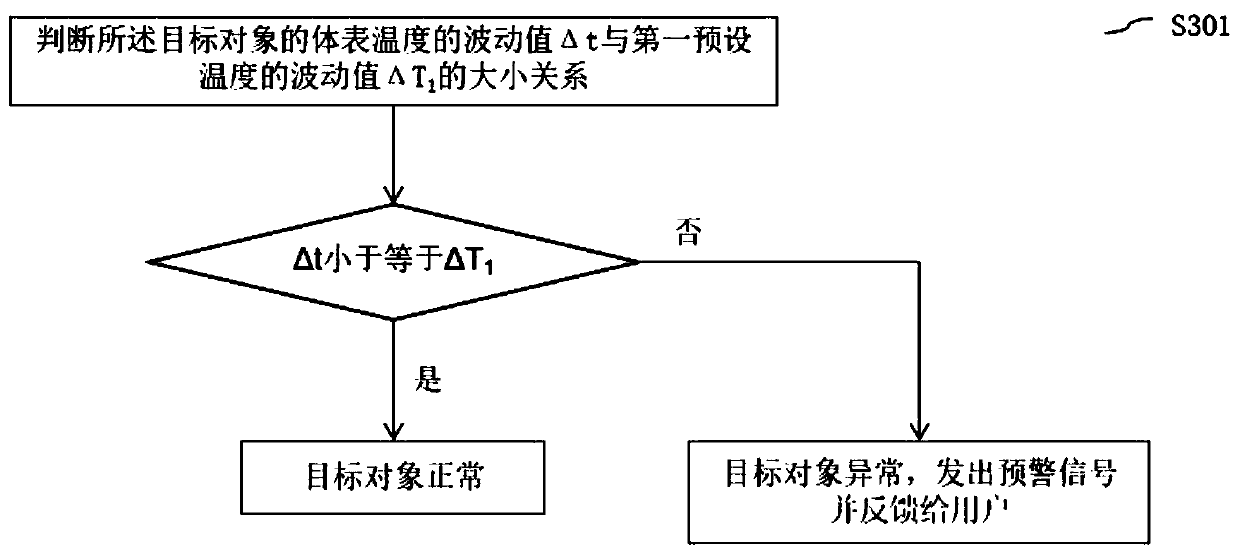

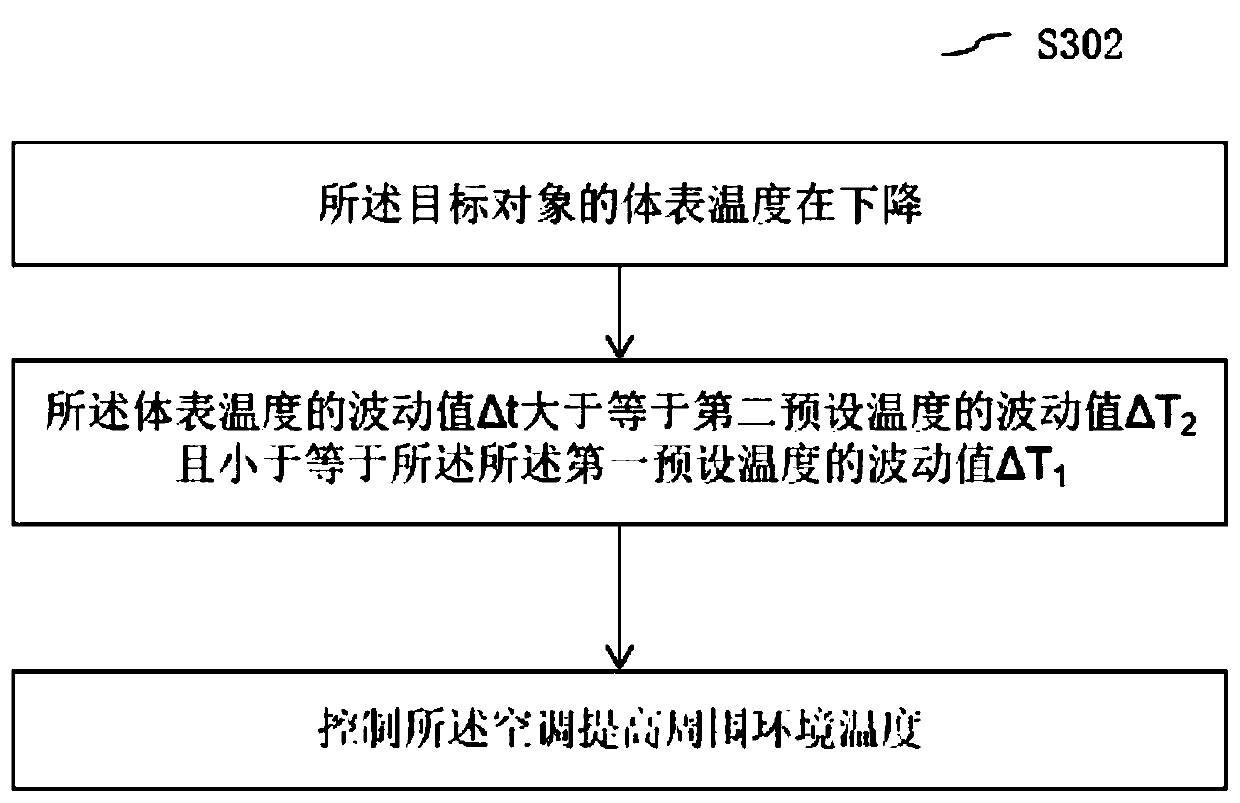

Control method and control system of air conditioner with monitoring function and air conditioner

InactiveCN111089389AImprove comfortImprove temperature measurement efficiencyMechanical apparatusSpace heating and ventilation safety systemsControl systemControl engineering

The invention relates to a control method and a control system of an air conditioner with a monitoring function and the air conditioner. The control method of the air conditioner with the monitoring function comprises the steps that a target object is recognized, and the distance between the target object and the air conditioner is measured; a temperature of the environment around the target object is detected; and operating parameters of the air conditioner are adjusted based on the distance and the ambient environment temperature. According to the method, after the target object is recognized, the distance between the target object and the air conditioner is measured, the temperature of the environment around the target object is detected, and the operating parameters of the air conditioner are adjusted based on the distance and the ambient temperature, so that on one hand, the target object is locked firstly, the temperature measurement efficiency is improved, on the other hand, thecomfort of the environment of the target object is improved.

Owner:NINGBO AUX ELECTRIC +1

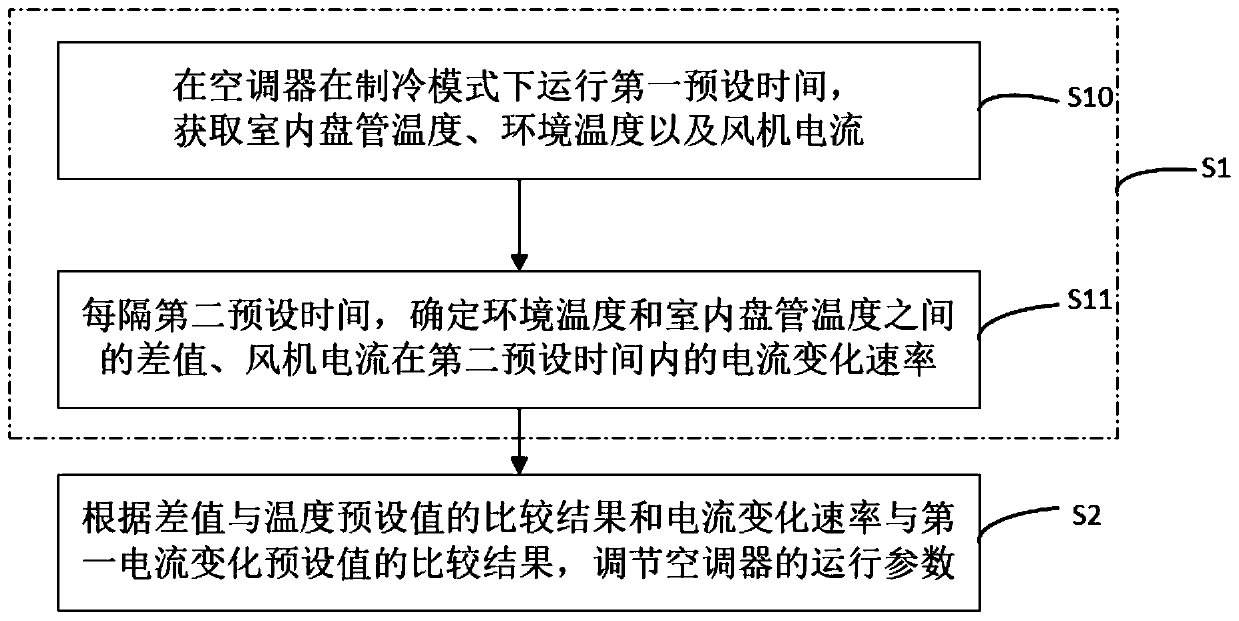

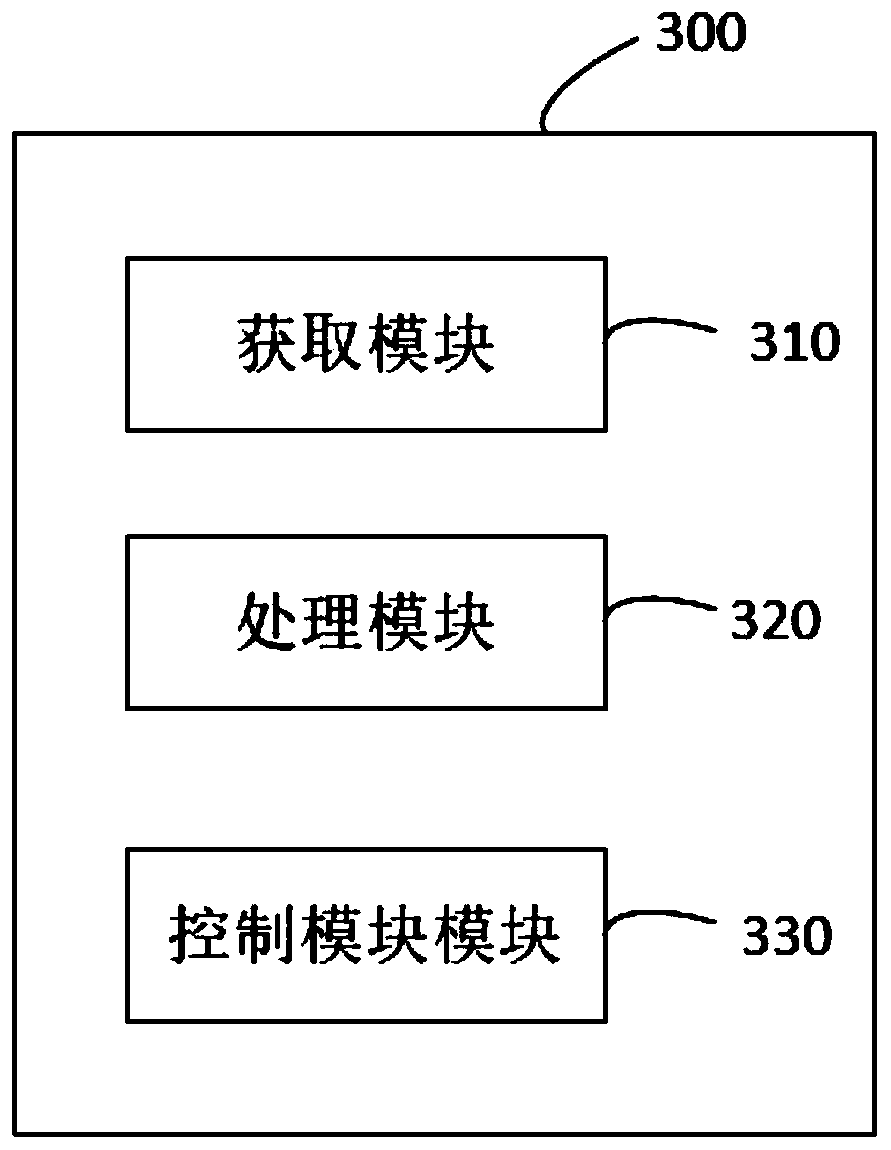

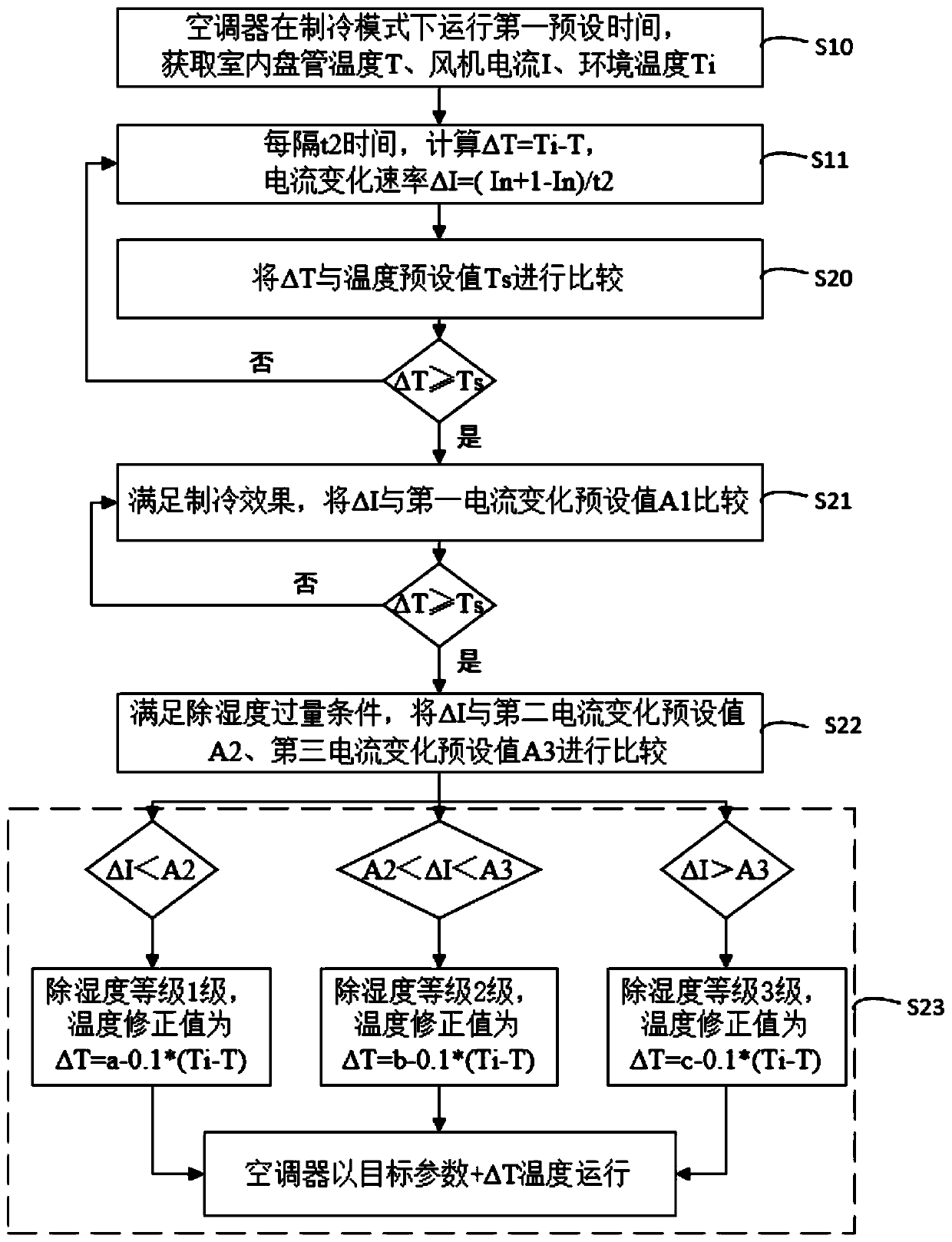

Control method and device for dehumidification of air conditioner, air conditioner, and storage medium

ActiveCN110671783ASimplify the operation control processAvoid the problem of poor comfortMechanical apparatusSpace heating and ventilation safety systemsControl theoryRefrigeration

The invention provides a control method and device for dehumidification of an air conditioner, the air conditioner, and a storage medium. The control method comprises the steps that after the air conditioner operates in a refrigeration mode for a first preset time, an indoor coiler temperature, an environment temperature and a fan current are acquired, and a difference between the environment temperature and the indoor coiler temperature and a current change rate of the fan current within a second preset time are determined; and operating parameters of the air conditioner are adjusted according to a comparison result of the difference and a preset temperature value as well as a comparison result of the current change rate and a first preset current change value. By the adoption of the method, the operating parameters of the air conditioner can be corrected if necessary while the refrigeration effect is guaranteed, unnecessary dehumidification is reduced, the energy efficiency is improved, and meanwhile, the problem of poor comfort caused when the indoor space is too dry is solved.

Owner:NINGBO AUX ELECTRIC

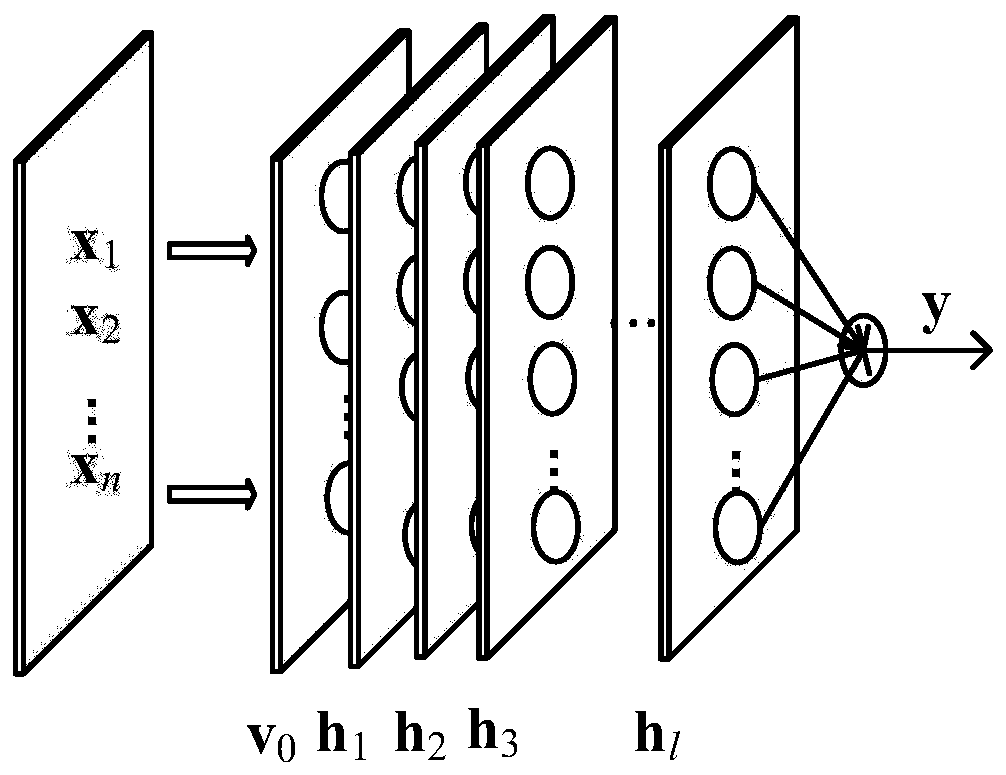

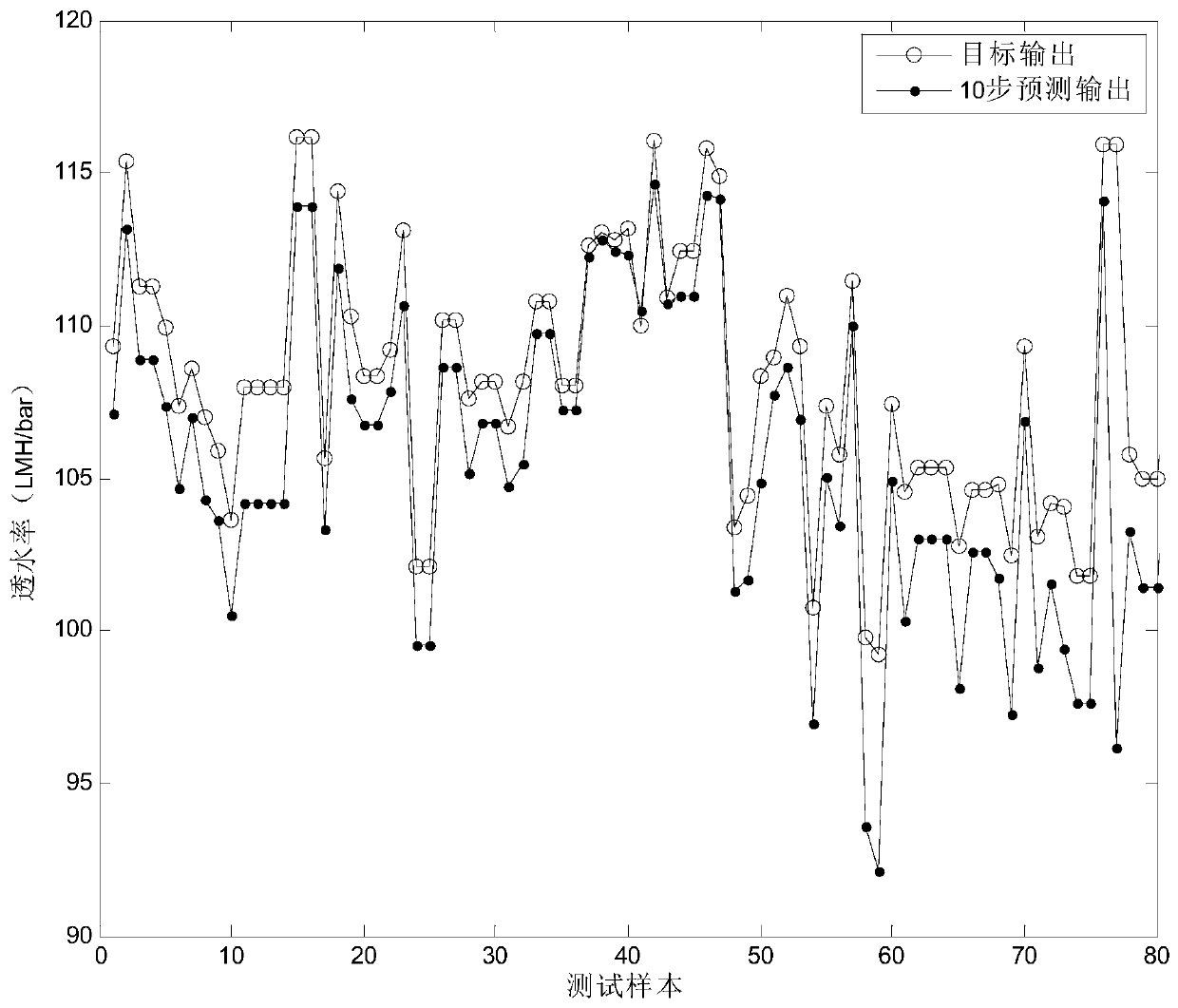

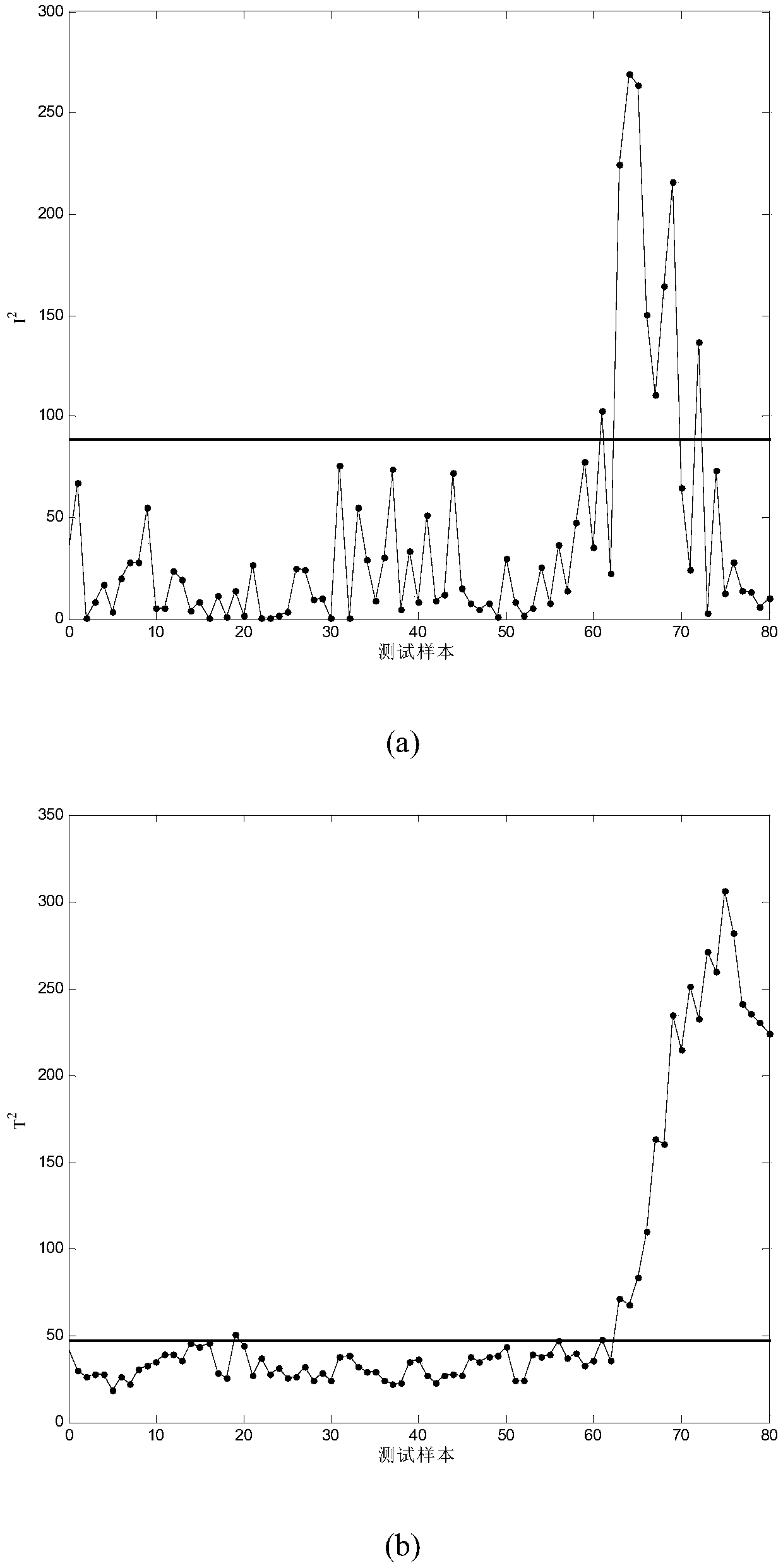

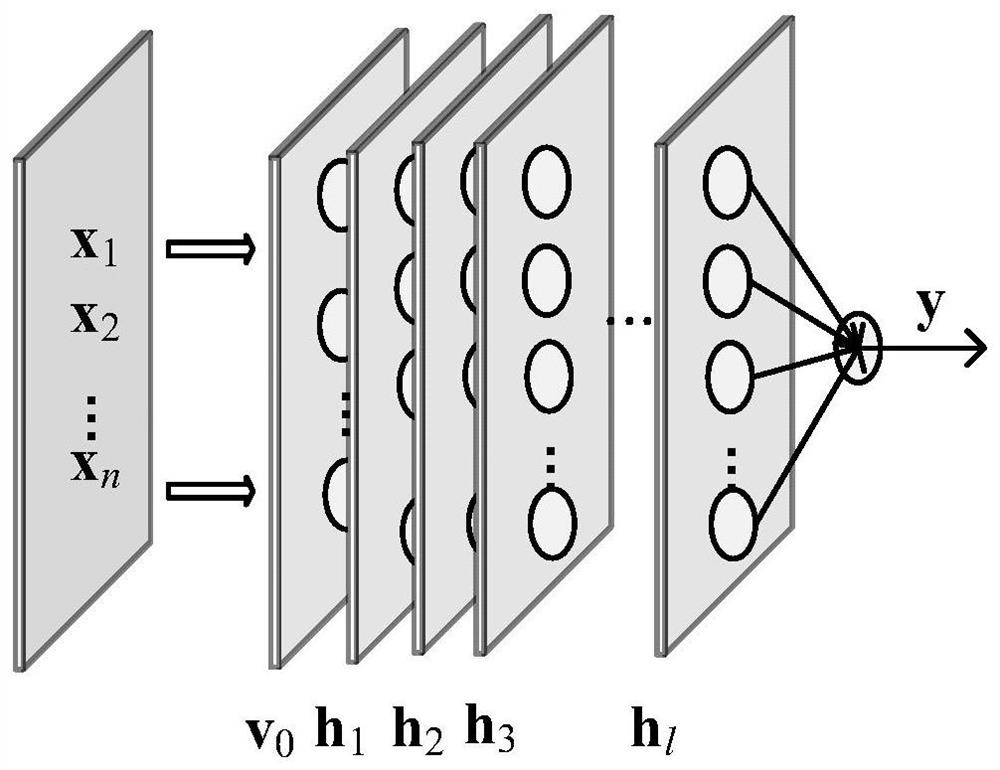

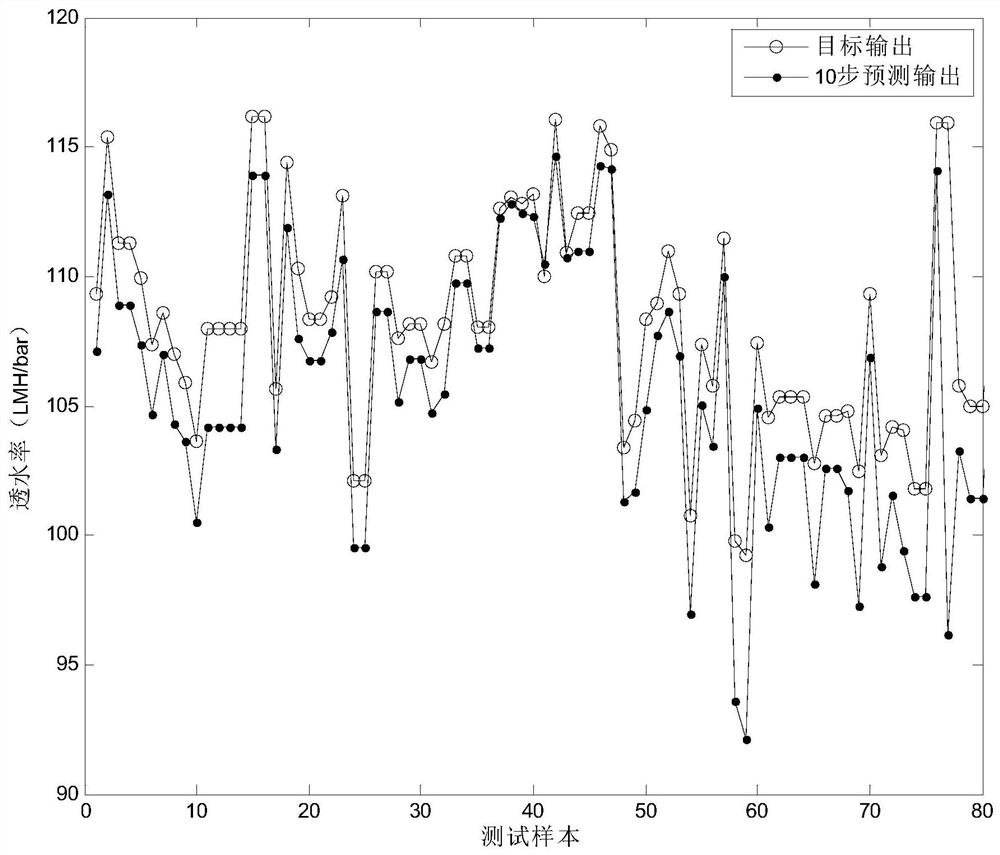

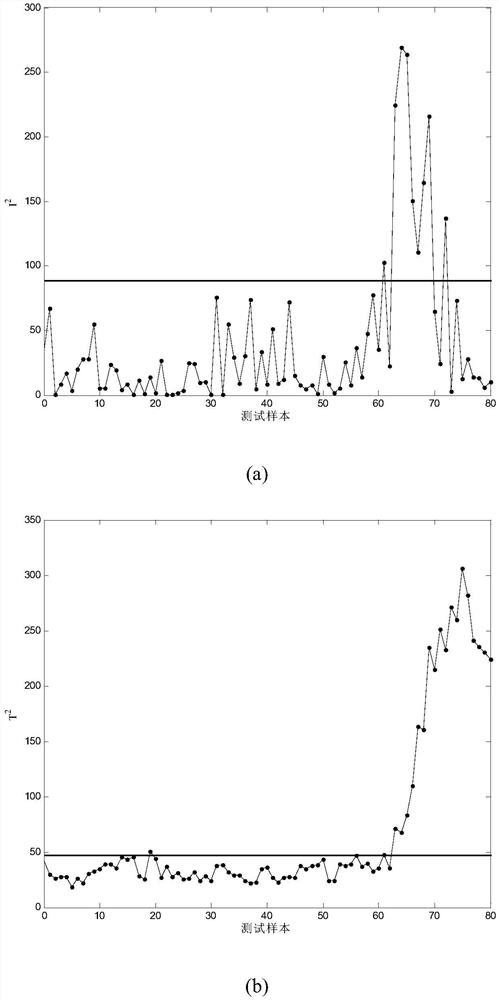

Membrane bioreactor-MBR membrane pollution intelligent decision-making method

ActiveCN111204867AReduce water productionAdjust operating parametersWater treatment parameter controlGeneral water supply conservationDeep belief networkMembrane permeability

The invention discloses a membrane bioreactor-MBR membrane pollution intelligent decision-making method, and belongs to the field of online early warning of sewage treatment water quality parameters.The method comprises the following steps: firstly, deeply analyzing a membrane pollution mechanism, constructing a membrane pollution prediction model based on a deep belief network, and realizing accurate prediction of the membrane permeability; realizing intelligent early warning of membrane pollution based on comprehensive evaluation of the membrane pollution by utilizing fusion of the predicted value of the water permeability and related parameter variables; based on main factors of membrane pollution, establishing an intelligent decision-making model based on data and knowledge, and providing decision-making support for operators, so that harm caused by membrane pollution is reduced, the occurrence rate of membrane pollution is reduced, the safety of the MBR sewage treatment process is guaranteed, and efficient and stable operation of an MBR sewage treatment plant is promoted.

Owner:BEIJING UNIV OF TECH

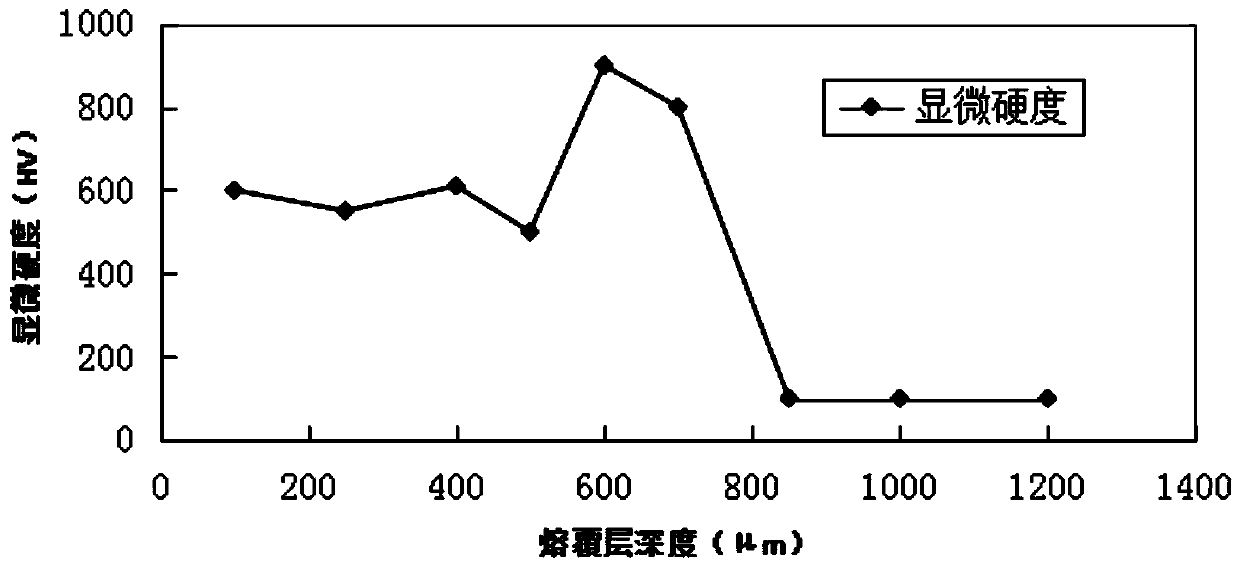

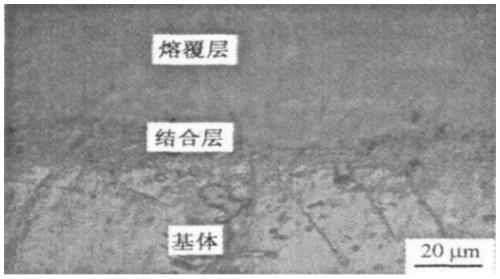

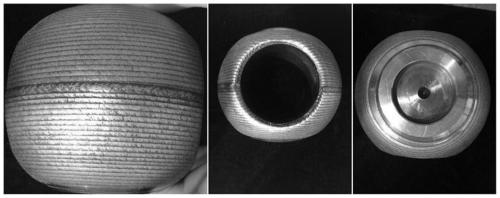

Cladding layer of valve sealing surface

InactiveCN111041471AImprove performanceAdaptability improvement or optimizationMetallic material coating processesLap jointVALVE PORT

The invention discloses a cladding layer of a valve sealing surface. The alloy powder of the cladding layer comprises iron, chromium, nickel, molybdenum, boron, silicon, carbon, tungsten and vanadiumelements, wherein the iron is used as a main body, the content of the iron is more than 50%, the content of the chromium is more than 15%, the content of the boron is 2.0%, and the content of the silicon is 2.0%; the preparation technological process of the alloy powder comprises the steps of burdening, smelting, atomizing, drying and screening; and the cladding method of the cladding layer adoptsa laser cladding process, cladding lap joint is carried out on the valve sealing surface, and the thickness of the cladding layer is 1000-2000 microns. According to the obtained cladding layer, cobalt-free alloy with iron and chromium as main bodies is utilized, the wear resistance, the impact resistance, the corrosion resistance and the like of the sealing surface of the ball valve are more excellent through a specific alloy powder preparation process and a cladding method of the cladding layer, the quality of the valve sealing surface is improved, and the service life of the valve is prolonged.

Owner:河北瑞驰伟业科技有限公司

Alternated fixed-bed residual oil hydrotreatment method and system

ActiveCN110499189ARealize long-term operationHigh metal capacityTreatment with hydrotreatment processesPre treatmentProcess engineering

The invention discloses an alternated fixed-bed residual oil hydrotreatment method and system. According to the method, a first hydropretreating reactor and a second hydropretreating reactor are in series connection to be served as online hydropretreating reactors, the first hydropretreating reactor is switched over and serves as a non-online hydropretreating reactor when pressure drop in the first hydropretreating reactor rises to a pressure drop design upper limit or the activity of a catalyst is lower than a required value, and then, switchover is carried out according to a sequence that the second hydropretreating reactor and a third hydropretreating reactor are connected in parallel, the third hydropretreating reactor and the first hydropretreating reactor are connected in parallel, and the first hydropretreating reactor and the second hydropretreating reactor are connected in series, so that the condition that two hydropretreating reactors are online simultaneously is achieved, and an uninterrupted hydropretreating reaction can be achieved. According to the method, the utilization efficiency of a main catalyst and the stability of device operation can be improved, and the operating time of a hydrotreating reactor is greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

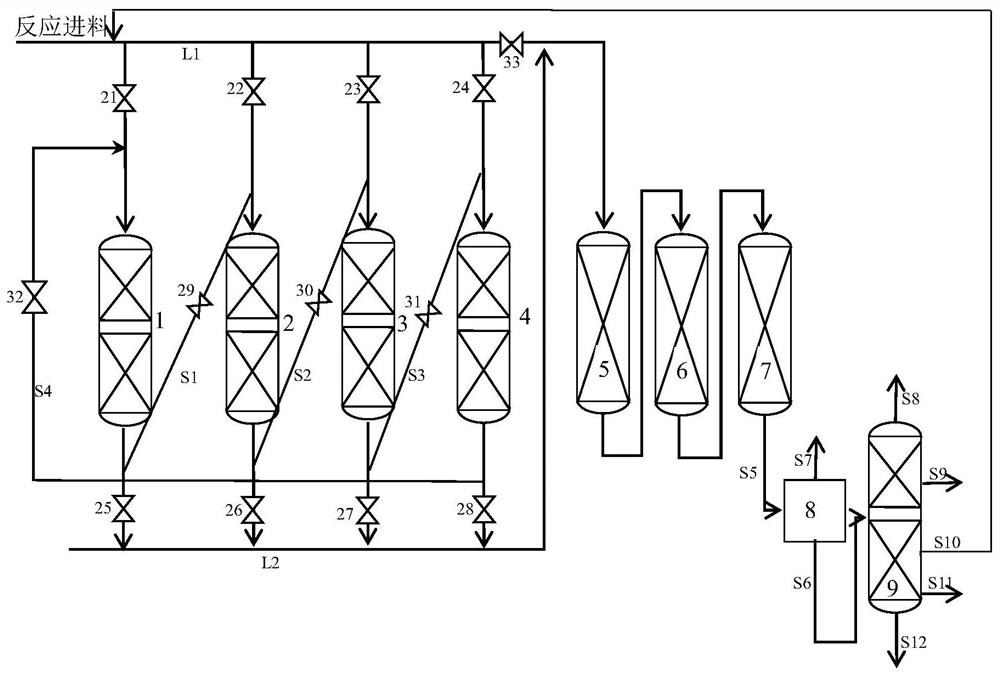

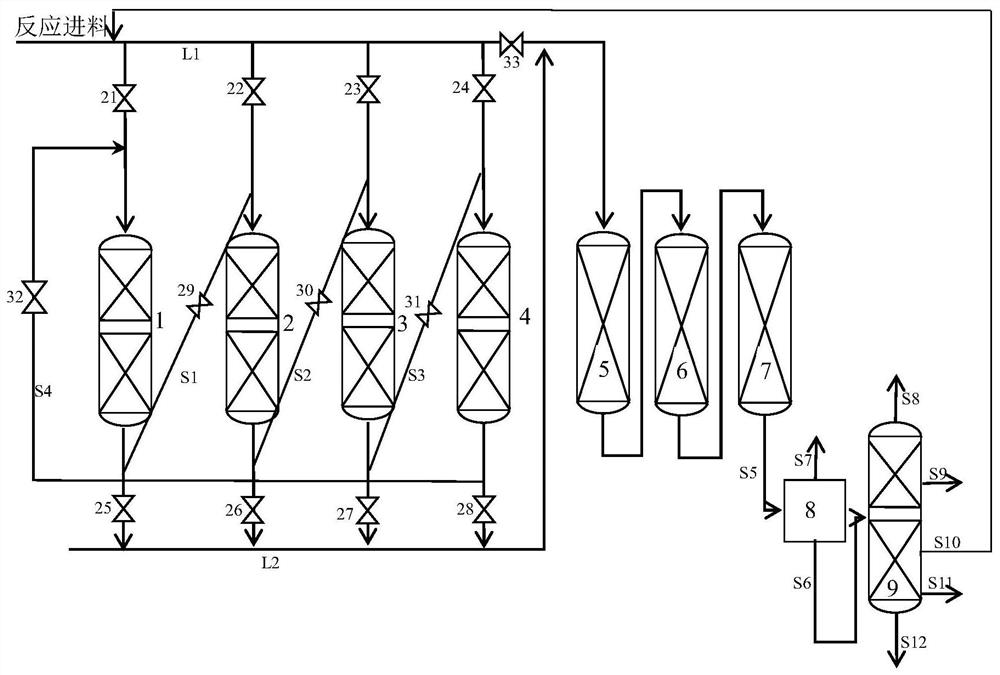

Series alternate residual oil hydrotreatment-catalytic cracking combined process method and system

ActiveCN112210401ARealize long-term operationExtended run timeTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystProcess engineering

The invention discloses a series alternate residual oil hydrotreatment-catalytic cracking combined process method and system. The method comprises the following steps: mixing a residual oil raw material and at least part of a catalytically cracked diesel fraction with hydrogen, allowing the obtained mixture to sequentially pass through a hydrogenation pretreatment zone and a hydrotreating reactionzone which are connected in series, carrying out gas-liquid separation on the reaction effluent of the hydrotreating reaction zone, and allowing the separated liquid phase to directly enter a catalytically cracked reaction zone to carry out a catalytic cracking reaction. The hydrogenation pretreatment reaction zone comprises N hydrogenation pretreatment reactors, the first hydrogenation pretreatment reactor to the N-1th hydrogenation pretreatment reactor are sequentially connected in series and are used as N1-stage online hydrogenation pretreatment reactors, and the Nth hydrogenation pretreatment reactor is used as an offline hydrogenation pretreatment reactor. According to the method and the system, the operation time of the hydrotreating pretreatment process is long without shutdown, the stable exertion of the overall catalytic activity of the hydrotreating main catalyst is facilitated, reasonable and limited alternating times are ensured, and the operation time and the working efficiency of the hydrotreating reactor are prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

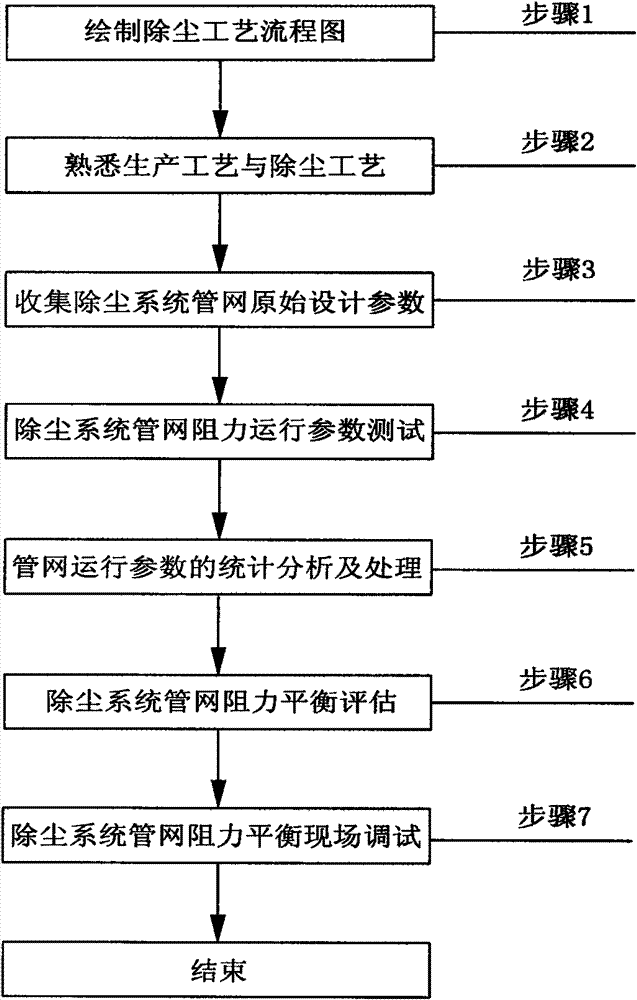

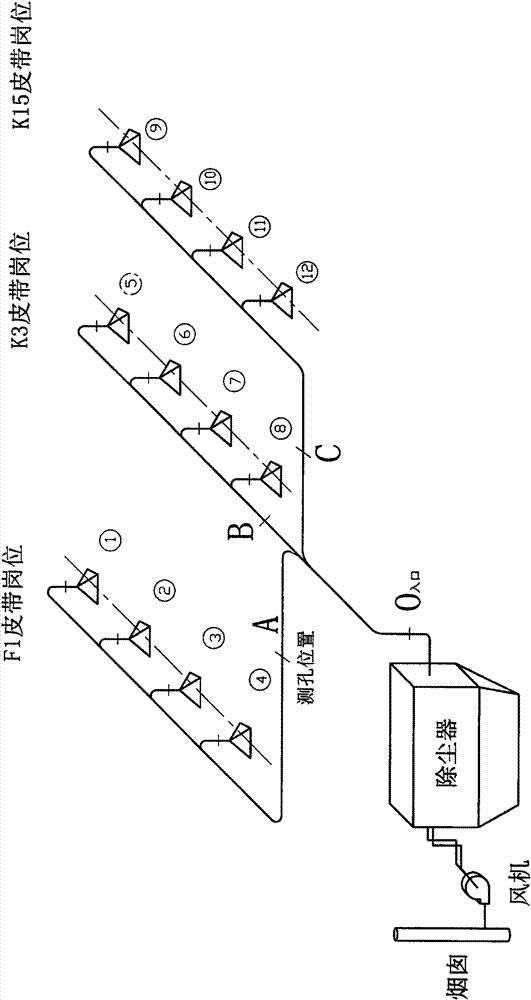

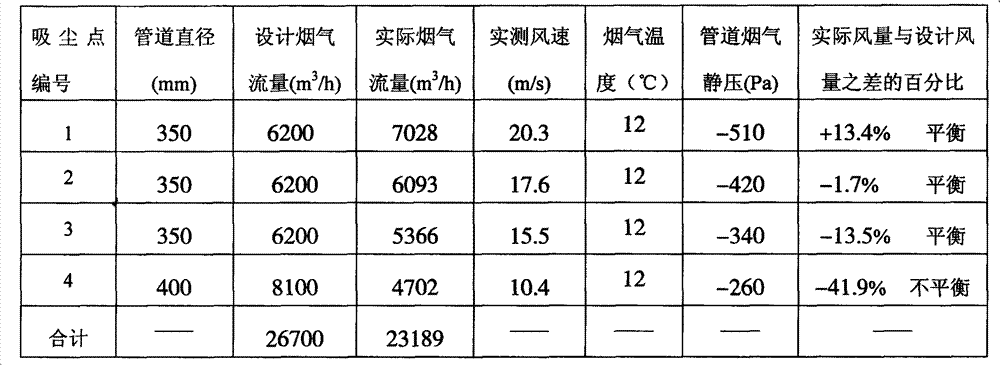

Dust removing system pipe network resistance balance evaluation and debugging method

ActiveCN103185610BProduction runAdjust operating parametersMeasurement devicesSpecial data processing applicationsSystems managementWorking environment

The invention discloses a dust removing system pipe network resistance balance evaluation and debugging method. Benchmarking comparison is conducted between dust removing system pipe network operating parameters and pipe network original design parameters on the basis of dust removing system pipe network operating parameter testing, so that evaluation is conducted on resistance balance condition of a dust removing system pipe network, and dust removing system pipe network resistance reaches balance again through field debugging of the dust removing system pipe network resistance, the fact that a dust removing system effectively trap and gather dust produced by all dust absorption points is guaranteed, and work environment is purified. The dust removing system pipe network resistance balance evaluation and debugging method not only provides reliable technical parameters and a theoretical basis for manufacturer removing system management and enables production run, management, maintenance and repair to be conducted with purposes, but also has a theoretical and practical guiding significance for dust removing system pipe network field debugging and major-medium maintenance and repairing. The dust removing system pipe network resistance balance evaluation and debugging method can guarantee the fact that the dust removing system pipe network operating parameters are adjusted under the circumstance that cost is low and production is not influenced, and enables the operating parameters to reach design demands. The problem which only can be solved through major maintenance and repairing to an original dust removing system is solved, and fund is saved.

Owner:鞍钢集团工程技术有限公司

A series-rotatable fixed-bed residual oil hydrotreating method and system

ActiveCN110499188BRealize long-term operationExtended run timeTreatment with hydrotreatment processesPtru catalystFixed bed

The invention discloses a method and a system for hydrogenation treatment of residual oil in a fixed bed which can be rotated in series. The method comprises: the residual oil hydrotreating is provided with a hydrotreating reaction zone and a hydrotreating reaction zone connected in series, and the hydrotreating reaction zone includes N hydrotreating reactors; wherein the first to The N-1th hydrogenation pretreatment reactors are successively connected in series and used as N-1 online hydrogenation pretreatment reactors, and the Nth one is used as an off-line hydrogenation pretreatment reactor; when the first hydrogenation pretreatment reaction When the pressure drop in the reactor rises to the design upper limit of the pressure drop or the catalyst activity is lower than the requirement, the first hydrogenation pretreatment reactor is switched out, and the Nth hydrogenation pretreatment reactor is used as the N‑1 online hydrogenation pretreatment Reactor; switching in the above manner can realize uninterrupted N‑1 stage hydrogenation pretreatment reaction. The method can improve the utilization efficiency of the main catalyst and the stability of the device operation, and greatly prolong the operation time of the hydrogenation reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

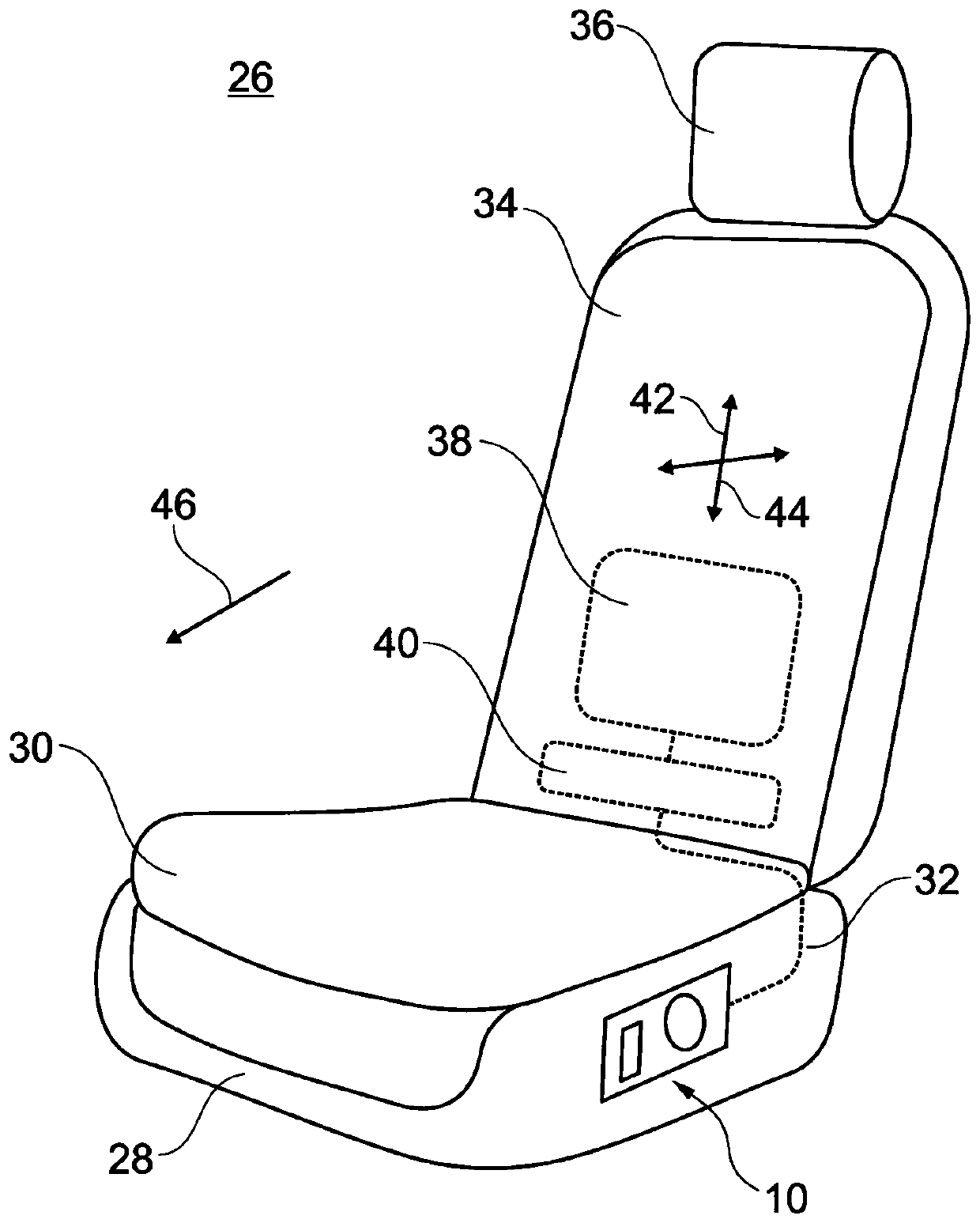

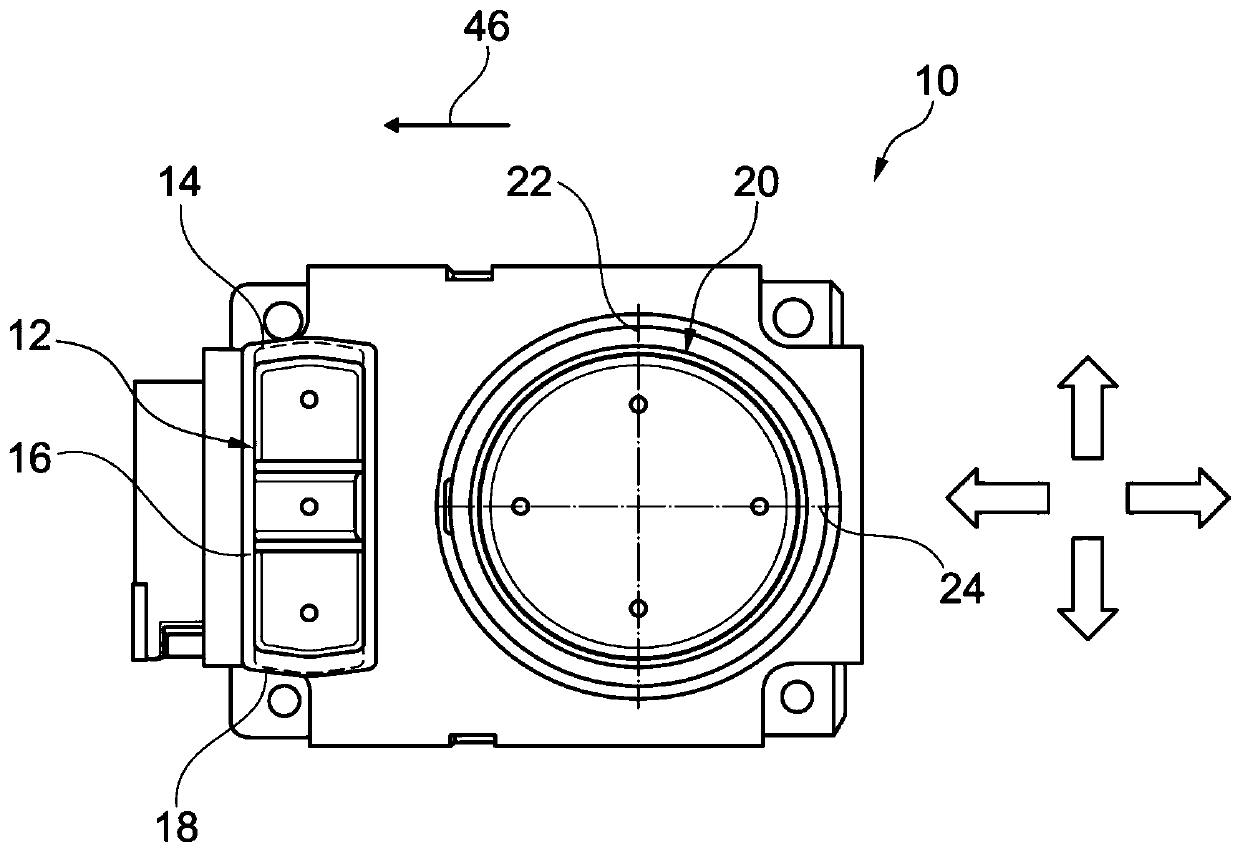

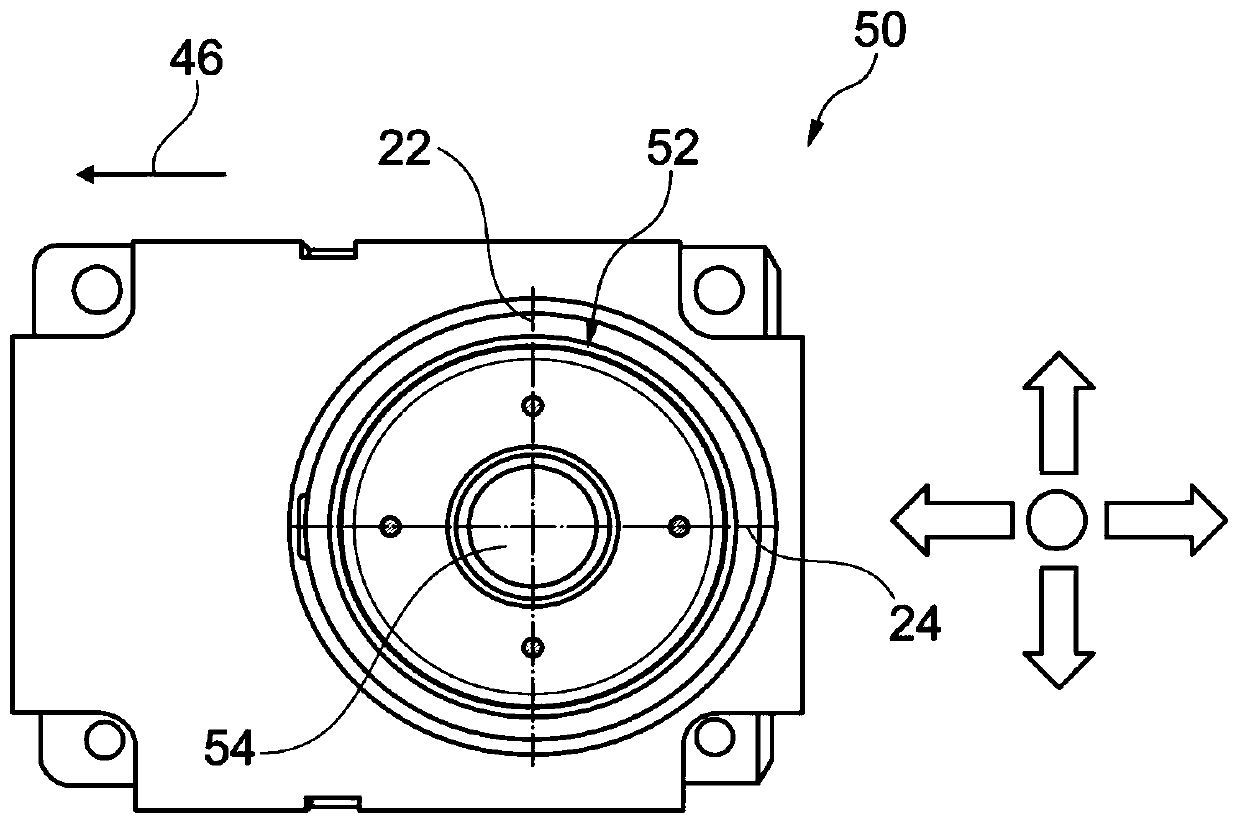

Operator control unit that controls an electrically adjustable lumbar support of a motor vehicle seat

PendingCN110281859AAdjust operating parametersRealize the massage functionBack restsVibration massageMobile vehicleMotor vehicle part

The invention relates to an operator control unit (10) controls an electrically adjustable lumbar support (38) of a motor vehicle seat (26), where the lumbar support (38) is provided for performing a massage function. A four-way button (20) for setting an inoperative position of the lumbar support (38) and a three-way switching element (12) for selecting a predetermined value for a massage parameter of the lumbar support (38) are provided in the operator control unit (38).

Owner:FORD GLOBAL TECH LLC

A control method, control system and air conditioner for adjusting frosting of air conditioner

ActiveCN111141007BAvoid reliabilityAvoid lifeMechanical apparatusSpace heating and ventilation safety systemsControl systemAir conditioning

The invention relates to a control method, a control system, and an air conditioner for adjusting frosting of an air conditioner, wherein the control method for adjusting frosting of an air conditioner includes: when the air conditioner is in a heating mode, detecting the outdoor ambient temperature T 1 ;Judging the outdoor ambient temperature T 1 The relationship with the first temperature preset value; when the outdoor ambient temperature T 1 When the temperature is greater than the first preset temperature, the air conditioner enters into a frosting adjustment mode. In the present invention, by setting the outdoor ambient temperature to meet certain conditions, the air conditioner does not stop for heating operation, and the air conditioner enters the heating defrost or heating suppression frost mode, so as to prevent the frost layer from weakening the heating capacity of the air conditioner and avoid traditional refrigeration defrosting In this way, because the compressor accumulates too much refrigerant, it will affect the reliability and life of the compressor; defrosting or frost suppression during the heating process will not cause a decrease in the indoor temperature, improve the comfort of the room, and improve user experience.

Owner:NINGBO AUX ELECTRIC

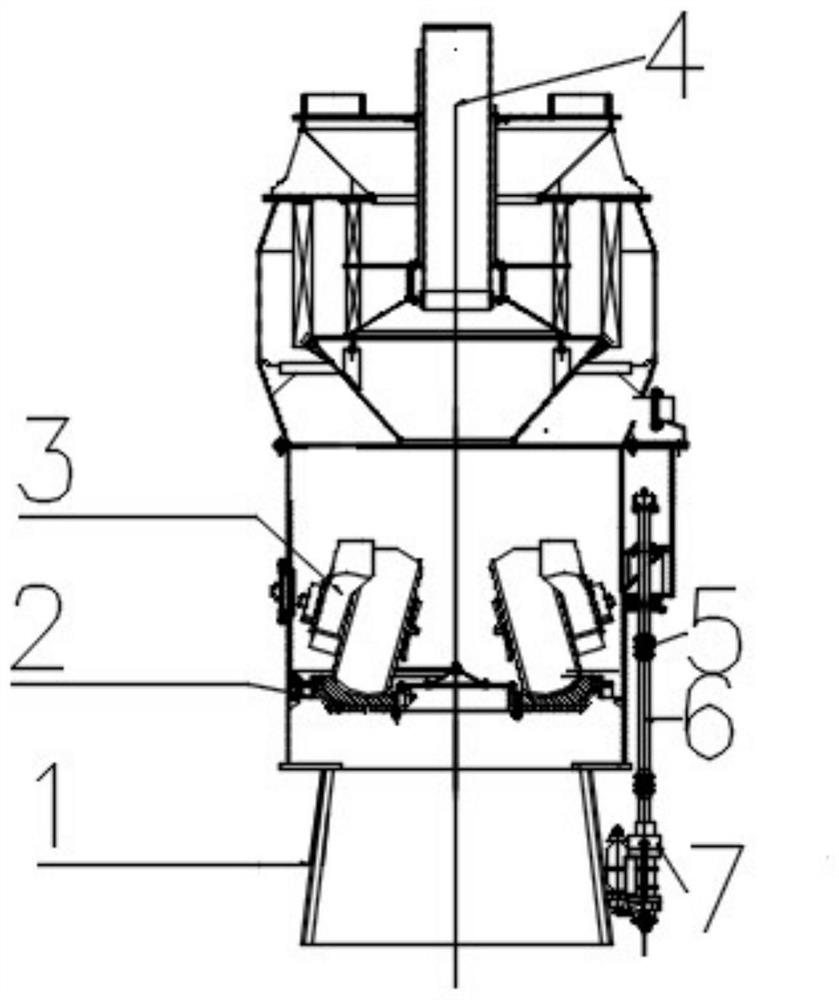

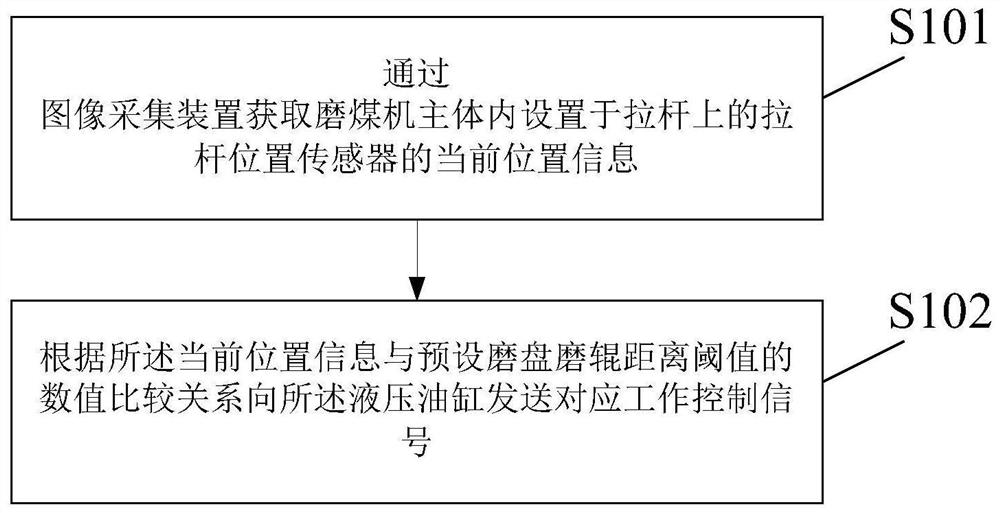

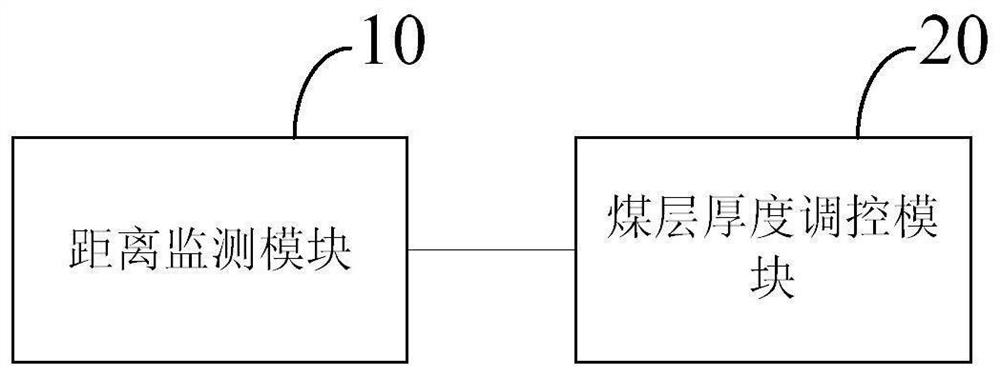

Coal mill and coal mill coal seam thickness operation control method and device

ActiveCN113967528AGuaranteed uptimeAdjust operating parametersGrain treatmentsThermodynamicsControl signal

The embodiment of the invention provides a coal mill and a coal mill coal seam thickness operation control method and device. The coal mill comprises a coal mill body, a millstone and at least one milling roller, the millstone and the milling roller are arranged in the coal mill body, the millstone is arranged at a coal falling opening of the coal mill body, the milling roller is provided with a hydraulic oil cylinder and a pull rod in a linkage mode, and a pull rod position sensor is arranged on the pull rod; the coal mill further comprises an image acquisition device and a processor, the image acquisition device is used for acquiring current position information of the pull rod position sensor, and the processor is used for receiving the current position information sent by the image acquisition device and sending a corresponding working control signal to the hydraulic oil cylinder according to a numerical comparison relationship between the current position information and a preset millstone and milling roller distance threshold value; and operation parameters of the coal mill can be effectively adjusted by controlling the thickness of a coal seam in the coal mill, and operation safety of the coal mill is guaranteed.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

Combination Process Method and System for Residual Oil Hydrotreating-FCC with Rotation in Series

ActiveCN112210401BRealize long-term operationExtended run timeTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystProcess engineering

The invention discloses a combined process method and system of series-rotatable residual oil hydrogenation treatment-catalytic cracking. The method comprises: the residual oil raw material and at least part of the catalytic cracking diesel fraction are mixed with hydrogen, and then sequentially pass through a hydrotreating pretreatment zone and a hydrotreating reaction zone arranged in series; the reaction effluent in the hydrotreating reaction zone is subjected to gas-liquid separation, The obtained liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction; the hydrogenation pretreatment reaction zone includes N hydrogenation pretreatment reactors, and the 1st to N-1th hydrogenation pretreatment reactors are successively They are connected in series in sequence and used as N‑1 online hydrogenation pretreatment reactors, and the Nth one is used as an off-line hydrogenation pretreatment reactor. The method and system can realize the operation time of the hydrogenation pretreatment process for a long time without stopping, which is beneficial to the stable performance of the overall catalytic activity of the main catalyst for hydrogenation treatment, ensures reasonable and limited rotation times, and prolongs the operation of the hydrogenation treatment reactor. time and work efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method and system for rotating fixed-bed residual oil hydrotreating

ActiveCN110499189BRealize long-term operationHigh metal capacityTreatment with hydrotreatment processesThermodynamicsPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Membrane bioreactor-mbr membrane fouling intelligent decision-making method

ActiveCN111204867BReduce water productionAdjust operating parametersWater treatment parameter controlGeneral water supply conservationDeep belief networkWater quality

Membrane bioreactor-MBR membrane fouling intelligent decision-making method belongs to the field of online early warning of water quality parameters in sewage treatment. Firstly, the mechanism of membrane fouling was deeply analyzed, and a membrane fouling prediction model based on deep belief network was constructed to realize the accurate prediction of membrane permeability; secondly, based on the comprehensive evaluation of membrane fouling, by using the fusion of the predicted value of permeability and related parameter variables, the Intelligent early warning of membrane fouling; Secondly, based on the main factors of membrane fouling, an intelligent decision-making model based on data and knowledge is established to provide decision support for operators, reduce the harm caused by membrane fouling, reduce the incidence of membrane fouling, and ensure MBR The sewage treatment process is safe and promotes the efficient and stable operation of the MBR sewage treatment plant.

Owner:BEIJING UNIV OF TECH

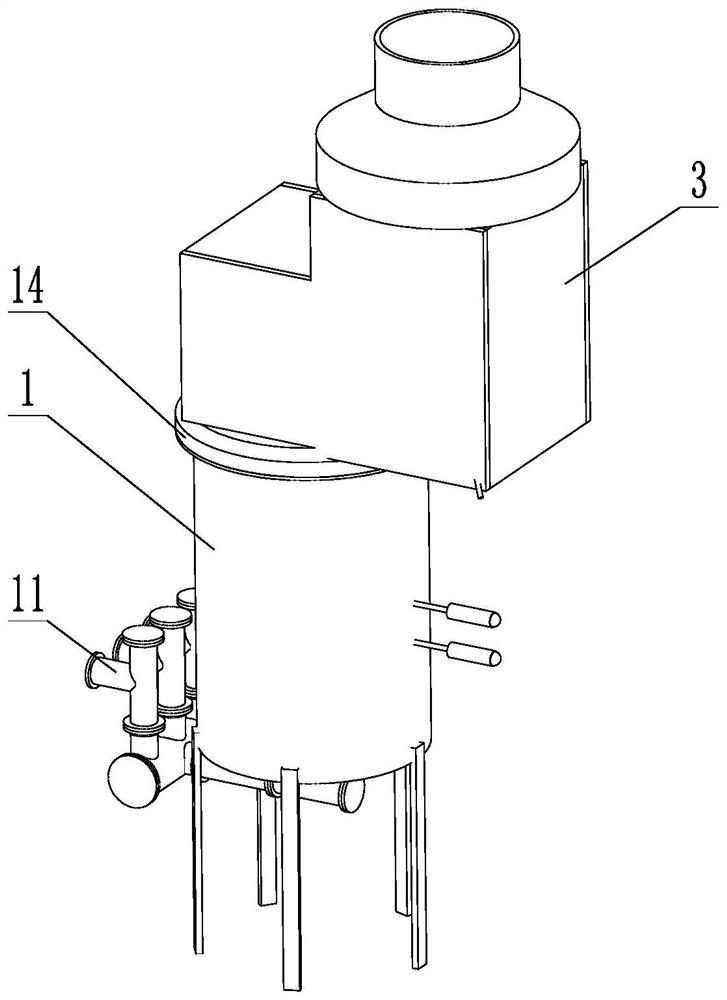

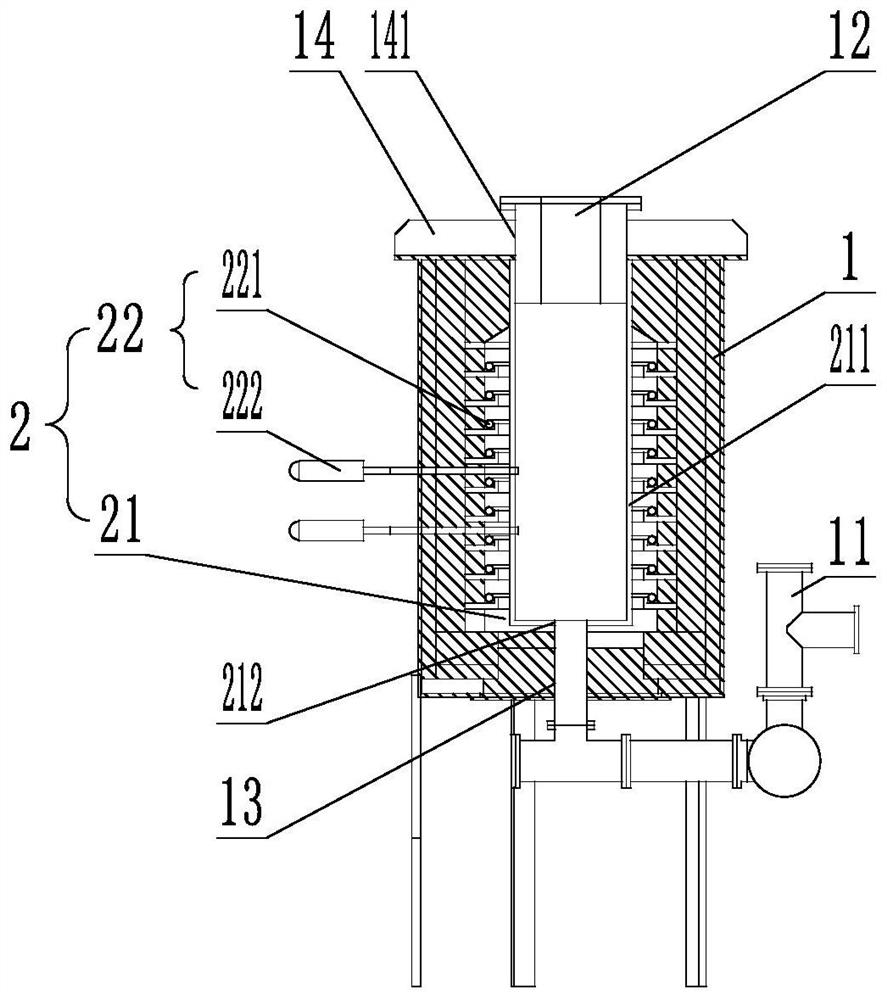

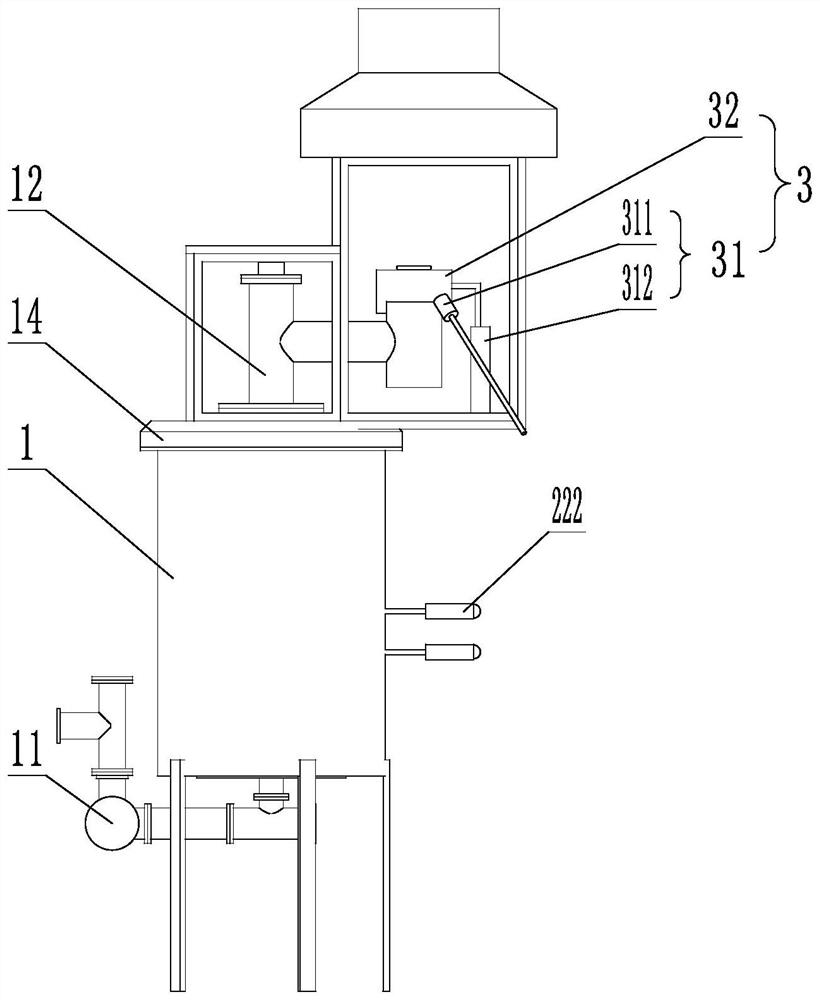

Ammonia decomposition furnace for exhaust of heat treatment nitriding furnace

PendingCN114797448AImprove decomposition rateEfficient working stateThermometers using electric/magnetic elementsDispersed particle separationTemperature controlExhaust fumes

The invention relates to the technical field of waste gas purification, in particular to an ammonia decomposition furnace for exhaust of a heat treatment nitriding furnace. The bottom of the furnace body is fixedly connected with an air inlet pipe, and the top is fixedly connected with an exhaust pipe; the gas purification device is arranged in the furnace body; the ammonia gas purification device comprises an ammonia gas decomposition mechanism which is fixedly connected to the center of the furnace body and makes contact with waste gas and a temperature control mechanism which is fixedly connected to the inner wall of the furnace body and used for controlling the temperature in the furnace body. After waste gas containing ammonia gas is fed into the furnace body through the gas inlet pipe, the waste gas passes through the ammonia gas decomposition mechanism, the ammonia gas decomposition mechanism decomposes the ammonia gas in the waste gas to enable the ammonia gas to be decomposed into nitrogen and hydrogen, the waste gas purified by the ammonia gas decomposition mechanism is exhausted out of the furnace body through the gas exhaust pipe, and the effect of purifying the ammonia gas in the tail gas is achieved.

Owner:TIANJIN FENGDONG CHENXU METAL TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com